Nickel alloys represent one of the most versatile and indispensable material families in modern industrial applications, offering exceptional corrosion resistance, high-temperature performance, and mechanical strength across diverse operating environments. At MWalloys, we have identified six primary nickel alloy classifications that dominate today's market: pure nickel grades (200/201), nickel-copper alloys (Monel series), nickel-chromium-iron systems (Inconel/Incoloy families), nickel-molybdenum-chromium compositions (Hastelloy series), nickel-iron alloys (Invar series), and specialty formulations. Each category serves specific industrial niches, from petrochemical processing and marine environments to aerospace propulsion and electronic components. Understanding the distinct characteristics, performance parameters, and selection criteria for these alloy grades enables engineers to optimize material choices, reduce lifecycle costs, and ensure operational reliability in demanding service conditions.

What is Nickel Alloys

Nickel alloys have evolved significantly since their commercial introduction in the early 20th century, when the Monel alloy family first demonstrated superior seawater resistance compared to conventional steels. Today, these sophisticated metallic compositions occupy a critical position in industries where standard materials fail to meet performance requirements.

The fundamental appeal of nickel-based alloys stems from nickel's inherent properties: excellent corrosion resistance in both oxidizing and reducing environments, retention of mechanical strength at elevated temperatures, and compatibility with various alloying elements that enhance specific characteristics. We observe that nickel's face-centered cubic crystal structure provides exceptional ductility and toughness, while its electron configuration enables formation of protective oxide films.

Modern nickel alloy development focuses on optimizing chemical compositions to address increasingly demanding applications. The global nickel alloy market has expanded substantially, driven by growth in chemical processing, oil and gas extraction, power generation, and aerospace sectors. Current market valuation exceeds $15 billion annually, with projected growth rates of 6-8% through the next decade.

The strategic importance of nickel alloys becomes evident when considering their role in enabling advanced technologies. From supercritical steam cycles in power plants to extreme environment applications in space exploration, these materials often represent the difference between operational success and catastrophic failure.

Classification of Nickel Alloy Families

1.1 Pure Nickel Grades

Pure nickel grades, primarily represented by Nickel 200 and Nickel 201 (UNS N02200 and N02201 respectively), serve as the foundation for understanding nickel alloy behavior. These commercially pure compositions contain minimum 99.0% nickel, with carbon content being the primary differentiator between grades.

Nickel 200 contains 0.15% maximum carbon, making it suitable for service temperatures up to 315°C (600°F). The higher carbon content provides increased strength but limits high-temperature applications due to potential carbide precipitation. We recommend Nickel 200 for caustic processing environments, food handling equipment, and electronic components where magnetic permeability must remain low.

Nickel 201, with carbon content restricted to 0.02% maximum, offers superior performance at elevated temperatures up to 650°C (1200°F). The low carbon specification prevents carbide formation during thermal exposure, maintaining ductility and corrosion resistance. Applications include high-temperature caustic processing, aerospace components, and specialized chemical reactors.

JLC Electromet and similar specialty suppliers provide these pure nickel grades in various forms, including sheet, plate, bar, and wire products. Manufacturing processes typically involve vacuum induction melting followed by electroslag remelting to achieve the required purity levels.

-

UNS N02200 / N02201

-

Composition: ≥99% Ni; C ≤0.15% (200) vs ≤0.02% (201)

-

Key Traits: Excellent resistance to caustic and reducing chemistries; good low-temperature toughness; magnetic permeability control.

-

Temperature Limits: 200: ≤315 °C; 201: ≤650 °C.

-

Forms: Plate, sheet, bar, wire, tube.

1.2 Nickel-Copper Alloys (Monel® Series)

The Monel family represents one of the most successful nickel alloy series, combining nickel's corrosion resistance with copper's strength and workability. Monel alloys typically contain 63-70% nickel and 28-34% copper, with small additions of iron, manganese, and other elements.

