Mold and Die Steels

Products

Mold and die steels are purpose-engineered tool alloys selected to balance toughness, wear resistance, dimensional stability and thermal fatigue resistance for molding and die applications. For most injection-molding and plastic-mold bases, P20 / 1.2311 (pre-hardened) remains the economical, machinable workhorse; for hot-work or high-temperature die casting and extrusion H13 / 1.2344 (hot-work chromium–molybdenum) is the standard choice; for long runs, abrasive materials or extreme hardness requirements cold-work grades (D-series, A-series) or high-chrome, high-vanadium tool steels are used. Choosing the right grade depends on part material, cycle life, finish, size and budget — and that selection drives cost, delivery lead time and downstream processing.

What is a mold steel?

A mold or die is a capital asset whose life is determined by the steel selected, its heat treatment, and how it is processed and maintained. Key priorities most engineers optimize for are:

-

Dimensional stability (so features stay in tolerance after hardening and in service)

-

Toughness & crack resistance (for high-cycle or thermal-shock conditions)

-

Wear / abrasion resistance (for abrasive resins, glass-filled plastics or high shot weights)

-

Polishability & surface finish (optical parts, medical, consumer goods)

-

Thermal fatigue / heat-checking resistance (for high-temperature die casting/extrusion)

-

Machinability & EDM characteristics (affects lead time and total cost)

The trade-offs are real: higher hardness improves wear resistance but reduces toughness and increases machining difficulty; more alloying improves red hardness and thermal resistance but raises price. Make the selection based on the dominant failure mode expected for your tooling.

mold steel grades

-

Pre-hardened plastic mold steels — ready to machine, good machinability and polish, used for medium-life production or prototype molds.

-

Through-hardened tool steels (cold-work) — higher wear resistance for long-run molds, require heat treatment (hardening + tempering).

-

Hot-work tool steels — for die casting, hot stamping, and molds that run at elevated cavity temperatures (high thermal shock & tempering resistance).

-

Stainless / corrosion-resistant mold steels — for corrosive plastics, long polish life, or clear/optical parts.

-

Nitridable / surface-hardenable steels — improve surface wear without making the whole block extremely hard (good when core toughness is needed).

-

Powder-metallurgy tool steels — very high wear resistance and toughness for extreme run lengths and tight tolerances.

P20 (pre-hardened, general purpose)

-

Type: Pre-hardened, low alloy mould steel for plastic injection tooling.

-

Typical hardness: ~28–32 HRC (pre-hardened).

-

Pros: Excellent machinability, good dimensional stability after machining, economical.

-

Cons: Moderate wear resistance — not ideal for very long runs or abrasive-filled plastics.

-

Use: Medium-run injection molds, large cores & cavities where ease of machining and cost matter.

NAK-series (e.g., NAK80) / other pre-hardened mold steels

-

Type: Pre-hardened, designed for good polishability and stability.

-

Typical hardness: ~30–36 HRC.

-

Pros: Better polishability and surface finish than standard P20; often chosen for optical/visible parts.

-

Use: High-surface-finish plastic molds, prototype and production inserts.

H13 (hot-work tool steel)

-

Type: Chromium-molybdenum-vanadium hot-work steel.

-

Typical hardness: ~44–52 HRC (after hardening & tempering).

-

Pros: Excellent thermal fatigue resistance, good toughness and hot strength.

-

Cons: More difficult to machine in the hardened state; pricier than P20.

-

Use: Die casting cores/inserts, hot stamping, molds with high thermal cycles.

D2 (high carbon, high chromium cold-work tool steel)

-

Type: High wear cold-work steel (high chromium).

-

Typical hardness: ~56–62 HRC (hardened).

-

Pros: Excellent wear resistance and edge retention.

-

Cons: Lower toughness (can be brittle), more difficult to polish to optical finish than some stainless grades.

-

Use: Long-run tooling where abrasion/wear dominates (but careful with impact/shock).

