MP35N Alloy (UNS R30035) is a vacuum-melted nickel-cobalt-chromium-molybdenum multiphase alloy engineered to combine ultra-high strength (work-strengthened/treatment-strengthened tensile strengths commonly 260–300 ksi / ~1.8–2.1 GPa), excellent toughness and ductility, and outstanding resistance to general corrosion, crevice/pitting and sulfide stress cracking — a unique balance that makes it a first-choice material for high-performance medical implants, oil & gas sour-service hardware, spring/wire components and precision fasteners.

What is MP35N material?

MP35N (often sold under that trade name and identified as UNS R30035) is produced by vacuum induction melting followed by vacuum arc remelting (VIM-VAR) to achieve very low residuals and tight chemistry control. It is normally delivered in either an annealed/solution-treated condition for forming, or in cold-worked and aged conditions that produce its very high strengths. The alloy uniquely resists hydrogen embrittlement and sulfide stress corrosion cracking while retaining ductility at cryogenic temperatures and stability up to moderately elevated temperatures (~300–450°C depending on temper). These attributes underpin its widespread use in demanding offshore, downhole, biomedical and aerospace hardware.

Chemical composition (typical / nominal)

Below is a widely accepted nominal composition range for MP35N (weight %). Individual mill product sheets may list small variation windows — always confirm certificate data for design calculations.

| Element | Nominal / Typical wt.% |

|---|---|

| C (Carbon) | ≤ 0.02–0.03 |

| Mn (Manganese) | ≤ 0.10–0.15 |

| Si (Silicon) | ≤ 0.10–0.15 |

| P (Phosphorus) | ≤ 0.015 |

| S (Sulfur) | ≤ 0.010 |

| Cr (Chromium) | ~19.0 – 21.0 |

| Ni (Nickel) | ~33.0 – 37.0 |

| Mo (Molybdenum) | ~9.0 – 10.5 |

| Co (Cobalt) | balance (~30–35%) |

| Fe (Iron) | trace / balance in some specifications |

Notes: The canonical description—35% Co, 35% Ni, ~20% Cr, ~10% Mo—appears across datasheets; trace elements are kept very low for corrosion and mechanical performance control. Always refer to the manufacturer Certificate of Analysis for exact batch chemistry.

Microstructure and why MP35N gets its properties

-

Matrix: MP35N retains an fcc (face-centred cubic) matrix at room temperature composed primarily of the Ni-Co solid solution.

-

Strengthening mechanism: The alloy is work-strengthened by heavy cold deformation (drawing, rolling, swaging) followed by an ageing step that precipitates fine hardening phases (complex carbides/intermetallics and/or segregated Mo/Cr clusters depending on processing). The combination of cold work and ageing gives much greater strength than solution heat treatment alone.

-

Multiphase character: Controlled precipitation during ageing creates a multiphase microstructure that improves yield and tensile strength without catastrophic loss of ductility — crucial for tough spring and wire applications and for resisting crack initiation under corrosive stress.

Mechanical properties (typical values by condition)

Important: Property values depend strongly on cold work and ageing schedule, cross-section and test method. Use certified mill data for final design.

Representative mechanical properties (typical ranges):

| Condition | Tensile strength (UTS) | Yield strength (0.2% approx.) | Elongation (in 4D) | Hardness (HRC) |

|---|---|---|---|---|

| Annealed / Solution treated | 115–160 ksi (790–1100 MPa) | ~90–120 ksi (620–830 MPa) | 20–40% | ~20–30 HRC |

| Cold-worked (spring temper) | 200–260 ksi (1380–1793 MPa) | 170–230 ksi | 8–18% | ~35–50 HRC |

| Cold-worked + Aged (full strength) | 260–300 ksi (1793–2068 MPa) | 240–280 ksi | ≥6–12% | up to mid-50s HRC (depending on process) |

These ranges are consistent with producer datasheets and industrial supplier references. When MP35N is processed for NACE MR0175 sour service, ageing/cold work limits and hardness caps are enforced to retain sulfide stress cracking resistance.

