O1 tool steel (AISI O1, often referenced as DIN 1.2510 / JIS SKS3) is a dependable oil-hardening cold-work grade prized for its mix of machinability, dimensional stability and wear resistance — making it an economical choice for short-run dies, blades, punches and precision tooling where predictable heat-treat behavior and tight dimensional control are required. For engineers choosing a tool steel that balances toughness and hardness without the aggressive quench stresses of water-hardening grades, O1 is commonly the first practical option.

What is O1 tool steel?

O1 is an oil-hardening, high-carbon, manganese-chromium-tungsten cold-work tool steel originally developed for tooling that must retain very good dimensional stability during hardening. It is a versatile grade used when a combination of wear resistance, toughness and easy machining is required. The grade is commonly supplied in an annealed/soft condition and takes predictable, uniform hardening in oil quench cycles; after tempering it attains service hardnesses suitable for many dies, shear blades and forming tools.

Quick technical snapshot

-

Common names / designations: AISI O1, ASTM A681 O1, DIN 1.2510, JIS SKS3, UNS T31501.

-

Typical delivered condition: annealed (soft) for easy machining; can be supplied ground or precision-finished.

-

Hardening method: oil quench (hence “O” series).

-

Typical hardened hardness range: ~58–64 HRC depending on tempering schedule and section size.

-

Best used for: short-to-medium run cold work tooling, punches, shear blades, small molds, gauges, and precision fixtures.

Chemical composition (typical ranges)

The table below can be used as a design reference. Individual mill certificates should be consulted for exact compositions.

| Element | Typical range (wt%) |

|---|---|

| Carbon (C) | 0.90 – 1.00 |

| Manganese (Mn) | 0.50 – 1.00 |

| Chromium (Cr) | 0.60 – 1.00 |

| Tungsten (W) | 0.20 – 0.40 |

| Vanadium (V) | 0.03 – 0.08 (trace) |

| Silicon (Si) | 0.15 – 0.35 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.03 |

Notes: variations exist between suppliers and national standards (AISI/ASTM, DIN, JIS). The tungsten and chromium content give O1 better wear resistance and tempering stability than plain high-carbon steels.

Material properties and mechanical data

Below is a pragmatic set of mechanical properties you can apply in design and specification. Always use supplier mill data for final verification.

| Property | Typical value (annealed) | Typical value (hardened & tempered) |

|---|---|---|

| Hardness (annealed) | ~200 HB (~18–25 HRC) | 58–64 HRC (dependent on heat treat) |

| Tensile strength (Rm) | ~600–900 MPa (depends on condition) | Varies widely after heat treat; use mill data |

| Yield strength (Rp0.2) | ~350–600 MPa | Section dependent |

| Elongation (A)% | 8–15% (annealed) | reduced after hardening |

| Toughness/impact | Good for oil-hardening class; better than many high-Cr cold-work steels | |

| Density | ~7.85 g/cm³ | |

| Thermal conductivity | Moderate (steel category) | |

| Machinability | Good in annealed state; can be ground to tight finish |

Practical note: O1 is considered to have predictable dimensional stability (low distortion) compared to many water-quenched grades, which is why it is often called a “non-shrinking” tool steel in workshop literature.

Specifications and equivalents

O1 is represented in multiple naming systems. Use this table when translating documents or ordering internationally.

| Common designation system | Equivalent name |

|---|---|

| AISI / SAE | O1 |

| ASTM | ASTM A681 (tool steel specifications reference; use exact spec for details) |

| UNS | T31501 |

| DIN | 1.2510 |

| JIS | SKS3 (or similar SK series high-carbon tool steel) |

| ISO | Often referenced under ISO 4957 (tool steels standard) |

Comment: Exact sub-grades, tolerances and surface finishes are defined by the relevant standard (ASTM, ISO, DIN). Check the mill certificate and the standard referenced in your purchase order for heat-treatment parameters, delivery hardness and allowable tolerances.

Heat treatment and metal processing

This section provides workshop-level best practices accepted by experienced toolmakers.

A. Typical blank production and machining

-

Received condition: O1 is usually delivered soft-annealed for ease of machining.

-

Machining: Use sharp carbide or high-speed tooling; cut rates similar to medium alloy steels. Maintain light depth of cut near final dimensions to allow for heat-treatment distortion.

-

Deburring & inspection: Remove mill scale and inspect for decarburization before hardening.

B. Hardening cycle (typical industrial practice)

-

Austenitize (rough guide): heat to ~740–780°C (1380–1436°F) — exact temperature depends on section size and supplier recommendation. Hold to dissolve carbides evenly.

-

Quench medium: oil quench at recommended temperature and agitation to avoid hardening cracks — this is core to O-series behavior. Allow controlled cooling to room temperature.

