Monel 400 Wire (UNS N04400) remains the definitive metallurgical solution for applications requiring high strength retention and immunity to corrosion in reducing environments, specifically marine engineering and chemical processing involving hydrofluoric acid. The conclusion for procurement officers and materials engineers is straightforward: while newer superalloys exist, Monel 400 offers the most efficient cost-to-performance ratio for wire components exposed to flowing seawater and harsh alkalis. It is a solid-solution binary alloy that cannot be hardened by heat treatment, meaning its mechanical strength is determined entirely by the level of cold work (drawing) applied during manufacturing.

1. Why choose MWalloys?

At MWalloys, we operate as a dedicated manufacturer rather than a mere stockist. This allows us to control the precise temper of the wire, from fully annealed (soft) for weaving applications to spring temper (hard) for fasteners and snap rings. By sourcing directly from our facility in China, buyers bypass the 30% to 40% markup typical of Western distribution networks while receiving material that is fully compliant with ASTM B164 and AMS 4730 standards. We guarantee 100% mill test transparency and offer rapid logistics for global projects.

2. Material Definition: What is Monel 400?

Monel 400 is a single-phase, solid-solution alloy primarily composed of Nickel (roughly 63-70%) and Copper. Unlike stainless steels which rely on a chromium-oxide passive layer, Monel 400 inherently resists corrosion through the nobility of its base elements. It was one of the earliest nickel alloys developed and remains relevant due to its unique ability to resist both reducing acids (like hydrochloric) and oxidizing agents, though it performs best under reducing conditions.

Key Metallurgical Characteristics:

-

Structure: Face-Centered Cubic (FCC) lattice.

-

Magnetic Permeability: This is a crucial distinction. Monel 400 is slightly magnetic at room temperature. Its Curie point is near ambient temperature, meaning its magnetic properties can shift based on minor temperature variations. This distinguishes it from Monel K-500, which is non-magnetic.

-

Work Hardening: Since thermal hardening is impossible, the wire achieves high tensile strength only through cold drawing. This process elongates the grain structure, increasing strength but reducing ductility.

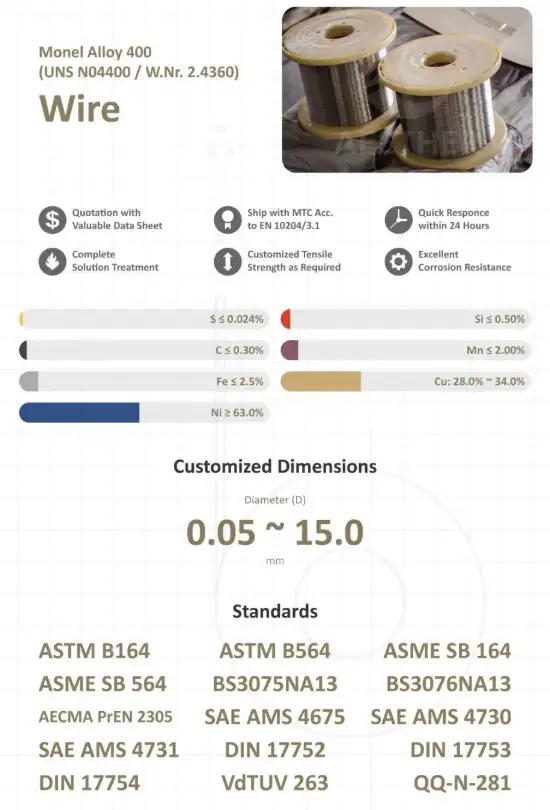

3. Chemical Composition Analysis

The purity of the melt determines the longevity of the wire. MWalloys adheres to strict strict composition limits to ensure the material performs predictably in critical environments like salt production or alkylation units.

Table 1: Chemical Composition (Weight %)

| Element | Symbol | Minimum % | Maximum % | Function in Alloy |

| Nickel | Ni | 63.0 | 70.0 | Provides the matrix structure and primary corrosion resistance. |

| Copper | Cu | Balance | Balance | Improves resistance to sea water and reducing acids. |

| Iron | Fe | - | 2.5 | Kept low to minimize magnetic variance and prevent contamination. |

| Manganese | Mn | - | 2.0 | Acts as a deoxidizer during the melt; improves ductility. |

| Carbon | C | - | 0.3 | Controlled to prevent embrittlement. |

| Silicon | Si | - | 0.5 | Minor addition for oxidation resistance. |

| Sulfur | S | - | 0.024 | Strictly limited to prevent hot cracking during drawing. |

Note: The "Balance" of Copper generally lands between 28% and 34%.

4. Mechanical Properties and Temper Conditions

For wire products, the "condition" or "temper" is the most critical specification. A buyer needing wire for weaving mesh requires vastly different properties than a buyer manufacturing springs.

