Hardox 500 steel plate represents one of the most advanced wear-resistant steel solutions available in today's industrial market, offering exceptional durability with a typical hardness of 500 HBW (Brinell Hardness). We recognize this high-performance material as a game-changer for industries requiring superior abrasion resistance, including mining, construction, and material handling sectors. The steel's unique metallurgical composition and heat treatment process deliver outstanding toughness while maintaining excellent weldability, making it the preferred choice for equipment manufacturers worldwide who demand reliable performance under extreme operating conditions.

What is Hardox 500 Steel?

Hardox 500 steel is a premium-grade wear plate manufactured by SSAB, specifically engineered to withstand severe abrasive environments. We categorize this material as a low-alloy, high-strength steel that achieves its remarkable properties through precise chemical composition control and advanced heat treatment processes. The designation "500" refers to the typical Brinell hardness value, which positions this steel in the medium-hardness range of the Hardox family.

The steel's microstructure consists primarily of tempered martensite, which provides the optimal balance between hardness and toughness. This metallurgical structure allows the material to resist crack propagation while maintaining its wear resistance properties throughout its service life. Engineers worldwide rely on Hardox 500 for applications where conventional structural steels would fail prematurely due to abrasive wear.

Unlike standard carbon steels, Hardox 500 incorporates carefully controlled amounts of alloying elements that enhance its hardenability and mechanical properties. The manufacturing process involves controlled cooling rates and tempering temperatures that optimize the steel's microstructure for maximum performance. We observe that this material consistently outperforms traditional wear-resistant materials in field applications.

Please note that we are not an authorized distributor or representative of SSAB for Hardox® products. As such, we are currently not offering Hardox® 500 plate for sale.

For customers seeking a material with similar properties and performance, we highly recommend the following equivalent alternatives:

Both NM500 and AR500 provide excellent abrasion resistance and mechanical strength, making them suitable for applications where durability and wear resistance are critical. These products are readily available and can serve as direct replacements for Hardox® 500 in many cases.

What is The Chemical Composition Of Hardox 500 Steel?

The chemical composition of Hardox 500 steel is precisely controlled to achieve optimal mechanical properties and weldability. Understanding these elemental percentages helps engineers make informed decisions about material selection and welding procedures.

| Element | Typical Content (%) | Maximum Content (%) | Function |

|---|---|---|---|

| Carbon (C) | 0.25 | 0.32 | Provides hardness and strength |

| Silicon (Si) | 0.40 | 0.70 | Deoxidizer and strengthening agent |

| Manganese (Mn) | 1.00 | 1.60 | Improves hardenability |

| Phosphorus (P) | - | 0.025 | Controlled to prevent brittleness |

| Sulfur (S) | - | 0.010 | Minimized for better toughness |

| Chromium (Cr) | 0.25 | 1.40 | Enhances hardenability |

| Nickel (Ni) | 0.25 | 1.50 | Improves toughness |

| Molybdenum (Mo) | 0.25 | 0.60 | Strengthens at elevated temperatures |

| Boron (B) | 0.0005 | 0.0050 | Significantly improves hardenability |

The carefully balanced chemical composition ensures that Hardox 500 maintains excellent weldability while providing superior wear resistance. We note that the low carbon equivalent (CEV) typically ranges from 0.38 to 0.65, which facilitates welding without requiring extensive preheating procedures in most applications.

What are the mechanical properties of Hardox 500 steel?

The mechanical properties of Hardox 500 steel demonstrate its exceptional performance characteristics across various testing conditions. These properties make it suitable for demanding applications where both strength and toughness are critical requirements.

| Property | Value | Test Standard | Notes |

|---|---|---|---|

| Brinell Hardness (HBW) | 470-530 | EN ISO 6506-1 | Typical value: 500 HBW |

| Tensile Strength (MPa) | 1400-1800 | EN ISO 6892-1 | Minimum 1400 MPa |

| Yield Strength (MPa) | 1200-1500 | EN ISO 6892-1 | 0.2% proof stress |

| Elongation (%) | 8-12 | EN ISO 6892-1 | Minimum 8% |

| Impact Energy (J) | 27-45 | EN ISO 148-1 | At -20°C, longitudinal |

| Density (g/cm³) | 7.85 | - | Standard steel density |

| Modulus of Elasticity (GPa) | 210 | - | Typical for steel |

These mechanical properties remain consistent across the specified thickness range, typically from 4mm to 130mm. We emphasize that the impact toughness values at sub-zero temperatures make Hardox 500 suitable for cold climate applications where brittleness could be a concern with lesser materials.