Monel 400 (UNS N04400) stands as the flagship alloy in this series, offering excellent resistance to seawater, hydrofluoric acid, and various organic compounds. Its mechanical properties remain stable across a wide temperature range, from cryogenic conditions to 480°C (900°F). We frequently specify Monel 400 for marine hardware, chemical processing equipment, and petroleum refining applications.

Monel K-500 (UNS N05500) incorporates aluminum and titanium additions, enabling age hardening to achieve higher strength levels. After proper heat treatment, K-500 develops tensile strengths exceeding 1000 MPa while maintaining excellent corrosion resistance. This combination makes it ideal for pump shafts, valve components, and fasteners in corrosive environments.

Monel 450 offers enhanced sulfur resistance compared to standard grades, making it suitable for sour gas applications in oil and gas production. Continental Steel & Tube Company and other major distributors maintain extensive inventories of Monel products to serve diverse industrial requirements.

-

Monel 400 (UNS N04400): 63% Ni, 28–34% Cu; superb seawater and acid resistance; service to 480 °C.

-

Monel K-500 (UNS N05500): Age-hardenable via Al + Ti additions; >1000 MPa tensile strength after treatment.

-

Monel 450: Enhanced sulfuric/hydrofluoric acid resistance for sour-gas applications.

1.3 Nickel-Chromium-Iron Alloys (Inconel®/Incoloy®)

This extensive alloy family encompasses some of the most widely used high-performance materials in modern industry. The addition of chromium provides oxidation resistance, while iron content helps control costs and thermal expansion characteristics.

Inconel 600 (UNS N06600) contains approximately 76% nickel, 15.5% chromium, and 8% iron, creating an excellent balance of high-temperature strength and oxidation resistance. Service temperatures can reach 1095°C (2000°F) in oxidizing atmospheres, making it suitable for heat treating equipment, chemical processing vessels, and nuclear reactor components.

Inconel 601 (UNS N06601) incorporates aluminum additions to enhance oxidation resistance at extreme temperatures. The aluminum forms a protective alumina scale that provides superior protection compared to chromia scales formed by other alloys. We recommend Inconel 601 for furnace components, heat treating fixtures, and gas turbine components operating above 980°C (1800°F).

Inconel 625 (UNS N06625) represents a more complex composition with significant molybdenum and niobium additions. These elements provide exceptional strength through solid solution strengthening and precipitation hardening mechanisms. The alloy maintains mechanical properties to 650°C (1200°F) while offering outstanding corrosion resistance in marine and chemical environments.

Inconel 718 (UNS N07718) has become the standard for aerospace applications requiring high strength at elevated temperatures. Its unique precipitation hardening response, achieved through controlled additions of aluminum, titanium, and niobium, enables tensile strengths exceeding 1400 MPa at room temperature while maintaining 1000 MPa at 650°C (1200°F).

The Incoloy series, including grades 800, 825, and 925, typically contains higher iron content than Inconel alloys, resulting in lower costs and different thermal expansion characteristics. Incoloy 825 (UNS N08825) provides excellent resistance to sulfuric and phosphoric acids, making it valuable for chemical processing applications.

-

Inconel 600 (N06600): 76% Ni, 15.5% Cr; oxidation resistance to 1095 °C.

-

Inconel 601 (N06601): +Al (1–1.7%) for alumina scale; ideal above 980 °C.

-

Inconel 625 (N06625): +Mo (8–10%), Nb+Ta (3.15–4.15%); solid-solution & precipitation strengthening.

-

Inconel 718 (N07718): Precipitation hardening; 1400 MPa tensile at RT, 1000 MPa at 650 °C.

-

Incoloy 800/825/925 (N08800/825/925): Higher Fe content for cost control; specialized acid resistance.

1.4 Nickel-Molybdenum-Chromium Alloys (Hastelloy® Series)

Hastelloy alloys represent the pinnacle of corrosion-resistant materials, designed specifically for the most aggressive chemical environments. These alloys typically contain 50-65% nickel with substantial molybdenum additions (15-28%) and varying chromium content.

