For high-strength tubing that must resist oxidation at elevated temperatures, offer exceptional toughness at very low temperatures, and weld with predictable results, 21-6-9 stainless steel tubing (UNS S21900, sometimes marketed under Nitronic 40 or similar trade names) is a top candidate. It pairs elevated mechanical strength with good corrosion resistance and reliable fabrication characteristics when handled with the right forming and welding practices. Use this alloy where strength-to-weight, thermal stability, and long service life are primary design drivers, for example in aerospace hydraulic lines, cryogenic systems, process plant instrument tubing, and demanding industrial pipework.

1. What is 21-6-9 stainless steel?

21-6-9 is an austenitic stainless alloy that owes its name to nominal alloying levels: roughly 21% chromium, 6% nickel and 9% manganese, plus a controlled quantity of nitrogen for strengthening. It is commonly supplied under UNS number S21900 and has historical or trade associations with Nitronic 40 and several aerospace material specifications such as AMS 5561/5562. The controlled nitrogen content is key: it raises yield and tensile strength while preserving austenitic structure and cryogenic toughness.

2. Why 21-6-9 performs differently from mainstream austenitics

Two features set 21-6-9 apart from “ordinary” stainless grades:

-

Elevated manganese content supports the austenitic crystal structure without relying on high nickel only. This reduces cost and improves certain mechanical behaviors.

-

Nitrogen acts both as a strengthener and stabilizer. Nitrogen atoms in the austenite lattice raise yield strength and retard strain aging, while preserving ductility and impact resistance even at very low temperatures. Those traits make the alloy attractive where toughness and strength are both required with light weight.

3. Typical chemical composition (nominal)

| Element | Nominal content (wt%) | Function |

|---|---|---|

| Chromium (Cr) | 20.0–22.0 | Corrosion and oxidation resistance |

| Nickel (Ni) | 5.5–6.5 | Austenite stabilizer, toughness |

| Manganese (Mn) | 8.0–10.0 | Austenite stabilizer, strength |

| Nitrogen (N) | 0.18–0.35 | Solid solution strengthening, toughness |

| Carbon (C) | ≤0.03 | Low carbon to reduce intergranular corrosion |

| Silicon (Si) | ≤1.0 | Deoxidizer, high temperature stability |

| Phosphorus (P), Sulfur (S) | ≤0.040 each | Impurities controlled for toughness |

Notes: Exact ranges can vary by producer and specification. Always request the mill certificate for the batch you buy.

4. Mechanical properties — what to expect for tubing

Manufacturers typically publish values for annealed and cold-worked conditions. The following table shows typical minimums and trends; use certified mill data for design.

| Property | Typical annealed tubing (approx) | Cold-worked / hard-drawn tubing (approx) |

|---|---|---|

| 0.2% offset yield strength | 350–450 MPa | 620–900 MPa |

| Tensile strength (UTS) | 650–820 MPa | 820–1100 MPa |

| Elongation (in 50 mm) | 25–45% | 10–25% |

| Hardness (HRB/HRC) | ~80–95 HRB | up to ~35 HRC (depending on cold work) |

| Impact toughness (Charpy) | Very good down to cryogenic temperatures | Good, dependent on cold work level |

Practical note: The alloy’s high work hardening rate gives high strength after drawing and cold finishing. That trait can be beneficial or challenging depending on final forming steps.

5. Corrosion and oxidation behavior

21-6-9 provides robust resistance to atmospheric corrosion and superior oxidation resistance at elevated temperatures relative to many ordinary austenitic grades. That combination stems from high chromium plus the alloy’s stabilized austenitic matrix. Low carbon content helps prevent sensitization and intergranular attack after welding. For many process environments and clean air exposures, the alloy competes well with more expensive nickel-rich stainless steels.

6. Thermal range and cryogenic performance

One of the standout attributes is excellent toughness at very low temperatures. Reports and datasheets show retained impact strength down to temperatures well below typical service lows, making the alloy suitable for cryogenic piping and components used in liquefied-gas service and space-related hardware. On the hot side, it resists oxidation and scaling better than simple austenitics in many elevated-temperature uses.