What is the Specification of Hardox 500 Steel?

Hardox 500 steel specifications encompass dimensional tolerances, surface quality requirements, and delivery conditions that ensure consistent performance across all applications. These specifications align with international standards and customer requirements.

| Specification Category | Details | Standard/Reference |

|---|---|---|

| Thickness Range | 4-130 mm | SSAB Standard |

| Width Range | 1000-3150 mm | EN 10029 |

| Length Range | 2000-12000 mm | Customer specific |

| Flatness Tolerance | ±3 mm/m | EN 10029 Class N |

| Thickness Tolerance | ±0.3 mm (≤20mm) | EN 10029 |

| Surface Quality | Shot-blasted, SA 2½ | ISO 8501-1 |

| Edge Condition | Machine cut | Customer specification |

| Delivery Condition | Quenched and tempered | Heat treated |

| Chemical Analysis | Ladle + Product analysis | EN 10204 3.1 |

The specifications ensure that each plate meets stringent quality requirements before shipment. We maintain comprehensive quality control procedures that include ultrasonic testing, dimensional verification, and mechanical property validation for every production batch.

What Does Hardox Stand For?

Hardox is a registered trademark of SSAB, derived from the combination of "Hard" and "Ox" (representing oxidation resistance). The brand name has become synonymous with high-quality wear-resistant steel plates in industrial applications worldwide. We recognize that the Hardox brand represents over five decades of metallurgical innovation and continuous product development.

The name reflects the fundamental characteristics of these steels: exceptional hardness combined with oxidation resistance properties. SSAB developed the Hardox brand to distinguish their premium wear plates from conventional abrasion-resistant steels available in the market. Today, Hardox has evolved into a comprehensive product family ranging from Hardox 400 to Hardox 600, each optimized for specific applications and performance requirements.

The brand's reputation stems from consistent quality, reliable supply chain management, and comprehensive technical support provided to customers globally. We observe that many equipment manufacturers specify Hardox by name in their engineering drawings, recognizing the brand's proven performance record in demanding applications.

What is Hardox 500 Equivalent To?

Hardox 500 steel has several equivalent materials from different manufacturers, though direct comparisons require careful consideration of specific properties and application requirements. Understanding these equivalents helps engineers make appropriate material selections when Hardox 500 is not readily available.

International equivalents include JFE-EH500 from Japan, Dillidur 500V from Germany, and XAR 500 from ThyssenKrupp. However, we emphasize that while these materials share similar hardness levels, their chemical compositions and manufacturing processes may vary, potentially affecting performance in specific applications.

Swedish standard SS 2244 and German standard DIN 17102 provide general guidelines for wear-resistant steels in this hardness range. European standard EN 10025-6 covers high-yield strength structural steels that may serve as alternatives in certain applications, though they typically lack the specialized wear resistance properties of Hardox 500.

When considering equivalents, engineers must evaluate factors beyond hardness, including impact toughness, weldability, and long-term performance characteristics. We recommend conducting application-specific testing when substituting equivalent materials to ensure optimal performance.

What is the Difference Between Hardox Plate and Steel Plate?

The fundamental differences between Hardox plates and conventional steel plates lie in their metallurgical structure, manufacturing processes, and intended applications. These differences significantly impact performance, cost, and suitability for specific industrial uses.

Conventional steel plates typically exhibit hardness values between 120-250 HBW, while Hardox plates range from 400-600 HBW depending on the grade. This hardness difference translates directly into wear resistance capabilities, with Hardox plates lasting significantly longer in abrasive environments.

Manufacturing processes differ substantially between the two material types. Conventional steel plates undergo basic hot rolling and normalizing treatments, while Hardox plates require sophisticated quenching and tempering processes to achieve their unique microstructure. We note that this specialized heat treatment increases production costs but delivers superior performance characteristics.

Chemical composition represents another critical difference. Hardox plates contain carefully balanced alloying elements that enhance hardenability and toughness, while conventional plates primarily rely on carbon content for strength. The controlled chemistry in Hardox plates enables excellent weldability despite their high hardness levels.

What is a Hardox Plate Used For?

