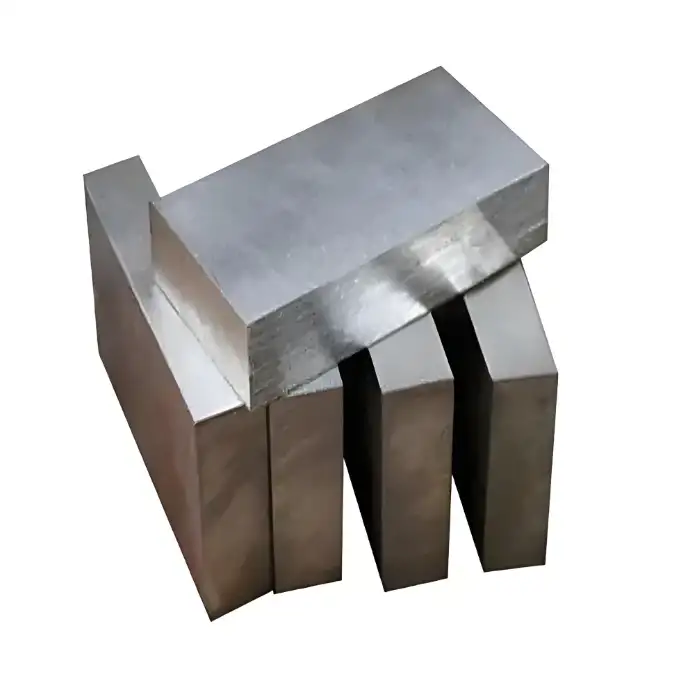

S7 is a high-toughness, shock-resisting, air-hardening tool steel prized where heavy impact, sudden loads and dimensional stability during heat treatment matter more than ultimate wear resistance; it is a go-to grade for punches, shear blades, driving components and medium hot-work dies, and when specified and heat-treated correctly it delivers an excellent balance of toughness, strength and machinability.

What is S7 tool steel?

S7 belongs to the “S” group of shock-resisting tool steels in the AISI/SAE system and is formulated to retain hardness while delivering very high impact toughness and resistance to chipping under shock loading. It is produced as an air- or oil-hardening alloy (many mills supply it as an air-hardening variant), and because of its composition it hardens with minimal distortion compared with water-quenched grades. Typical uses include heavy-duty punches, chisels, shear blades, forging dies, and components that see repeated impact or abrupt loading.

Why engineers pick S7: compared with higher-chrome, high-wear grades (e.g., D2), S7 trades some wear resistance for markedly higher toughness and lower sensitivity to heat-treatment distortion — this makes it safer and more reliable for shock service.

S7 Steel Chemical composition

Below is a consolidated, industry-accepted nominal composition range for AISI S7 (UNS T41907). Individual mill certificates should be checked for exact values.

| Element | Typical range (wt. %) |

|---|---|

| Carbon (C) | 0.45 – 0.55 (nom. 0.50) |

| Manganese (Mn) | 0.20 – 0.80 (nom. 0.70) |

| Silicon (Si) | 0.20 – 1.00 (nom. 0.30) |

| Chromium (Cr) | 3.00 – 3.50 (nom. 3.25) |

| Molybdenum (Mo) | 1.30 – 1.80 (nom. 1.40) |

| Vanadium (V) | 0.20 – 0.30 |

| Copper (Cu) | ≤ 0.25 (trace) |

| Phosphorus (P) | ≤ 0.03 (max) |

| Sulfur (S) | ≤ 0.03 (max) |

| Iron (Fe) | Balance |

Sources for these nominal ranges: manufacturer datasheets and independent technical reviews. Always confirm actual certificate from the mill or supplier.

S7 Steel Material properties

Practical design and selection require both annealed (soft) condition data and heat-treated (hardened/tempered) performance. The following tables summarize commonly referenced properties.

