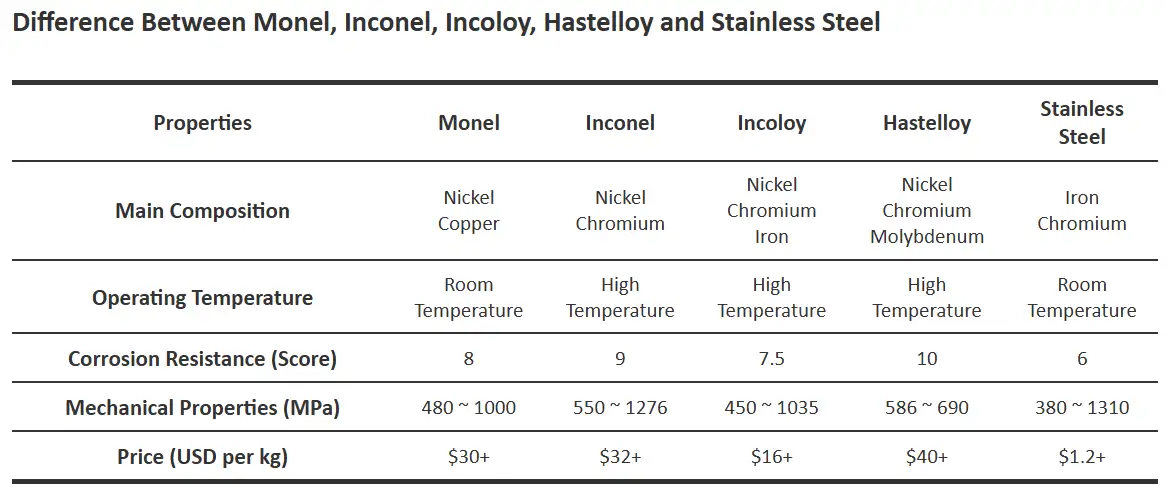

Inconel alloys are generally stronger than the most commonly used stainless steels — especially when the service requires high tensile/yield strength at elevated temperature, outstanding creep resistance, and sustained performance in oxidizing or carburizing atmospheres. For room-temperature toughness and everyday corrosion resistance in benign media, many stainless steels (e.g., 304/316) are fully adequate and much more economical. When the application pushes temperature, creep life, or extreme corrosive environments, Inconel (and other nickel-base superalloys) typically outperforms stainless steels.

What are Inconel and stainless steels?

Inconel is a registered trade name for several nickel-chromium based alloys (sometimes with Fe, Mo, Nb, Ti, Al depending on grade) engineered for high strength and corrosion resistance at elevated temperatures. Typical Inconel grades encountered in industry include Inconel 600 (a general-purpose Ni-Cr alloy), Inconel 625 (a solid-solution strengthened Ni-Cr-Mo alloy), and Inconel 718 (a precipitation-hardened Ni-Cr-Nb alloy with very high strength). These alloys are classed among nickel-base “superalloys” and are intentionally designed for aggressive, high-temperature environments.

Stainless steels are iron-based alloys with a minimum of ~10.5% chromium that gain corrosion resistance from a passive chromium oxide film. The family is large: ferritic (e.g., 430), austenitic (e.g., 304, 316), martensitic (e.g., 410, 420), and precipitation-hardening stainless steels (e.g., 17-4 PH). Strength and temperature capability vary widely across this family. Austenitic grades offer good corrosion resistance and toughness; martensitic and PH grades can achieve high room-temperature strength but typically lose strength and oxidation resistance at high temperatures.

Chemistry and microstructure: why they behave differently

-

Nickel content & matrix: Inconel alloys have high nickel content (often 50%+), which stabilizes a face-centered cubic (fcc) matrix that resists phase changes at high temperature and supports solid-solution and precipitation strengthening strategies. Nickel also slows diffusion and oxidation kinetics, boosting creep life.

