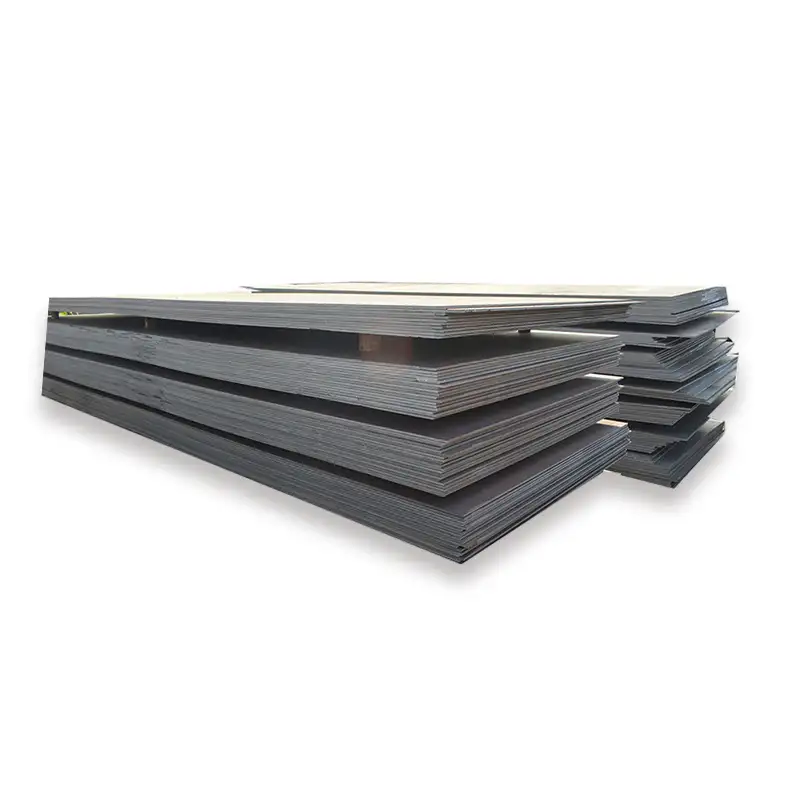

1045 cold rolled steel plate is a medium-carbon engineering grade that balances strength, machinability and wear resistance for structural and mechanical parts; when supplied cold-rolled and normalized it is commonly used for shafts, gears and heavy plates where better surface finish and dimensional accuracy are required than hot-rolled alternatives.

What is 1045 Cold Rolled Steel Plate?

AISI/SAE 1045 (often written simply “1045”) is a medium-carbon steel with nominal carbon around 0.45% that is produced for applications requiring a mid-level of mechanical strength and wear resistance. When supplied cold-rolled as plate or sheet, the material benefits from tighter dimensional tolerances, a smoother surface, improved straightness and often slightly higher yield characteristics (due to strain hardening) compared with comparable hot-rolled grades. Typical end uses include shafts, couplings, machine components, fabricated frames, and wear parts that are subsequently machined or heat-treated.

For purchasers who need a readily machinable, robust medium-carbon plate with good geometry and surface finish, 1045 cold rolled plate is a pragmatic choice. It is not a stainless or alloy steel (so corrosion protection is required in exposed environments), and it is not a through-hardening tool steel — but it is economical and widely available in global markets.

Also read: AISI/SAE 1023 Cold Rolled Steel Plate.

Chemical composition (typical ranges)

Below is a compact, industry-accepted composition table for 1045 / C45 / 1.0503. Actual supplier certificates (COC / mill test report) must be consulted for exact batch values.

| Element | Typical range / wt.% |

|---|---|

| Carbon (C) | 0.42 – 0.50 |

| Manganese (Mn) | 0.50 – 0.90 |

| Silicon (Si) | ≤ 0.40 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.045 |

| Chromium (Cr) | ≤ 0.40 (often trace) |

| Nickel (Ni) | ≤ 0.40 (trace) |

| Molybdenum (Mo) | ≤ 0.10 (trace) |

| Iron (Fe) | balance |

Source note: This composition matches the EN/DIN designation C45 / 1.0503 and the SAE/AISI 1045 family used in international practice.

Material mechanical properties

Mechanical properties depend on the delivery condition (hot-rolled, normalized, cold-rolled, quenched & tempered). The table below collects commonly used nominal ranges for cold-rolled / normalized 1045 plate used in engineering design:

| Property | Typical value (cold-rolled / normalized) |

|---|---|

| Density | 7.85 g/cm³ (7850 kg/m³) |

| Modulus of Elasticity (E) | ≈ 200 GPa |

| Yield strength (0.2% offset) | ≈ 275 – 410 MPa (depends on thickness & heat treatment) |

| Ultimate tensile strength (Rm) | ≈ 560 – 700 MPa. Common normative band 570–700 MPa |

| Elongation (A, % on 50 mm) | ≈ 12 – 18 % (varies with heat treatment and thickness) |

| Brinell hardness (HB) | Typical: 160–210 HB (hot rolled lower, cold drawn/rolled higher) |

Practical design note: If your application requires higher strength or controlled hardness, 1045 responds well to quench & temper cycles but has limited through-hardening in thick sections; designers often specify normalized or T-treated conditions for consistent properties.