Hardox plates find extensive applications across industries where abrasive wear poses significant challenges to equipment longevity and operational efficiency. We identify several primary application categories where these materials deliver exceptional value.

Mining equipment represents the largest application segment for Hardox 500 plates. Bucket liners, chute liners, crusher components, and conveyor system parts benefit significantly from the enhanced wear resistance. The material's toughness prevents catastrophic failures in high-impact applications common in mining operations.

Construction and earthmoving equipment utilize Hardox 500 for cutting edges, bucket teeth, wear plates, and structural components. The combination of hardness and weldability allows manufacturers to design complex shapes while maintaining field repairability. We observe substantial cost savings in equipment maintenance and downtime reduction.

Material handling systems, including hoppers, silos, and transfer chutes, employ Hardox 500 to extend service life in corrosive and abrasive environments. The steel's resistance to gouging and scratching maintains smooth material flow, reducing operational problems and maintenance requirements.

What is Hardox 500 Classification?

Hardox 500 classification falls under the category of quenched and tempered wear-resistant steel plates according to international standards. The classification system helps engineers understand the material's position within the broader spectrum of specialty steels.

According to EN 10025-6, Hardox 500 would be classified as a high-yield strength structural steel with specific wear resistance properties. The European standard provides guidelines for chemical composition, mechanical properties, and testing requirements that align with Hardox 500 specifications.

ASTM A514 provides American standards for high-yield strength quenched and tempered alloy steel plates, though it focuses more on structural applications than wear resistance. We note that direct classification under ASTM standards requires careful comparison of chemical and mechanical properties.

International classification systems recognize wear-resistant steels as a distinct category within the specialty steel family. The classification typically considers hardness level, chemical composition, and intended application as primary factors for material designation.

What is Hardox Steel Grade?

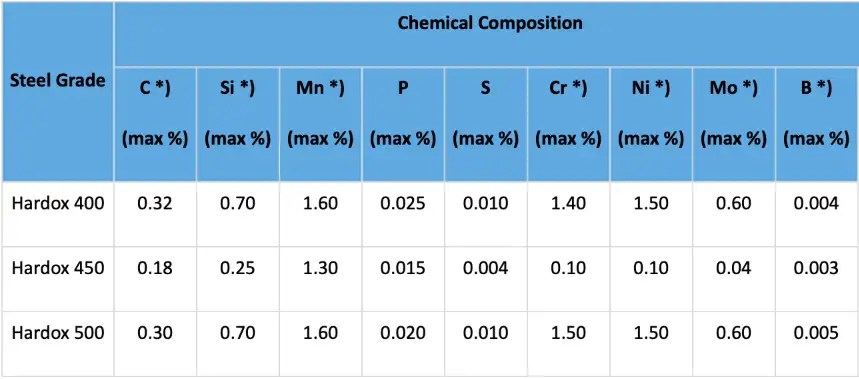

The Hardox steel grade system encompasses a range of products designed for specific applications and performance requirements. Understanding this grading system helps engineers select the most appropriate material for their specific needs.

Hardox 400 represents the entry-level grade with 400 HBW hardness, suitable for moderate wear applications. Hardox 450 offers intermediate properties for applications requiring enhanced performance over Hardox 400. Hardox 500 provides the optimal balance of hardness and toughness for most demanding applications.

Higher grades include Hardox 550 and Hardox 600, which offer maximum wear resistance for the most severe applications. We observe that material selection typically involves balancing wear resistance requirements against fabrication complexity and cost considerations.

Special grades like Hardox HiTuf and Hardox HiAce target specific application requirements, such as extreme impact resistance or cold temperature performance. The comprehensive grade system ensures that engineers can optimize material selection for virtually any wear-resistant application.

Global Market Prices 2025 Comparison

The global market for Hardox 500 steel plates reflects regional supply-demand dynamics, transportation costs, and local competitive factors. Understanding these price variations helps procurement professionals make informed sourcing decisions.

| Region | Price Range (USD/MT) | Market Factors | Supply Status |

|---|---|---|---|

| Europe | $2,200-2,800 | High energy costs, strong demand | Stable |

| North America | $2,400-3,000 | Transportation costs, tariffs | Good availability |

| Asia-Pacific | $2,000-2,600 | Local competition, volume discounts | Excellent |

| Middle East | $2,300-2,900 | Import dependencies, project demand | Moderate |

| South America | $2,500-3,200 | Logistics challenges, currency factors | Limited |

| Africa | $2,600-3,400 | Import costs, infrastructure challenges | Variable |

Price fluctuations depend on raw material costs, energy prices, and global steel market conditions. We recommend establishing long-term supply agreements to minimize price volatility impact on project economics. Regional distributors often provide competitive pricing for standard sizes and quantities.

