Inconel Alloys

Products

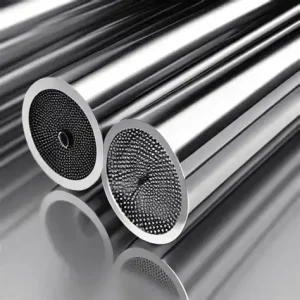

At Mwalloys, we specialize in the production and supply of Inconel Alloys, known for their high performance in extreme environments. Inconel is a family of austenitic nickel-chromium-based superalloys designed for high-temperature applications and exceptional resistance to oxidation, corrosion, and thermal fatigue. Our Inconel alloys are engineered to withstand the most demanding conditions in industries such as aerospace, power generation, chemical processing, and more.

We offer a wide range of Inconel alloys to meet your specific needs:

-

Inconel 600: A versatile nickel-chromium alloy with excellent oxidation and corrosion resistance at elevated temperatures.

-

Inconel 625: Known for its exceptional fatigue and thermal-fatigue strength, high weldability, and resistance to oxidation.

-

Inconel 718: Ideal for applications in gas turbines, nuclear reactors, and aerospace components due to its high strength, durability, and resistance to both oxidation and corrosion.

-

Inconel 230: Designed for high-temperature applications, this alloy is highly resistant to oxidation, creep, and corrosion.

-

Inconel X-750: Offering high tensile, yield, and creep-rupture strength, it is suitable for high-temperature applications such as gas turbines and heat exchangers.

Each of our Inconel alloys is meticulously manufactured to the highest standards, providing you with a reliable solution for even the toughest environments.

Product Specifications & Technical Data

We provide detailed product specifications to ensure our Inconel alloys meet the required standards for your applications. Below are the specifications for some of our key Inconel alloys:

| Alloy Grade | Chemical Composition (%) | Mechanical Properties | Applications | Size & Shape Options | Weight per Unit |

|---|---|---|---|---|---|

| Inconel 600 | Ni: 72, Cr: 14, Fe: 6, C: 0.15 | Yield Strength: 40-60 ksi | Aerospace, Chemical Processing | Plate, Bar, Pipe, Coil | Varies by dimension |

| Inconel 625 | Ni: 58, Cr: 21, Mo: 9, Nb: 3.5 | Ultimate Tensile Strength: 130 ksi | Marine, Aerospace, Chemical Industries | Plate, Bar, Pipe, Coil | Varies by dimension |

| Inconel 718 | Ni: 50, Cr: 19, Fe: 18, Nb: 5.1 | Yield Strength: 180 ksi | Aerospace, Turbine Blades, Reactor Components | Plate, Bar, Pipe, Coil | Varies by dimension |

| Inconel 230 | Ni: 98, Cr: 20, Fe: 0.5 | Tensile Strength: 120 ksi | High-temperature Furnaces, Gas Turbines | Plate, Bar, Pipe, Coil | Varies by dimension |

| Inconel X-750 | Ni: 70, Cr: 15, Fe: 7 | Creep Strength: 80 ksi | Gas Turbines, Heat Exchangers | Plate, Bar, Pipe, Coil | Varies by dimension |

Note: The sizes and shapes are customizable based on customer requirements. All products come with detailed technical specifications, including certifications to ensure the highest quality and performance.

Why Choose Mwalloys for Inconel Alloys?

-

Quality Assurance: Our Inconel alloys are produced with the highest standards of quality and precision to meet the most demanding industrial applications. Each batch undergoes rigorous testing to ensure consistent performance and reliability.

-

Global Reach: With a global sales network, Mwalloys offers direct pricing from our Chinese factory, allowing us to offer competitive rates while maintaining exceptional quality.

-

Custom Solutions: We offer a wide range of sizes, shapes, and finishes to meet your specific needs. Whether you require large or small quantities, we can accommodate your order with customized solutions.

-

Experienced Team: With years of expertise in the field of high-performance alloys, our team is ready to provide expert guidance and support to help you find the best Inconel alloy for your application.

-

Fast Delivery: Our efficient logistics network ensures that you receive your Inconel products on time, no matter where you are located.

Logistics and Order Process

At Mwalloys, we aim to provide an efficient and seamless experience for our customers. Our order process is designed for ease and clarity:

-

Request a Quote: Get a free quotation within 24 hours. Simply provide us with your requirements, including the alloy grade, size, and quantity.

-

Order Confirmation: Once you approve the quote, we will confirm your order and provide a production timeline.

-

Production and Quality Control: Your order will be processed in our state-of-the-art facility, where each product undergoes stringent quality control checks.

-

Shipping and Delivery: We work with leading logistics partners to ensure timely delivery worldwide. Choose from a variety of shipping options to suit your needs.

Frequently Asked Questions (FAQs)

-

What are Inconel alloys used for?

Inconel alloys are primarily used in high-temperature, high-stress environments such as aerospace, chemical processing, power generation, and marine applications. They are resistant to oxidation, corrosion, and thermal fatigue. -

How do I place an order for Inconel alloys?

To place an order, simply contact us with your specifications or request a free quotation. We will guide you through the order process, from selection to delivery. -

What sizes do you offer for Inconel alloys?

We offer a wide range of sizes, including plates, bars, pipes, and coils. Custom sizes and shapes are also available upon request. -

Can you provide certificates of compliance for your Inconel alloys?

Yes, each batch of Inconel alloys comes with certificates of compliance, ensuring that the material meets the required industry standards. -

Do you offer international shipping?

Yes, we offer global shipping, with logistics tailored to your location and delivery requirements. -

What is the lead time for orders?

The lead time varies depending on the product size, quantity, and customization. Typically, we provide a delivery time range upon order confirmation.