Table 2: Mechanical Properties by Temper

| Temper Condition | Tensile Strength (MPa) | Tensile Strength (ksi) | Elongation (%) | Typical Application |

| Annealed (Soft) | 480 - 600 | 70 - 85 | 35% - 50% | Weaving, Lock Wire, Tie Wire |

| 1/4 Hard | 600 - 750 | 85 - 110 | 20% - 30% | Cold Heading, Forming |

| 1/2 Hard | 750 - 900 | 110 - 130 | 10% - 20% | Pins, Clips |

| Full Hard (Spring) | 1000 - 1200 | 145 - 175 | 2% - 5% | Springs, Snap Rings |

Physical Constants:

-

Density: 8.80 g/cm³ (0.318 lb/in³)

-

Melting Range: 1300°C - 1350°C (2370°F - 2460°F)

-

Electrical Resistivity: 0.511 µΩ·m (At 20°C)

-

Modulus of Elasticity: 179 GPa (26,000 ksi)

5. The Manufacturing Process: From Rod to Wire

At MWalloys, the production of Monel 400 wire involves a sophisticated cold-reduction process. Because the alloy work-hardens rapidly, the process requires intermediate annealing stages.

-

Raw Material Selection: We start with hot-rolled wire rod (typically 5.5mm or 6.5mm) produced via Vacuum Induction Melting (VIM) to ensure low gas content.

-

Acid Pickling: The rod is cleaned in an acid bath to remove surface oxides. Monel scale is tenacious, so this step is critical for surface quality.

-

Cold Drawing: The rod is pulled through a series of Tungsten Carbide or Diamond dies. Each pass reduces the diameter and increases the tensile strength.

-

Lubrication: A specialized carrier coating (often lime or soap-based) is applied to prevent the wire from seizing in the die, as nickel alloys are prone to galling.

-

-

Intermediate Annealing: If the target diameter is very small (fine wire), the material will become too brittle to draw further. We pass it through a hydrogen atmosphere strand annealing furnace at roughly 900°C to reset the grain structure.

-

Final Tempering: The final draw determines the end usage. For "Spring Temper," the final reduction is heavy (often >60% reduction in area) to maximize stiffness.

-

Finishing: The wire is cleaned, spooled, or cut to straight lengths.

6. Corrosion Resistance Profile

This is the primary reason engineers specify Monel 400. Its resistance profile is distinct from stainless steel.

Hydrofluoric Acid (HF):

Monel 400 is one of the few alloys that can withstand hydrofluoric acid in all concentrations up to the boiling point. This makes it the standard material for alkylation units in oil refineries.

Marine Environments:

In flowing seawater, Monel 400 exhibits negligible corrosion rates. However, in stagnant or slow-moving seawater, pitting can occur if marine organisms (barnacles) attach to the wire, creating a crevice.

Acids and Alkalis:

-

Sulfuric Acid: Resistant in reducing conditions (no air dissolved).

-

Hydrochloric Acid: Good resistance at concentrations up to 20% at room temperature.

-

Alkalis: Totally immune to chloride-ion stress corrosion cracking, unlike 304 or 316 stainless steel.

7. Specifications and Standards Cross-Reference

To ensure global compatibility, MWalloys produces wire to the following international standards.

| Organization | Standard | Description |

| ASTM | ASTM B164 | Standard Specification for Nickel-Copper Alloy Rod, Bar, and Wire. |

| AMS | AMS 4730 | Wire specification for aerospace applications (Chemical purity focus). |

| QQ-N-281 | Federal Specification (legacy, but still referenced in US defense). | |

| DIN | 17753 | German specification for wire. |

| ISO | 9723/9724 | International standards for nickel alloy wire. |

| ASME | SB-164 | Boiler and Pressure Vessel Code compliance. |

8. Critical Applications

The usage of Monel 400 wire spans industries that demand fail-safe performance.

Petrochemical & Oil Refining:

Used in demister pads (knitted wire mesh) inside separation towers. The wire must resist sour gas and HF acid vapors.

Marine Fasteners:

Cold-headed wire is used to manufacture rivets and screws for ship hulls. The wire must be galvanically compatible with steel to prevent rapid corrosion of the hull, or used in wood where it resists bio-fouling.

Electronic Components:

Due to its electrical resistance and durability, it is used in specialized resistors and bimetal contacts.

Aerospace Safety Wire:

Annealed Monel 400 wire is used as lock wire (safety wire) on aircraft engine bolts to prevent loosening due to vibration. It withstands the high heat of the engine block without losing integrity.

9. Monel 400 Wire Sizes and Weight Calculation

MWalloys offers a vast range of diameters, from ultra-fine filament to thick coil.

