Stainless steel typically has a bulk density between 7.5 and 8.0 g/cm³ (7,500–8,000 kg/m³). Specific grades show small but important differences: type 304 is about 7.93–8.00 g/cm³, type 316 near 7.98–8.00 g/cm³, and duplex grades commonly fall near 7.8 g/cm³. These values control weight estimates, structural design, shipping costs, buoyancy checks, and quality testing.

What “density” means for stainless steel

Density equals mass divided by volume. For alloys, this physical constant depends on the amounts and atomic masses of constituent elements plus any internal voids. In everyday engineering practice, density converts part volume to mass, and vice versa. Designers use density to size structures, estimate transport weight, and check whether an incoming batch matches expected chemistry and processing. Typical engineering units are g/cm³, kg/m³, and lb/in³.

Typical density ranges by stainless steel family and common grades

Quick reference — densities at ~20 °C (typical nominal values)

| Stainless family | Grade / common name | Nominal density (g/cm³) | Nominal density (kg/m³) | Notes |

|---|---|---|---|---|

| Austenitic (300 series) | 304 (AISI 304 / EN 1.4301) | 7.93–8.00 | 7,930–8,000 | Widely used; high Ni content raises density slightly. |

| Austenitic (300 series) | 316 (AISI 316 / EN 1.4401) | 7.98–8.00 | 7,980–8,000 | Molybdenum and slightly different Ni produce small upward shift. |

| Ferritic (400 series) | 430, 444 | ~7.70–7.85 | 7,700–7,850 | Lower Ni or Ni-free; lower density vs typical austenitics. |

| Martensitic | 410, 420 | ~7.70–7.80 | 7,700–7,800 | Heat-treatable grades; density similar to ferritics |

| Duplex (ferritic–austenitic) | 2205 (UNS S32205) | ~7.80 | 7,800 | Duplex has balanced phases; overall density slightly lower than 316 |

| Super duplex / duplex variants | 2507, others | ~7.8–7.9 | 7,800–7,900 | Alloying changes give small shifts |

| High-nickel / special alloys | 904L, 6%Mo variants | ~7.95–8.05 | 7,950–8,050 | Heavy alloying can push density near 8.0 |

Notes on the table

-

Values are nominal typical engineering values used for calculation and procurement. Real-world measurements vary with exact composition and heat treatment.

-

Many supplier datasheets and national standards list 'typical' densities. For traceable specification use, request supplier MTR or datasheet.

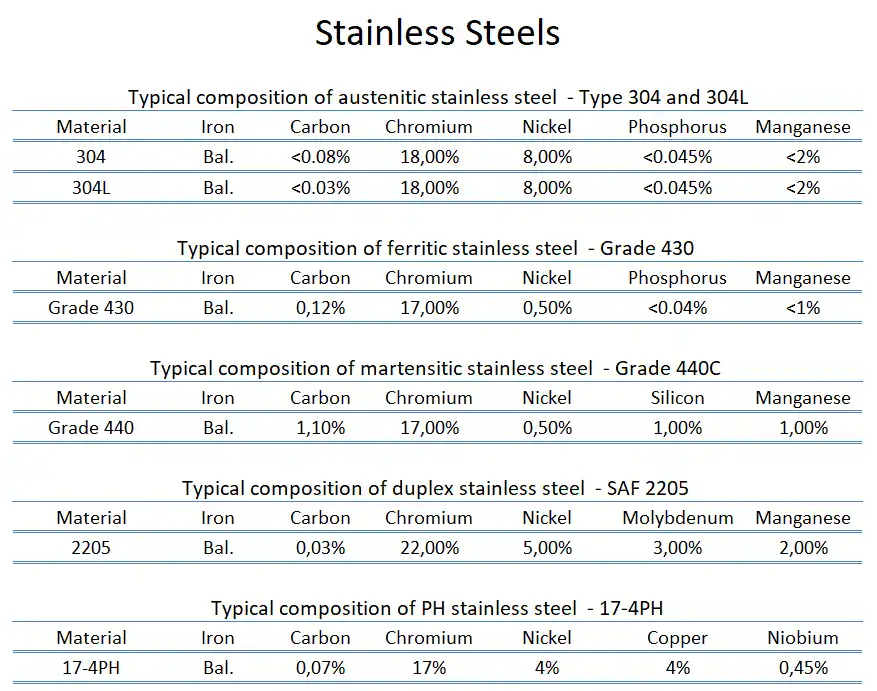

Why composition changes density

Atomic weight matters. Nickel (atomic mass ~58.7) and molybdenum (~95.9) are heavier than iron (~55.8) and chromium (~52.0). When a grade has higher Ni or Mo content, the bulk density usually increases slightly. Conversely, low-Ni ferritic grades, or grades with higher amounts of light elements (e.g., nitrogen in some engineered alloys), can show reduced density. Phase fraction also affects density: the body-centered cubic ferrite lattice packs atoms slightly differently vs face-centered cubic austenite, causing subtle density shifts for the same chemistry.

