D2 is a high-carbon, high-chromium cold-work tool steel valued for exceptional abrasive wear resistance and dimensional stability after heat treatment; it is best for long-run punches, dies, shear blades and cold-work tooling where edge retention and low distortion are priorities rather than maximum toughness. For procurement, MWAlloys supplies D2 (AISI D2 / DIN 1.2379 / JIS SKD11 equivalents) from China with 100% factory pricing and fast stock delivery for standard bar, plate and billet sizes.

What is D2 Steel?

D2 is a cold-work, air-hardening tool steel with high carbon (~1.4–1.6%) and high chromium (~11–13%) levels, which produces numerous hard chromium carbides in the microstructure. These carbides give very high abrasive wear resistance and good edge retention after hardening; D2 can be hardened to the high 50s–low 60s HRC depending on tempering and section size. Because its strength comes from carbides rather than a tough matrix, D2 is less fracture-tough than certain lower-alloy tool steels but is preferred when sliding / abrasive wear dominates failure modes.

Typical chemical composition

Note: composition limits vary slightly by standard and producer. The table below shows commonly cited ranges used by mills and datasheets; use mill certificates for purchase orders.

| Element | Typical range (wt.%) | Notes |

|---|---|---|

| Carbon (C) | 1.40 – 1.60 | high carbon produces abundant carbides → wear resistance. |

| Chromium (Cr) | 11.0 – 13.0 | forms chromium-rich carbides; gives mild corrosion resistance in hardened state. |

| Molybdenum (Mo) | 0.70 – 1.20 | improves hardenability and toughness. |

| Vanadium (V) | 0.15 – 1.10 (commonly 0.20–0.50) | refines carbides; improves wear resistance. |

| Manganese (Mn) | ≤ 0.60 | |

| Silicon (Si) | ≤ 0.60 | |

| Phosphorus (P) | ≤ 0.03 | impurity control |

| Sulfur (S) | ≤ 0.03 | impurity control |

| Iron (Fe) | balance (~80–87%) | rest of alloy |

Sources / typical datasheets: MatWeb / industrial datasheets, manufacturer PDFs and tool-steel handbooks all list composition in the ranges above — always confirm with the supplier mill certificate.

D2 Steel Material properties

Values depend strongly on heat treatment and tempering; specify the condition (annealed, hardened & tempered) when buying.

Physical properties (typical):

| Property | Typical value |

|---|---|

| Density | 7.70 – 7.75 g/cm³ (≈7,700–7,750 kg/m³). |

| Modulus of Elasticity | ~200–210 GPa. |

| Thermal conductivity | ~20–25 W/m·K (room temp). |

| Melting point | ~1,420–1,460 °C (literature variations). |

Mechanical / hardness (typical after heat treatment):

| Condition | Hardness (HRC) | Approx. tensile strength |

|---|---|---|

| Annealed | ~220 HB (≈ Rockwell B ~95–100) | UTS ≈ 700–850 MPa (depends on source). |

| Quenched & tempered (typical tooling) | 55–62 HRC (depends on tempering temperature and section) | Hardened UTS can approach ~1,400–1,800 MPa for high hardness conditions. |

| Working hardness range | 55–62 HRC is common for cutting and shear tooling. |

Notes: D2 is air-hardening (so it can be hardened without oil/water quenching) and exhibits low distortion during heat treatment when processed correctly — one reason it is chosen for precision dies.

Specifications, standards and equivalents

Common specifications and identifiers

-

AISI / SAE D2 (commonly cited): classic US designation.

-

DIN 1.2379 / X153CrMoV12 (Europe / Germany).

-

JIS SKD11 (Japan) — often used as functional equivalent.

-

ASTM A681 lists D-series tool steels within the tool-steel specification family (use for purchase and inspection requirements).

-

UNS T30402 sometimes used as a registry designation.

How to interpret ‘equivalents’: equivalent names reflect small chemistry or processing differences; for critical tooling orders specify the exact standard (e.g., “DIN 1.2379 grade to EN/ISO / DCF finish per mill spec”) and request mill certificate (C of C).

Typical manufacturing and metalworking

Melt and mill considerations

-

D2 is usually produced as vacuum-induction melted (VIM) or electric-arc and then refined in a secondary process for low-inclusion quality when intended for precision dies. DeCarb-Free (DCF) bars and precision ground stock are common for tooling to avoid surface decarburization.

Forging & hot work

-

Forge carefully: common practice is to heat slowly to ~700 °C then rapidly to 900–1040 °C with forging completed above ~925 °C; do not continue forging below recommended temperatures. After forging cool slowly and then anneal. Follow mill forging instructions.

Annealing

-

Full anneal to soften for machining — typical cycles bring material to ~760–820 °C then slow cool to minimize residual stresses. Annealed D2 is workable but still tougher to machine than low-alloy steels.

Hardening & tempering (typical sequence)

-

Preheat to ~700–750 °C.

-

Austenitize to ~1000–1040 °C (exact temperatures depend on standard and section).