Key mechanical & physical data (typical)

| Property | Typical value / range |

|---|---|

| Density | 7.83 g/cm³ (0.283 lb/in³). |

| Modulus of Elasticity | ≈ 207 GPa (30 × 10⁶ psi). |

| Annealed hardness | ~ 200–240 HB (approx. 18–24 HRC equivalent after normalization). |

| Hardened hardness (tempered) | 50–58 HRC achievable (depends on tempering). Typical handbook values: 52–57 HRC for air-cooled & tempered S7. |

| Tensile strength (hardened) | up to ≈ 900–1100 MPa (130–160 ksi) depending on heat treatment. |

| Impact toughness (Charpy) | High — among S-series this grade shows the largest unnotched and notched energy retention; values depend on heat treatment (example datasheets show > 20–60 J in specific conditions). |

| Thermal conductivity | ≈ 28.5 W/m·K (16.5 BTU/hr-ft-°F). |

| Machinability | Roughly 70–75% of a 1% carbon steel in the annealed condition (very good). |

Practical note: property values vary with clean-liness (sulfide/phosphide inclusions), microstructure, and precise thermal cycle. When specifying for critical tooling, mandate a mill test report (chemical + heat-treatment trace) and specify decarburization limits for surface critical parts.

Specifications and designations

-

AISI / SAE designation: S7 (shock-resisting). UNS: T41907.

-

Common mill numbers / EN / DIN cross references: 1.2355 (European mold/steel reference sometimes used in trade listings), 50CrMoV13-15 (older mapping variants). Cross-reference lists vary by region and should be used only as an approximate mapping.

-

Relevant ASTM standards: ASTM A681 (Standard Specification for Tool Steels, Alloy) covers wrought alloy tool steels; ASTM A686/A681 family includes related practices for testing, composition and mechanical requirements. Use ASTM standards to specify delivery conditions, macroetch, and chemical analysis test methods.

Authority & testing: For chemical analysis of tool steels and referee testing methods, ASTM E352 provides standard test methods; for bar and forgings, see ASTM A686/A681 listings. Including these standards in purchase orders improves traceability and helps ensure compliance with intended service conditions.

Heat treatment behaviour & recommended cycles

S7 is typically supplied in an annealed condition for machining and finished then through quench/temper cycles to reach design hardness.

Typical heat-treat sequence (industry practice):

-

Preheat: raise slowly to ~650–760 °C (1200–1400 °F) to reduce thermal gradients.

-

Austenitize (hardening): common austenitizing range ≈ 815–870 °C (1500–1600 °F) depending on section thickness and desired hardness. For higher hardenability and toughness, some mills specify 850–880 °C.

-

Quench: air or oil quench — S7 is air-hardening to a significant extent which reduces distortion; large sections may still use controlled oil quench to ensure the desired structure.

-

Temper: temper at 150–650 °C (300–1200 °F) depending on the target hardness. Multiple tempers (double tempering) are common to stabilize the microstructure and reduce retained austenite. Higher temper temperatures reduce hardness but increase toughness.

Key behaviour notes:

-

S7 is forgiving in heat treatment relative to water-quenched steels — lower distortion and cracking risk.

-

Tempering response: S7 retains good hardness at moderate temper temperatures, providing useful retention of wear resistance while keeping toughness.

Metal moulding & manufacturing processes

S7 is compatible with common manufacturing routes typical of tool steels. The following summarizes best practice considerations.

Forging & hot work

-

S7 can be forged for heavy-section tooling; controlled forging temperatures and post-forge normalization reduce segregation and produce a uniform microstructure. Because S7 carries moderate alloy additions, maintain forging temperatures recommended by the mill to avoid grain coarsening.

Machining

-

In annealed condition S7 machines well (70–75% machinability of low-carbon steel). For finishing passes and precision features, machine in the annealed condition then finish-grind after final heat treat. Carbide tooling and appropriate feeds/speeds recommended when machining hardened sections.

Grinding & EDM

-

For hardened tooling, grinding with suitable abrasives and coolant control gives best surface finish. EDM is widely used for intricate cavities (mold inserts) but requires post-EDM grinding/polishing and sometimes re-tempering to restore properties.