-

Tempering: multiple tempers usually between 150–540°C (300–1000°F) based on desired final hardness; higher temper temperatures reduce hardness and improve toughness. Typical tempering schedules produce stable hardness in the 58–64 HRC range for O1.

C. Stress relief and finishing

-

Always stress relieve after rough machining if a lengthy section will undergo final heat treatment.

-

For components requiring tight tolerances, perform a cycle of tempering and an iteration of light grinding to final size.

D. Surface hardening and coatings

O1 is not normally used for induction or nitriding where a higher alloy content is required, but thin hard coatings (PVD/CVD) or carburizing are possible on specific tool geometries if wear life needs extension.

Typical uses and application examples

O1 is selected where precision and cost effectiveness are primary concerns. Representative examples:

-

Blanking and forming dies for short to medium runs (sheet metal presses).

-

Cutting tools and shear blades where edge retention matters but tooling cycle and part size do not justify high alloy, high-cost steels.

-

Punches, broaches and small dies intended for frequent regrind/resharpen cycles.

-

Gauges, jigs and mandrels requiring close dimensional stability after hardening.

-

Knife blades, hand tools and hobby blades in smaller specialty supply channels.

Case note: For long production runs or extremely abrasive service, higher-chromium, oil or air-hardening tool steels (D-series, A-series) or hot-work grades can be more economical over the life cycle despite higher initial cost.

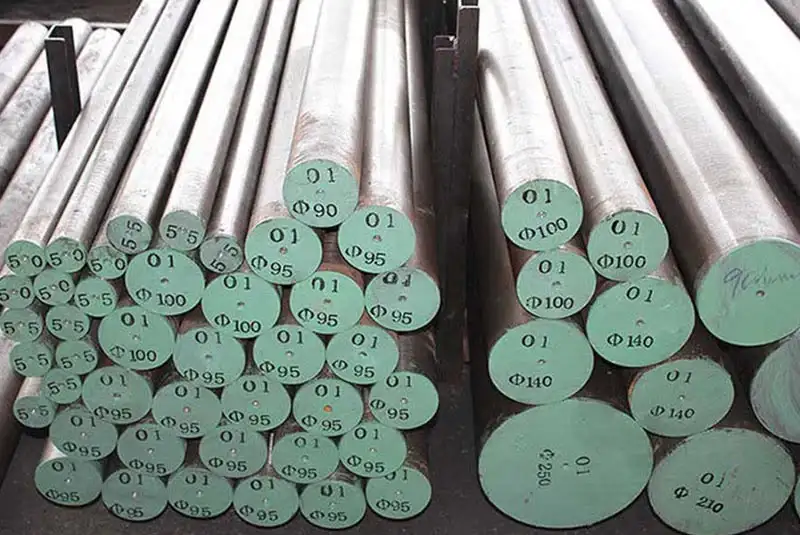

Sizes, stock forms and precise weights (useful for costing and logistics)

O1 is normally stocked in rounds, flats, squares and ground plate. The table gives a practical weight per metre for round bars (density = 7.85 g/cm³). These figures are useful when converting distributor prices (per piece) into per-tonne or per-kg.

Weight per metre — round bar (density 7.85 g/cm³)

| Diameter (mm) | Weight (kg/m) |

|---|---|

| 10 | 0.6165 |

| 12 | 0.8878 |

| 16 | 1.5783 |

| 20 | 2.4662 |

| 25 | 3.8534 |

| 30 | 5.5488 |

| 40 | 9.8646 |

| 50 | 15.4134 |

| 60 | 22.1954 |

| 80 | 39.4584 |

| 100 | 61.6538 |

(Computed from area × density; these are rounded to four decimals for engineering convenience. Use the exact supplier dimensions and density for final invoicing.)

Stock forms frequently available from MWAlloys and other stockists: annealed rounds, ground flats, precision ground plate, and custom cut lengths or blanks.

O1 tool steel price comparison snapshot

Market prices for tool steels change depending on mill lot, finishing (ground vs. hot-rolled), minimum order quantity, and freight. Below are representative published price ranges and sample supplier quotes collected from stockist listings and B2B platforms in 2025. Use them as a procurement reference and confirm with MWAlloys or your chosen supplier for firm quotes.

