Identifying Inconel requires a combination of physical, chemical, and visual tests. For immediate field identification without expensive equipment, the Spark Test is the most reliable method; Inconel produces short, thin, dark-red to orange sparks that do not burst, distinguishing it from stainless steel. For absolute certainty, X-Ray Fluorescence (XRF) analysis is the industry standard, providing an exact breakdown of Nickel (usually 50%+) and Chromium. Simple magnet tests can help rule out carbon steels (as Inconel is non-magnetic), but cannot distinguish it from 300-series stainless steel.

At MWalloys, we prioritize material verification. Whether you handle scrap metal sorting, aerospace manufacturing, or marine engineering, knowing the specific grade: such as Inconel 625 versus 718 is critical for safety and value.

What Makes Inconel Unique?

Inconel is a family of austenitic nickel-chromium-based superalloys. These superalloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a stable, passivating oxide layer protecting the surface from further attack.

This chemical composition is exactly what makes identification tricky. It looks remarkably similar to stainless steel and titanium to the naked eye. However, its density, reaction to abrasion, and atomic structure differ significantly.

Quick Field Tests (Non-Destructive)

You often need to make a decision quickly on the shop floor or in a scrap yard. These initial tests act as a filter to remove obvious non-Inconel candidates.

The Magnet Test

The first step in metal identification involves a strong neodymium magnet.

-

Carbon Steel/400 Series Stainless: Strongly magnetic.

-

Inconel: Generally non-magnetic.

-

300 Series Stainless: Non-magnetic (though can become slightly magnetic when cold-worked).

The Result: If the magnet sticks firmly, it is likely not Inconel. If there is zero attraction or a very faint pull, it remains a candidate. Do not rely on this solely. Inconel 718 and X-750 can exhibit magnetic permeability shifts after specific heat treatments, leading to false negatives if you rely only on magnetism.

Color and Surface Oxidation

Inspect the metal surface under natural light.

-

Stainless Steel: Usually has a bright, shiny silver luster.

-

Titanium: A darker, distinct grey.

-

Inconel: often presents a slightly darker, more "milky" stainless look. If the material has been exposed to high heat, Inconel develops a tightly adherent oxide scale that does not flake off, unlike steel which rusts and flakes.

The Density Check

Inconel is heavy. It is significantly denser than titanium and slightly denser than standard steel.

-

Titanium Density: ~4.5 g/cm³

-

Stainless Steel (304) Density: ~8.0 g/cm³

-

Inconel 625 Density: ~8.44 g/cm³

If you have a precise scale and a way to measure water displacement (Archimedes' principle), you can calculate the specific gravity. A piece of Inconel will feel noticeably heavier in the hand than a piece of titanium of the same size.

Advanced Workshop Identification Methods

When simple observation fails, physical interaction with the metal provides better data.

The Spark Test

This remains the most practiced shop-floor method for differentiating nickel alloys from stainless steel. It requires a bench grinder and a trained eye.

Procedure:

-

Safety First: Wear eye protection and flame-resistant clothing.

-

Power up a bench grinder.

-

Apply the metal sample to the wheel with consistent pressure.

-

Observe the spark stream length, color, and "bursts."

What to look for:

| Material | Spark Color | Spark Length | Characteristics |

| Carbon Steel | White/Yellow | Long | Many star-like bursts (carbon explosions). |

| Stainless Steel (304/316) | Orange/Red | Medium | Few forks/bursts near the end of the stream. |

| Inconel (Ni Alloys) | Dark Red / Orange | Very Short | Thick stream, no bursts, "lazy" sparks. |

| Titanium | Brilliant White | Medium/Long | Blindingly bright white sparks that end in a bloom. |

Interpretation:

Inconel sparks are distinct because nickel suppresses the carbon explosion. You will see a short, dull red trail that seems to die out quickly. If you see bright white sparks, it is Titanium. If you see "sparklers" or star-bursts, it is likely standard steel.

The Acid Spot Test

Chemical reaction tests can confirm the presence of high nickel concentrations.

Warning: This involves strong acids. Use gloves and ventilation.

-

Drop Test: Apply a drop of cupric chloride in hydrochloric acid to a clean metal surface.

-

Observation:

-

Stainless Steel: Will often show a copper-colored deposit after a minute.

-

Inconel: Is highly resistant. It generally shows no reaction or a very slow, dull mark.

-

Monel: Reacts differently due to high copper content.

-

This method confirms the corrosion-resistant nature of the superalloy but does not tell you the specific grade.

Professional Laboratory Verification (PMI)

For MWalloys and our industrial clients, "guessing" is not an option. Positive Material Identification (PMI) is mandatory.

X-Ray Fluorescence (XRF)

Handheld XRF analyzers (guns) are the industry standard. These devices blast the sample with X-rays, causing the elements to fluoresce. The analyzer reads the energy signatures to provide a chemical breakdown.

Why XRF is best:

-

It is non-destructive.

-

It gives results in seconds.

-

It distinguishes between Inconel 600, 625, and 718 by reading Molybdenum and Niobium levels.