-

Air cool (D2 is air-hardening) or controlled gas quench — minimal distortion compared with oil/water quench steels.

-

Tempering — two or three tempers commonly applied; temper temperature controls final hardness vs toughness trade-off. Lower temper → higher hardness (and lower toughness); higher temper → more toughness, lower hardness. Cryogenic treatments (deep cryo) are sometimes used to convert retained austenite to martensite and stabilize hardness. Recent research shows cyclic deep cryogenic treatments can further refine properties for certain tooling applications.

Machining & grinding

-

D2 is abrasive and work-hardening; it machines poorly in the hardened condition. Typical practice: machine in annealed condition, then heat treat and do final grinding in the hardened state. Use carbide or ceramic tooling for any finish machining; grinding requires diamond or CBN wheels for efficiency.

Welding

-

Welding D2 is difficult because of high carbon and carbide networks; preheat and controlled post-weld heat treatment required; welded repairs are possible but require specialist procedures and are generally a last resort for tooling repair.

what D2 Steel is used for

D2 is optimized for abrasive wear resistance and edge retention. Common uses include:

-

Blanking, piercing and forming dies for long-run stampings.

-

Shear blades, slitters and knives where abrasion dominates.

-

Cold work molds and dies (complex shapes, large cross sections).

-

Cutting tools for non-ferrous and ferrous materials where a long life between regrinds is required.

-

Wear components (scrap choppers, tyre shredders), punches, and gauge components.

Where D2 is not recommended

-

High-shock applications where toughness is critical (e.g., impact dies) — consider S7 or other shock-resistant steels.

-

High temperature hot-work applications — choose H-series hot-work steels (H13 etc.).

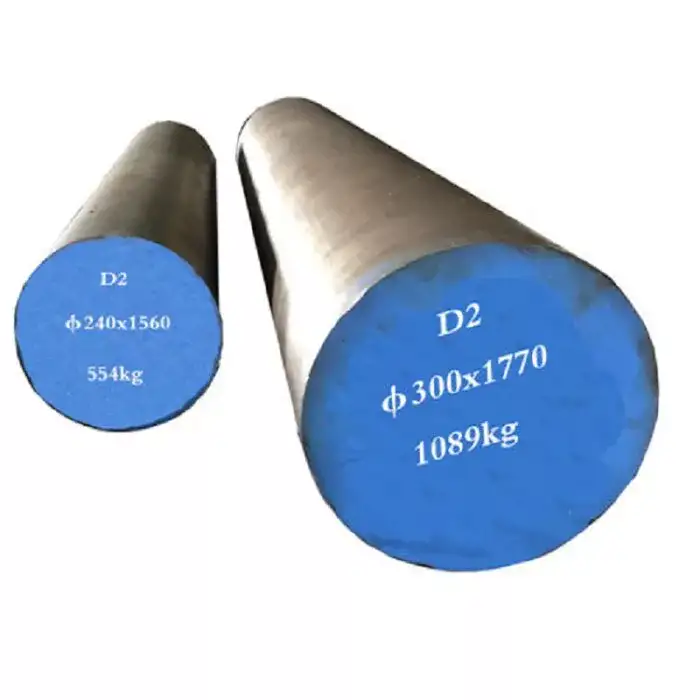

D2 Steel Sizes, weight and common product forms

Common product forms

-

Precision ground plates, annealed plates, cold-drawn / ground bars, forged billets, EDM blocks, and precision ground rod. Suppliers commonly stock round bars (e.g., 6–200 mm), flat bars and plates (e.g., 10–400+ mm thickness) and EDM blocks.

Density & weight calculation

Use density ≈ 7.70 g/cm³ (7,700 kg/m³) for calculation.

-

Example (step-by-step digit calculation for a 100 mm × 100 mm × 100 mm EDM block):

-

Volume (V) = length × width × height = 0.100 m × 0.100 m × 0.100 m = 0.001 m³.

-

Density (ρ) = 7,700 kg/m³.

-

Mass = ρ × V = 7,700 kg/m³ × 0.001 m³ = 7.7 kg.

So a 100 mm cube of D2 weighs about 7.7 kg.

-

-

Example for a round bar (step calculation): 1-inch (~25.4 mm) diameter, length 1 m:

-

Radius r = 12.7 mm = 0.0127 m.

-

Cross-sectional area A = π r² = 3.14159265 × (0.0127 m)² = 3.14159265 × 0.00016129 m² = 0.0005067 m².

-

Volume V = A × length = 0.0005067 m² × 1 m = 0.0005067 m³.

-

Mass = 7,700 kg/m³ × 0.0005067 m³ ≈ 3.90 kg.

So a 1-inch × 1 m D2 bar ≈ 3.9 kg.

-

Stock lengths and tolerances — commercial sellers offer precision ground tolerances and oversized dimensions for machining allowances; specify finish and flatness / straightness tolerance on PO.