-

Strengthening mechanisms: Inconel 718 is strengthened primarily by precipitation of γ'' and other Nb/Ti-rich phases; 625 relies on solid-solution and some carbide formation; 600 is a simpler Ni-Cr system with good high-temperature stability. Stainless steels get strength by solution strengthening (austenitics), martensitic transformation (martensitics), or precipitation hardening (e.g., 17-4PH). The mechanisms determine temperature limits and how strength changes with heat.

-

Phase stability: Many stainless steels form deleterious phases (sigma, carbides) if exposed to certain temperatures or long times; superalloys are engineered to avoid such embrittling phases in the intended service window.

Direct mechanical comparison (tables)

Below are condensed, representative property ranges for commonly compared grades. Materials data vary with temper, processing, and supplier; values listed are typical annealed/standard temp conditions and are intended for direct, practical comparison.

Table 1 — Typical tensile and yield strength (room temperature, typical heats)

| Alloy / Condition | Typical Ultimate Tensile Strength (MPa / ksi) | 0.2% Yield Strength (MPa / ksi) | Source (typical datasheet) |

|---|---|---|---|

| Inconel 718 (peak-aged) | 1375 MPa (199 ksi) | ≈ 1035 MPa (150 ksi) | Special Metals / ASM data |

| Inconel 625 (annealed) | ≈ 880 MPa (128 ksi) | ≈ 460 MPa (67 ksi) | Special Metals datasheet |

| AISI 304 (annealed) | ≈ 505 MPa (73 ksi) | ≈ 215 MPa (31 ksi) | ASM / MatWeb |

| AISI 316 (annealed) | ≈ 580 MPa (84 ksi) | ≈ 290 MPa (42 ksi) | ASM / MatWeb |

| 17-4 PH (H900 condition) | ≈ 1310–1315 MPa (190–191 ksi) UTS, Yield ≈ 1170 MPa (170 ksi) (varies by temper) | PH stainless — high room-temp strength | Manufacturer datasheets |

Interpretation: Inconel 718 delivers much higher sustained tensile and yield than common austenitic stainless steels; Inconel 625 also typically exceeds 304/316 in tensile strength. A specialized PH stainless like 17-4PH in certain tempers can rival or exceed some Inconel grades in room-temperature strength, but it lacks the same high-temperature creep/oxidation resistance.

Table 2 — High-temperature capability (qualitative)

| Property | Typical stainless steels (304/316) | Inconel (625 / 718) |

|---|---|---|

| Useful continuous service temp | up to ~400–600°C (some grades lower) | 600–700°C (718 creep strength) and higher for specific alloys |

| Creep resistance | Poor to moderate | Excellent (especially 718 and high-temp Ni alloys) |

| Oxidation resistance at 600–800°C | Variable; 304/316 form oxide but suffer more scaling | Far superior; designed for this service |

Key point: If temperature is a primary driver, Inconel and other nickel-base superalloys were designed for that environment and maintain mechanical integrity where stainless steels soften or oxidize.

Inconel Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 2.4816 | N06600 | МНЖМц 28-2,5-1,5 | NC15FE11M | NCF 600 | NA 13 | NiCr15Fe | ЭИ868 |

| Inconel 601 | 2.4851 | N06601 | XH60BT | NC23FeA | NCF 601 | NA 49 | NiCr23Fe | ЭИ868 |

| Inconel 617 | 2.4663 | N06617 | ||||||

| Inconel 625 | 2.4856 | N06625 | ХН75МБТЮ | NC22DNB4M | NCF 625 | NA 21 | NiCr22Mo9Nb | ЭИ602 |

| Inconel 690 | 2.4642 | N06690 | ||||||

| Inconel 718 | 2.4668 | N07718 | ||||||

| Inconel 725 | - | N07725 | ||||||

| Inconel X-750 | 2.4669 | N07750 |

Inconel Melting Point, Density and Tensile Strength

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | |

|---|---|---|---|---|---|

| 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

| 617 | 8.3g/cm³ | 1363°C | ≥ 485 MPa | ≥ 275 MPa | 25 % |

| 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

| 690 | 8.3g/cm³ | 1363°C | ≥ 485 MPa | ≥ 275 MPa | 25 % |

| 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 70,000 , MPa – 482 | 45 % |