If the readout shows Nickel > 50%, Chromium ~20%, and significant Molybdenum, you have confirmed Inconel.

Optical Emission Spectroscopy (OES)

While XRF is great for heavy elements, it struggles with light elements like Carbon. OES creates a plasma on the metal surface and analyzes the light spectrum. This is necessary if you need to distinguish low-carbon variants (like 316L vs 316) or check specific carbon content in Inconel grades for nuclear applications.

Distinguishing Inconel from Lookalikes

Mixing up metals can cause catastrophic failure. Here is how Inconel compares to its common doppelgangers.

Inconel vs. Stainless Steel (304/316)

Stainless steel is the most common metal mistaken for Inconel.

-

Cost: Inconel is vastly more expensive.

-

Heat Tolerance: Stainless 304 loses structural integrity around 600°C. Inconel maintains strength well above 900°C.

-

Identification: The spark test is the easiest differentiator. Stainless sparks fly further and have small forks. Inconel sparks are short and straight.

Inconel vs. Titanium

-

Weight: Titanium is light (4.5g/cm³). Inconel is heavy (8.4g/cm³).

-

Sparks: Titanium sparks are blinding white. Inconel sparks are dull red.

-

Application: Titanium is used for weight reduction; Inconel is used for heat resistance.

Inconel vs. Monel

Both are high-nickel alloys.

-

Composition: Monel is Nickel-Copper. Inconel is Nickel-Chromium.

-

Color: Monel has a slight yellowish/greenish hue compared to Inconel’s silver-grey.

-

Acid Test: A drop of nitric acid will react with the copper in Monel, turning green/blue. It will not affect Inconel.

Specific Grade Identification: Inconel 625 vs 718

At MWalloys, we often handle requests to separate these two specific grades. They look identical but behave differently.

-

Inconel 625: Known for high corrosion resistance and fabricability.

-

Inconel 718: Known for high creep-rupture strength and ability to be age-hardened.

Chemical Differences Table:

| Element | Inconel 625 | Inconel 718 |

| Nickel | ~58% min | 50-55% |

| Chromium | 20-23% | 17-21% |

| Molybdenum | 8-10% | 2.8-3.3% |

| Niobium | 3.15-4.15% | 4.75-5.5% |

| Iron | 5% max | Balance (~17%) |

How to tell them apart:

-

XRF: Look at the Iron (Fe) content. Inconel 718 has roughly 17-19% Iron, whereas 625 has less than 5%. This is the clearest indicator.

-

Hardness: In the age-hardened condition, 718 is significantly harder (Rockwell C 40+) than annealed 625.

Case Study: Urgent Verification in Offshore Drilling

Location: Galveston, Texas

Date: February 2024

Client: Tier-1 Subsea Equipment Manufacturer

The Problem:

A maintenance crew on an offshore rig identified premature corrosion on a valve assembly that was supposed to be Inconel 625. The documentation claimed 625, but the component was pitting after only three months of service. The client sent the damaged valve stem to the MWalloys partner lab for forensic analysis.

The Process:

-

Visual Inspection: The pitting suggested chloride attack, which Inconel 625 usually resists.

-

PMI (XRF): Our technicians ran an XRF scan. The composition showed 18% Chromium and 8% Nickel, with 70% Iron.

-

Result: The material was actually 304 Stainless Steel. The supplier had mixed stock.

-

Resolution: MWalloys supplied certified Inconel 625 bar stock immediately. The correct material was machined and installed.

The Outcome:

The replacement part has now been in service for 10 months with zero signs of degradation. This failure highlighted the massive financial risk of relying on paperwork without physical material verification.

Why Correct Identification Matters

Using the wrong alloy is not just a financial error; it is a liability.

-

Aerospace: A turbine blade made of stainless steel instead of Inconel would melt and shatter at operating temperatures, causing engine failure.

-

Chemical Processing: Inconel is used to hold aggressive acids. If a tank is made of a lesser alloy, it will leak dangerous chemicals.

-

Scrap Value: Inconel scrap trades at a much higher price than stainless steel. Selling Inconel as "mixed stainless" loses the seller thousands of dollars per ton.

MWalloys Quality Assurance

At MWalloys, we understand that "close enough" does not work in high-performance metallurgy. Every bar, sheet, and pipe that leaves our facility undergoes rigorous PMI. We do not rely solely on mill certificates; we verify.