Hastelloy C-276 (UNS N10276) stands as the most versatile member of this family, offering exceptional resistance to oxidizing and reducing acids, chlorine-containing solutions, and high-temperature corrosive gases. The carefully balanced composition provides resistance to localized corrosion phenomena, including pitting, crevice corrosion, and stress corrosion cracking.

Hastelloy X (UNS N06002) incorporates higher chromium content (20-23%) and iron additions, optimizing it for high-temperature oxidizing environments while maintaining strength to 815°C (1500°F). Gas turbine combustors, industrial furnace components, and aerospace applications frequently utilize this grade.

Continental Steel & Tube Company and other specialty suppliers maintain technical expertise in Hastelloy applications, providing guidance on fabrication techniques and service limitations. These alloys require careful attention to welding procedures and heat treatment practices to maintain optimum properties.

-

Hastelloy C-276 (N10276): 15–17% Mo, 14.5–16.5% Cr; exceptional pitting & crevice corrosion resistance.

-

Hastelloy X (N06002): 20–23% Cr, 17–20% Fe; high-temperature strength to 815 °C.

1.5 Nickel-Iron Alloys (Invar® Series)

Invar alloys represent a unique category optimized for dimensional stability rather than corrosion resistance or high-temperature strength. Alloy 36 (UNS K93600), containing 36% nickel and 64% iron, exhibits minimal thermal expansion from -80°C to 100°C (-112°F to 212°F).

This exceptional dimensional stability results from the specific magnetic properties of the 36% nickel composition, where thermal expansion and magnetic effects nearly cancel each other. We specify Invar 36 for precision instruments, optical equipment, and aerospace structures requiring dimensional stability across temperature cycles.

Super Invar compositions, containing small cobalt additions, achieve even lower thermal expansion coefficients for the most demanding applications. These materials find use in satellite components, laser systems, and scientific instrumentation.

-

Alloy 36 (K93600): 36% Ni, 64% Fe; near-zero thermal expansion (–80 °C to 100 °C).

-

Super Invar: +Co for ultra-low expansion in precision optics and aerospace instrumentation.

1.6 Other Specialty Alloys

Several important nickel alloys fall outside the major family classifications but serve critical niche applications. Alloy 20 (UNS N08020) combines nickel, chromium, iron, molybdenum, and copper to provide exceptional resistance to sulfuric acid environments, particularly in chemical processing applications.

Nichrome alloys, containing 80% nickel and 20% chromium, serve as standard resistance heating elements due to their high electrical resistivity and oxidation resistance. These compositions maintain stable properties through repeated heating cycles, making them essential for furnaces, toasters, and other heating applications.

Nimonic alloys represent high-strength, high-temperature materials developed primarily for gas turbine applications. These precipitation-hardened alloys maintain strength above 700°C (1290°F) through carefully controlled additions of aluminum, titanium, and other strengthening elements.

-

Alloy 20 (N08020): Ni-Cr-Mo-Cu mix for sulfuric acid service.

-

Nichrome (80Ni–20Cr): High resistivity heating elements to 1200 °C.

-

Nimonic Series: Precipitation-hardened turbine alloys for >700 °C.