| 725 | 8.31 g/cm3 | 1271°C-1343 °C | 1137 MPa | 827 MPa | 20 % |

| X-750 | 8.28 g/cm3 | 1430°C | 1267 MPa | 868 MPa | 25 % |

Stainless Steel

Stainless Steel Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306/1.4307 | S30403 | SUS 304L | 304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 310 | 1.4845 | S31000 | - | - | - | - | - |

| SS 310S | 1.4845 | S31008 | SUS310S | - | 20Ch23N18 | - | X8CrNi25-21 |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐032 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 317 | 1.4449 | S31700 | SUS 317 | - | - | - | X6CrNiMo19-13-4 |

| SS 317L | 1.4438 | S31703 | SUS 317L | - | - | - | X2CrNiMo18154 |

| SS 321 | 1.4541 | S32100 | SUS 321 | - | 08Ch18N10T | - | X6CrNiTi18-10 |

| SS 321H | 1.4541 | S32109 | SUS 321H | - | - | - | X6CrNiTi18-10 |

| SS 347 | 1.4550 | S34700 | SUS 347 | - | 08Ch18N12B | - | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | - | - | - | X7CrNiNb18-10 |

| SS 446 | 1.4762 | S44600 | - | - | - | - | - |

Stainless Steel Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.040 max | 0.030 max | 18 – 20 | - | 8 – 11 | - |

| SS 304L | 0.03 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | - | 8 – 12 | 0.10 max |

| SS 310 | 0.25 max | 2 max | 1.50 max | 0.045 max | 0.030 max | 24 - 26 | - | 19 - 22 | - |

| SS 310S | 0.08 max | 2 max | 1.50 max | 0.045 max | 0.030 max | 24 - 26 | - | 19 - 22 | - |

| SS 316 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 16 - 18 | 2 - 3 | 10 - 14 | 0.1 max |

| SS 316L | 0.3 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 16 - 18 | 2 - 3 | 10 - 14 | 0.10 max |

| SS 317 | 008 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 - 20 | 3 - 4 | 11 - 14 | 0.10 max |

| SS 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 - 20 | 3 - 4 | 11 - 15 | - |

| SS 321 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 17 - 19 | 5xC min 0.60% max |

9 - 12 | 0.10 max |

| SS 321H | 0.04 - 0.10 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 17 - 19 | 4xC min 0.60% max |

9 - 12 | 0.10 max |

| SS 347 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 17 - 20 | 10xC min 1.00 max |

9 - 13 | 62.74 |

| SS 347H | 0.04 – 0.10 | 2 max | 0.75 max | 0.045 max | 0.03 max | 17 - 20 | 8xC min 1.00 max |

9 - 13 | 62.74 |

| SS 446 | 0.2 max | 1.5 max | 0.75 max | 0.040 max | 0.03 max | 23 – 30 | 0.10 – 0.25 | 0.50 max | Balance |

Stainless Steel Melting Point, Density and Tensile Strength

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 304 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

| SS 310 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 310S | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 316 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 316L | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

| SS 317 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 317L | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 321 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 321H | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 347 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

| SS 347H | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

| SS 446 | 7.5 g/cm3 | 1510 °C (2750 °F) | Psi – 75,000 , MPa – 485 | Psi – 40,000 , MPa – 275 | 20 % |

Elevated temperature behavior: where Inconel pulls ahead

-

Strength retention: Many Inconel grades maintain a much higher fraction of their room-temperature strength at elevated temperatures compared with stainless steels. For example, Inconel 718 retains high tensile and creep strength up to ~650°C due to its precipitation-hardened microstructure.

-

Creep and rupture life: Creep — time-dependent deformation under load — is a critical failure mode for hot components. Nickel-base alloys have slower diffusion rates and engineered precipitates to resist creep; this results in substantially longer creep life at a given stress and temperature than most stainless steels. The Nickel Institute practical guides and ASM data describe classifying alloys by creep strength and intended service.