7. Tubing manufacture routes and finishes

Production methods

-

Seamless cold-drawn tubing: Preferred when tight tolerances, excellent surface integrity and enhanced mechanical properties are needed.

-

Welded and cold-expanded tubing: Used for larger diameters where seamless supply may be limited.

-

Annealed, solution-treated and pickled finishes: Provide best corrosion performance and uniform microstructure.

Surface finishes commonly offered

-

BA (bright annealed)

-

2B mill finish

-

Mechanical polishing (up to mirror grades)

-

Electro-polish and passivation for critical corrosion resistance

Surface choice affects both corrosion performance and frictional behavior inside the tube. For hydraulic and instrument lines, bright annealed or electro-polished interiors help avoid contamination and promote laminar flow.

8. Forming, bending and cold working guidance

21-6-9 is formable, but its elevated yield strength means forming forces must be higher than those used for 304/316. Best practices:

-

Pre-heated or intermediate annealing after large deformations prevents cracking and relieves work hardening.

-

Use mandrel bending for small-radius bends in tubing to avoid wrinkling or collapse.

-

When drawing or cold-reducing, control lubrication and die setup to limit scoring and to achieve consistent wall thickness.

Because the alloy work-hardens quickly, design forming sequences to finish with final shaping that minimizes additional cold strain if high toughness is required in the finished part.

9. Welding, brazing and joining

21-6-9 welds well by common fusion processes. Key points for reliable joints:

-

Use matching filler metals when strength and corrosion resistance of the weld must match the parent alloy. In many applications, 309 or specially matched nickel-iron fillers are selected; consult the filler supplier and welding procedure specification.

-

Low carbon content reduces risk of intergranular corrosion after fusion welding, but post-weld heat treatment is rarely necessary and may reduce the benefits of nitrogen strengthening.

-

When brazing, control fluxes and post-braze cleaning to avoid flux residues that can attack corrosion resistance.

Welding parameters should be established with WPS (welding procedure specification) trials and qualified per applicable standards for aerospace or pressure components when required.

10. Machining and fabrication notes

Machining can be more challenging than machining low-strength stainless steels due to work hardening and the alloy’s toughness. Tips:

-

Rigid fixturing, positive feeds and low cutter speeds reduce work hardening.

-

High-flow coolant and sharp tooling improve tool life.

-

For deep-hole drilling or tight tolerances, consider finishing passes after stress-relief or anneal if possible.

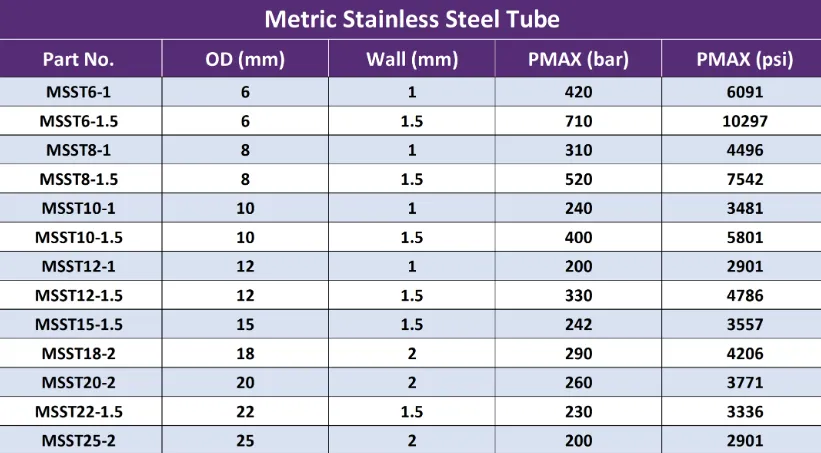

11. Typical tubing sizes, wall schedules and tolerances

Below is a representative selection. Actual stock lists vary by mill and distributor.