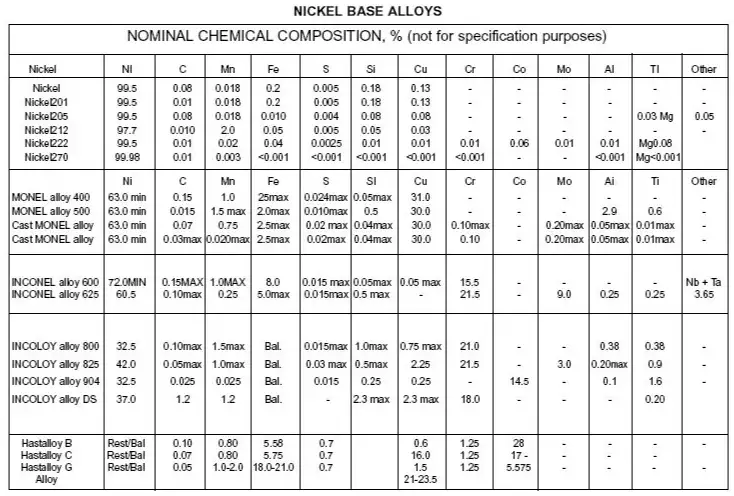

Chemical Composition & Mechanical Properties

| Family | Key Elements | Tensile (MPa) | Hardness (HV) | Temp. Limit (°C) |

|---|---|---|---|---|

| Pure Ni 200 | Ni ≥99% | 310–450 | 90–130 | 315 |

| Monel 400 | Ni 63–70%, Cu 28–34% | 490–620 | 170–210 | 480 |

| Inconel 625 | Ni 58%, Mo 8–10%, Nb 3–4% | 690–930 | 200–260 | 650 |

| Inconel 718 | Ni 52–55%, Nb 4.75–5.5%, Ti 0.65–1.15% | 1100–1400 | 280–340 | 650 |

| Hastelloy C-276 | Ni 57%, Mo 15–17%, Cr 14.5–16.5% | 550–690 | 200–240 | 650 |

| Invar 36 | Ni 36%, Fe 64% | 450–620 | 140–180 | 100 |

Key Material Properties Comparison

Understanding the relative performance characteristics of different nickel alloy families enables proper material selection for specific applications. We have developed comprehensive comparison matrices based on critical properties including corrosion resistance, temperature capability, mechanical strength, and thermal expansion behavior.

Corrosion resistance varies significantly among nickel alloy families depending on the specific environment. Pure nickel grades excel in caustic solutions but show limited performance in oxidizing acids. Monel alloys provide outstanding seawater resistance but struggle in strongly oxidizing environments. Inconel alloys offer balanced performance across various corrosive media, while Hastelloy compositions excel in the most aggressive chemical environments.

Temperature capability represents another critical selection criterion. Pure nickel grades typically limit service to 315-650°C depending on carbon content and stress levels. Monel alloys generally restrict applications to 480°C maximum. Inconel and Incoloy alloys extend service temperatures to 650-1095°C depending on specific composition and loading conditions. Hastelloy alloys typically operate to 650-815°C in corrosive environments.

Mechanical strength properties show substantial variation within and between alloy families. Solution-annealed conditions typically provide moderate strength with excellent ductility, while precipitation-hardened grades achieve much higher strength levels. Age-hardened Inconel 718 can exceed 1400 MPa tensile strength, while solution-annealed Hastelloy C-276 typically develops 690 MPa tensile strength.

Thermal expansion coefficients impact design considerations for applications involving temperature cycling or dimensional stability requirements. Most nickel alloys exhibit coefficients between 11-15 × 10⁻⁶/°C, significantly lower than austenitic stainless steels. Invar alloys represent notable exceptions with coefficients near zero at specific temperature ranges.

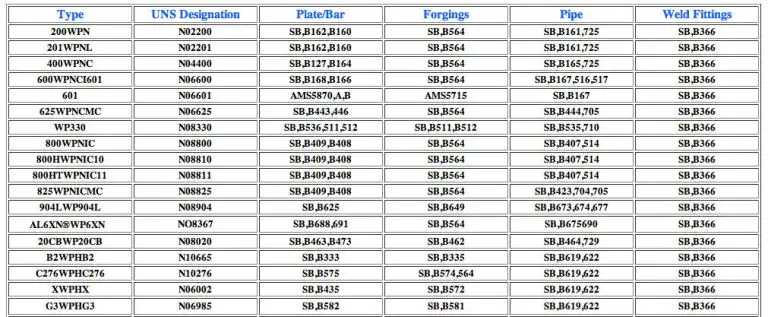

Standard Specifications & UNS Designations

The Unified Numbering System (UNS) provides standardized designations for nickel alloys, facilitating clear communication between designers, purchasers, and suppliers. UNS numbers for nickel alloys begin with "N" followed by five digits, with the first digit indicating the primary alloy family.