| Region | Representative retail / FOB range (USD per tonne) | Representative source notes |

|---|---|---|

| China (export FOB from Chinese mills / traders) | ~US$900 – US$2,500 / tonne (depending on alloy finish, MOQ and processing). | Many Chinese factories and trading houses list O1 in this spread; lower end for bulk hot-rolled, higher end for precision ground bars. |

| USA (distributor / cut-length retail) | Unit prices vary widely: small precision ground parts sold per piece (example: O1 flat stock and bars priced per cut length; retail listings show prices from tens to hundreds of USD per item). Representative retail distributor listings indicate higher unit cost versus bulk mill FOB; per-tonne equivalent varies by cut-size and finish (often >US$2,500/t when bought in small quantities). | US supply tends to be distributed via service centers; retail pricing for small orders is higher than bulk mill shipments. |

| Europe (stockholder / service center) | Typical stockist surcharge / premium on base steel; specific published surcharge examples exist (example: data points showing surcharge figures in the low hundreds of GBP per tonne). Final per-tonne cost depends on finish and local market. | European prices include local VAT, handling and service center margins. |

How to read this table: the Chinese FOB numbers are mill/trader export listings (useful when importing in bulk). North American and European numbers shown are representative of retail or service-center pricing for smaller orders and precision ground stock and thus are commonly higher per tonne than bulk mill FOB. Always request a commercial invoice with Incoterms and mill certificate.

Procurement notes & why buy O1 from MWAlloys

MWAlloys is a specialized supplier of tool and mold steels with inventory in China and international shipping capability. When ordering O1 from MWAlloys you can expect:

-

Factory direct pricing — MWAlloys works directly with mills and selected foundries; we supply 100% factory price for bulk orders (FOB incoterms available) and competitive cut-length pricing for smaller quantities.

-

Available stock & quick dispatch — MWAlloys keeps a rolling stock of common dimensions for O1; typical lead times for stock items are expedited compared with full mill production lots.

-

Certificate & traceability — full mill certificates (chemical & mechanical) and optional third-party test reports.

-

Custom processing — precision grinding, EDM blanks, pre-hardening machining and heat-treat services via vetted partners.

-

Global logistics support — export packaging, freight booking and customs documentation for North America, Europe and Asia.

If your project requires a precise comparison (cost per finished piece, finished tolerance and expected regrind life), MWAlloys’ technical sales team can provide a firm quote with production drawings and lifecycle recommendations.

Frequently Asked Questions

1. Is O1 a good choice for long production runs?

O1 performs well for short to medium production runs. For long, abrasive operations or very high cycle counts, consider higher alloy or high-chromium grades (D-series) or hot-work steels — they often deliver better lifecycle value despite higher initial cost.

2. What hardness can I expect after standard heat treatment?

Typical hardness after oil quench and appropriate tempering is in the 58–64 HRC band for many section sizes. Exact results depend on austenitizing temperature, section thickness and tempering schedule.

3. How does O1 compare to D2?

D2 is a high-chromium, high-carbon cold-work tool steel with higher wear resistance (due to more carbides) and lower toughness than O1. O1 is easier to machine in the annealed state and will typically resist cracking better. Choose D2 for maximum wear life; choose O1 when better toughness, easier machining and lower distortion are priorities.

4. Are there direct equivalents in DIN / JIS?

Yes. A common DIN equivalent is 1.2510; JIS equivalents are often labelled in the SK series (e.g., SKS3 mapping may appear). Confirm exact composition and standard numbering when substituting between systems.

5. Can O1 be nitrided or case-hardened?

O1 is normally used as a through-hardening oil-quenched grade. It can accept thin surface coatings or PVD finishes; conventional nitriding may be less effective than on alloyed steel with higher alloying elements designed for diffusion processes.

6. Is O1 prone to cracking during quench?

All quenches carry some risk. O1 is oil-hardening and exhibits better controlled hardening than water-quenched grades; however, improper austenitizing, excessive section restraint or thermal gradients can cause cracking. Use recommended preheat, agitation and tempering parameters.

7. What tolerances and finishes are available?

O1 is sold hot-rolled, annealed, ground and precision ground. Tolerances depend on supplier stock type; precision ground plate and ground bars are available to tight tolerances from service centers.

8. How should leftover O1 swarf and chips be handled?

As with any steel, collect and recycle through appropriate scrap channels. O1 machining swarf is ferrous recycling material; abide by local waste and recycling regulations.

9. How to specify O1 on a purchase order?

Include: Grade (AISI O1 / 1.2510), supply standard (e.g., ASTM A681 or specific mill standard), condition (annealed/hard/ground), dimensions, surface finish, number of pieces, required mill certificate (EN 10204 type), and delivery terms (Incoterms). Provide drawings when blanks require special machining.

10. What is the expected lifetime vs cost tradeoff for O1?

For short runs and regrind-based tools, O1’s lower cost and ease of rework often make it the most economical choice. For heavy abrasion, upgrading to D2/A2 or other high-alloy steels may reduce total cost of ownership despite higher upfront cost.