Surface treatments

-

Nitriding: possible; S7 can benefit from diffusion nitriding to increase surface hardness without significant distortion.

-

Plating / coatings: PVD/CVD coatings after proper substrate heat treatment and finishing are used where wear is a concern.

S7 Steel Equivalent grades (cross-reference)

Below are commonly quoted equivalents used for comparison or sourcing. Equivalency is approximate — verify chemistry and properties before substitution.

| System | Equivalent / close match |

|---|---|

| SAE / AISI | S7 (UNS T41907) |

| European (trade / sometimes used) | 1.2355 (used in trade lists) |

| Werkstoff / DIN | sometimes mapped to 50CrMoV13-15 variants (check exact chemistry) |

| Trade names | Super-7, Bearcat (historical), manufacturer trade names (CarTech S7, etc.) |

Source cross-checks and equivalence tables.

Important: “Equivalent” in trade listings can be imprecise; order by UNS/AISI or by a strict chemical and mechanical specification (e.g., ASTM A681 with the desired certificate) when interchangeability matters.

What S7 is used for (applications)

Common end-uses and why S7 is chosen:

-

Shear blades and cutters: where sudden shock and heavy shearing loads occur — S7 resists chipping.

-

Punches & chisels: impact-loaded tooling benefits from the toughness of S7.

-

Forging dies & die blocks (medium hot work): S7’s resistance to softening at higher temperatures makes it suitable for specific hot work applications.

-

Mold inserts for heavy-duty plastic forming: for inserts requiring shock resistance and dimensional stability.

-

Master hobs, shear hands, impact tools and components subjected to repetitive shock loading.

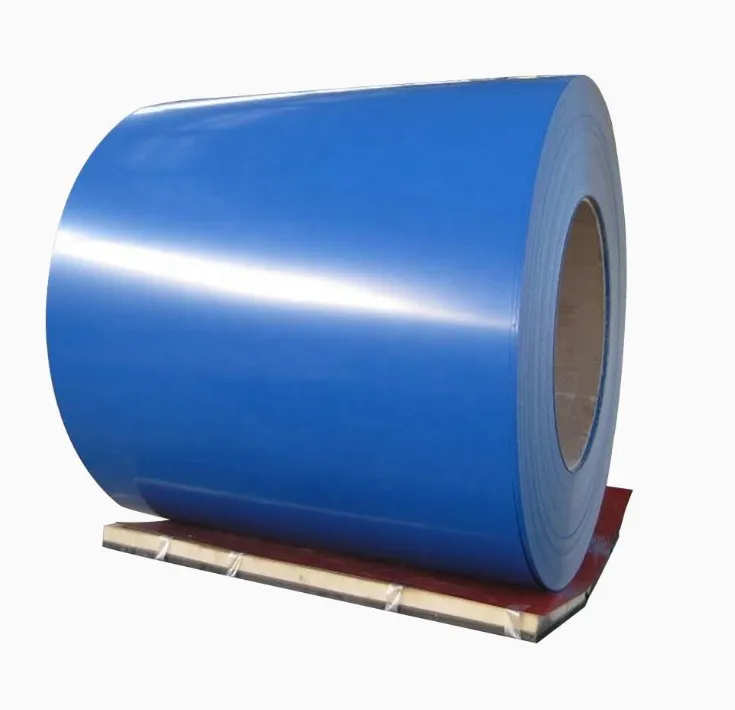

S7 Steel Sizes, density and weight examples

Density: 7.83 g/cm³ (0.283 lb/in³). Use this to estimate mass from dimensions.

Common stock forms and a quick weight reference

| Stock shape | Typical sizes sold | Example: weight per 1 m (approx.) |

|---|---|---|

| Round bar | Ø 6 mm → Ø 200 mm; common 12", 18" bars sold retail | Ø 20 mm × 1 m ≈ 2.46 kg |

| Rectangular flat | e.g., 10 × 50 mm × 1 m | ≈ 3.915 kg |

| Plate | thickness 5–60 mm, wide widths | depends on dimensions (density used for calc) |

(Use density 7.83 g/cm³ × volume to compute exact weight; retailers such as Grainger and OnlineMetals provide slabbing and cut-to-size pricing/data for stock pieces.)