S7 (shock-resistant tool steel)

-

Type: Air-hardening, high-toughness tool steel.

-

Typical hardness: ~46–56 HRC (depending on heat treat).

-

Pros: Very good toughness and resistance to shock and chipping.

-

Cons: Not as wear-resistant as D2.

-

Use: Tools/molds subject to impact or heavy ejection forces.

O1 (oil-hardening cold-work tool steel)

-

Type: General purpose tool steel for cold work.

-

Typical hardness: ~58–62 HRC (hardened).

-

Pros: Good dimensional stability after heat treat, decent wear resistance for many cold-work applications.

-

Use: Dies, punches, simple mold components for moderate runs.

Stainless mold steels (e.g., 420, 440C, S136)

-

Type: Martensitic stainless steels and dedicated mold stainless grades.

-

Typical hardness: 420 / 440C: ~48–56 HRC; S136 and special mold stainless grades often ~48–52 HRC.

-

Pros: Corrosion resistance, excellent polishability (especially stainless tool steels made for molding), long cosmetic life for transparent/medical parts.

-

Cons: Costlier, some stainless grades are less tough or harder to EDM. 440C is very wear resistant but can be brittle/less polishable than dedicated stainless mold steels.

-

Use: Molds for corrosive resins, transparent/optical parts, long-life cosmetic surfaces.

Powder-metallurgy steels (e.g., PM grades, high alloy)

-

Type: PM tool steels built for high wear resistance + toughness.

-

Pros: Exceptional wear resistance with better toughness than conventional steels.

-

Cons: Higher material cost and sometimes more difficult to machine (but they finish very well once heat treated).

-

Use: Extremely long runs, abrasive plastics, precision molds.

Quick selection checklist

-

Part material: abrasive (glass-filled) → choose high wear steel (D2, PM steels); corrosive/resin with release agents → stainless.

-

Surface finish required: optical/shine → choose stainless (S136) or NAK80/other polishable pre-hardened steels.

-

Shot count / production life: prototype / small run → P20/NAK80; long runs → hardened D2, PM steels or hardened stainless inserts.

-

Thermal cycling / hot-work: die casting or hot stamping → H13 or equivalent hot-work steels.

-

Complex geometry & EDM: if heavy EDM needed, select steels that EDM and stabilize well; consider provision for post-EDM heat treatment.

-

Budget & lead time: pre-hardened steels shorten production time (no post-machining hardening), but may trade off lifetime.

Chemical composition (comparison table)

The table below gives representative nominal composition ranges for the three most referenced grades in molding and die work (P20, H13, and a typical cold-work D-grade such as D2). These are typical ranges; always confirm mill/test certificates for procurement.

| Element (wt%) | P20 (1.2311 / 3Cr2Mo) (typ.) | H13 (1.2344 / SKD61) (typ.) | D2 (cold work) (typ.) |

|---|---|---|---|

| C | 0.28–0.38 | 0.32–0.45 | 1.40–1.60 |

| Si | 0.10–0.40 | 0.80–1.20 | 0.20–0.60 |

| Mn | 0.50–0.90 | 0.20–0.50 | 0.30–0.60 |

| Cr | 1.30–1.80 | 4.75–5.50 | 11.00–13.00 |

| Mo | 0.30–0.70 | 1.10–1.75 | 0.70–1.50 |

| V | trace–0.15 | 0.80–1.20 | 0.90–1.50 |

| Ni | 0–0.30 | ≤0.30 | ≤0.30 |

Sources & notes: P-type compositions are commonly published by tool steel suppliers; H13 ranges are documented in AISI/ASM literature and European equivalents (1.2344 / SKD61). Always check the material test report (MTR) and any ESR/VD/PM labels for premium steels.

What each alloying element does (practical summary)

-

Carbon (C): controls baseline hardness & wear resistance; high C increases wear but reduces toughness.

