Nitronic 60 round bar (UNS S21800) is a nitrogen-strengthened austenitic stainless steel specifically engineered for outstanding anti-galling, wear resistance, and high yield strength in both ambient and elevated temperatures. For engineers selecting a material for valve stems, fasteners, pump shafts, pins, bushings or other sliding/wear interfaces, Nitronic 60 is often the optimal choice because it combines strength nearly twice that of 304/316 in the annealed condition with superior resistance to seizure and good general corrosion performance. MWAlloys offers factory-direct Nitronic 60 round bar from China with competitive 100% factory pricing, routine inventory for fast shipment, and full material certifications to support procurement for OEM and MRO projects.

What is Nitronic 60?

Nitronic is a trade name for a family of nitrogen-strengthened austenitic stainless steels developed originally by Armco (now under Cleveland-Cliffs / AK Steel ownership). Nitronic 60 (UNS S21800, sometimes listed as Alloy 218) was created to solve galling and adhesive wear problems where conventional 300-series stainless steels tend to seize under sliding contact. The alloy achieves this through relatively high manganese and silicon levels plus distributed nitrogen, which raises yield strength and creates a microstructure that resists adhesive wear and fretting. Nitronic 60 is available in a solution-annealed (standard) form and in higher-strength cold-worked variants (HS grades) for applications requiring greater static strength.

Nitronic 60 Chemical composition

Below is a concise, engineering-grade composition table (typical range by weight %) compiled from manufacturer datasheets and technical bulletins. These are design values; always confirm with the supplier’s mill test certificate for procurement lots.

| Element | Typical range (wt %) |

|---|---|

| Carbon (C) | ≤ 0.10 |

| Chromium (Cr) | 16.0 – 18.0 |

| Nickel (Ni) | 8.0 – 9.0 |

| Manganese (Mn) | 7.0 – 9.0 |

| Silicon (Si) | 3.5 – 4.5 |

| Nitrogen (N) | 0.08 – 0.18 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Molybdenum (Mo) | trace (~0–0.75 in some variants) |

| Iron (Fe) | Balance |

-

Si and Mn: unusually high compared with conventional 300-series stainless steels; they play a central role in forming a microstructure that resists transfer and adhesive wear.

-

Nitrogen: raises yield strength and helps stabilize austenite without heavy nickel additions — efficient strengthening that keeps cost down relative to high-Ni alloys.

Nitronic 60 Mechanical properties

Designers should treat Nitronic 60 as a high-strength austenitic stainless alloy in the annealed state and recognize optional cold-worked “High Strength” (HS) levels when very high yield/UTS are required.

Representative mechanical properties (typical / minimum values):

| Condition | Ultimate tensile strength (ksi / MPa) | Yield strength (0.2% offset) (ksi / MPa) | Elongation (%) | Hardness (HB / HRC) |

|---|---|---|---|---|

| Solution annealed (bar ≤0.5") | ~95–105 ksi (655–724 MPa) | ~50–55 ksi (345–379 MPa) | 35% | 170–255 HB |

| Solution annealed (bar >0.5") | ~95 ksi (655 MPa) | ~50 ksi (345 MPa) | 35% | 170–255 HB |

| High-Strength (cold-worked) Level 1–6 | range from ~110 ksi up to >200 ksi (760 → 1379 MPa) depending on HS level | yield from ~90 ksi up to ~180 ksi | elongation reduced progressively (10–35%) | increases with cold work |

-

The typical annealed yield is approximately double that of Type 304/316 in the annealed state — a practical advantage when designers want higher stiffness and load capacity without moving to precipitation-hardening steels.

-

High-strength grades are produced by controlled cold work; mechanical values and formability change accordingly. For critical fatigue or dynamic components, request supplier test certificates and fatigue data.