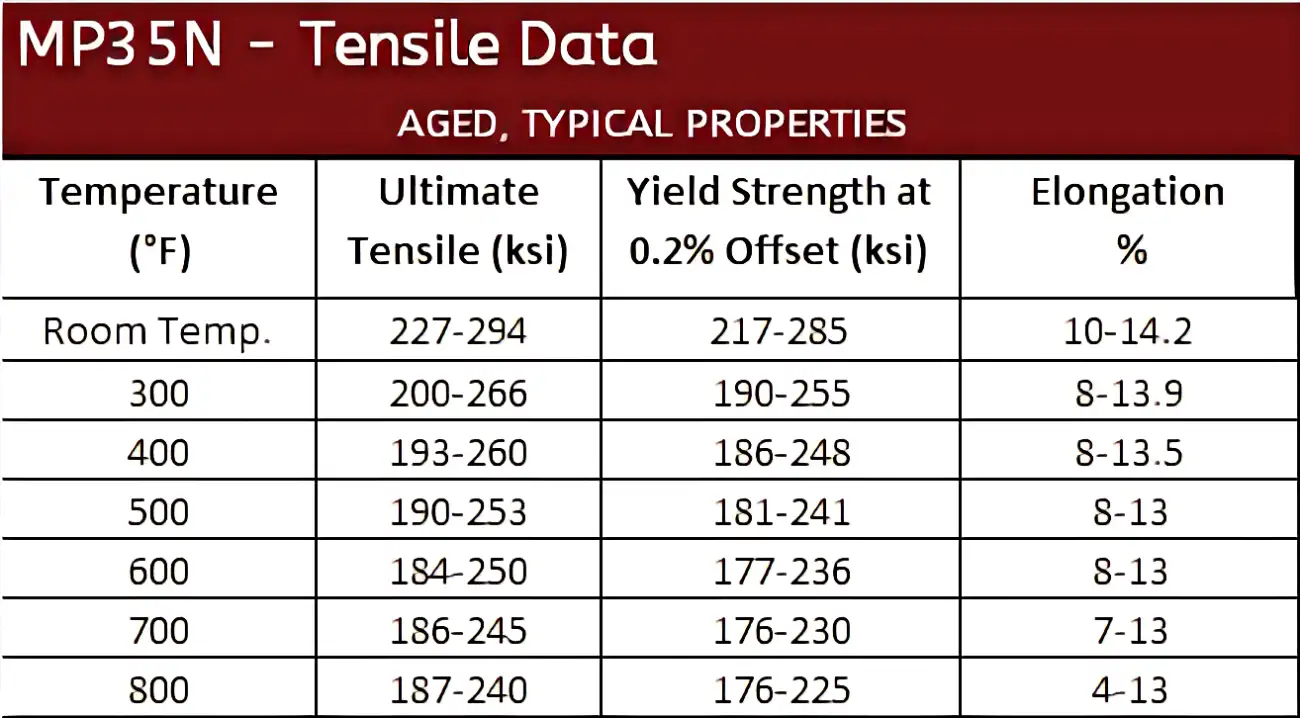

AGED, TYPICAL PROPERTIES

Heat treatment, cold work and ageing

MP35N cannot attain its highest strengths by heat treat alone — cold deformation is essential before ageing. Typical industrial practice:

| Step | Typical parameters (representative) | Purpose |

|---|---|---|

| Solution anneal | 1900–2150°F (1040–1175°C) — rapid quench | Homogenize, soften for forming |

| Cold work (drawing/rolling/swaging) | Varies widely — 30–70% reduction typical for wire/spring | Introduce dislocations for work hardening |

| Ageing | 1000–1200°F (540–650°C) for 1–4 hours (depending on temper and part size) | Precipitation hardening — develop full strength |

| Stress relief | 900–1100°F depending on condition | Reduce residual stress without losing desired temper |

Practical notes:

-

Over-ageing or excessive ageing temperature reduces peak strength.

