3Cr13 (often written 30Cr13) is a cost-effective martensitic stainless steel that delivers useful hardness and wear resistance after hardening, plus acceptable corrosion resistance in mild environments; therefore it is a good choice when budget, edge/hardness, or wear resistance matter more than top-tier corrosion performance or premium edge-holding (knife/precision) requirements. For load-bearing components, valves, basic cutlery, injector nozzles, shafts and many common industrial parts, 3Cr13 offers an attractive balance of strength, hardenability and price — provided its limitations (moderate corrosion resistance, modest toughness, careful heat treatment required) are respected.

What 3Cr13 means (names and standards)

“3Cr13” and “30Cr13” appear in Chinese/GB grading systems and identify a martensitic stainless steel roughly centered on ~0.26–0.35% carbon and 12–14% chromium. Equivalent international labels include AISI/ASTM 420 family, JIS SUS420J2 and EN X30Cr13 / W. Nr. ~1.4028 in common cross-reference tables. Manufacturers and suppliers sometimes use slight variant names (3Cr13, 30Cr13, S42030) so confirm the standard referenced in purchase documents.

3Cr13 Chemical composition

| Element | Typical range (wt%) | Primary effect on properties |

|---|---|---|

| C (carbon) | 0.20 – 0.35% | Hardening potential; higher C → higher hardness and wear resistance, but lower toughness and weldability. |

| Cr (chromium) | 12.0 – 14.0% | Forms passive film for corrosion resistance; enables martensitic hardening. |

| Si (silicon) | ≤ 1.0% | Deoxidation during melting; minor strength influence. |

| Mn (manganese) | ≤ 1.0% | Improves hot-working and strength. |

| P (phosphorus) | ≤ 0.04% | Impurity — excess reduces toughness. |

| S (sulfur) | ≤ 0.03% | Improves machinability in some variants but reduces corrosion resistance. |

| Ni (nickel) | ≤ 0.60% (often not present) | Slightly improves toughness/corrosion but usually minimal in this grade. |

Key takeaway: chromium level gives the grade its stainless character, while carbon level controls how hard and wear-resistant it can become after quenching and tempering. The composition makes the alloy fit for martensitic hardening routes rather than for high-nickel corrosion resistance grades.

Microstructure and metallurgy behavior

In the annealed condition the alloy is mainly ferritic/pearlitic, but after quench-and-temper cycles it becomes martensitic — a hard, body-centered tetragonal microstructure that confers wear resistance and edge retention. Grain size, prior austenite structure, and tempering regime determine the balance between hardness and toughness. Over-tempering reduces hardness; under-tempering leaves residual brittleness. Real-world heat-treat practice strongly affects performance, so specify hardness or mechanical property ranges in procurement documents rather than relying on “grade name” alone.

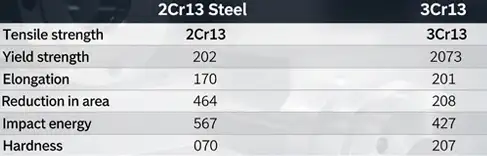

Mechanical properties (typical ranges)

Below are representative values drawn from manufacturer datasheets, GB tables and industry references; always confirm with mill test certificates (MTC) for a supplied lot.

| Property | Typical range / value |

|---|---|

| Tensile strength (Rm) | ~540 – 780 MPa (depends on heat treatment). |

| Yield strength (0.2% Rp0.2) | ~225 – 540 MPa (depends on hardening). |

| Elongation (A%) | ~10 – 20% |

| Hardness (HRC) | Annealed: ~20–30 HRC; quenched & tempered: up to ~50–52 HRC (typical working range HRC 38–50). |

| Elastic modulus | ~200 GPa (typical stainless steel range). |

Interpretation: 3Cr13 can reach high hardness suitable for wear parts and basic cutting tools, but higher hardness sacrifices toughness and machinability. Cite required hardness and toughness thresholds on drawings.

Heat treatment: recommended practice and effects

Successful use of 3Cr13 depends on disciplined quench-and-temper processing. General industrial recommendations (typical ranges; confirm with mill datasheet):

-

Austenitize (hardening heat): heat to about 980–1030 °C (some sources use ~1010–1030 °C for full austenitization), hold to equalize.

-

Quench medium: oil quench or controlled gas quench to avoid distortion and cracking. Rapid water quench increases risk of cracking unless section sizes small.

-

Tempering: typical tempering at 150–250 °C yields high hardness and reduced brittleness; higher tempering (200–600 °C) trades hardness for toughness and stability. Select tempering temperature to hit specified HRC.

Practical note: small differences in austenitizing temperature or quench severity create large effects on hardness and toughness. For components that must resist impact, favor lower maximum hardness and validate via Charpy/impact testing where required.

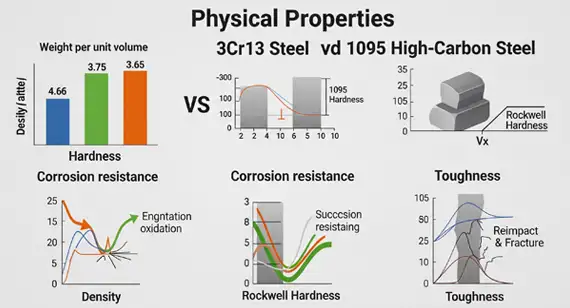

Corrosion resistance: what to expect

With 12–14% chromium, 3Cr13 is stainless in the sense of forming a passive film, but it is not highly corrosion-resistant compared with austenitic grades (304/316). It performs well in air, mildly corrosive waters and non-chloride environments; it does poorly in saline/marine or strongly acidic chloride environments where pitting and crevice corrosion risk increases. Polishing, passivation and protective coatings improve service life. For continuous wet salt exposure, select a stainless grade with higher chromium and molybdenum (e.g., 316) or duplex/austenitic alloy.