Typical specifications and dimension tolerances

Cold-rolled plates are normally supplied against national/industry standards (SAE J403 chemistry listing, EN 10277 or EN 10083 series for C45 / 1.0503, plus mill or purchaser quality clauses).

| Item | Typical spec / note |

|---|---|

| Common standards | SAE/AISI J403 (chemistry listing), EN 10083/EN 10277 (European forms for non-alloy steels), national mill specs |

| Thickness range (plate) | Cold-rolled plates commonly 1.0 mm → 12 mm (thin plates/sheets). For heavier plates, hot-rolled or normalized plate is typical. |

| Width & length | Custom; standard mill coil slitting & cut sizes available; check mill’s max width/length. |

| Flatness & surface | Milder tolerances than hot-rolled; surface finish: 2B, cold-rolled bright, pickled & oiled options. |

| Tensile test | 1 test per heat or per lot; purchaser often requests mechanical test certificate (EN 10204 / 3.1). |

| Hardness test | When required by purchase order. |

| Coating/finish | Bare, mill oiled, phosphated, or cut & coated for export. |

Heat treatment states and effects

-

As cold-rolled (no anneal): highest surface quality, some residual strain-hardening — beneficial for finish parts but can reduce formability.

-

Annealed / soft annealed: reduces yield and hardness for forming; easier machining.

-

Normalized: gives a balanced microstructure that improves toughness and evens out mechanical properties across thickness.

-

Quenched & tempered: used where higher strength is required; be aware 1045 has limited through-hardening at large sections — consult heat-treatment vendor.

What is equivalent to 1045 Cold Rolled Steel?

Common cross-references used by purchasing and engineering teams:

| System | Equivalent grade |

|---|---|

| SAE / AISI | 1045 |

| EN / DIN | C45, 1.0503 (sometimes C45E / C45R variants depending on delivery state) |

| JIS (Japan) | S45C |

| GOST (Russia) | 45 (various) |

These equivalents are widely accepted for design and procurement, but always compare exact chemical and mechanical requirements (standards can differ in tolerances and required proofs).

Sizes and weight (how to calculate)

Weight formula (metric):Weight (kg) = Length (m) × Width (m) × Thickness (m) × Density (7850 kg/m³)

Examples (rounded):

-

1 m × 2 m × 5 mm (0.005 m) → Weight = 1 × 2 × 0.005 × 7850 = 78.5 kg

-

2 m × 3 m × 10 mm (0.01 m) → 2 × 3 × 0.01 × 7850 = 471 kg

Common thicknesses for cold-rolled plates/sheets: 0.5 mm, 0.8 mm, 1.0 mm, 1.5 mm, 2.0 mm, 3.0 mm, 5.0 mm, 6.0 mm, 8.0 mm, 10.0 mm, 12.0 mm. Plate beyond ~12 mm is typically hot-rolled. Always confirm supplier rolling capability.

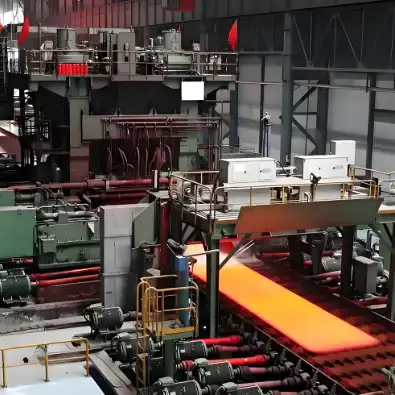

Manufacturing notes: cold-rolling process and surface finish

Cold-rolled 1045 plate is produced by cold reducing hot-rolled or pickled steel to achieve smaller thickness, better flatness and a smoother finish. Common finishes: 2B (bright, ground), cold-rolled bright (mirror-like) and oiled (for protection). Cold work increases yield and tensile slightly; if the application involves forming, many mills offer an annealed cold-rolled delivery.

Welding, machining and forming behavior

-

Machining: 1045 machines well in annealed or normalized condition; cold-rolled and higher hardness states require more robust tooling. Typical tooling feeds/rpms follow medium-carbon steel practice.

-

Welding: Because carbon ~0.45% is moderate, preheat is often recommended and welding consumable selection (e.g., matching filler metal) must account for cracking risk and desired post-weld toughness. Use controlled heat input and consider post-weld tempering for critical components.

-

Forming: Cold-rolled 1045 has reduced formability compared with low-carbon steels; consider annealing prior to forming or use hot-forming techniques for large deformations.