-

Chromium (Cr): improves hardenability, wear and corrosion resistance; crucial for red hardness in H-grades.

-

Molybdenum (Mo): increases temper resistance and toughness at high temperatures; helps prevent softening.

-

Vanadium (V): forms hard carbides — improves wear resistance and refines grain size (improves toughness).

-

Silicon (Si) & Manganese (Mn): improve strength and hardenability, but too much can affect toughness and machinability.

This functional mapping helps engineering teams decide which property to prioritize based on expected failure modes.

Material properties (typical working ranges)

| Property | P20 (pre-hardened) | H13 (hot-work) | D2 (cold, high wear) |

|---|---|---|---|

| Typical supply hardness | 28–34 HRC | Annealed ~220 HB — hardened 40–52 HRC (depending on treatment) | 26–32 HRC (annealed) — hardened up to 60 HRC |

| Density | ≈ 7.85 g/cm³ | ≈ 7.8–7.9 g/cm³ | ≈ 7.7–7.9 g/cm³ |

| Thermal conductivity | moderate | moderate | lower |

| Toughness | good | high (thermal shock resistance) | lower |

| Machinability | excellent | fair to good (pre-hardened easier) | poor (higher tool wear) |

| Typical uses | plastic injection molds, mold bases | die casting, extrusion, hot forging dies | cutting tools, high-abrasion molds |

For accurate mechanical data (tensile, yield, impact toughness, fatigue) consult supplier datasheets and MTRs; H13 thermal fatigue performance and hot-hardness behavior are widely documented in ASM/industry literature.

Specifications, standards & procurement controls

Important international standards and specifications commonly referenced when specifying mold & die steels:

-

ASTM A681 — Standard specification for alloy tool steels (chemical/mechanical requirements and supply conditions).

-

ISO 4957 — Tool steels — designation and general requirements (widely used in Europe / global supply chains).

-

AISI / ASM datasheets — provides typical compositions, heat treatment practice and property ranges for named grades (e.g., H13).

-

DIN / EN equivalents — e.g., 1.2311 (P20), 1.2344 (H13) — used in European procurement and mill certifications.

Procurement notes: Always require: mill certificate (EN 10204 3.1 or equivalent), hardness range in the order, inclusion of ESR/VD/PM labeling where applicable, and clear acceptance criteria for defects, inclusions and heat treatment. For critical tooling, require a sample coupon for destructive testing or a certified nondestructive inspection plan.

Metal molding processes & steel selection matrix

-

Injection molding (thermoplastics): Typical plastics (ABS, PP) → P20 / pre-hardened steels for cavities and bases. For abrasive glass-filled resins or long runs, upgrade cavity inserts to higher-hardness steels or nitrided P-variants.

-

Compression molding / transfer molding: May use H11/H13 for heat and thermal shock resistance for higher temperature resins.

-

Die casting (aluminum, magnesium, zinc): H13 and its equivalents are standard for hot-work cavities and core inserts due to excellent red hardness and thermal fatigue resistance.

-

Extrusion dies & forging dies: H13 or premium hot-work PM grades; design for cooling and re-tempering cycles.

-

Cold stamping & blanking: D-type / A-type cold-work steels for high abrasion resistance.

Selecting the correct grade directly reduces downtime and repair frequency; many high-value molds rely on a combination (P20 base + hardened inserts).