-

For oil & gas sour service, manufacturers follow NACE/NACE MR0175 / ISO 15156 heat treatment guidance to satisfy hydrogen sulfide resistance; hardness limits (e.g., ≤ 35 HRC for certain uses, higher maxima in some controlled tempers) must be respected.

Corrosion resistance, sour service and standards

MP35N is broadly more resistant to chloride, seawater, and hydrogen-sulfide environments than common stainless steels because of high Cr and Mo levels and low residuals.

Key corrosion performance highlights:

-

Seawater and chloride: Excellent resistance to pitting and crevice corrosion at most strength levels; performance often comparable to high-nickel alloys for localized corrosion resistance.

-

Sulfide stress cracking (SSC) & hydrogen embrittlement: MP35N is one of the highest strength alloys approved for NACE MR0175/ISO 15156 sour service, when processed within the specified hardness and temper guidelines. This makes it valuable for downhole and subsea components exposed to H₂S.

-

Mineral acids: Shows good resistance to many mineral acids but selection should be application-specific and temperature-dependent. Laboratory exposure and corrosion testing are recommended for aggressive chemistries.

Standards and specs commonly referenced for corrosion and medical use:

-

NACE MR0175 / ISO 15156 (oil & gas sour service approval) — referenced for allowable hardness/heat treatment to resist SSC.

-

ASTM F562 and ISO 5832-6 (medical implant material specification end-use references in some supplier sheets).

Biocompatibility and medical device use

MP35N has established pedigree in cardiovascular implants (stents, structural heart components), orthodontic wire/brackets and other implantable applications because of:

-

Inherent corrosion resistance in physiological environments, limiting ion release.

-

High fatigue resistance which is critical in cyclic-loaded implants (e.g., cardiac devices).

-

Demonstrated biocompatibility in OEM testing and peer-reviewed studies (e.g., evaluations of MIM vs wrought MP35N show acceptable biocompatibility under standard test protocols).

Clinical and experimental literature shows MP35N components can meet implant performance needs when surface finish, processing route and sterilization are controlled. For implant designers, confirm compliance with the specific implant standard required (ASTM/ISO for surgical implants) and perform device-level biological testing per regulatory expectations.

Fabrication: forming, machining, joining

Forming & drawing

-

The alloy is workable in the annealed condition; heavy cold work is routine for wire/spring manufacture.

-

For rod/bar forming, warm working sometimes used; cold-work followed by ageing is how designers achieve high strengths.

Machining

-

MP35N is moderately difficult to machine compared with stainless steels; typical recommendations include:

-

Rigid tooling, heavy-duty CNC setups

-

Carbide tooling with positive rake, sharp edges

-

Slower speeds and generous coolant to control work hardening and tool wear

-

-

Micro-machining or EDM may be preferable for intricate medical components.

Welding & joining

-

Welding is possible but requires process control. Welds are best performed on solution-treated material with subsequent controlled ageing; filler metal selection must account for galvanic and corrosion considerations.

-

For critical components (e.g., threaded fasteners, springs), mechanical joining is often preferred to preserve temper.

Surface finish and treatments

-

Surface grinding, polishing, electropolishing and passivation improve corrosion resistance and reduce fatigue initiation sites — particularly critical for medical implants and dynamic components.

Typical product forms, specifications and traceability

Common product forms:

-

Wire (round, flat, shaped), springs, strip, bar, rod, tubing, plate (limited), forgings, and custom precision parts.

Common specifications / standards:

-

UNS R30035 — unified numbering designation for MP35N family.

-

AMS 5844 / AMS 5845 / AMS 5758 — aerospace material specs often used for bar and wire product in defined tempers.

-

ASTM F562 / ISO 5832-6 — cited for surgical implant material acceptance (manufacturer or design may use these references).