Size Range:

-

Fine Wire: 0.05mm to 0.8mm (Spools)

-

Coarse Wire: 0.8mm to 12mm (Coils or Cut Lengths)

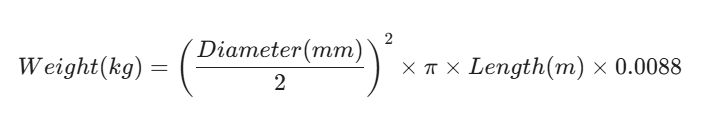

Weight Calculation Formula:

Engineers and logistics planners can estimate the weight of their order using the density factor.

Example: 1000 meters of 2mm diameter wire.

Radius = 1mm.

Volume = 1² × 3.14159 ×1000 = 3141.59 c³.

Weight = 3141.59×8.80 g/c³ = 27,646 g or 27.65 kg.

10. 2025 Global Pricing Analysis: Why Sourcing Strategy Matters

The price of Monel 400 is heavily tied to the London Metal Exchange (LME) Nickel and Copper indices. However, the manufacturing premium varies by region.

Price Structure Drivers:

-

Nickel Surcharge: Since the alloy is ~65% Nickel, price volatility is high.

-

Processing Cost: Drawing wire is energy-intensive.

Regional Price Comparison (Estimated Q1 2025):

| Region | Estimated Price Range (USD/kg) | Market Attributes |

| USA / North America | $45.00 - $60.00 | High labor costs; DFARS compliance premiums. |

| Western Europe | $42.00 - $55.00 | High energy costs affecting annealing/smelting. |

| China (MWalloys) | $28.00 - $35.00 | Integrated supply chain; lower conversion costs. Same ASTM compliance. |

The MWalloys Advantage:

We utilize efficient rotary drawing machines and in-house annealing. By removing the middleman, we offer a price point that makes Monel 400 viable for projects where it might otherwise be value-engineered out for cheaper, less reliable materials.

11. Frequently Asked Questions (FAQs)

Q1: Is Monel 400 wire magnetic?

Yes, it is slightly magnetic at room temperature. Its Curie temperature is approximately 20-50°C. If you require a non-magnetic nickel-copper alloy, you should opt for Monel K-500, although K-500 is age-hardenable and more expensive.

Q2: Can Monel 400 wire be welded?

Yes. If the wire is being used as filler metal (TIG/MIG welding), it is designated as ERNiCu-7 (AWS A5.14). It has excellent weldability and does not require post-weld heat treatment to restore corrosion resistance.

Q3: How does Monel 400 perform in sulfuric acid?

It performs well in air-free sulfuric acid at temperatures up to 60°C. However, if the acid is aerated (contains oxygen), the corrosion rate accelerates significantly.

Q4: What is the difference between "Monel 400" and "Alloy 400"?

There is no technical difference. "Monel" was originally a trademark of Special Metals Corporation. "Alloy 400" or "UNS N04400" is the generic industry designation used by other manufacturers like MWalloys to denote the same chemical composition.

Q5: Why is my Monel wire turning green?

In humid atmospheres, Monel can develop a green patina (copper oxide), similar to pure copper. This does not affect the structural integrity of the wire and typically stabilizes over time.

Q6: Can MWalloys supply Monel 400 wire for springs?

Absolutely. You must specify "Spring Temper" or "Full Hard" condition. We will cold-draw the wire to achieve the necessary tensile strength (approx. 1100-1200 MPa) required for spring memory.

Q7: What is the maximum operating temperature for Monel 400?

It can be used in oxidizing atmospheres up to 538°C (1000°F). Above this temperature, oxidation rates increase, and nickel-chromium alloys (like Inconel 600) become a better choice.

Q8: Is Monel 400 suitable for ammonia handling?

No. Monel 400 and all high-copper alloys are susceptible to rapid stress-corrosion cracking in the presence of wet ammonia.

Q9: Does MWalloys provide samples for testing?

Yes. For serious inquiries, we provide 1-meter samples of our wire for chemical analysis (PMI) and tensile testing to verify compliance with your specific ASTM standards.

Q10: What is the lead time for 500kg of 2mm wire?

If the rod is in stock, our drawing and annealing process takes approximately 7-10 days. Shipping via sea freight to the US or Europe takes 25-35 days. Air freight is available for urgent MRO requirements.

Next Steps for Your Project

Are you currently sourcing wire for a knitting application or a spring manufacturing project? The temper requirements are vastly different.

Contact MWalloys today. Send us your required diameter and condition (Annealed vs. Hard). We will generate a formal factory-price quotation within 24 hours, ensuring your supply chain remains robust and cost-effective for 2025 and beyond.