Machinability, weldability and surface finishing

-

Machinability: moderate to good. Some 3Cr13 variants include sulfur additions for free-cutting; higher final hardness reduces machinability dramatically. Machine in softer temper condition when possible and finalize heat treatment after critical machining passes.

-

Weldability: limited. Martensitic stainless steels are prone to cracking and require preheating and post-weld tempering. For welded assemblies, consider designing weld zones in softer condition and apply suitable post-weld heat treatment.

-

Surface finishing: polishes to good surface quality; hardened surfaces respond well to grinding and surface grinding when correct tooling is used.

Comparison with related grades (handy table)

| Grade | Typical carbon | Cr% | Typical use-case advantage | Quick verdict |

|---|---|---|---|---|

| 3Cr13 / 30Cr13 | 0.20–0.35 | 12–14 | Economical hardenable stainless; good wear, good polish | Good value for wear parts/low-cost knives. |

| AISI 420 / X20Cr13 | 0.15–0.30 | 12–14 | Similar corrosion resistance; 420 variants may have slightly different C and processing | Comparable; verify exact subgrade (420A/420B/420D). |

| SUS420J2 (JIS) | ~0.15–0.30 | 13 | Common knife/valve grade in Japan | Very similar; often treated as equivalent. |

| 4Cr13 / 40Cr13 | slightly higher C | 13 | Higher hardness achievable; used for wear-critical tools | Slightly more wear-resistant after quench. |

Buyers’ note: the “3Cr13 vs 420” distinction frequently reduces to specific carbon, sulfur and heat-treatment practice rather than intrinsic chemistry alone. Require mill test certs and heat-treatment history for critical components.

Common applications and performance in service

Typical uses where 3Cr13 performs well:

-

Low- to mid-range knife blades and cutlery (cheap to mid-market). Good polish and edge with moderate retention.

-

Valve seats, valve parts, nozzles, shafts, small bearings where wear resistance and reasonable corrosion resistance are needed below ~300–400 °C.

-

Fasteners and machine components that are hardened for wear, provided environment is not aggressively corrosive.

Field observation: many end-users praise 3Cr13 for affordability and for predictable performance when heat-treated correctly; however, in wet salt or marine exposure its life can be much shorter than higher-alloy stainless parts.

Quality, sourcing and specification checks for buyers / engineers

When specifying or buying 3Cr13 parts, include:

-

Exact standard reference (GB/T number, or “equivalent to X30Cr13 / SUS420J2 / AISI 420” and subvariant).

-

Chemical analysis limits on the certificate (C, Cr, S, P, Ni).

-

Required heat-treatment route and target hardness (HRC with tolerance).

-

Non-destructive testing or mechanical test requirements (tensile/impact), if part is safety-critical.

-

Surface finish and polishing class, corrosion test (salt spray) where needed.

Supplier audits: request mill test certificates (MTC) and, for safety items, sample parts for destructive testing. Purchase from reputable mills or distributors who provide traceability to batch/heat numbers.

Advantages and limitations — quick checklist

Advantages

-

Cost-efficient relative to higher-alloy stainless grades.

-

Achieves high hardness and excellent wear resistance after proper heat treatment.

-

Polishes well; good for parts where finished appearance matters.

Limitations

-

Moderate corrosion resistance compared with austenitic grades (304/316) — not ideal for saltwater or highly acidic/chloride environments.

-

Limited weldability without careful preheat/post-heat.

-

Toughness declines at very high hardness levels.

Frequently asked questions

-

Is 3Cr13 stainless steel the same as 420 stainless?

They are close equivalents; 3Cr13 is commonly considered similar to AISI 420 family and SUS420J2, though exact carbon and impurity levels and naming conventions vary by standard. Verify with supplier MTC. -

Can 3Cr13 be hardened to hold a good knife edge?

Yes — after quench and temper it can reach HRC ~48–52, offering decent edge retention for inexpensive to mid-market knives. However, premium edge-holding steels (e.g., VG-10, S35VN) outperform it. -

Is 3Cr13 corrosion resistant?

It is “stainless” in mild environments but not highly resistant in saline or chloride-rich conditions; for marine use choose higher alloyed grades. -

Is 3Cr13 weldable?

Limited. Preheating and post-weld tempering are advised to avoid cracking. For welded structures, consider alternative grades or design changes. -

What industries commonly use 3Cr13?

Cutlery, valves, fasteners, small shafts, nozzles, wear parts and inexpensive precision tools used in non-aggressive environments. -

How should I specify heat treatment on drawings?

State austenitizing temperature, quench medium, temper temperature and target hardness range (HRC) plus acceptance tests. Also require MTC covering post-HT properties. -

Does 3Cr13 rust easily?

Under normal dry conditions it resists rusting; in salt-laden wet environments it may corrode faster than higher chromium/molybdenum stainless alloys. Surface finish and passivation help. -

Is 3Cr13 magnetic?

Yes. like most martensitic stainless steels it is magnetic in annealed and hardened states. -

What hardness should I ask for in a wear part?

Typical working hardnesses are HRC 38–50 depending on required wear life and toughness; specify testing or run lab trials. -

How to choose between 3Cr13 and 304 for a component?

Choose 3Cr13 when wear/hardness and cost matter, 304 when corrosion resistance and ductility matter more. If both are needed, consider duplex or higher alloy stainless steels.