-

NACE MR0175 / ISO 15156 — for sour-service oil & gas acceptance; sets allowable heat treatment and hardness windows.

Traceability:

For critical industries (medical, aerospace, oil & gas), full material traceability (mill certificates, heat numbers, heat treatment records, test reports) is mandatory. Specify required test coupons, mechanical tests, and corrosion/SSC acceptance testing at procurement.

Applications and comparative selection

Where MP35N excels

-

Medical implants & structural heart devices: high fatigue life + biocompatibility + high strength for miniaturized structures.

-

Oil & gas downhole hardware (sour service): fasteners, wirelines, springs, and components requiring SCC resistance at high strength.

-

Springs & precision wire: micro-springs, connector springs, and high-cycle dynamic parts where high strength and corrosion resistance reduce part size.

-

Aerospace / high-performance actuation: small high-strength components exposed to aggressive environments.

Comparison snapshot (qualitative):

| Property / comparison | 316L | 17-4 PH | Inconel 718 | MP35N |

|---|---|---|---|---|

| Max UTS (typical) | ~75–100 ksi | ~150–200 ksi (PH) | ~150–220 ksi | 260–300 ksi (CW+aged) |

| Corrosion (seawater/SSC) | Good to fair | Good | Excellent localized resistance | Excellent (pitting/SSC resistant) |

| Biocompatibility | Good | High (depending on grade) | Limited for implants | High (used in implants) |

| Fatigue (high cycle) | Moderate | Good | Very good | Exceptional when processed |

| Machinability | Good | Good | Difficult | Moderate–difficult |

| Typical use case | General corrosion environments | Structural parts | High temperature & stress | High strength + corrosive/biological environments |

Design note: MP35N often permits significant part size reduction to achieve the same functional strength compared with stainless steels or some nickel alloys, but material cost and processing complexity are higher.

Design considerations, failure modes and inspection

Design rules of thumb

-

Avoid unnecessary notches and sharp transitions in high-cycle components—MP35N’s fatigue strength benefits from generous fillets and fine surface finishes.

-

For threaded components, control of heat treatment and hardness is critical to avoid SSC in sour environments.

-

Wherever feasible, specify post-processing surface finishing (polish/electropolish) for implants and deep-sea connectors.

Failure modes to watch

-

Surface-initiated fatigue: poor surface finish, machining marks or corrosion pits can initiate cracks.

-

Overageing or improper ageing: reduces strength or introduces embrittlement; always follow supplier recommended tempers.

-

Improper weld procedures: residual stresses, local overheating or wrong filler metal can degrade corrosion resistance.

Inspection and qualification

-

Mechanical testing (UTS, YS, elongation) on lot samples.

-

Hardness checks for NACE/ISO service acceptance.

-

Corrosion/SSC testing for sour service projects.

-

For implants: device-level biocompatibility per ISO 10993 / regulatory test plans.

Cost and supply-chain considerations

MP35N is more expensive than common stainless steels and many nickel alloys owing to cobalt and molybdenum content, and specialized melting (VIM-VAR) plus extra processing (cold-work + ageing). Typical buyer considerations:

-

Economy of design: smaller, lighter parts may offset higher material cost.

-

Lead times & minimums: wire, strip and specialty sizes can have longer lead times; specify required condition and traceability up front.

-

Multiple qualified sources: for critical applications, source from qualified mills that supply AMS / NACE / ISO certified material and provide full batch certification.