D2 steel price comparison 2025

Important — price caution: tool steel prices change with global alloy markets, freight, tariffs and MOQ. The ranges below are market snapshots compiled from supplier listings and marketplace quotes in 2024–2025; use them only as ballpark reference and request up-to-date mill quotes and firm lead-time pricing.

China (domestic mill / exporter) — typical export pricing (range)

-

Typical range: ≈ US$700 – US$1,100 per tonne for bulk orders of standard D2 forged bars/round (some vendor listings show $700–950/tonne; other product forms or small MOQs show higher prices). Lower per-tonne prices appear with large MOQ and mill contracts; precision ground or EDM blocks cost more.

USA (domestic distributor / retail)

-

Typical retail / small-lot prices: US distributors commonly list small items (round bars, EDM blocks) at USD $8–$15 per kg for small retail quantities (prices per piece vary by dimension and finish). Bulk coil/tonne procurement via mill distributors will be lower per kg but depends on supplier contracts. Examples of retail block pricing: hardened EDM squares ~US$80–$500 per block depending on size.

Europe (distributor / service center)

-

Prices typically sit between China-export and US retail for small lots. European distributors list D2 sheet and bar prices showing premium for heat-treated/precision ground stock and CE/EN certification. Expect several hundred to >1,000 USD per tonne in spot retail, rising with processing (grinding, hardening, QC).

Practical buyer note

-

Small piece retail (knife/knife-making stock, small rods) can show high unit price (per kg) because of machining and cutting costs. Bulk buyers should request mill quotes (specify standard e.g., ASTM A681 / DIN 1.2379), shipping Incoterms, and mill C of C. Online marketplaces (Alibaba / Made-in-China) show wide ranges; vet supplier capability, certification, and stock photos carefully.

Buying from MWAlloys

MWAlloys is positioned to supply D2 tool steel (AISI D2 / DIN 1.2379 / SKD11) directly from our partner Chinese mills and stock locations. Key buyer advantages:

-

Factory price (mill direct): we source directly from mills — we pass mill pricing and minimize distributor margins. Typical contracts and MOQ options available.

-

Stock & fast delivery: common diameters and plate sizes kept in regional stock; for standard sizes we can ship within reduced lead times compared with remelted or special-treatment orders.

-

Quality control: we provide mill certificates (chemical & mechanical), hardness reports and optional third-party inspection for critical tooling orders.

-

Value-added services: annealing, precision grinding, EDM block cutting, or pre-hardening service can be arranged prior to shipment.

FAQs

-

Is D2 stainless?

No — D2 is not stainless. It contains high chromium (~11–13%) but not enough to meet stainless corrosion resistance; in hardened condition it shows mild corrosion resistance after polishing, but it is not a stainless grade. -

Can D2 be welded?

Welding is difficult because of high carbon and carbide content — preheat, controlled heat input and post-weld tempering are required; weld repairs should be performed only by specialists. -

What hardness should I specify for a die?

Typical working hardness for long-run cold work dies: 55–62 HRC depending on the balance you want between wear resistance and toughness. Specify tempering schedule and target HRC on the PO. -

How do I machine D2?

Machine in annealed condition whenever possible. For finishing in hardened condition use CBN or diamond grinding wheels; carbide tooling required for any milling in hardened condition. -

What are the equivalents to AISI D2?

DIN 1.2379, JIS SKD11, and UNS T30402 are commonly cited equivalents — confirm final decision by chemistry and property requirements. -

Can D2 be nitrided or surface treated?

Surface hardening by nitriding or PVD coating is used to extend life in wear-critical tools, but pre-treatment grinding and process controls are necessary due to high chromium carbides. Consult coatings vendor. -

What tolerances and finishes are available?

Precision ground bars and plates are available to tight thickness and flatness tolerances; EDM blocks are sold in hardened condition with specific flatness specs. Request supplier tolerance sheet. -

Is D2 suitable for knives?

Many knife makers choose D2 for excellent edge retention and wear resistance; however, D2 can be harder to sharpen and is more prone to chipping than some tougher blade steels. -

How do I control distortion during heat treatment?

Proper austenitizing temperature control, slow cooling before final temper, and multi-step tempering are typical measures. Because D2 is air-hardening it usually distorts less than oil- or water-quenched steels if correctly processed. -

What documentation to require from the mill?

Request mill test certificate (chemical & mechanical) to the specified standard (e.g., ASTM A681 / DIN 1.2379), heat numbers, heat-treatment records and hardness reading. For critical dies request third-party inspection or sample coupons.

Helpful procurement & engineering tips

-

Specify the standard and the required condition (annealed/hardened & tempered to X HRC) on the purchase order — chemistry alone is insufficient.

-

Ask for DeCarb-Free (DCF) if surface decarburization will affect finish or precision.

-

Order oversize and finish-grind after hardening for tight tolerances to avoid final distortion surprises.

-

If high impact is expected use a more shock-resistant grade (S7) or consider local reinforcement / backup designs.

-

For long-run blanking install regrind allowances and track tool life to calculate total cost per part (D2 often wins on life but costs more up front).