S7 Steel Price snapshot (USA / Europe / China — 2025 guidance)

Important: alloy steel prices fluctuate daily with raw material markets, mill capacity and logistics. The table below aggregates available supplier listings and marketplace quotes captured during 2025; treat these as indicative ranges for bulk (tonne) or small retail pieces where noted. Always request supplier quotations with Incoterms, lead time, and a material test certificate.

| Region | Typical 2025 indicative price (per metric tonne) | Notes / sources |

|---|---|---|

| China (mill / factory-gate) | ~US$1,800 – 3,500 / t (range across suppliers & quantity). | Chinese B2B listings and Alibaba/ Made-in-China show ranges roughly US$1,850–3,500/ton depending on grade, processing and MOQ. |

| USA (domestic mill & distribution) | ~US$3,000 – 6,000 / t (or higher for small retail cuts). | Domestic billet/rounds sold by distributors at per-bar retail prices translate to higher per-ton costs; distributors like OnlineMetals show small piece pricing (retail). Larger industrial orders via service centers are more competitive. |

| Europe (producer / distributor) | ~US$2,500 – 5,000 / t | European price indices (MEPS) show base steel movements and distributors add premium for alloy/processing. |

Why ranges are wide: S7 is an alloyed tool steel; price depends on whether material is delivered as hot-rolled, forged, decarb-free, ground/oversize, and the required certificates. Small-quantity retail bars cost significantly more per kg than tonnage purchases. Market turmoil, energy costs and alloy shortages (Cr, Mo, V) also push variability in 2025.

MWAlloys supply advantage (what we offer)

MWAlloys is a China-based specialty steel supplier (factory direct) focused on tool & mold steels. For S7 we provide:

-

100% factory-to-buyer pricing (no middleman markup for bulk orders).

-

Stock items for quick delivery: common bars and plates kept in inventory for fast turnaround; custom forgings and ground/oversize cuts available with short lead times for stock items.

-

Mill test certificates (MTC) and decarburization controls supplied with every batch on request.

-

Custom heat treatment & finishing services: pre-hardening, stress relief, double temper cycles, and nitriding coordination available.

-

Export experience & global logistics — packaging, inspection and export documentation handled according to buyer requirements.

Frequently asked questions

S7 Tool Steel: High Toughness & Shock Resistance FAQ

1. Can S7 be used for both cold-work and hot-work tooling?

Yes. S7 is highly versatile. While primarily a cold-work steel for heavy-duty punches and chisels, it is also used for medium-temperature hot-work dies because it resists softening at elevated temperatures better than many other cold-work steels.

2. What hardness can I expect after heat treatment?

Typically, S7 reaches a tempered hardness range of 50 to 58 HRC. For applications requiring maximum toughness (like jackhammer bits), it is often tempered to the lower end (50-54 HRC), while precision punches may be kept at 56-58 HRC.

3. Is S7 an air-hardening steel?

4. Is S7 a good substitute for D2?

5. Can S7 tool steel be nitrided?

6. How do I specify S7 to avoid decarburization?

7. Are there corrosion concerns with S7?

8. What inspection documentation should I demand?

- Mill Test Certificate (MTC): Showing chemistry and mechanical test results.

- Heat Treatment Report: Documenting the tempering cycles.

- Ultrasonic Testing (UT) Report: Ensuring the steel is free of internal voids or cracks.

9. What are the typical lead times for S7 from MWAlloys?

10. How do I calculate the weight for a custom S7 part?

| Shape | Formula |

|---|---|

| Plate | Length × Width × Thickness × 0.00000783 |

| Round Bar | Radius² × 3.1415 × Length × 0.00000783 |

*Note: Dimensions in mm, Result in kg.