Schedule 80 steel pipe is the heavy wall option for Nominal Pipe Sizes that provides higher working pressure capability, smaller internal diameter, and greater weight per foot compared with lighter schedules; For industrial applications demanding superior structural integrity, elevated pressure tolerance, and resistance to mechanical stress, Schedule 80 steel pipe stands as the definitive engineering choice over standard Schedule 40 alternatives. The increased wall thickness of Schedule 80 (often designated as Extra Strong or XS for smaller diameters) provides a critical safety margin for high-pressure fluid transport, steam lines, and corrosive environments.

Decoding Schedule 80: Dimensions, Wall Thickness, and Structural Integrity

The term "Schedule" (SCH) is not a direct measurement of thickness but rather a non-dimensional designator established by the American National Standards Institute (ANSI) to define pipe wall thickness relative to the Nominal Pipe Size (NPS). Understanding Schedule 80 requires a technical grasp of ASME B36.10M, the governing standard for welded and seamless wrought steel pipe.

The Engineering Logic Behind Schedule 80

Unlike older specification methods that used static gauges (Standard, Extra Strong, Double Extra Strong), the schedule number system relates to the pressure rating. Mathematically, the schedule number is approximately equal to:

Schedule=1000×P/SWhere P is the internal service pressure and S is the allowable stress of the material. Consequently, Schedule 80 represents a significantly higher pressure capability than Schedule 40.

It is critical for engineers to note that as the schedule number increases, the Outside Diameter (OD) of the pipe remains constant to ensure compatibility with fittings and flanges. The increase in wall thickness occurs by reducing the Inside Diameter (ID). This reduction impacts flow rates and must be calculated during the system design phase to prevent pressure drops.

What Do Pipe Schedules Mean?

Industry standards and common material grades

Common steel specifications used to supply Schedule 80 pipe include:

-

ASTM A53 / ASME SA-53 for black and galvanized steel pipe, seamless and welded, used for mechanical and pressure applications.

-

ASTM A106 for seamless carbon steel pipe for high-temperature service. Also read: ASTM A53 VS A106.

-

ASTM A333 for low temperature service when needed.

-

Stainless grade options exist and follow similar dimensional charts using the SCH 80S designation.

Buyers should request the exact ASTM/ASME designation on the purchase order plus required mill test reports, heat numbers and any post-manufacture treatments.

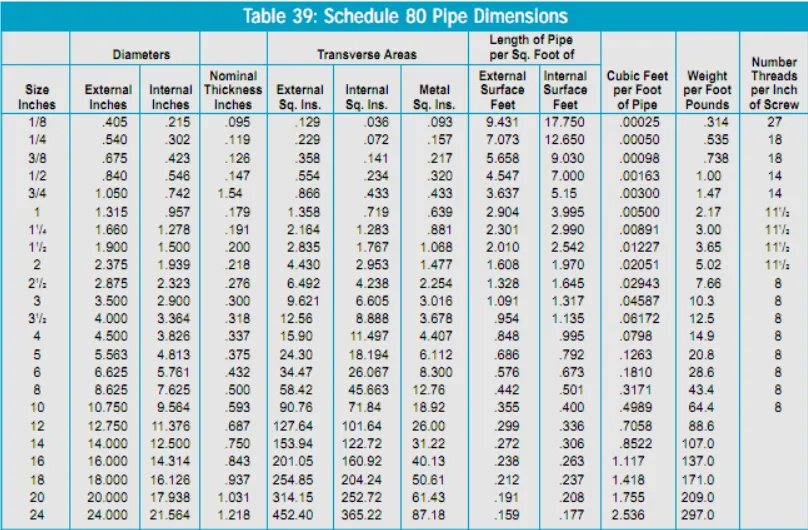

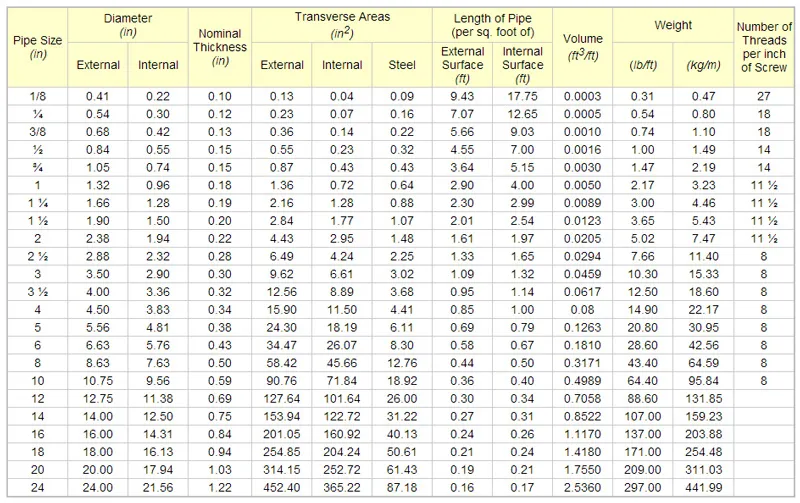

MWalloys Standard Schedule 80 Dimensional Data

The following table details the precise specifications for the most requested sizes produced at the MWalloys facility. We maintain strict tolerance controls to ensure concentricity and uniform wall thickness.