N02xxx designations cover pure nickel and low-alloy compositions, including N02200 (Nickel 200) and N02201 (Nickel 201). N04xxx numbers identify nickel-copper alloys such as N04400 (Monel 400). N06xxx designations encompass nickel-chromium alloys including N06600 (Inconel 600) and N06625 (Inconel 625). N07xxx numbers cover precipitation-hardened alloys like N07718 (Inconel 718). N08xxx designations include iron-nickel-chromium alloys such as N08825 (Incoloy 825). N10xxx numbers identify nickel-molybdenum alloys including N10276 (Hastelloy C-276).

ASTM specifications provide detailed requirements for composition, mechanical properties, and manufacturing processes. Key ASTM standards include B160/B161 for pure nickel products, B164/B165 for Monel alloys, B166/B167 for Inconel 600, B443/B444 for Inconel 625, and B574/B575 for Hastelloy alloys.

AMS (Aerospace Material Specifications) provide additional requirements for aerospace applications, often specifying tighter composition controls, enhanced mechanical properties, and specialized testing requirements. EN (European Norm) standards provide equivalent specifications for European markets, while JIS (Japanese Industrial Standards) and GB (Chinese National Standards) serve Asian markets.

Understanding these specification relationships enables proper material procurement and quality verification. Cross-reference tables help identify equivalent grades between different specification systems, though subtle differences may exist in composition limits or testing requirements.

Market Pricing & Cost Trends

-

Nickel Commodity: $15,000–35,000/MT in past five years driven by EV demand, supply policies.

-

Alloy Premiums: Monel ≈1.3× stainless steel; Inconel 625 ≈2.5×; Hastelloy C-276 ≈3–4×.

-

Regional Variations: Asia often 10–20% cheaper than North America/EU; long lead times for specialty grades.

-

Value Engineering: Substitute lower-cost grades when corrosion/temperature demands permit; leverage recycled alloy streams.

Typical Applications by Industry

Petrochemical Industry

The petrochemical industry represents one of the largest consumers of nickel alloys, utilizing these materials throughout processing facilities where corrosive environments, high temperatures, and mechanical stresses combine to challenge conventional materials. We observe that process conditions often involve multiple degradation mechanisms acting simultaneously, requiring careful alloy selection.

Refinery applications frequently specify Monel 400 for crude distillation units handling sulfur-containing feedstocks. The alloy's resistance to sulfidation and hydrogen sulfide makes it suitable for heat exchanger tubing and process piping. Inconel 625 provides superior performance in catalytic reforming units where high temperatures and hydrogen-rich environments predominate.

Ethylene production facilities utilize Inconel 600 and 601 for furnace tubing and radiant section components operating at temperatures approaching 1050°C (1925°F). The chromium-rich oxide scales provide protection against carburization and metal dusting phenomena common in hydrocarbon processing.

Marine and Offshore Applications

Seawater environments present unique challenges combining chloride-induced corrosion, biofouling, and mechanical loading from waves and currents. Monel 400 has established itself as the standard material for seawater applications, offering excellent resistance to general corrosion, pitting, and stress corrosion cracking.

Offshore oil platforms utilize extensive quantities of Monel 400 for seawater cooling systems, ballast water handling, and process equipment exposed to marine environments. The alloy's resistance to biofouling reduces maintenance requirements compared to copper-based alternatives.

Inconel 625 finds application in deeper water environments where higher strength requirements combine with corrosive conditions. Subsea manifolds, wellhead components, and production tubing often specify this alloy for critical applications.

Aerospace and Defense

Aerospace applications demand materials capable of maintaining properties under extreme conditions while minimizing weight penalties. Inconel 718 dominates this sector due to its exceptional combination of high-temperature strength, fabricability, and service reliability.

