Alloy Springs

Products

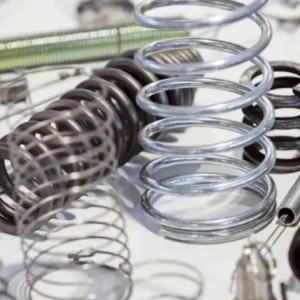

MWAlloys is a China-based specialist in high-performance alloy springs, offering factory-direct pricing, full customization and rapid lead times. Serving aerospace, petrochemical, automotive and precision machinery sectors, our expert team delivers springs in Nickel, Inconel, Monel, Hastelloy, Incoloy, Titanium and Carbon Steel—each engineered for maximum resilience in extreme environments.

What Is an Alloy Spring?

An alloy spring is a mechanical component fabricated from corrosion- and heat-resistant metallic alloys. Unlike standard carbon-steel springs, alloy springs maintain high tensile strength, excellent fatigue life and dimensional stability under high temperatures and corrosive media. Common applications include valve actuators, sealing assemblies, aerospace fasteners and chemical-process equipment.

Chemical Composition of Alloy Springs

| Material | Key Elements (wt %) |

|---|---|

| Nickel | Ni ≥ 99.0 |

| Inconel | Ni 72 – 76, Cr 14 – 17, Fe 6 – 10, Nb + Ta 3.0 – 5.0, Ti ≤ 1.0 |

| Monel | Ni 63 – 70, Cu 28 – 34, Fe ≤ 2.5, Mn ≤ 2.0, C ≤ 0.30 |

| Hastelloy (C276) | Ni 57 – 63, Mo 15 – 17, Cr 14.5 – 16.5, Fe 4.0 – 7.0, W 3.0 – 4.5, Co ≤ 2.5 |

| Incoloy (825) | Ni 38 – 46, Fe 19.5 – 23.5, Cr 19.5 – 23.5, Mo 2.5 – 3.5, Cu 1.5 – 3.0, Ti + Al ≤ 1.0 |

| Titanium (Grade 5) | Ti balance, Al 5.5 – 6.75, V 3.5 – 4.5, Fe ≤ 0.30, O ≤ 0.20 |

| Carbon Steel | C 0.45 – 0.95, Si 0.15 – 0.40, Mn 0.60 – 1.05, P ≤ 0.035, S ≤ 0.040 |

Mechanical Properties of Alloy Springs

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|

| Nickel | 400 – 550 | 200 – 300 | ≥ 40 | ≤ 20 |

| Inconel | 750 – 1,100 | 350 – 690 | ≥ 30 | 35 – 45 |

| Monel | 580 – 930 | 200 – 415 | ≥ 30 | 25 – 35 |

| Hastelloy C276 | 630 – 860 | 240 – 460 | ≥ 35 | 30 – 40 |

| Incoloy 825 | 620 – 850 | 275 – 480 | ≥ 30 | 28 – 38 |

| Ti Grade 5 | 895 – 1,100 | 825 – 950 | ≥ 10 | 36 – 41 |

| Carbon Steel | 1,650 – 2,100 | 1,250 – 1,800 | ≥ 8 | 45 – 55 |

Common Grades, Standards & Advantages

| Grade / Standard | Material | Standard | Key Advantages |

|---|---|---|---|

| UNS N02200 | Nickel | ASTM B161 | Excellent ductility, low-temperature performance |

| Alloy 600 | Inconel | ASTM B168 | Oxidation resistance, high-temperature strength |

| Monel 400 | Monel | ASTM B164 | Outstanding seawater resistance, toughness |

| Hastelloy C276 | Hastelloy | ASTM B575 | Superior corrosion resistance in harsh acids |

| Incoloy 825 | Incoloy | ASTM B407 | Stress-corrosion cracking resistance, versatility |

| Ti Grade 5 | Titanium | ASTM B348 | Exceptional strength-to-weight, biocompatibility |

| ASTM A227 | Carbon Steel | ASTM A227 | High fatigue life, cost-effective for general spring use |

Global Price Comparison for 2025 (USD/kg)

| Material | China (¥→$) | USA | Germany | India |

|---|---|---|---|---|

| Nickel Springs | $42 | $52 | $58 | $47 |

| Inconel Springs | $65 | $78 | $85 | $70 |

| Monel Springs | $55 | $65 | $72 | $60 |

| Hastelloy C276 | $72 | $85 | $95 | $80 |

| Incoloy 825 | $60 | $72 | $80 | $68 |

| Titanium G5 | $50 | $62 | $70 | $58 |

| Carbon Steel | $15 | $18 | $20 | $16 |

French Procurement Case Study

In Q3 2024, a leading French aerospace OEM required 2,000 custom Inconel 718 springs for turbine blade retention. MWAlloys collaborated on detailed CAD reviews, delivered first prototypes in just 3 weeks, and completed full order in 6 weeks—including heat treatment and 100% dimensional inspection. The springs exceeded fatigue-life targets by 15% and are now in serial production on two new engine platforms.

Why Choose MWAlloys for Alloy Springs

- Factory-Direct Pricing: Eliminate middlemen for best-in-market rates.

- Full Customization: Springs tailored to tolerances as tight as ± 0.02 mm.

- Rapid Lead Times: Standard runs in 2–4 weeks; expedited service in as little as 7 days.

- Global Quality Standards: ISO 9001, API, ASTM certifications.

- Technical Support: Application engineering from initial design through post-delivery.

Frequently Asked Questions

- Q: What tolerances can MWAlloys achieve on spring dimensions?

A: We routinely hold ± 0.02 mm on wire diameter and ± 0.05 mm on coil OD; tighter tolerances available on request. - Q: Can you provide springs pre-loaded or pre-set?

A: Yes—our process includes custom pre-load testing, set treatment and shot peening per AMS-SQ standards. - Q: What surface finishes are available?

A: We offer passivation, electropolishing, phosphate coating, PTFE coating and custom plating (Ni, Zn, etc.). - Q: Do you supply material test reports (MTRs)?

A: All orders include full MTRs per EN 10204 3.1 or 3.2, plus dimensional and load-deflection certificates. - Q: How do I request a custom spring quote?

A: Send your spring specs (material, wire size, coils, free height, load requirements) to sales@mwalloys.com for a rapid quotation.