AISI H13 is the industrial standard for hot-work tool steel where toughness, resistance to thermal fatigue (heat-checking) and dimensional stability after heat treatment are critical. For die-casting, hot forging, extrusion tooling and large press dies, H13 offers the best balance of red-hardness, wear resistance and shock resistance in a single, economical grade. MWAlloys supplies H13 (ASTM A681 / DIN 1.2344 / JIS SKD61) in bars, plates and blocks at 100% factory pricing from China with fast stock dispatch and traceable mill certification — a practical choice when tool life and lead time both matter.

What is H13 tool steel

H13 is a chromium-molybdenum-vanadium hot-work tool steel developed for tooling that faces repeated cycles of high temperature and mechanical load. It is an air-hardening grade with good hardenability and high red hardness (retains strength at elevated temperature). Typical industries: aluminum/zinc/magnesium die casting, hot forging and extrusion dies, warm tooling, core pins, shear knives and heavy press tooling. H13’s combination of high toughness and thermal fatigue resistance makes it the default hot-work choice where tooling suffers alternating heating and quenching cycles.

Quick purchasing recommendation

If your application requires resistance to heat-checking and moderate abrasive wear at elevated temperature, order H13 with the following minimums:

-

Request certification to ASTM A681 / ISO 4957 for traceability.

-

Prefer ESR (electroslag remelted) or vacuum-treated billets for large dies to reduce segregation and improve homogeneity.

-

State supply condition (annealed, pre-hardened) and required hardness after heat treatment.

-

For fast turnaround and cost control, MWAlloys can provide mill-certified H13 from China at factory pricing, with common stock sizes in both annealed and pre-hardened conditions.

Chemical composition (AISI H13 — typical ranges)

| Element | Typical AISI H13 range (wt.%) |

|---|---|

| Carbon (C) | 0.32 – 0.45 |

| Chromium (Cr) | 4.75 – 5.50 |

| Molybdenum (Mo) | 1.10 – 1.75 |

| Vanadium (V) | 0.80 – 1.20 |

| Silicon (Si) | 0.80 – 1.20 |

| Manganese (Mn) | 0.20 – 0.50 |

| Nickel (Ni) | ≤ 0.30 |

| Copper (Cu) | ≤ 0.25 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

Why these elements matter (brief):

-

Cr (4.8–5.5%) — main contributor to hardenability, red hardness and wear resistance.

-

Mo (1.1–1.75%) — stabilises carbides, improves hot strength and secondary hardening.

-

V (0.8–1.2%) — forms fine vanadium carbides that improve wear resistance and toughness.

-

C (0.32–0.45%) — controls achievable hardness and wear performance; moderate carbon keeps toughness high while allowing sufficient hardness.

(Chemical ranges from manufacturer datasheets and material databases.)

Material properties — mechanical & thermal (typical values / ranges)

| Property | Typical value / range | Notes |

|---|---|---|

| Density | ~7.8 g/cm³ (0.282 lb/in³) | Standard steel density used for weight calc. |

| Hardness (annealed) | ~200–250 HB (≈HB 230 max typical supply) | Annealed supply condition for machining. |

| Hardness (hardened & tempered) | 45 – 52 HRC (typical working range) | Final hardness depends on tempering schedule. |

| Ultimate tensile strength (UTS) | ~1200 – 1590 MPa (174 – 231 ksi) | Depends on heat treatment and section size. |

| Yield strength | ~1000 – 1380 MPa | Typical after appropriate hardening. |

| Modulus of elasticity | ~200 – 210 GPa | Standard for ferrous alloys. |

| Thermal conductivity | ~25 – 35 W/(m·K) (dependent on condition) | Approximate; reduced by alloying. |

| Max working temperature (red hardness) | Retains hardness up to ~500–550 °C (≈930–1020 °F) | Good hot strength; tempering required for service. |

| Machinability (relative) | ≈ 60–70% of B1112 (industry scale) | Acceptable for pre-machining in annealed condition. |

Notes: actual mechanical numbers vary with supplier, melting route (AOD, ESR), section size and heat-treatment path. When specifying a die that will cycle between hot and cold, yield to the supplier for detailed tempering curves (temper twice, at recommended 560–620 °C ranges) to achieve stable secondary hardening.

Specifications and standard cross-references

H13 is covered by the general tool-steel specifications and is referenced by several national systems:

-

ASTM A681 — covers alloy tool steels; H13 is commonly supplied to the A681 family.