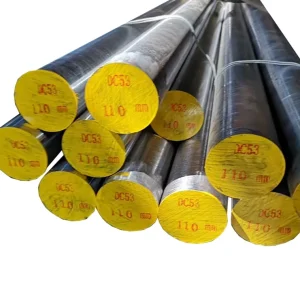

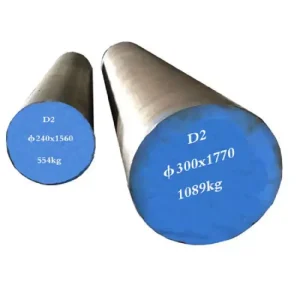

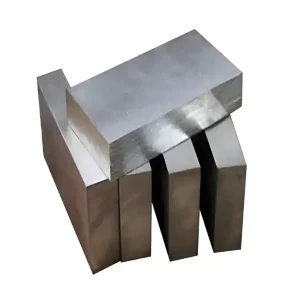

Typical sizes, weight and supply forms

Common supply forms: plates, blocks, forged bars and round stock, pre-hardened plate, and PM-produced blanks. Typical plate thickness and weight conversions used in procurement:

-

Plate density ~7.85 g/cm³ (7.85 t/m³) — so a 1,000 × 2,000 mm × 100 mm plate ≈ 1.57 metric tonnes.

-

Round bar weight (kg/m) ≈ (π/4) × D²(mm) × 7.85 × 10⁻⁶ — quick rule for estimating shipping and FOBs.

-

Size ranges: P20 plates often available from 16 mm up to 800 mm thickness (depending on mill), H13 forged round stock frequently in Ø50–800 mm lengths to 4–6 m depending on mill and forging capacity.

Machining & EDM: Pre-hardened materials speed early machining but may require finish-hardening or nitriding; hardened inserts require careful EDM practices to avoid cracking (use slow roughing, proper flushing, tempering cycles).

2025 price snapshot (USA / Europe / China)

Important: steel pricing is volatile — the ranges below are market-level budgets gathered from current supplier listings, industrial marketplaces and distributor price points in mid-2024 through mid-2025. Use them for ballpark planning only; obtain current quotes for procurement. The ranges are FOB/EXW per metric tonne for typical commercial forms (plate, round) and do not include machining, heat treatment, or freight.

Representative 2025 budget ranges (USD / metric tonne):

| Grade | China (factory/market listings) | USA (retail/distributor) | Europe (trade/MEPS & distributors) |

|---|---|---|---|

| P20 / 1.2311 (pre-hardened) | ~USD 520–1,100 / t (multiple China factory listings). | ~USD 1,000–2,500 / t (retail & small volume premium). | ~EUR 800–2,000 / t (~USD 900–2,300) depending on remelt, surface and mill. |

| H13 / 1.2344 (hot-work) | ~USD 1,600–2,700 / t (China forged/ESR listings). | ~USD 1,500–3,500 / t (varies widely by shape & quantity — retail prices per ton equivalent). | ~EUR 1,200–3,000 / t (~USD 1,300–3,200) (premium remelt or PM grades cost more). |

| D2 / cold-work premium | ~USD 1,500–3,000 / t (depending on remelt & supply). | ~USD 2,000–4,500 / t | ~EUR 1,800–4,000 / t |

Notes & sourcing: China wholesale platforms (Made-in-China / Alibaba / manufacturer listings) show low-end P20 offerings starting below USD 700/t for high-MOQ FOBs; H13 and premium remelt/ESR bars are higher. U.S. retail distributors (OnlineMetals, Xometry) show higher unit prices for cut & small quantities. Market intelligence and regional commodity steel trends also influence tooling-grade prices. Always request certified MTRs and confirm if quoted prices are for raw forged/rolled material or include value-added processing (flatness, machining, heat-treatment, ESR/VD).

Heat treatment, surface options & post-processing

Common finishing and thermal processes for molds and dies:

-

Pre-hardening + final hardening: P20 commonly supplied pre-hardened; cavities sometimes hardened locally or inserts hardened to higher HRC.

-

Nitriding / ion nitriding: Improves surface wear and reduces galling while preserving core toughness—common for P20 variants.

-

ESR / VIM / PM remelting: Premium remelting reduces inclusions, improves toughness, and is recommended for high-duty die casting molds.

-

Cryogenic tempering & subzero treatments: For extremely tight dimensional stability or to reduce retained austenite in some PM steels.