Gas turbine hot sections utilize various Inconel alloys depending on specific temperature and stress conditions. Combustor liners typically employ Inconel X-750 or Hastelloy X, while turbine blades may use directionally solidified or single-crystal versions of advanced compositions.

Rocket propulsion systems require materials resistant to extreme temperatures and aggressive propellants. Inconel 718 provides excellent compatibility with liquid oxygen systems, while specialized compositions handle hypergolic propellants and hot gas environments.

Power Generation

Both conventional and renewable energy systems utilize nickel alloys for critical components operating under demanding conditions. Coal-fired power plants specify Inconel 625 for superheater and reheater tubing operating at steam temperatures above 565°C (1050°F).

Nuclear power applications utilize Inconel 600 and 690 for steam generator tubing, where resistance to primary water stress corrosion cracking represents a critical requirement. The higher chromium content of Inconel 690 provides enhanced resistance to this degradation mechanism.

Geothermal power systems expose materials to high-temperature brines containing chlorides, sulfides, and other aggressive species. Hastelloy C-276 and similar molybdenum-bearing alloys provide the corrosion resistance necessary for reliable operation in these environments.

Chemical Processing

Chemical manufacturing facilities present perhaps the most diverse range of corrosive environments encountered in industrial applications. Material selection requires detailed understanding of process chemistry, operating conditions, and potential upset scenarios.

Hydrofluoric acid production and handling systems almost exclusively utilize Monel alloys due to their unique resistance to this highly aggressive chemical. Monel 400 serves for ambient temperature applications, while Monel K-500 provides higher strength for pressurized systems.

Sulfuric acid plants utilize various nickel alloys depending on acid concentration and temperature conditions. Hastelloy C-276 provides excellent performance in concentrated sulfuric acid at elevated temperatures, while Alloy 20 offers cost-effective solutions for moderate conditions.

Selection Criteria & Decision Guide

Proper nickel alloy selection requires systematic evaluation of multiple criteria including environmental conditions, mechanical requirements, fabrication considerations, and economic factors. We have developed decision matrices that guide engineers through this complex process.

Environmental analysis begins with identification of all chemical species present in the service environment, including primary constituents, trace contaminants, and potential upset conditions. Temperature and pressure ranges must be clearly defined, along with any cycling or transient conditions that may occur during operation.

Mechanical requirements encompass static and dynamic loading conditions, creep resistance needs, and fatigue life expectations. High-temperature applications require particular attention to creep-rupture properties and microstructural stability over extended service periods.

Fabrication considerations significantly impact total project costs and schedule requirements. Some alloys require specialized welding procedures, heat treatment capabilities, or machining techniques that may not be readily available. We recommend early consultation with fabricators to identify potential constraints.

Economic analysis must consider both initial material costs and lifecycle expenses including maintenance, downtime, and replacement costs. While nickel alloys typically command premium prices compared to conventional materials, their superior performance often justifies the investment through extended service life and reduced maintenance requirements.

Fabrication & Processing Considerations

Successful fabrication of nickel alloy components requires understanding of the unique characteristics these materials exhibit during forming, joining, and heat treatment operations. We have observed that many fabrication problems result from application of techniques appropriate for carbon steels or stainless steels without considering nickel alloy-specific requirements.

Welding represents the most critical fabrication operation for most nickel alloy applications. These materials generally exhibit excellent weldability but require attention to cleanliness, heat input control, and post-weld treatment. Contamination from sulfur, phosphorus, or lead can cause hot cracking, while excessive heat input may lead to grain boundary precipitation or loss of corrosion resistance.

Inconel 718 and other precipitation-hardened alloys require careful control of welding parameters and post-weld heat treatment to maintain optimum properties. Welding in the solution-annealed condition followed by complete re-aging typically provides the best results, though this approach may not be practical for large assemblies.