2025 Price comparison (USA | Europe | China)

Market context (short): Steel prices in 2025 showed regional variation driven by tariffs, local capacity, scrap dynamics and demand for flat products. Cold-rolled coil (CRC) and cold-rolled plate prices are not fixed to a single “1045 plate” line item but follow underlying CRC/HRC markets plus processing/grade adjustments. The values below are representative market ranges aggregated from recent mid-2025 industry price summaries and real-time market monitors; use them as procurement guidance and get firm mill or trader quotations for final orders.

Representative price ranges (USD per metric ton) — mid-2025 (indicative):

| Region | Cold-rolled coil / base (USD/mt) | Typical premium for 1045 plate / processing | Indicative landed price for finished 1045 cold-rolled plate (USD/mt) |

|---|---|---|---|

| USA | $1,075 – $1,140 (CRC spot mid-2025). | +$60–$120 (processing, cutting, certification) | $1,140 – $1,300 / mt |

| Europe (Western) | $1,000 – $1,150 (CRC indices vary by country) | +€50–€150 equivalent | $1,080 – $1,350 / mt |

| China (mainland) | $430 – $520 / mt for base coils / domestic price signals (spot varies widely). | +$80–$180 (export processing, packing, port fees) | $520 – $800 / mt (ex-works China) |

Important procurement notes:

-

The China ex-works numbers are commonly lower due to large domestic production and competitive mills, but export offers vary with quotas, duties, and shipping.

-

USA numbers reflect domestic mill pricing plus the effect of tariffs and higher domestic raw material costs during parts of 2025.

-

European prices depend on local scrap, energy costs and mill capacity; import offers often include anti-dumping duties and VAT considerations.

-

These are indicative bands — always obtain current pro-forma quotes and confirm minimum order quantities, delivery lead time and incoterms.

MWAlloys supply proposition

MWAlloys is a specialized supplier and manufacturer serving industrial buyers with the following value points for 1045 Cold Rolled Steel Plate:

-

Factory direct pricing: MWAlloys sources product from selected mills in China and offers 100% factory ex-works pricing for buyers seeking competitive unit cost.

-

Inventory & lead time: We maintain buffer stocks for common cold-rolled thicknesses (1–12 mm) and can usually dispatch standard sizes within 7–21 days depending on order size and destination. (Contact for live lead time.)

-

Quality & inspection: All deliveries include MTR / EN 10204 3.1 where requested; options for third-party inspection (SGS, BV) are available.

-

Customization: Cut-to-size, edge-trim, surface protection (oiled / phosphate), and export packing.

-

After-sales: Material certificates and test reports are delivered with each consignment; MWAlloys supports technical queries on heat treatment and finish.

FAQs

-

Q: Is 1045 the same as C45?

A: Yes. in most international mappings, AISI/SAE 1045 corresponds to EN/DIN C45 / 1.0503 (check specific delivery state and tolerances). -

Q: Can 1045 cold-rolled plate be heat treated?

A: Yes, 1045 responds to normalizing and quench & temper; quench & temper produces higher strength but through-hardening is limited in thick sections. -

Q: What surface finishes are available?

A: Typical finishes: bright cold-rolled (2B), ground, pickled & oiled, and bare oiled. -

Q: Is 1045 weldable?

A: It is weldable with precautions — preheat and controlled heat input are recommended; post-weld tempering may be required for critical parts. -

Q: Typical hardness for cold-rolled 1045?

A: Expect roughly 160–210 HB depending on delivered condition; cold drawing/rolling pushes the value up. -

Q: Are certificates available?

A: Yes. MWAlloys provides MTR / EN 10204 3.1 certificates on request and offers SGS/BV inspection options. -

Q: Minimum order quantity (MOQ)?

A: MOQs vary by thickness/size; for standard plates MWAlloys can supply single-sheet orders for small buyers or containers for bulk procurement — request a custom quote. -

Q: Can dimensions be cut to length?

A: Yes, cut-to-size services are standard; edge remain straight and burrs are deburred for machining orders. -

Q: Price volatility — how often do prices change?

A: Flat steel prices move with scrap, energy, tariffs and demand; in 2025 we saw regional swings across quarters. Always lock price with confirmed POs and outlines. -

Q: Typical lead time for shipment to overseas buyers?

A: Ex-works preparations typically 7–21 days; FOB/EXW plus shipping times depend on destination port and customs.

Closing summary

1045 cold rolled steel plate remains a pragmatic engineering grade for applications that require a balance of strength, machinability and reasonably good surface finish. For procurement teams, the key decisions are delivery condition (annealed / normalized / quenched & tempered), finish (2B / oiled / pickled), and the total landed cost including certification, cutting and testing. MWAlloys can provide factory pricing, quick stock shipments from China and full documentation for international projects.