Practical tables

Table A — Quick property lookup (engineering start point)

| Characteristic | Typical / Design note |

|---|---|

| Operating temperature | −200°C to ≈ +315°C (depends on temper; limited above ~450°C) |

| Density | ~8.2–8.6 g/cm³ (varies with exact alloy balance) |

| Young’s Modulus | ~200–230 GPa (approx. — confirm for design) |

| Thermal conductivity | Low to moderate (check supplier data) |

| Magnetic behavior | Non-magnetic in many tempers (useful for MRI implants/sensors) |

Table B — When to choose MP35N vs alternatives

| Scenario | Preferred? |

|---|---|

| High strength + saline exposure | MP35N |

| Surgical implant with long fatigue life | MP35N or Ti-alloys (compare biocompatibility & imaging needs) |

| High temp >500°C | Consider nickel-based superalloys (e.g., IN718, Nimonic) instead of MP35N |

| Cost-sensitive non-critical fasteners | Stainless steels or lower-alloy steels |

FAQs

Q: What is the maximum tensile strength MP35N can achieve?

A: In commercial cold-worked and aged tempers MP35N can reach roughly 260–300 ksi (~1.8–2.07 GPa). Use mill test reports for precise values per lot.

Q: Is MP35N suitable for sour oil & gas service?

A: Yes, MP35N is one of the highest strength alloys approved for NACE MR0175/ISO 15156 sour service when processed within the specified hardness/tempers. Confirm supplier certification.

Q: Can MP35N be used for implants?

A: Yes — it has been used in cardiovascular implants and orthodontic devices and appears in implant material specifications (e.g., ASTM F562 / ISO 5832-6 references). Device-level biocompatibility testing is still required.

Q: How is MP35N strengthened?

A: By mechanical cold deformation (work hardening) followed by controlled ageing (precipitation hardening). Heat treatment alone does not produce the highest strengths.

Q: Is MP35N magnetic?

A: It is generally described as non-magnetic in many product tempers, which is useful for medical imaging compatibility — but check specific heat treatments and parts for residual magnetism.

Q: What are common failure modes?

A: Surface-initiated fatigue, improper heat treat leading to loss of fracture toughness, and weld/processing errors that compromise corrosion resistance.

Q: Can MP35N be welded?

A: Yes, but welding requires careful control, post-weld heat treatment considerations, and compatibility checks; for many high-performance parts mechanical joining or avoiding welded joints is preferred.

Q: How does MP35N compare to titanium for implants?

A: MP35N offers much higher strength and excellent fatigue resistance; titanium has lower density and is widely used for osseointegration. Choice depends on design loads, size, imaging needs and biocompatibility profile.

Q: Is MP35N available in wire form?

A: Yes. round, flat, and shaped wire are common commercial forms, especially for springs, orthodontics and electrical contacts.

Q: Which standards should I specify for procurement?

A: Include UNS R30035, AMS/ASTM specs required by your industry (e.g., AMS 5844/5845, ASTM F562, ISO 5832-6, NACE MR0175 / ISO 15156 as applicable) and require mill certificates and heat treatment records.

Final practical checklist for engineers and buyers

-

Specify exact temper and required mechanical properties on PO (don’t buy “MP35N” generically).

-

Require full mill certification and heat-treatment records for critical parts.

-

For sour service, specify NACE MR0175 / ISO 15156 conformance and allowable hardness.

-

For implants, require device-level biological testing and regulatory compliance evidence.

-

Where fatigue life matters, inspect surface finish and require finishing steps (electropolish, passivation).

-

Plan for higher material cost and potential longer lead times; consider vendor auditing for critical supply chains.

What I could not cover in depth

This technical overview synthesizes industry datasheets, peer-reviewed studies and supplier guidance. It does not replace:

-

Exact, certified material test reports for a specific heat/lot (mandatory for design).

-

Device-level regulatory test plans for implants (ISO 10993 / FDA or CE technical file requirements).

-

Specific weld procedures (WPS/PQR) for each joining process — these must be developed and qualified by fabricators.

Authoritative references

- Carpenter Technology — MP35N® alloy technical overview and datasheets

- Johnson Matthey (datasheet) — MP35N® technical data (composition, properties, standards)

- PubMed / NIH — Biocompatibility study references for MP35N (peer-reviewed study)

- ASM International — Alloy Digest entries and technical commentary for MP35N