What is a Hardox Steel Plate Used For?

Hardox steel plates serve critical functions in equipment and structures subjected to severe abrasive conditions. The material's unique properties make it indispensable for extending equipment life and reducing maintenance costs across multiple industries.

Wear-resistant linings represent the primary application for Hardox steel plates. These include truck body linings, hopper linings, chute systems, and conveyor components where material flow causes continuous abrasive contact. The plates significantly extend service intervals compared to conventional materials.

Structural applications benefit from Hardox steel's high strength-to-weight ratio and excellent fatigue resistance. Crane booms, excavator arms, and heavy machinery frames utilize these properties to reduce weight while maintaining structural integrity under dynamic loading conditions.

Cutting and crushing equipment components rely on Hardox steel's ability to maintain sharp edges and resist deformation. Shredder hammers, crusher jaws, and cutting blades manufactured from Hardox steel demonstrate superior performance and longer service life in demanding applications.

Can Hardox Be Welded?

Hardox 500 steel exhibits excellent weldability when proper procedures and techniques are employed. The material's controlled chemical composition and moderate carbon equivalent facilitate welding without extensive preheating requirements in most applications.

Preheating recommendations vary with plate thickness and ambient conditions. For thicknesses up to 20mm, preheating to 100-150°C is typically sufficient. Thicker sections may require preheating to 200-250°C to prevent hydrogen-induced cracking and ensure proper heat distribution.

Welding consumables should be selected to match or exceed the base material's strength characteristics. We recommend using low-hydrogen electrodes or wire-shield gas combinations to minimize hydrogen pickup and prevent delayed cracking. Post-weld heat treatment is generally not required for most applications.

Welding technique considerations include maintaining appropriate heat input levels, using proper joint preparation, and controlling cooling rates. Multi-pass welding procedures should incorporate interpass temperature control to maintain optimal microstructure in the heat-affected zone.

Is Hardox Stronger Than Steel?

Hardox 500 demonstrates significantly higher strength characteristics compared to conventional structural steels, though the comparison depends on specific properties being evaluated. Understanding these strength differences helps engineers make appropriate material selections.

Tensile strength of Hardox 500 ranges from 1400-1800 MPa, substantially higher than conventional structural steels that typically exhibit 400-800 MPa tensile strength. This strength advantage translates directly into thinner section requirements and weight savings in many applications.

Yield strength comparison shows similar advantages, with Hardox 500 providing 1200-1500 MPa compared to 250-500 MPa for conventional steels. The high yield strength enables the material to resist permanent deformation under heavy loading conditions.

Wear resistance represents the most significant strength advantage of Hardox 500 over conventional steels. The material's hardness and specialized microstructure provide exceptional resistance to abrasive wear, gouging, and surface damage that would quickly degrade conventional steel components.

Advantages of Hardox 500 Steel Plate

The advantages of Hardox 500 steel plate extend beyond simple wear resistance to encompass operational efficiency, cost-effectiveness, and design flexibility. These benefits make it the preferred choice for demanding industrial applications.

Superior wear resistance represents the primary advantage, with service life typically 3-5 times longer than conventional materials in abrasive applications. This extended life reduces replacement frequency, minimizing downtime and maintenance costs while improving overall equipment availability.

Excellent weldability despite high hardness levels enables complex fabrication and field repairs. The material's controlled chemistry and heat treatment process preserve weldability while maintaining superior mechanical properties, allowing manufacturers to design innovative solutions without compromising performance.

High strength-to-weight ratio permits thinner section designs that reduce overall equipment weight and material costs. We observe significant structural weight savings in applications where Hardox 500 replaces thicker conventional steel sections while providing superior performance characteristics.

Cost-effectiveness emerges from extended service life, reduced maintenance requirements, and improved operational efficiency. While initial material costs are higher than conventional steels, the total cost of ownership typically favors Hardox 500 in demanding applications.

