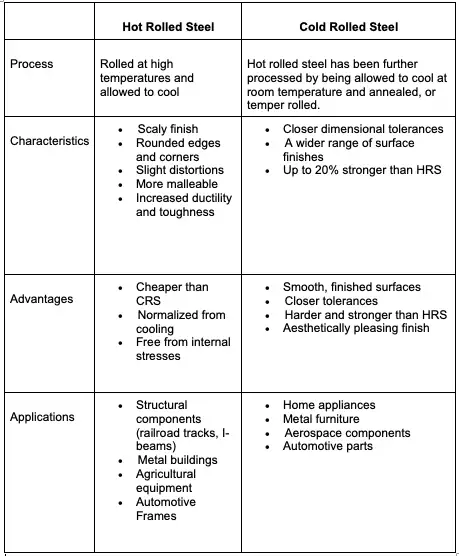

Cold-rolled steel is essentially hot-rolled steel that has been processed further at or near room temperature to produce a smoother surface, tighter dimensional tolerances and higher strength (through strain hardening and controlled heat treatments); it is typically chosen when surface finish, precise gauge control and improved mechanical properties are priorities. Hot-rolled steel is produced at high temperatures, is more economical in thick sections and large shapes, and offers greater ductility and ease of forming for heavy structural parts where exact surface finish or tight tolerance are not critical. The correct choice therefore depends on the application’s required tolerances, surface requirements, mechanical limits and budget.

What is Cold-Rolled and Hot-Rolled Steel?

-

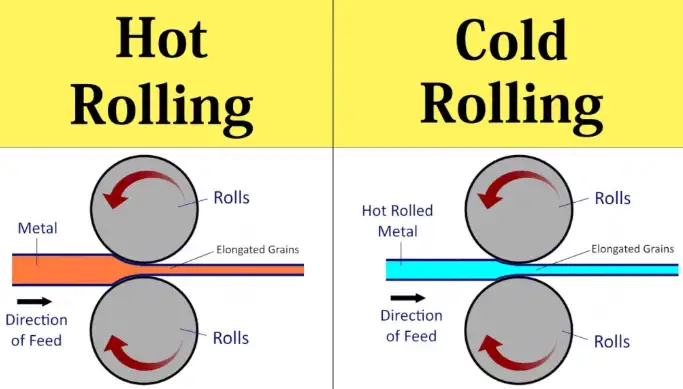

Hot-rolled steel: flat products (sheets, plates, coils) or long products (bars, sections) produced by rolling steel at temperatures well above the metal’s recrystallization temperature. That high temperature (often >900–1,200 °C depending on chemistry) keeps the steel soft during deformation and allows large reductions per pass.

-

Cold-rolled steel: sheet or strip that was rolled at or below the metal’s recrystallization temperature (usually room temperature) after an initial hot-rolling step (i.e., cold rolling is a secondary finishing step). Cold rolling may be followed by annealing and temper rolling to tailor mechanical and surface properties.

Production flow — step-by-step

Hot rolling (typical sequence)

-

Steelmaking & casting: liquid steel is cast into slabs or blooms.

-

Reheating furnace: slab is reheated to rolling temperature.

-

Roughing mill: large reductions and elongation.

-

Finishing mill: fine thickness reductions and crown/shape control.

-

Coiling / cooling: hot strip is coiled or cut to plate; scale (oxide) forms on surface.

-

Optional pickling & oiling (HRPO) to remove scale and protect the surface for storage/painting.

Cold rolling (typical sequence)

-

Start with hot-rolled coil (often pickled and oiled to remove scale).

-

Cold reduction in tandem or reversing mills — successive passes through rollers at room temperature; thickness reduced and strain hardening occurs.

-

Annealing (batch or continuous) — restores ductility, adjusts grain size, removes internal stress.

-

Temper rolling / skin pass — small reduction to improve flatness and surface appearance and set final physical properties.

-

Final finishing — oiling, coating or surface treatments depending on end use.

What the processes do to the metal

-

Hot rolling occurs above recrystallization temperature. Deformation is followed by dynamic recrystallization and relatively coarse grains on cooling. Because recrystallization occurs, the dislocation density after deformation is low compared with cold rolled products; the result is lower strength and higher ductility for a given chemistry.

-

Cold rolling work-hardens the metal (increasing dislocation density) and produces anisotropy in properties if not properly annealed. Annealing between reductions can restore ductility and refine the microstructure. The interplay between cold reduction % and anneal cycle determines final hardness, yield strength and elongation.

Mechanical properties

Key trends (summary):

-

Cold-rolled steel typically has higher yield and tensile strength than hot-rolled steel of the same chemistry due to strain hardening (unless fully annealed back to the same temper).