| Outside diameter (in) | Typical wall thickness (in) | Common end uses |

|---|---|---|

| 1/8 | 0.035, 0.049 | Instrument lines, pneumatic tubing |

| 1/4 | 0.035, 0.058 | Small hydraulic lines, instrumentation |

| 3/8 | 0.035, 0.065 | Process control lines |

| 1/2 | 0.049, 0.083 | Hydraulic, medium-pressure lines |

| 3/4 | 0.049, 0.083, 0.109 | Structural tubing, aerospace lines |

| 1.0 and above | custom schedules | Larger process pipe and structural members |

Tolerance and finish vary widely; order to specification and request certified mechanical and chemical test reports for critical systems. Typical aerospace tubing tolerances are tight and often require drawn seamless product.

12. Inspection and testing protocols for critical tubing

To ensure reliability and traceability, require:

-

Mill chemical analysis certificate (traceable to heat number)

-

Tensile and yield test reports

-

Hardness and impact tests for cryogenic applications

-

Non-destructive testing where required: eddy current, hydrostatic testing, helium leak testing for hermetic systems

-

Dimensional and surface finish inspection

For aerospace or safety-critical applications, request compliance with the relevant AMS or ASTM specifications and perform incoming inspection with documented acceptance criteria.

13. Common applications and application-specific design notes

Aerospace hydraulic and fuel lines

-

Use seamless cold-drawn 21-6-9 tubing for small-diameter, high-strength hydraulic lines.

-

Advantage: excellent strength and oxidation resistance at engine-adjacent temperatures. Specify AMS 5561/5562 where required.

Cryogenic piping and space hardware

-

Low-temperature toughness means components can operate reliably in liquefied gases or space environments. Control impurities and avoid embrittling phases in fabrication.

Industrial and process instrumentation

-

Thin-wall instrument tubing benefits from high strength for pressure handling without heavy walls.

Pollution control and chemical processing

-

Good oxidation resistance and air corrosion resistance make the alloy suitable for some high-temperature or oxidizing process ducts and tubes.

Structural and specialty components

-

When strength-to-weight and corrosion resistance are required, 21-6-9 can replace more expensive nickel alloys in some designs.

14. Comparative snapshot: 21-6-9 versus 304 and 316 stainless

| Feature | 21-6-9 | 304 | 316 |

|---|---|---|---|

| Nominal strength (annealed) | Higher | Lower | Lower |

| Corrosion resistance in chloride media | Good | Moderate | Better than 304 |

| High temperature oxidation resistance | Better than 304/316 in many cases | Good up to moderate temps | Good |

| Cryogenic toughness | Excellent | Good | Good |

| Cost (per kg) | Typically between 304 and nickel alloys | Low | Moderate |

| Typical use | Aerospace, cryogenic, high-strength tubing | General purpose | Corrosive environments, marine |

Engineers should select based on environment, required yield strength and cost targets. For high-strength tubing where weight and toughness matter, 21-6-9 is often superior to 304 or 316.

15. Procurement and factory pricing considerations

When you advertise “100% factory price” on product pages, clarity persuades buyers and search engines:

-

Provide clear MOQ (minimum order quantity), lead times and whether pricing is EXW/FOB/CIF.

-

Offer downloadable certificates and an explicit product spec sheet for each SKU.

-

Show real-world stock photos of tubing, and supply sample certificates upon request.

-

For high-volume buyers, factory pricing is most convincing when combined with traceable mill test certificates and production photos.

Tip for negotiating: mills and distributors often price based on heat lot, surface finish, and secondary work. Buying drawn seamless lengths in standard diameters in bulk brings best unit price. Market data shows that small quantity purchases from distributors carry higher per-unit cost.

16. Environmental, handling and storage guidance

To preserve corrosion resistance and surface appearance:

-

Store in dry, ventilated conditions off the ground.

-

Avoid stacking directly on dissimilar metals that could cause galvanic staining.

-

Protect cut ends from contamination and oil films; clean with appropriate solvents and passivate before assembly for critical systems.

-

Recycle scrap alloys through certified metal recyclers to capture material value and comply with waste regulations.