Heat treatment of nickel alloys varies significantly between alloy families and specific grades. Solution annealing temperatures typically range from 980-1180°C (1800-2150°F) depending on composition, with rapid cooling required to prevent carbide precipitation. Age hardening treatments for precipitation-strengthened alloys involve precise time-temperature cycles to achieve desired strength levels.

Machining nickel alloys requires recognition of their work-hardening characteristics and tendency to generate heat during cutting operations. Sharp tools, positive rake angles, and adequate coolant flow help prevent work hardening and tool wear. Speeds and feeds must be adjusted compared to steel machining parameters.

Cold forming operations can be performed on most nickel alloys, though work hardening occurs more rapidly than in austenitic stainless steels. Intermediate annealing may be required for severe forming operations. Hot forming at temperatures between 870-1150°C (1600-2100°F) provides maximum ductility for complex shapes.

Market Pricing & Cost Trends

Nickel alloy pricing exhibits significant volatility due to the underlying nickel commodity market and the specialized nature of alloy production. Base nickel prices fluctuate based on global supply and demand factors, with major influences including Indonesian export policies, Russian sanctions, and electric vehicle battery demand.

Recent market analysis shows nickel prices ranging from $15,000 to $35,000 per metric ton over the past five years, with corresponding impacts on finished alloy prices. Premium alloys like Hastelloy C-276 and Inconel 718 typically command prices 3-5 times higher than standard stainless steels due to their complex compositions and specialized production requirements.

Supply chain considerations significantly impact pricing and availability. The limited number of primary producers creates potential bottlenecks during periods of high demand. Long lead times for specialty products require careful project planning and inventory management.

Regional pricing variations reflect transportation costs, local demand patterns, and currency fluctuations. Asian markets often show different pricing dynamics compared to North American and European markets due to varying industrial activity levels and supply chain structures.

Value engineering approaches can help optimize material costs while maintaining performance requirements. Substitution of lower-cost alternatives where appropriate, design optimization to minimize material usage, and consideration of recycled content options all contribute to cost management strategies.

Sustainability & Recycling Perspectives

Nickel alloys demonstrate excellent recyclability characteristics, with recycling rates exceeding 95% for many applications. The high intrinsic value of nickel and alloying elements provides strong economic incentives for material recovery and reprocessing.

Closed-loop recycling systems have been established for many aerospace applications, where strict quality control enables direct reuse of recycled material in new components. Open-loop recycling typically involves reprocessing into lower-grade applications or blending with primary materials.

Life cycle assessment studies indicate that recycled nickel alloys typically exhibit 60-80% lower environmental impact compared to primary production. Energy requirements for recycling are substantially lower than primary extraction and refining processes.

Circular economy initiatives within the aerospace and chemical processing industries focus on extending component service life through advanced repair techniques, remanufacturing of worn components, and design for disassembly to facilitate recycling.

Environmental regulations increasingly emphasize sustainable material practices, creating additional drivers for recycling programs. Carbon footprint reduction initiatives often identify material selection and recycling as significant opportunities for improvement.

Emerging Technologies & Future Directions

Additive manufacturing technologies have opened new possibilities for nickel alloy applications, enabling complex geometries impossible with conventional manufacturing methods. Powder bed fusion and directed energy deposition processes show particular promise for aerospace and medical applications.

Inconel 718 and 625 have been successfully qualified for additive manufacturing, with mechanical properties approaching or exceeding conventionally manufactured materials. Process optimization continues to address challenges including residual stress, microstructural control, and surface finish requirements.

Nanostructured nickel alloys represent an emerging technology area with potential for enhanced mechanical properties and corrosion resistance. Severe plastic deformation techniques and powder metallurgy approaches can create ultrafine grain structures with superior performance characteristics.

Surface modification technologies including ion implantation, laser surface alloying, and plasma-enhanced chemical vapor deposition enable property enhancement of existing alloys. These techniques can improve wear resistance, corrosion performance, or biocompatibility for specific applications.