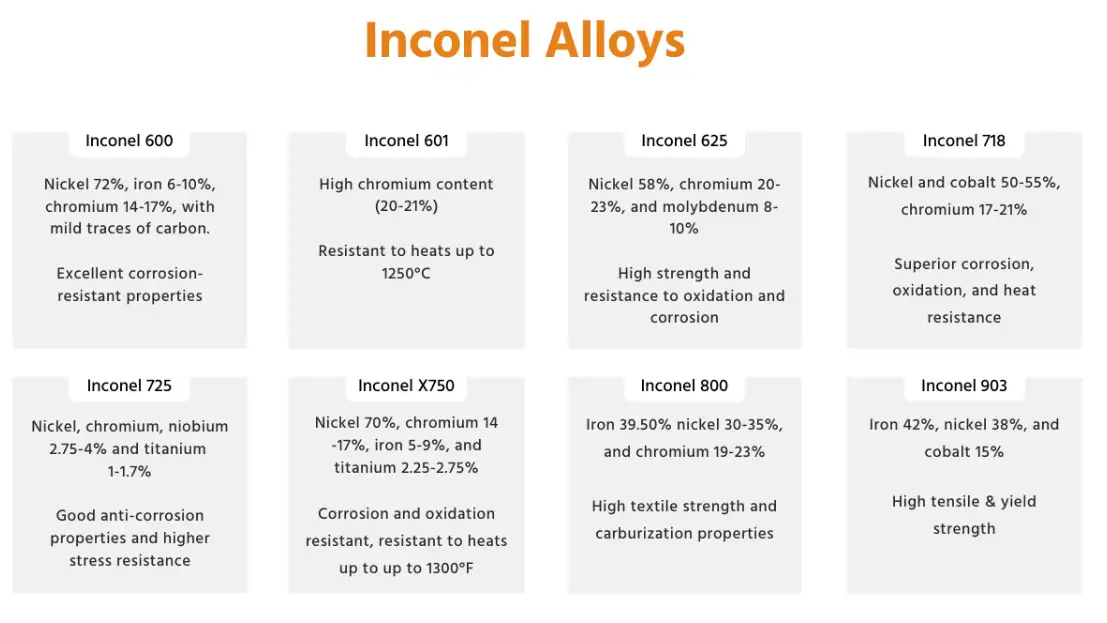

Our inventory management systems ensure that Inconel 600, 601, 625, and 718 are segregated and color-coded. When you order from MWalloys, you receive material that has been tested, verified, and guaranteed to meet ASTM, AMS, and ASME standards.

Frequently Asked Questions (FAQs)

1. Can I identify Inconel with a magnet?

Generally, Inconel is non-magnetic. However, this is not a definitive test. Many stainless steels are also non-magnetic. Furthermore, some Inconel grades can develop slight magnetism from work-hardening. The magnet test helps rule out carbon steel but cannot confirm Inconel.

2. What does Inconel look like compared to stainless steel?

Inconel is very similar to stainless steel but often has a slightly darker, more grayish luster rather than the bright chrome-like shine of polished stainless. If it has been used in heat, it may have a thick, non-flaking oxide layer.

3. Does Inconel rust?

No, Inconel does not rust in the traditional sense. It is a superalloy designed to resist oxidation. Instead of red rust, it may develop a protective oxide layer that prevents further corrosion, even in saltwater or acidic environments.

4. How can I tell the difference between Inconel 625 and 718 without a lab?

It is very difficult to do this without XRF equipment. However, 718 is magnetic in certain conditions and contains significantly more iron (~17%) than 625 (<5%). A high-end portable XRF gun identifies this difference instantly.

5. Why is Inconel so expensive?

Inconel contains high levels of Nickel (often over 50%) and Cobalt, which are expensive commodities. Additionally, the manufacturing process—vacuum induction melting and complex annealing—adds to the cost.

6. What is the spark test result for Inconel?

Inconel produces a very short, dark red or orange spark stream that tapers off quickly. Unlike steel, the sparks do not "burst" or "flower" at the end. The stream looks lazy and dense.

7. Is Inconel heavier than steel?

Yes. The density of Inconel generally ranges from 8.19 to 8.44 g/cm³, whereas stainless steel is around 7.9 to 8.0 g/cm³. While the difference is small, a large piece of Inconel will weigh noticeably more than a steel piece of the same dimensions.

8. Can I use a chemical test kit for Inconel?

Yes, electrochemical spot test kits (molybdenum testers) can detect the presence of specific elements. However, these kits are often subjective and less accurate than digital analyzers.

9. What happens if I weld Inconel with the wrong filler rod?

If you weld Inconel with a stainless steel rod, the weld zone will likely crack or corrode rapidly. The dilution of the nickel content compromises the superalloy's properties. Always use matching filler material (e.g., Inconel 625 filler for 625 parent metal).

10. Does MWalloys provide material certificates?

Yes. MWalloys provides full Mill Test Reports (MTRs) with every shipment. These documents trace the heat number, chemical composition, and mechanical properties back to the original melt source.

Summary of Identification Methods

| Method | Accuracy | Cost | Best For |

| Magnet Test | Low | Low | Ruling out carbon steel. |

| Spark Test | Medium | Low | Sorting scrap quickly. |

| Density Test | Medium | Low | Differentiating Titanium vs Inconel. |

| Chemical Spot Test | Medium | Medium | Confirming Nickel content. |

| XRF Analysis | High | High | Definitive Grade Identification. |

Identifying Inconel correctly protects your machinery, ensures safety, and guarantees you get the value you paid for. Whether you are sorting a scrap bin or verifying a critical component for a jet engine, using the protocols outlined above will yield accurate results.

For certified, high-quality Inconel alloys that you never have to second-guess, trust MWalloys. We supply confidence, not just metal.