Table 1: Schedule 80 Steel Pipe Dimensions & Weight (Carbon Steel)

| NPS (Inches) | OD (Inches) | OD (mm) | Wall Thickness (Inches) | Wall Thickness (mm) | ID (Inches) | Weight (lbs/ft) | Weight ( kg/m ) |

| 1/2" | 0.840 | 21.34 | 0.147 | 3.73 | 0.546 | 1.09 | 1.62 |

| 3/4" | 1.050 | 26.67 | 0.154 | 3.91 | 0.742 | 1.47 | 2.19 |

| 1" | 1.315 | 33.40 | 0.179 | 4.55 | 0.957 | 2.17 | 3.23 |

| 1-1/2" | 1.900 | 48.26 | 0.200 | 5.08 | 1.500 | 3.63 | 5.41 |

| 2" | 2.375 | 60.33 | 0.218 | 5.54 | 1.939 | 5.02 | 7.48 |

| 2-1/2" | 2.875 | 73.03 | 0.276 | 7.01 | 2.323 | 7.66 | 11.41 |

| 3" | 3.500 | 88.90 | 0.300 | 7.62 | 2.900 | 10.25 | 15.27 |

| 4" | 4.500 | 114.30 | 0.337 | 8.56 | 3.826 | 14.98 | 22.32 |

| 6" | 6.625 | 168.28 | 0.432 | 10.97 | 5.761 | 28.57 | 42.56 |

| 8" | 8.625 | 219.08 | 0.500 | 12.70 | 7.625 | 43.39 | 64.64 |

| 10" | 10.750 | 273.05 | 0.594 | 15.09 | 9.562 | 64.43 | 96.01 |

| 12" | 12.750 | 323.85 | 0.688 | 17.48 | 11.374 | 88.63 | 132.04 |

Note: For sizes NPS 1/8 to NPS 10, Schedule 80 is identical to "Extra Strong" (XS) wall thickness. For larger diameters, variations may exist, and specific ASTM charts should be consulted.

Example approximate allowable pressures (carbon steel, room temperature, simplified)

Below are representative maximum allowable working pressures for Schedule 80 carbon steel pipe at near ambient temperature. These examples use standard allowable stresses; for design use ASME B31.3 calculations or vendor data.

| NPS | Wall in | Approx allowable pressure (psi) SCH 80 at 100°F* |

|---|---|---|

| 1/2" | 0.147 | ~2,600 psi |

| 1" | 0.179 | ~2,200 psi |

| 2" | 0.218 | ~1,900–2,100 psi |

| 4" | 0.337 | ~1,200–1,500 psi |

| 8" | 0.500 | ~900–1,100 psi |

*Exact allowable working pressure depends on steel grade, temperature and code; quoted numbers are approximations for planning. Use ASME B31.3 or vendor pressure tables for final design.

Schedule 40 vs. Schedule 80: A Comparative Engineering Analysis

A frequent query from procurement teams involves the distinct operational differences between Schedule 40 and Schedule 80. While both look identical externally, their internal mechanics serve different industrial purposes.

Wall Thickness and Pressure Correlation

The primary differentiator is the volume of metal used in the sidewall. Schedule 80 pipes possess a thicker wall—ranging from roughly 25% to 45% thicker than Schedule 40 depending on the NPS. This added material directly correlates to:

-

Higher Burst Pressure: Sch 80 can withstand significantly higher internal PSI forces.

-

Increased Tensile Strength: Better resistance to external mechanical damage, such as impact from heavy machinery or environmental stressors like soil weight in underground applications.

-

Corrosion Allowance: In chemical processing, the interior of the pipe erodes over time. The thicker wall of Sch 80 offers a longer service lifespan before the pipe wall becomes critically thin.

Flow Characteristics and Efficiency

Engineers must account for the Flow Coefficient (Cv). Because Sch 80 has a smaller ID, it restricts fluid volume compared to a Sch 40 pipe of the same NPS.