-

Thermal stability & phase control: Superalloys resist microstructural transformations that embrittle or soften alloys at certain temperature ranges. Many stainless grades can form sigma or carbides that weaken the matrix after long exposure at intermediate temperatures — a problem rarely seen in purpose-designed nickel superalloys.

Practical implication: For gas-turbine discs, hot section fasteners, high-temperature exhaust hardware, and chemical plant components operating at elevated temperature, nickel superalloys are the accepted solution; stainless steels are not usually suitable for long-term strength at those temperatures.

Corrosion and oxidation resistance

-

General corrosion in aqueous environments: Austenitic stainless steels (304/316) are excellent for many water, food, and low-chloride environments because of their chromium-rich passive film. Inconel alloys (e.g., 625) have exceptional resistance to many aggressive media (pitting, crevice, reducing acids, sea water) because of high nickel, molybdenum, and chromium levels. Which is “better” depends heavily on environment chemistry.

-

Pitting and crevice corrosion: In chloride-rich environments (seawater, brines), 316 will pit sooner than Inconel 625, which was specifically designed for resistance to localized attack.

-

Oxidation at high temperature: Inconel alloys form stable chromia and alumina scales and resist rapid scaling/oxidation compared to most stainless steels, enabling longer service in oxidizing high-temperature atmospheres.

Bottom line: Corrosion performance is application specific. Inconel often provides superior performance in aggressive and high-temperature corrosion regimes; stainless steels do well for many less severe aqueous environments and are more economical.

Fabrication, welding, and heat treatment considerations

-

Forming and machining: Stainless steels (especially austenitics like 304/316) are generally easier and cheaper to form and cut than nickel superalloys. Superalloys can work-harden quickly and are abrasive on tooling; machining strategies and carbide tooling are common.

-

Welding: Both families can be welded but with different concerns. Inconel alloys (618/625/718) can be welded with compatible filler metals and maintain strength after appropriate heat treatment; some Inconel grades do require specific procedures to avoid cracking. Stainless steels are well understood for welding in industry but may need post-weld heat treatment (PWHT) for martensitics or care to avoid sensitization of austenitics.

-

Heat treatment: Many Inconel alloys are age-hardened (e.g., 718) and require controlled solution + aging cycles to reach peak properties. PH stainless steels (17-4PH) also need specific aging cycles to develop high strength. Improper heat treatment reduces performance.

Cost, availability, and manufacturing scale

-

Raw material cost: Nickel and certain alloying elements (Nb, Mo) make Inconel markedly more expensive than common stainless steel grades. Cost differential can be multiple-times depending on market. Stainless steel remains the economical choice when performance requirements permit.

-

Lead time & availability: Stainless steels are widely stocked worldwide in many sizes and tempers. Some Inconel grades are stocked, but special tempers, large sections, or exotic fabrication steps add lead time.

-

Lifecycle cost: For high-temperature or highly corrosive services, the higher alloy cost can be offset by longer life, fewer shutdowns, and lower maintenance. A life-cycle cost analysis is essential for engineering selection.

Standards, specifications, and authoritative references

When specifying materials for engineering, reference recognized standards (ASTM, AMS, EN, UNS) and supplier datasheets. Examples:

-

Inconel 718: UNS N07718 / AMS 5662 / ASTM B637 etc. (refer to Special Metals technical bulletins for behavior and recommended practices).

-

Inconel 625: UNS N06625 / ASTM B443 / AMS 5666 etc. (Special Metals datasheet outlines applications and limits).

-

Stainless steels: AISI/ASTM specifications for 304/316, and AMS/ASTM documents for PH or martensitic stainless. Use supplier material certifications (mill test reports) for traceability.

How to choose: practical selection checklist

Use this quick checklist to decide between Inconel and stainless steel:

-

Operating temperature > 400–500°C? If yes, prioritize Inconel or high-temp stainless (e.g., 309/310) — Inconel preferred for sustained load/creep.

-

Creep or rupture life required? Inconel likely necessary.

-

Chloride, acidic brines, or oxidizing high-temp atmosphere? Consider Inconel 625/718 or other nickel alloys.