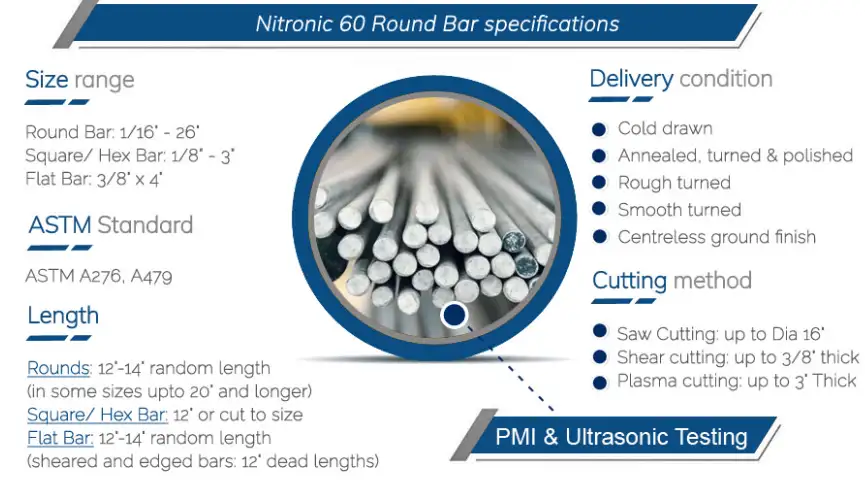

Nitronic 60 Specifications, standards, and available forms

Common specifications and standards where Nitronic 60 appears:

-

UNS S21800 (Wrought) — primary alloy designation.

-

ASTM A276 (bars & shapes) — common for bar stock.

-

AMS 5848 (solution treated product form used in aerospace applications).

-

ASME / ASTM fastener specifications (used when material is certified for bolting).

Typical supply forms:

-

Solid round bar (bright finish / hot-rolled / cold-drawn), hollow bar, flat bars, hex/square, wire, forgings, billets, and specialty cast forms (CF10SMnN family for cast equivalents). Nitronic 60 is widely stocked by specialty stainless distributors in bar diameters commonly used for pins/shafts and fasteners.

Certification & testing: MWAlloys supplies Nitronic 60 with full mill test reports (EN 10204 3.1 or equivalent), PMI / spectrochemical certificates on request, and third-party testing when required by critical contracts.

Why designers specify Nitronic 60 — typical applications

Nitronic 60 is commonly chosen for parts that combine sliding contact, wear, possible lubricity loss, and corrosive environments:

-

Valve stems, seats and trim — excellent anti-galling for metal-to-metal seated valves.

-

Fasteners and threaded connections — nuts/bolts where galling of austenitic stainless steel threads (e.g., 316) is a known failure mode.

-

Pump shafts, wear rings, lobes, and bearings — where fretting or adhesive wear reduces life of conventional stainless components.

-

Rail pins, bridge pins and construction components — applications requiring high wear resistance and toughness.

-

Aerospace and NASA heritage parts — used in some high-reliability pump/coolant components in space applications.

Why it works: The combination of high Si/Mn and dissolved N produces a surface behavior and subsurface microstructure that limits adhesive transfer and localized welding between contacting surfaces, reducing galling and extending service life relative to many stainless steels.

Nitronic 60 vs Inconel and other common equivalents

Nitronic 60 vs Inconel (nickel-based superalloys):

-

Different families: Nitronic 60 is an austenitic stainless steel (Fe-base) strengthened with nitrogen, Mn and Si; Inconel alloys are nickel-base alloys designed primarily for high temperature strength and corrosion/oxidation resistance.

-

Galling & wear: Nitronic 60 is specifically tailored for galling and adhesive wear resistance; Inconel grades do not generally match Nitronic 60 for anti-galling behavior unless specially treated or coated.

-

High-temperature creep and oxidation: Inconel alloys (e.g., Inconel 600/625/718) outperform Nitronic 60 at sustained very high temperatures and in certain corrosive high-T environments. Choose Inconel for extreme temperature creep, Nitronic 60 for wear/galling at moderate to elevated temperatures (up to ~900°F–1000°F operating window for useful anti-galling behavior).

What Nitronic 60 is equivalent to (cross-references):

-

UNS S21800 is the accepted wrought designation. Cast equivalents are listed as CF10SMnN / J92972 in some catalogs. It is commonly cross-referenced to Alloy 218 in some supplier literature. When a direct “drop-in” substitution is needed, check mechanical/chemical parity rather than a single name — many vendors list Nitronic 60 as the functional equivalent to “Alloy 218 / S21800.”