-

Result: To maintain the same flow rate (GPM) in a Sch 80 system, the fluid velocity must increase, or a larger pump is required.

-

Recommendation: If the primary goal is high-volume water transport at low pressure, Sch 40 is economical. If the system involves high-pressure steam, hydraulic fluid, or aggressive chemicals, Sch 80 is the mandatory specification.

Table 2: Comparative Analysis (Example: 2-Inch Pipe)

| Feature | Schedule 40 (Standard) | Schedule 80 (Extra Heavy) |

| Wall Thickness | 0.154 inches | 0.218 inches |

| Inside Diameter | 2.067 inches | 1.939 inches |

| Approx. Burst Pressure | 2,500 PSI | 4,200 PSI |

| Primary Use Case | Water lines, HVAC, low-pressure gas | High-pressure steam, chemical plants, oil refineries |

| Threading | Standard NPT | Robust NPT (Less risk of wall failure during cutting) |

| Cost Factor | Baseline | Premium (More raw material) |

At MWalloys, we assist clients in performing this cost-benefit analysis. While Sch 80 carries a higher initial material cost, its longevity in harsh environments often results in a lower Total Cost of Ownership (TCO).

Material Grades and Manufacturing Protocols at MWalloys

The "Schedule 80" designation refers only to dimensions. The performance of the pipe is equally dependent on the material grade and manufacturing method. MWalloys utilizes premium steel billets and advanced rolling technologies to produce pipes that exceed industry expectations.

Primary Material Specifications

We manufacture and stock Schedule 80 pipe in several key ASTM standards:

-

ASTM A106 Grade B / C (Seamless Carbon Steel):

-

The industry standard for high-temperature service.

-

Application: Refineries, power plants, and boilers.

-

MWalloys Advantage: We utilize a killed steel process to ensure a fine grain structure, enhancing heat resistance.

-

-

ASTM A53 Grade B (Seamless & ERW):

-

Suitable for mechanical and pressure applications; capable of being coiled, bent, and flanged.

-

Dual Certification: Many of our pipes are dual-certified A106/A53 to simplify inventory for our clients.

-

-

ASTM A333 Grade 6 (Low-Temperature Carbon Steel):

-

Designed for service where notch toughness at temperatures as low as -50°F (-45°C) is required.

-

Application: Cryogenic services and artic pipelines.

-

-

-

Used for transporting gas, water, and oil in the natural gas and petroleum industries. Available in grades from B to X70.

-

Manufacturing Methods: Seamless vs. Welded

-

Seamless (SMLS): MWalloys produces seamless Sch 80 pipe by extruding a solid steel billet through a piercing rod. This eliminates the weld seam—the weakest point of a pipe. Seamless is the preferred choice for ultra-high pressure.

-

ERW (Electric Resistance Welded): For less critical applications or larger diameters, we offer ERW pipe. Our process involves high-frequency induction welding followed by full-body heat treatment to normalize the weld zone, making it structurally nearly equivalent to the parent metal.

Customization Services

Since we are the factory, MWalloys offers customization unavailable through generic distributors:

-

Custom Lengths: We cut to precise project requirements (e.g., 18ft, 22ft) to minimize onsite waste.

-

Surface Coatings: Options include Black Lacquer, Hot Dip Galvanized (Zinc), FBE (Fusion Bonded Epoxy), or 3LPE for underground corrosion protection.

-

End Preparation: Plain End (PE), Beveled End (BE) for welding, or Threaded & Coupled (T&C).

Pressure Ratings, Temperature Tolerances, and Performance Metrics

Determining the Safe Working Pressure (SWP) for Schedule 80 pipe is complex, as it relies on temperature and material strength. Engineers typically utilize Barlow’s Formula for internal pressure calculations:

P=2×S×t/D-

P = Internal Pressure

-

S = Yield Strength of Material (PSI)

-

t = Wall Thickness (inches)

-

D = Outside Diameter (inches)

However, strictly relying on Barlow’s formula is insufficient for high-temperature applications where the yield strength of steel diminishes.

Temperature Derating Factors

Carbon steel loses strength as temperatures rise. A pipe rated for 3000 PSI at 100°F might only be rated for 2200 PSI at 700°F.

-

400°F - 600°F: Minimal reduction in strength for A106 Gr B.

-

700°F+: Creep rupture properties become significant.

-

MWalloys Assurance: We provide Mill Test Reports (MTRs) with every shipment, detailing the chemical composition and yield strength, allowing your engineers to calculate exact safety margins.