-

DIN / EN / ISO — H13 corresponds to 1.2344 / X40CrMoV5-1 under EN ISO 4957.

-

JIS (Japan) — SKD61 is the commonly used equivalent.

-

GB (China) — commonly referred to as 4Cr5MoSiV1.

When ordering, specify: grade (H13 / 1.2344 / SKD61), supply form (annealed / pre-hardened / forged), required certificate type (mill test report EN 10204 3.1 or 3.2), and any remelt (ESR/VAR) preference for critical dies.

Metal moulding & production processes where H13 is recommended

Common processes and H13 behaviour

-

Aluminum / zinc / magnesium die casting: H13 resists heat-checking due to cyclic thermal shock between melt temperature and die cooling — one of the most frequent uses.

-

Hot forging dies & extrusion tooling: H13 tolerates heavy compressive loads and elevated temperatures; ESR-treated H13 helps when deep cavities and heavy flows concentrate stress.

-

Hot stamping and transfer press tooling: thermal fatigue and shock resistance make H13 a common choice for inserts and cores.

-

Shear blades & punches (when toughness + edge retention are needed): H13’s balance helps when impact and heat co-exist.

-

Toolmaking operations: H13 machines well in annealed condition but must be stress-relieved before hardening; quench in still air or controlled atmosphere after austenitizing (typical austenitizing 1000–1050 °C / 1830–1920 °F) and temper twice to final hardness.

Heat treatment summary (industrial practice):

-

Anneal (for machining): heat to ~820–860 °C, hold, slow cool in furnace (or controlled cooling) to produce a soft, machinable microstructure.

-

Austenitize (hardening): ~1000–1050 °C depending on section; quench in still air or oil (air-quench where possible to minimise distortion).

-

Tempering: double tempering at 500–600 °C (higher temp if you need lower hardness but better toughness). Secondary hardening occurs due to Mo/Cr carbides; temper schedule controls final HRC.

H13 Steel equivalents (conversion table)

| Region/system | Common designation |

|---|---|

| USA (AISI/ASTM) | H13 (ASTM A681 family) |

| Germany / Europe | 1.2344, X40CrMoV5-1 (EN ISO 4957) |

| Japan | SKD61 (JIS G4404) |

| China (GB) | 4Cr5MoSiV1 |

| UNS | T20813 (approximately) |

Practical note: Differences between equivalents are small but exist — always request chemical analysis and mechanical test certificates when interchangeability is required.

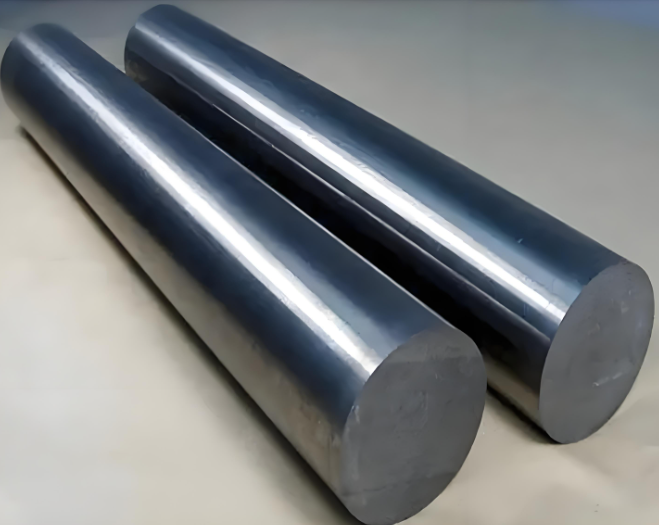

H13 Steel Sizes, weights and common supply forms

Typical supply forms

-

Round bars, peeled, turned, or bright drawn

-

Forged bars and blocks (for large presses)

-

Plates and blocks (machinable blanks)

-

Tubes and rings (special orders)

-

Pre-hardened or annealed

Common stock size ranges (typical supplier limits)

-

Round bars: Ø 5 mm – 400 mm (small to very large diameter).

-

Plates: thickness 10 mm – 500 mm; widths up to ~1400 mm.

-

Blocks: common max blocks in inventories ~210 × 500–810 mm (varies by mill).

Density & weight example

-

Density ≈ 7.8 g/cm³.

-

Example: 50 mm diameter × 200 mm long round bar — volume = π × (25 mm)² × 200 mm = 392,699 mm³ = 392.7 cm³ → mass ≈ 392.7 × 7.8 g = 3,060 g ≈ 3.06 kg.