-

Polishing & coating: PVD or DLC coatings are niche for ejector pins and high-friction contact points.

Specify the heat-treatment schedule and target hardness in the purchase order and require proof of treatment (hardness maps, microstructure if required).

Selection checklist for procurement teams

-

Define the dominant failure mode (wear, thermal shock, impact, corrosion, polishing requirement).

-

Choose grade family (P20 for general injection molding; H13 for hot-work; D/A for high abrasive cold work).

-

Specify form (plate, forged bar, round, PM blank) and supply condition (pre-hardened, annealed).

-

Require EN 10204 / MTR, remelt level (ESR/VD/PM), and hardness acceptance criteria.

-

Ask for sample coupons for critical molds or require destructive testing for first article.

-

Confirm delivery lead time, stock availability, and whether the supplier offers fast-cut services (MWalloys offers stock & quick delivery options; see below).

Frequently Asked Questions

Q1: What’s the easiest way to decide between P20 and H13?

A: If your mold works below 120–150°C and needs excellent machinability and polishability, P20 is usually the right first choice. If the tool will see molten metal, hot forging, or continuous high thermal shock, H13 is the safer choice.

Q2: Can P20 be hardened to very high HRC?

A: P20 is intended as a pre-hardened, machinable steel; it can be carburized or localized hardened but is not typically taken to the high HRC levels of cold-work steels. For high hardness needs consider nitriding or hardened D2/PM grades.

Q3: What is ESR/VD/PM and why pay more?

A: ESR (electroslag remelting), VD (vacuum degassing) and PM (powder metallurgy) minimize non-metallic inclusions and provide improved toughness and fatigue life — worth the premium for critical, high-duty molds.

Q4: How do I budget for tooling steel?

A: Use the per-ton ranges in section 9 as a starting point, then add machining, heat treatment, shipping and customs. Small-quantity retail orders carry a higher per-kg premium than bulk FOB.

Q5: Are China-sourced steels reliable?

A: Many reputable Chinese mills supply to global OEMs with full MTRs and remelt options. Vet the mill, request MTRs, and specify remelting/ESR/PM if required. MWalloys supplies factory-direct stock with certificates and expedited shipping for standard grades.

Q6: How should I specify surface finish and flatness?

A: Provide explicit tolerances (e.g., flatness mm per m, surface roughness Ra for polish) and require pre-heat-treatment milling and inspection if the application is tight.

Q7: What are typical lead times?

A: Stock items and pre-hardened plates are often available within days–weeks. Forged, remelted or custom PM blanks can take multiple weeks to months. MWalloys maintains stock for fast delivery on common sizes.

Q8: Can you weld H13 or P20?

A: Both can be welded with appropriate procedures (preheat, low hydrogen consumables, post-weld heat treat). Consult welding procedure specs and test coupons.

Q9: Is nitriding recommended for all molds?

A: Nitriding is valuable for improving surface wear and resistance to galling on cavities and cores but not for parts where high polish is required unless optimized for polishing.

Q10: How to prevent heat checking on die casting molds?

A: Use hot-work grades like H13, ensure good cooling design, follow recommended tempering cycles, consider surface treatments (nitriding/coatings) and schedule maintenance re-tempering.

Why buy Mold & Die Steel from MWalloys

MWalloys manufactures and supplies a wide range of mold and die steels including P20 (1.2311), H13 (1.2344) and premium remelted variants. Key customer advantages we operate with:

-

100% factory price — direct mill relationships reduce intermediaries and improve cost competitiveness; this is particularly attractive for bulk procurement.

-

Stock availability & fast dispatch — common plate and bar sizes held in inventory for expedited delivery to meet short lead-time projects.

-

Quality assurance — MTRs provided; ESR & PM options available on request for critical tooling.

-

Technical support — metallurgical consultation for grade selection, heat-treat guidance and finishing options to maximize mold life.