Fabrication: machining, welding and heat treatment guidance

Machining:

-

Machinability is similar to or slightly more difficult than 304/316 due to higher strength and work hardening tendency. Use sharp tooling, positive rake angles, rigid set-ups, and through-coolant where possible. Pre-machining stress-relief is rarely necessary for standard bar sizes; for heavy sections consider peening/cold work effects.

Welding:

-

Nitronic 60 can be welded using common stainless welding processes (GTAW, GMAW); the alloy is generally not heat-treatable and does not require precipitation hardening post weld. Autogenous welds and filler metal use are routine — however, follow supplier guidance for filler selection if matching galling resistance in the weld deposit is critical. No special preheat is typically required but normal stress-relief practices for heavy fabrication apply.

Heat treatment:

-

Nitronic 60 is not hardenable by heat treatment in the traditional sense (it is strengthened by cold work and alloy chemistry). Solution annealing is used to restore ductility, and HS conditions are achieved by controlled cold deformation.

2025 Global price comparison (rounded ranges, FOB / distributor pricing)

Important: stainless & specialty alloy prices move with global nickel, scrap, mill schedules, and processing. Below are observed market ranges in 2025 from distributor listings and China OEM offers; use them for budgetary comparison and request live quotes for purchasing decisions.

| Region / channel | Typical observed price (USD per metric ton) | Approx USD/kg | Notes / sources |

|---|---|---|---|

| China — factory / OEM FOB | $2,400 – $12,000 / ton | $2.4 – $12 / kg | Wide range depending on hot-rolled vs bright finish, diameter, MOQ, certification & finishing (examples from Alibaba / Chinese sheetmetal suppliers). |

| India — mill/trading houses | $3,000 – $10,500 / ton | $3 – $10.5 / kg | Competitive regional mills; lead times vary. (Representative supplier listings). |

| Europe — specialty distributor (FOB/EXW) | $4,000 – $15,000 / ton | $4 – $15 / kg | Stocks, small-lot cutting, and certification add cost; some European stocks show premium prices. |

| USA — distributor retail (small cuts) | $3,500 – $25,000 / ton | $3.5 – $25 / kg | Online retail examples (per-piece pricing converts higher due to cutting, packaging, and low volumes). Example: OnlineMetals sale prices for small lengths. |

-

Low end of the China OEM range typically reflects bulk FOB shipments with minimal added processing (hot-rolled, longer lead times). Higher figures reflect bright-finish, cold-drawn bars, length cuts, TIR tolerances, or high-strength HS conditions. Distributor prices in developed markets include inventorying, cutting, certification and freight and thus appear higher per kg for small orders. Always request a formal quote that includes material condition, testing/traceability (MTC/3.1), finish, geometry, and delivery terms to compare apples to apples.

Procurement & why MWAlloys

MWAlloys value proposition (what we provide to procurement engineers and buyers):

-

Factory pricing model: MWAlloys is vertically integrated with Chinese producers and supplies Nitronic 60 at 100% factory price (FOB) where possible — this reduces distributor markups for clients buying in larger lots.

-

Inventory and fast dispatch: routine stock kept for popular diameters (3–130 mm typical) and expedited cutting services; typical lead times for stocked items are 7–14 days depending on quantity and shipping mode. (Contact MWAlloys sales for exact ETAs).

-

Documentation & traceability: full EN 10204/3.1 mill test certificates, PMI reports on request, and test reports for mechanical properties — critical for qualifying parts into regulated assemblies.

-

QC & packaging: export packing, anti-corrosion wrap, and custom bar marking available; we can provide inspection photos, dimensional reports, and third-party inspection prior to shipment if required.

How to request a quote (recommended buy flow):

-

Provide drawing/diameter/length, required standard/spec (UNS S21800 / AMS 5848 if aerospace), HS level (if needed), quantity, and certificate level (e.g., 3.1).

-

Ask for FOB Tianjin/Shanghai quote or CIF to your port and lead time.

-

If surface finish is critical (ground/bright/cold-drawn), specify tolerance class (h7/h9 etc.) — this affects pricing significantly.

-

For small orders (samples), expect distributor retail pricing; for MOQ > 500 kg or full-truck lots you can access factory price tiers.

FAQs

1: Is Nitronic 60 magnetic?