Table 3: Estimated Maximum Working Pressure (PSI) for A106 Gr B Schedule 80

| NPS | @ 100°F (38°C) | @ 400°F (204°C) | @ 600°F (315°C) |

| 1/2" | 8,500 | 7,600 | 7,000 |

| 1" | 7,100 | 6,400 | 5,900 |

| 2" | 4,800 | 4,300 | 3,900 |

| 4" | 3,900 | 3,500 | 3,200 |

| 8" | 3,100 | 2,800 | 2,600 |

| 12" | 2,800 | 2,500 | 2,300 |

Disclaimer: These figures are estimates based on standard yield strengths. Always verify with a certified engineer and local codes (ASME B31.1 / B31.3).

Industrial Applications and Installation Best Practices

Schedule 80 pipe is the backbone of heavy industry. Its robust nature makes it indispensable in sectors where failure is not an option.

Key Industry Sectors

-

Petrochemical & Refining: Used in hydro-processing units and distillation columns where high pressures and corrosive fluids are constant.

-

Power Generation: Essential for high-pressure steam lines (superheated steam) in thermal power plants.

-

Hydraulic Systems: The heavy wall allows for the transmission of hydraulic fluid at pressures exceeding 5,000 PSI in smaller diameters.

-

Marine & Offshore: Resistant to the mechanical stresses of wave motion and the corrosive nature of saltwater (especially when galvanized).

Installation & Joining Techniques

-

Welding: Due to the thick wall, multiple weld passes are often required. Beveling is critical. MWalloys provides pipes with a standard 37.5° bevel to expedite onsite welding.

-

Threading: One specific advantage of Schedule 80 is that it maintains sufficient wall thickness even after threading. With Schedule 40, deep threads can weaken the pipe wall significantly. Schedule 80 retains structural integrity at the joint, making it the preferred choice for threaded high-pressure connections.

-

Support Spacing: Schedule 80 is heavier than Schedule 40. Pipe racks and hangers must be calculated to support the increased dead weight, especially when the pipe is fluid-filled.

Global Standards, Testing, and Quality Assurance

At MWalloys, quality is not a department; it is an integrated manufacturing philosophy. We understand that our pipes often end up in critical safety applications.

Non-Destructive Testing (NDT)

Before leaving our factory, Schedule 80 pipes undergo rigorous testing:

-

Hydrostatic Testing: Pipes are pressurized with water to 1.5 times their design pressure to detect leaks or structural weaknesses.

-

Ultrasonic Testing (UT): Used to detect internal imperfections or laminations in the steel wall.

-

Eddy Current Testing: Utilized for surface defect detection in ERW pipes.

Compliance Documentation

Every order from MWalloys is accompanied by:

-

MTR (Mill Test Report): Verifying chemical analysis (Carbon, Manganese, Sulfur, etc.) and mechanical properties (Yield, Tensile, Elongation).

-

Heat Number Traceability: Every pipe is stenciled with a heat number that links it back to the specific batch of molten steel.

-

Third-Party Inspection: We welcome inspections from agencies like SGS, BV, or Lloyds upon client request.

Purchasing Guide: Factory Direct Pricing and Customization

In the current global supply chain environment, procurement efficiency is paramount. Buying from distributors often involves markups of 20-40% and limited control over lead times.

Why MWalloys?

-

100% Factory Price: You are dealing with the source. No trading companies, no hidden fees.

-

Flexible MOQ: Whether you need a single bundle for a repair job or 50 containers for a pipeline project, we accommodate your needs.

-

Logistics Mastery: We handle export packaging (hexagonal bundles with steel strips, plastic caps, waterproof wrapping) and coordinate shipping to any major port globally.

How to Request a Quote:

When contacting MWalloys, please specify:

-

NPS & Schedule: (e.g., 4" Sch 80).

-

Material Grade: (e.g., ASTM A106 Gr B).

-

Quantity: (Feet, Meters, or Tons).

-

End Finish: (Beveled, Threaded, or Square Cut).

-

Coating Requirements.

Frequently Asked Questions (FAQs)

Can Schedule 80 pipe be threaded?

What is the difference between Schedule 80 and Schedule 80S?

Is Schedule 80 stronger than Schedule 40?

Does Schedule 80 pipe reduce flow rate?

Can I weld Schedule 40 pipe to Schedule 80 pipe?

What is "Extra Strong" (XS) pipe?

Can MWalloys provide galvanized Schedule 80 pipe?

What is the maximum temperature for Schedule 80 Carbon Steel pipe?

How do I identify Schedule 80 pipe on site?

What is the difference between seamless and welded Schedule 80?

Contact MWalloys today to discuss your Schedule 80 steel pipe requirements. Our engineering team is ready to optimize your procurement strategy with factory-direct precision and pricing.