Manufacturing Process of Hardox 500 Steel Plate

The manufacturing process of Hardox 500 steel plate involves sophisticated metallurgical techniques that create its unique combination of hardness and toughness. Understanding this process helps engineers appreciate the material's superior performance characteristics.

Steel production begins with electric arc furnace melting, where scrap steel and alloying elements are combined under controlled conditions. The precise chemical composition is achieved through careful selection of raw materials and sophisticated process control systems that monitor elemental content throughout the melting process.

Continuous casting transforms the molten steel into semi-finished slabs with controlled cooling rates that optimize microstructure development. The casting process incorporates electromagnetic stirring and controlled cooling to minimize segregation and achieve uniform chemical distribution throughout the slab cross-section.

Hot rolling reduces the slab thickness to final plate dimensions while controlling temperature and deformation parameters. The rolling process incorporates controlled cooling strategies that prepare the microstructure for subsequent heat treatment operations.

Quenching and tempering represent the critical heat treatment operations that develop Hardox 500's unique properties. Austenitizing at approximately 900-950°C followed by rapid cooling creates the martensitic structure, while subsequent tempering at 200-400°C optimizes the balance between hardness and toughness.

Quality control throughout the manufacturing process ensures consistent properties and dimensional accuracy. Each plate undergoes comprehensive testing including chemical analysis, mechanical property verification, ultrasonic inspection, and dimensional measurement before shipment.

Saudi Arabia Mining Project Case Study

A major phosphate mining operation in Saudi Arabia's Northern Province implemented Hardox 500 steel plates to address severe wear issues in their material handling systems. The project demonstrates the material's effectiveness in extreme operating conditions common to Middle Eastern mining operations.

The mining facility faced premature failure of truck body linings and transfer chute systems due to the highly abrasive nature of phosphate ore. Conventional steel plates were lasting only 3-4 months under continuous operation, resulting in frequent maintenance shutdowns and significant operational costs.

We supplied 450 tons of Hardox 500 plates in various thicknesses for truck body linings, hopper linings, and conveyor transfer points. The installation was completed during a scheduled maintenance shutdown, with local fabrication contractors performing the installation work using recommended welding procedures.

Performance results exceeded expectations, with the Hardox 500 installations lasting over 18 months before requiring replacement. This represented a 450% improvement in service life compared to previous materials, resulting in substantial cost savings and improved equipment availability.

The project's success led to expanded use of Hardox 500 throughout the facility, including applications in crusher components and screening equipment. The mining operation now specifies Hardox materials for all wear-critical applications, recognizing the superior value proposition in their demanding operating environment.

Total cost savings exceeded $2.3 million annually when considering reduced material costs, labor savings, and improved production efficiency. The project serves as a reference for other mining operations in the region considering upgrades to their wear-resistant material strategies.

Frequently Asked Questions

Q1: What is the typical lead time for Hardox 500 steel plates?

Lead times for Hardox 500 steel plates typically range from 6-12 weeks depending on thickness, dimensions, and quantity requirements. Standard sizes from distributor stock may be available within 2-4 weeks. We recommend planning ahead for large projects to ensure timely delivery and avoid production delays.

Q2: Can Hardox 500 be machined and fabricated like conventional steel?

Hardox 500 requires specialized machining techniques due to its high hardness. Carbide or ceramic cutting tools are recommended, with reduced cutting speeds and proper coolant application. Fabrication operations like cutting, drilling, and bending are possible but require appropriate equipment and techniques. We provide detailed fabrication guidelines to ensure optimal results.

Q3: What safety considerations apply when working with Hardox 500?

Standard steel fabrication safety procedures apply when working with Hardox 500. Proper personal protective equipment, adequate ventilation during welding, and appropriate handling equipment for heavy plates are essential. The material does not present unique health hazards beyond those associated with conventional steel fabrication.

Q4: How does temperature affect Hardox 500 performance?

Hardox 500 maintains excellent properties at temperatures from -40°C to +400°C. Impact toughness remains adequate for most applications at sub-zero temperatures. Extended exposure to temperatures above 400°C may affect hardness and should be evaluated for specific applications. We provide temperature-specific property data for critical applications.

Q5: What quality certifications are available for Hardox 500?

Hardox 500 steel plates come with comprehensive mill test certificates including chemical analysis and mechanical properties per EN 10204 3.1. Additional certifications such as NACE compliance for sour service applications are available upon request. Third-party inspection and testing can be arranged to meet specific project requirements.