(Always request actual net mass from supplier for shipping quotes; mill tolerances and surface machining change final weight.)

H13 price comparison (USA / Europe / China) 2025

Important: tool steel pricing varies widely with product form (round bar, plate, pre-hardened), remelt route (standard vs ESR/VAR), minimum order quantity, and currency/transport volatility. The numbers below are market snapshot ranges for 2025 and should be used for ballpark budgeting only. For firm quotes, request current mill offers and freight.

| Region | Typical 2025 price range (USD per kg) | Typical form / notes |

|---|---|---|

| USA (retail / small qty) | $15 – $25 / kg | Small cut lengths, retail suppliers (Onlinemetals example implies ~$19/kg on small bar purchases). |

| Europe (wholesale / distributor) | $10 – $28 / kg | Depends on EU mill, product form, and heat treatment; published ranges show wide spread. |

| China (mill / factory price) | $2.9 – $12 / kg | Chinese mill offers may show very low FOB prices for large tonnage (e.g., ~$2.95–3.00/ton quoted in some listings that are likely for raw tube or specific trade packaging) — expect realistic factory prices commonly in single digits USD/kg for bulk; premium ESR or small MOQ orders cost more. Be cautious: extremely low online listings may reflect minimum batch sizes, specific product forms or incomplete cost items (no MTR, no freight). |

Interpretation & procurement tips

-

Retail small-quantity purchases in the USA reflect machining, cutting and distribution costs — higher $/kg.

-

European prices reflect EU certification, logistics and energy costs; some EU mills are priced higher for guaranteed EN compliance.

-

China factory prices can be competitive for large orders; verify mill test reports (EN 10204 3.1/3.2), surface condition and exact chemical spec. MWAlloys can supply mill-certified H13 at 100% factory price with transparent lead times for stocked sizes.

How to specify H13 for longest tool life

-

Specify grade and equivalent: H13 / 1.2344 / SKD61 and cite the standard (ASTM A681 or ISO 4957).

-

Mill certificate: Require EN 10204 3.1 or 3.2 MTR.

-

Melting route for critical dies: Ask for ESR/VAR if die has deep cavities or critical fatigue life.

-

Supply condition: Annealed for complex machining; pre-hardened if minimal machining is required. State target hardness and roughness.

-

Heat-treatment instructions: Include recommended austenitize temperature and tempering ranges; for large sections specify slow heating and controlled cooling to avoid cracking.

-

Post-treatment options: Consider nitriding or PVD coatings for wear-critical surfaces, but be mindful coating removes thermal shock tolerance in some cases.

-

Inspection: Microstructure, ultrasonic tests (for large dies), and hardness maps where applicable.

FAQs

H13 Tool Steel: Thermal Fatigue & Performance FAQ

1. Is H13 the best steel for all hot-work dies?

No. While H13 is the most versatile "first-choice" grade, it isn't universal. For applications with extreme abrasive wear or where very high carbon is needed, specialized high-chromium steels might be better. However, for aluminum die casting and extrusion, H13's balance of toughness and heat-check resistance remains industry-standard.

2. What is the typical hardness for H13 in service?

3. Can H13 tool steel be nitrided?

4. What equivalents should I order if H13 is unavailable?

| JIS (Japan) | SKD61 |

| DIN/EN (Europe) | 1.2344 / X40CrMoV5-1 |

| GB (China) | 4Cr5MoSiV1 |

Always request a Mill Test Certificate (MTC) to verify the chemical analysis.

5. Is ESR or VAR necessary for H13 steel?

6. How does H13 behave in EDM and micro-machining?

7. How long should tempering be held during heat treatment?

8. What is H13’s density for weight calculations?

- Weight (kg) = Volume (cm³) × 0.0078

9. Are there modern additive manufacturing (3D printing) versions of H13?

10. How should I store H13 stock to avoid surface problems?

MWAlloys supply note

MWAlloys supplies H13 tool steel from China with full mill traceability and factory pricing. Typical highlights we offer:

-

Stocked sizes in common round bar and plate (annealed and pre-hardened).

-

100% factory prices — direct from mill; transparent invoices.

-

Fast delivery for stocked items (lead time depends on size and qty; small in-stock orders ship within days).

-

Quality: MTRs provided; ESR/VAR and special heat treatments available on request.

If you want a tailored quote, share required dimensions, condition (annealed/pre-hard), quantity and destination port and MWAlloys will provide an itemised mill-certified offer.