Advanced computational modeling tools increasingly support alloy development and application engineering. CALPHAD-based thermodynamic modeling, molecular dynamics simulations, and machine learning approaches accelerate material development and performance prediction.

Digital technologies including blockchain-based material traceability and IoT-enabled condition monitoring create new opportunities for optimizing material performance and lifecycle management. These tools support predictive maintenance strategies and enhanced quality control throughout the supply chain.

FAQs – Frequently Asked Questions

How can we distinguish between Monel and Inconel alloys in practical applications?

Monel alloys typically contain 63-70% nickel with copper as the primary alloying element, providing excellent seawater resistance and moderate temperature capability up to 480°C. Inconel alloys contain higher nickel content (72-76%) with chromium additions, offering superior high-temperature performance to 1095°C and oxidation resistance. Visual identification requires chemical analysis or spark testing, as both families exhibit similar appearance in the annealed condition.

Which nickel alloy provides optimal performance in seawater environments?

Monel 400 remains the standard choice for seawater applications due to its exceptional resistance to general corrosion, pitting, and stress corrosion cracking in chloride environments. For higher strength requirements, Monel K-500 offers age-hardened properties while maintaining corrosion resistance. Inconel 625 provides an alternative for applications requiring higher temperature capability or superior crevice corrosion resistance.

What are the key welding differences between Nickel 200 and Nickel 201?

Nickel 200's higher carbon content (0.15% max) can lead to carbide precipitation during welding thermal cycles, potentially causing hot cracking or reduced ductility. Nickel 201's low carbon content (0.02% max) minimizes this risk and allows welding without post-weld heat treatment in most applications. Both grades require clean welding conditions and controlled heat input to prevent contamination-related defects.

How do we select between Hastelloy C-276 and Inconel 625 for chemical processing applications?

Hastelloy C-276 excels in highly corrosive environments including wet chlorine, hypochlorites, and mixed acid solutions due to its high molybdenum content. Inconel 625 provides better high-temperature strength and lower cost for applications not requiring extreme corrosion resistance. Consider C-276 for maximum corrosion resistance and 625 for balanced performance with cost considerations.

What factors determine the service temperature limits for different nickel alloy families?

Service temperature limits depend on microstructural stability, oxidation resistance, and mechanical property retention. Pure nickel grades limit to 315-650°C based on carbon content and carbide stability. Monel alloys typically restrict to 480°C due to copper-rich phase formation. Inconel alloys extend to 650-1095°C depending on chromium content and precipitation reactions. Loading conditions, environment, and required service life all influence practical temperature limits.

Conclusion & Recommendations

Nickel alloys continue to enable technological advancement across critical industries through their unique combination of corrosion resistance, high-temperature capability, and mechanical properties. Our analysis demonstrates that proper alloy selection requires systematic evaluation of environmental conditions, mechanical requirements, fabrication constraints, and economic considerations.

For seawater and marine applications, Monel 400 remains the preferred choice offering proven performance and cost-effectiveness. Chemical processing environments typically benefit from Hastelloy compositions where maximum corrosion resistance justifies premium costs. Aerospace and high-temperature applications generally specify Inconel 718 and related precipitation-hardened grades for optimal strength-to-weight ratios.

Emerging technologies including additive manufacturing and surface modification techniques promise to expand application possibilities while improving performance characteristics. Sustainability considerations increasingly influence material selection decisions, favoring alloys with high recycling rates and extended service life.

We recommend early engagement with material suppliers and fabricators to optimize alloy selection and processing approaches. Pilot testing in actual service conditions provides valuable validation of material performance predictions. Comprehensive documentation of material specifications, fabrication procedures, and service experience supports continuous improvement in nickel alloy applications.

The future of nickel alloy technology will likely emphasize customized compositions for specific applications, advanced manufacturing techniques, and integrated approaches to material selection considering entire product lifecycles. Organizations investing in nickel alloy expertise and application knowledge will be best positioned to capitalize on these advancing capabilities.