A1: Nitronic 60 is primarily austenitic and therefore typically non-magnetic in the fully solution-annealed condition. Cold work can introduce slight magnetic response in some cases, but it remains essentially non-magnetic for most applications.

2: Can Nitronic 60 be used in seawater?

A2: Nitronic 60 exhibits better crevice/pitting resistance than Type 304 and in many test cases is similar or slightly better than Type 316 in quiet seawater exposure. For severe active seawater (high temperature, flow, biological fouling) evaluate specific test data for the intended geometry and consider cathodic protection or coatings as needed.

3: What is the best replacement for Nitronic 60 if not available?

A3: There is no perfect “drop-in” replacement for the anti-galling behavior; close alternatives are other Nitronic family alloys (e.g., N50) or specially coated stainless fasteners. If galling resistance is non-negotiable, sourcing actual Nitronic 60 is strongly recommended.

4: Does Nitronic 60 require special welding practice?

A4: No unusual preheat is required. Use standard austenitic stainless welding procedures (GTAW/GMAW) and suitable filler metal if full weld deposit performance is required. For high-corrosion service consider matching filler alloys and post-weld cleaning/pickling.

5: Is Nitronic 60 harder than 316?

A5: Yes. In the annealed condition Nitronic 60 exhibits higher yield/tensile strength and a higher hardness range compared with annealed 316 — this is one reason for improved wear performance.

6: What thread lubrication or anti-seize is recommended for Nitronic 60 fasteners?

A6: While Nitronic 60 reduces the need for anti-seize, best practice is still to use appropriate thread lubrication (e.g., PTFE-based or approved anti-seize) in service environments where corrosion or mixed metallurgy could cause risk. Evaluate the whole system (nut material, environment) before specifying “dry” threads.

7: Is Nitronic 60 suitable for cryogenic service?

A7: Nitronic family alloys include grades optimized for low temperatures (e.g., Nitronic 40). Nitronic 60 retains good low-temperature toughness but verify specific cryogenic requirements against data sheets and supplier test certificates.

8: Can Nitronic 60 replace 17-4PH or 410 in high strength applications?

A8: Nitronic 60 offers higher ductility and galling resistance than many martensitic or PH steels; for some load cases it is an effective alternative, but 17-4PH and other precipitation-hardening steels offer different strength-vs-temperature profiles. Evaluate corrosion, toughness, fatigue, and temperature requirements before substitution.

9: Do I need AR/Traceability for Nitronic 60?

A9: For aerospace, oil & gas, and safety-critical equipment, provide EN 10204/3.1 or equivalent mill test certificates and request third-party inspection where required. MWAlloys can provide required documentation.

10: How much more does Nitronic 60 cost than 316 stainless?

A10: Cost varies by region and form. In 2025 FOB China price gaps commonly range from ~1.5× to 5× the price of commodity 316 depending on finish, certification, and quantity. Use live quotes for procurement decisions.

Practical selection checklist

-

Prioritize Nitronic 60 when galling/adhesive wear is the dominant failure mode.

-

Request mill test certificate (3.1) and PMI report for critical buys.

-

Specify HS level if elevated static strength is necessary; otherwise standard solution-annealed is widely used.

-

For threaded assemblies, consider mating material and lubrication to prevent dissimilar-metal corrosion.

-

For high-temperature sustained loads (>600–700°C), evaluate nickel-base alloys (Inconel family) instead of Nitronic 60.

Final recommendations

-

If galling & wear are primary concerns in a corrosive environment but temperatures and creep are moderate, Nitronic 60 round bar is among the best cost/performance choices.

-

For procurement at scale, contact MWAlloys with detailed requirements (geometry, finish, certificates) so we can offer a factory-price FOB or CIF quote and confirm stock availability and lead time. MWAlloys can supply cut lengths, ground shafts, and pre-machined blanks with supporting documentation to accelerate qualification.

Authoritative references

- Nitronic — Wikipedia (overview & UNS cross-reference)

- ARMCO® NITRONIC® 60 — Cleveland-Cliffs / AK Steel Product Data Bulletin (technical datasheet, composition & properties)

- ASM International — Alloy Digest: ARMCO Nitronic 60 (historical & performance notes)

- Rolled Alloys — Nitronic 60 Data Sheet (stock forms, machinability & temperature notes)