-

Is cost the primary driver and conditions are moderate? Stainless steel (304/316) is usually adequate.

-

Is very high room-temperature static strength needed but temperature low? PH stainless (17-4PH) could be cost-effective vs. Inconel.

Decision matrix (simplified)

| Requirement | Recommend Stainless | Recommend Inconel |

|---|---|---|

| Low cost, ambient temp, general corrosion resistance | ✔ | |

| High strength at room temp (limited budget) | 17-4PH (✔) | |

| Sustained load at 600°C+ | ✔ | |

| Severe localized corrosion (sea water, halides) | ✔ (esp. 625) | |

| High-temperature oxidation resistance | ✔ |

Representative applications and short case notes

-

Inconel 718: turbine disks, cryogenic fasteners (also used at low temp), rocket motor components, high-temp bolts and shafts. High strength and toughness across a broad temperature span makes it a go-to superalloy for aerospace and power generation.

-

Inconel 625: chemical process piping, heat exchangers in corrosive media, marine components, subsea connectors — chosen for localized corrosion resistance plus high strength.

-

304/316 stainless: kitchenware, food processing, architectural components, many chemical plant internals where temperatures and stresses are moderate.

-

17-4 PH: shafts, fasteners, components where high static strength and good corrosion resistance at ambient temp are required (often used in aerospace, petrochemical).

Frequently asked questions

1. Is Inconel always “better” than stainless steel?

No. “Better” depends on application. For high temperature and extreme corrosion stress, Inconel often outperforms; for routine, low-stress, cost-sensitive uses, stainless steels are superior economically and fully capable.

2. Can a stainless steel ever match Inconel’s strength?

Some PH stainless steels (e.g., 17-4PH in certain tempers) can approach or match the room-temperature strength of some nickel alloys, but they typically fail to match high-temperature creep/oxidation performance.

3. Does Inconel corrode in seawater?

Certain Inconel grades (notably 625) have excellent seawater resistance, including pitting and crevice resistance. However, selection must account for temperature, dissolved oxygen, and crevice geometry.

4. Why is Inconel so expensive?

High nickel content and alloying with costly elements (Nb, Mo, Ti) plus more difficult machining and processing increase raw and manufacturing costs.

5. Are Inconel and “Hastelloy” the same?

No — both are nickel-base families, but different trademarks and chemistries. Hastelloy (Haynes) and Inconel (Special Metals) designations refer to different proprietary compositions and performance envelopes.

6. Which alloys are standard for gas-turbine hot sections?

Nickel-base superalloys (Inconel family and similarly engineered alloys) dominate due to exceptional creep/oxidation resistance; stainless steels are not suitable for the hottest sections.

7. Can you weld Inconel to stainless steel?

Yes, but you must select compatible filler metals and manage dilution/thermal cycles. Welding dissimilar metals needs engineering control to avoid galvanic issues and maintain needed mechanical properties.

8. Which material is lighter?

Density of nickel alloys (~8.4–8.5 g/cm³) is generally similar to stainless steels (about 7.7–8.0 g/cm³). So weight differences are modest; selection will be driven by properties rather than mass savings.

9. Does Inconel require special heat treatment?

Many Inconel alloys, notably 718, require specified solution and aging cycles to develop designed strength; follow supplier heat-treatment schedules.

10. How to specify between them in procurement?

Define service temperature, stresses, environment (corrosives), life target, and budget; request mill certificates, and ask suppliers for recommended grades and traceability. For critical parts specify relevant ASTM/AMS/EN standards.

Short wrap-up

If your primary design constraints are sustained mechanical load at high temperature, long creep life, oxidation resistance at elevated temperature or aggressive localized corrosion, Inconel (and other nickel superalloys) will usually provide superior performance — at a higher material and processing cost. For everyday corrosion resistance, formability, and lower cost, stainless steel is the practical choice. Select the alloy that matches the service envelope (temperature, mechanical load, environment, allowable life and budget), and use supplier datasheets, standards, and mill test reports for firm specifications and design inputs.