Short composition → density table (illustrative)

| Element ↑ (more of) | Typical effect on density |

|---|---|

| Nickel (Ni) | Small increase in bulk density |

| Molybdenum (Mo) | Noticeable increase per wt% |

| Chromium (Cr) | Small effect; similar atomic mass to Fe |

| Nitrogen (N) | Minor decrease if substituted for heavier alloying |

| Carbon (C) | Negligible effect at typical levels |

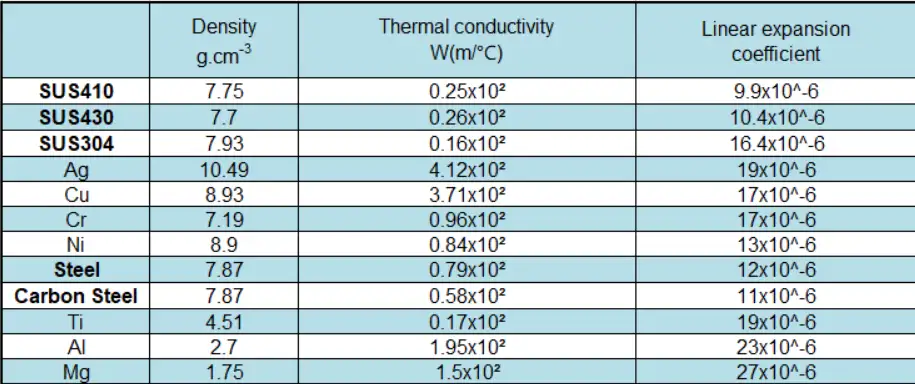

Temperature dependence and thermal expansion

Density is temperature sensitive because thermal expansion increases volume. For stainless steels, linear thermal expansion coefficients typically range ~10–17 ×10⁻⁶ /K. Over modest temperature ranges (room temperature to a few hundred °C), density drops with temperature following the volume expansion law. For quick engineering checks, use:

ρT=ρT0/1+3α(T−T0)

where ρ is density, α is linear coefficient, T in °C, T₀ is reference (commonly 20 °C). For precise work, use measured thermal expansion curves from the grade datasheet. Typical density change is small: tens of parts per thousand across a 300 °C rise.

How density is measured — practical methods and standards

Main practical techniques:

a) Archimedes buoyancy method (weigh in air, weigh in liquid)

-

Widely used for bulk parts and lab samples. Requirements: accurate balance, temperature-controlled fluid, good degassing, sample free of surface-connected open porosity that can absorb liquid. For powder metallurgy and porous items there are modified methods. A common standard that covers Archimedes-style practice for PM parts is ASTM B311.

b) Gas pycnometry

-

Useful for powders and porous materials. Volume measured by displaced gas leads to high precision.

c) Geometric volume + mass

-

For simple regular shapes, measure dimensions precisely, compute volume, then divide mass by volume.

d) X-ray and CT-based volumetry

-

For complex shapes or internal porosity mapping, computed tomography can yield accurate volume. This method is common in R&D and additive manufacturing qualification.

Standards and practice notes

-

For PM parts with possible porosity, follow ASTM B311 or related ASTM methods that include impregnation options for open pores. For AM parts, specialized assessment literature recommends careful control of immersion conditions.

Calculating weight quickly — formulas and worked examples

Basic formula

Mass (kg)=ρ(kg/m³)×Volume (m³)

Common unit conversions

| From | To | Factor |

|---|---|---|

| g/cm³ → kg/m³ | × | 1000 |

| lb/in³ → g/cm³ | × | 27.68 |

| g/cm³ → lb/in³ | ÷ | 27.68 |

Worked example 1 — flat plate

-

Plate dimensions: 2.0 m × 1.0 m × 6.0 mm (0.006 m)

-

Volume = 2 × 1 × 0.006 = 0.012 m³

-

Use 304 nominal density 7,930 kg/m³

-

Mass = 7,930 × 0.012 = 95.16 kg

Worked example 2 — pipe segment

-

Pipe length: 3 m, outer diameter 0.200 m, wall thickness 6 mm (0.006 m)

-

Outer radius rₒ = 0.100 m; inner radius rᵢ = 0.094 m

-

Volume per meter = π (rₒ² − rᵢ²) × length

-

Volume = π × (0.0100 − 0.008836) × 3 ≈ π × 0.001164 × 3 ≈ 0.01098 m³

-

Mass (304) ≈ 7,930 × 0.01098 ≈ 87.1 kg

Quick reference — weight per cubic meter

-

1 m³ of 304 ≈ 7,930 kg

-

1 m³ of 316 ≈ 7,980 kg

Include these calculators in spreadsheets for procurement quoting and logistics.