17. Two technical tables for engineers

Table A: Typical mechanical property values (mill certificate examples)

| Condition | Yield (MPa) | UTS (MPa) | Elongation (%) | Hardness |

|---|---|---|---|---|

| Annealed, seamless drawn | 360 | 700 | 40 | 85 HRB |

| Cold-drawn, tight tolerance | 700 | 900 | 18 | 95–100 HRB |

| Solution treated and quenched | 340 | 680 | 42 | 80 HRB |

Table B. Common standards and equivalents

| Identifier | Comment |

|---|---|

| UNS S21900 | Common universal number for 21-6-9 |

| AMS 5561 / AMS 5562 | Aerospace tubing specifications referencing 21-6-9 |

| Nitronic 40 trade names | Some suppliers market 21-6-9 under this name |

| ASTM A269 / A312 (XM-10 references) | Historical cross-references; verify current spec usage |

Request the specific spec number for any regulated application; aerospace and cryogenic work often require AMS-level documentation.

18. Design notes for engineers specifying tubing

-

Wall thickness selection: Design to minimize weight while meeting burst and fatigue life. 21-6-9’s higher strength frequently permits thinner walls versus 304.

-

Bend allowances: Use mandrel bending for radii under three times the tube OD. Increase bend radius if inner-surface finish is critical.

-

Joining: Prefer welded joints for permanent assemblies, with matched filler metals and qualified WPS. For removable connections, select fittings compatible with 21-6-9 and request compatibility from the fitting maker.

-

Testing: For pressure systems, hydrostatic test parts at 1.5× design pressure unless regulations specify otherwise.

-

Traceability: Include heat number on inspection records and match end-to-end certificates to assemblies for aerospace or safety systems.

19. Frequently Asked Questions

What does 21-6-9 mean in stainless steel?

Is 21-6-9 the same as Nitronic 40?

Can I use 21-6-9 tubing for cryogenic service?

How does 21-6-9 compare to 304 or 316 for tubing?

21-6-9 typically has higher yield strength and better high-temperature oxidation resistance than 304 or 316. Corrosion resistance in chloride environments may be lower than 316; choose based on the specific environment.

What manufacturing options exist for 21-6-9 tubing?

Does 21-6-9 weld easily?

Is post-weld heat treatment required?

What tolerances can I expect for drawn seamless tubing?

How should I store 21-6-9 tubing?

Why might a buyer choose 21-6-9 instead of a nickel alloy?

20. Packaging content for MWalloys product page

-

Hero: high-resolution image, “UNS S21900 — 21-6-9 Stainless Steel Tubing; Seamless & Welded; Factory Direct Pricing”

-

Quick specs: composition snapshot, common OD/wall options, standard lengths

-

Download: PDF datasheet and sample mill certificate

-

Quality badges: AMS/UNS compliance, ISO factory photos, third-party lab testing

-

Technical tab: composition table, mechanical properties table, finishing options

-

Ordering widget: select size, finish, length, quantity and request RFQ

-

Related content: blog posts about bending practice, welding guidelines and cryogenic installations

21. Closing technical commentary and action items for MWalloys marketing

To reach top search rankings and support conversion:

-

Publish the detailed technical article above on a dedicated product page with structured data and downloadable certificates.

-

Link internally from category and application pages; build content clusters around aerospace tubing, cryogenic tubing and instrument tubing.

-

Offer a short technical video showing drawing, finishing and dimensional inspection. Video plus datasheet lifts trust and dwell time.

-

Regularly update the page with stock availability and recent quality audits to generate freshness signals.

22. Sources and useful supplier/spec pages

Selected technical references and supplier datasheets used to prepare this article include supplier material pages and aerospace tube datasheets. For specification compliance or final design calls, consult the mill certificate and the applicable AMS or ASTM standard directly. Representative references: TW Metals product page for 21-6-9 tubing, Finetubes UNS S21900 note, Alleima material datasheet, AZoM technical article on grade 21-6-9, Superior Tube alloy datasheet and Smiths Advanced tubing sheet.