Manufacturing, porosity, surface finish, and density tolerances

-

Solid rolled or forged products: density normally close to the theoretical bulk value. Variations come from small composition differences and minor residual porosity (<0.1%), usually negligible for engineering weight checks. Supplier datasheets usually list a single 'typical' density.

-

Cast or additive parts: internal shrinkage pores may reduce effective density. For castings specification of soundness or a measured density check is often used.

-

Powder metallurgy: by design can have significant porosity; standards require reporting densification fraction or apparent density measured by ASTM methods.

-

Surface coatings and plating: add mass; include coating mass per area in final calculations.

Recommended procurement practice

-

Require MTRs (mill test reports) that include chemical composition and, when critical, measured density or specific gravity. When weight tolerance is critical, request an inspection sample or density test certificate.

When density matters — practical cases

-

Structural components: weight influences load paths and connections.

-

Rotating equipment: mass and mass distribution affect balancing.

-

Pressure piping and tanks: accurate weight required for support design and logistics.

-

Marine and buoyant systems: hull fittings, ballast, and displacement checks depend on density.

-

Additively manufactured parts: measured density often used as quality gate to indicate acceptable porosity.

Quick comparisons with other common metals (nominal at 20 °C)

| Metal | Density (g/cm³) | Relative note |

|---|---|---|

| Aluminum (common alloys) | 2.70 | Much lighter; when replacing stainless, designers reduce mass dramatically |

| Carbon steel (structural) | ~7.85 | Very close to many stainless grades; small shifts possible |

| Copper | 8.90 | Heavier than stainless |

| Titanium (commercial) | ~4.50 | Much lighter; used where weight saving outweighs cost |

| Stainless (typical) | 7.5–8.0 | Heavier than aluminum and titanium; near carbon steel in many cases. |

FAQs

-

What is the specific gravity of stainless steel?

Specific gravity is the ratio of density to water (1 g/cm³). For stainless steel, specific gravity typically ranges 7.5–8.0. -

Is 304 stainless heavier than 316?

Slightly. 316 commonly has a marginally higher nominal density than 304, mainly due to molybdenum and slightly higher Ni. -

How precise are typical supplier density numbers?

Supplier typical densities are suitable for procurement and logistics. For precise engineering or QA, measure density on a sample using Archimedes or gas pycnometry. -

Does heat treatment change density?

Heat treatment causes negligible direct change to chemical density. Microstructural changes affect packing fraction slightly, but volume changes are usually tiny compared with composition-induced differences. -

How do I convert density to weight per square meter for sheet?

Weight per m² = density (kg/m³) × thickness (m). Example: 1.0 mm 304 sheet: 7,930 kg/m³ × 0.001 m = 7.93 kg/m². -

Can density help detect wrong alloy?

Yes. Large deviations from expected density can indicate incorrect chemistry or porosity, but composition testing better confirms alloy identity. -

What measurement standard should I use for powders or porous parts?

ASTM B311 covers density measurement methods that work with powder metallurgy parts. For dense bulk parts, Archimedes practice and other ASTM methods are common. -

Do duplex stainless steels weigh less than austenitics?

Duplex grades often weigh slightly less per unit volume than heavy austenitics like 316, mostly due to different alloy balances. Use grade datasheet numbers for exact comparison. -

Does density vary between suppliers?

Minor variation can exist because compositions differ within the standard ranges. For critical projects, request MTR values or measure samples. -

What error sources affect Archimedes density measurement?

Bubble entrapment, temperature drift, surface-connected porosity, inaccurate balance calibration, and buoyant force from sample support. Follow standards and good lab practice to reduce errors.

Authoritative references

- AISI Type 304 stainless steel — MatWeb / ASM materials data

- AISI Type 316 stainless steel — MatWeb / ASM materials data

- Nickel Institute — Design guidelines for the selection and use of stainless steels (PDF)

- ASTM B311 — Test method for density measurements for powder metallurgy and related practices

Closing notes and practical checklist for engineers and buyers

-

For routine weight estimates use the nominal densities in section 2. For final acceptance or contract-critical weight, request measured density or include an agreed test method in the purchase order.

-

When switching grades for weight-sensitive designs, run the quick calculation in section 6 and check thermal expansion if operating at elevated temperature.

-

For additive-manufactured or cast components, embed density measurement in your inspection plan. Archimedes and gas pycnometry remain the two most practical methods.