-

Hot-rolled steel is more ductile and easier to form in heavy sections; it tolerates larger deformations without cracking.

-

Cold-rolled surfaces are smoother and therefore often preferred where painting or tight surface finish is required.

Table 1 — Typical mechanical properties (representative, engineering guidance)

Note: these are representative ranges. Always consult the specific mill certificate / ASTM grade for exact numbers.

| Property | Hot-Rolled (typical A1011 CS) | Cold-Rolled (typical A1008 / 1008-1010, full hard vs annealed) |

|---|---|---|

| Tensile strength (MPa) | 340–520 (varies by grade) | 350–550+ (cold-reduced/hardened); annealed lower. |

| Yield strength (MPa) | 205–420 depending on grade | Typically 240–450 (work-hardening and tempering dependent). |

| Elongation (%) | 20–35% (higher ductility) | 5–25% (lower for full-hard cold-rolled; higher if annealed) |

| Hardness (HB) | ~110 max (varies) | can be significantly higher for full-hard strip |

| Surface roughness | Mill scale — rough | Smooth, ready for painting or plating |

(Sources: ASTM grades & manufacturer typical ranges.)

Surface quality and finishing terms you will see on specs

-

Mill finish (hot-rolled): dark gray/black surface with oxide scale; visually coarse. Good for structural uses where finish is not critical.

-

HRPO (Hot-Rolled Pickled & Oiled): scale removed by acid pickling, then oiled — gives a cleaner, more uniform surface and better paint adhesion than mill finish.

-

Cold-rolled finish: bright, smooth surface; commonly oiled to prevent flash rust. Surface options include matte, bright, or skin-passed finishes.

Table 2 — Surface and end-use mapping

| Surface / Finish | Typical appearance | Common applications |

|---|---|---|

| Hot-rolled mill finish | Dark scale, uneven | Structural beams, agricultural equipment, welded fabrications |

| HRPO | Clean, slightly oily | General fabrication where painting or galvanizing follows |

| Cold-rolled bright | Smooth, reflective | Appliance panels, automotive inner panels, furniture |

| Cold-rolled oiled | Smooth, protected | Precision stamped parts, electrical panels |

Dimensional accuracy, tolerances and flatness

Cold-rolled products are rolled to tighter gauge tolerances and better flatness. Typical reasons:

-

Cold rolling can reduce thickness in controlled, small steps (tandem mills) so the final gauge can be held to narrower tolerances.

-

Skin pass and tension leveling after cold rolling improve flatness and surface texture.

Hot-rolled plates and coils are thicker and have wider tolerances—acceptable in structural applications where mill finish and micrometer tolerances are unnecessary.

Forming, bending, welding and machining

-

Forming / stamping: Cold-rolled strip (especially annealed or semi-hard tempers) gives consistent springback and tight feature control for stamping; however, full-hard cold strip may crack if over-formed. Hot-rolled sheet is more forgiving for large bends and heavy forming.

-

Welding: Hot-rolled products are generally easier to weld without pre- or post-weld treatment, because residual stresses are lower and the material is more ductile. Cold-rolled parts may require more attention to distortion control.

-

Machining: Cold-rolled steels often machine slightly easier and produce better surface finish because of the more uniform material and tighter tolerances.

Common grades, codes and standards

-

ASTM A1011 — standard specification for hot-rolled sheet and strip (commonly quoted for structural hot-rolled coil and sheet).

-

ASTM A1008 / A1008M — standard specification for cold-rolled sheet, in coils and cut lengths.

-

Common commercial alloys/UNS numbers: 1008, 1010 (cold-rolled commercial and drawing steels); A36 is a common structural hot-rolled plate/shape spec. Always verify the mill cert and temper.

When placing an order always specify: grade & spec (e.g., “ASTM A1008 CS Type B, matte finish, oiled”), thickness tolerance, width, length, edge trim, coil ID/OD, and any post-treatments (anneal, temper, coating).

Cost and supply chain considerations

-

Costs: Hot-rolled steel is generally cheaper per ton because it avoids the secondary cold-reduction and annealing steps. Cold-rolled adds processing costs (cold rolling mill time, annealing fuel/energy, skin pass).

-

Lead time: Cold-rolled products may have longer lead times depending on mill scheduling, temper requirements and finishing steps.

-

Yield & scrap: Cold reduction can produce narrow coils and tight tolerances which may increase usable yield for precision parts, but initial material cost is higher.

Typical applications and decision matrix

Table 3 — Quick selection matrix (practical)

| Requirement | Hot-Rolled | Cold-Rolled |

|---|---|---|

| Heavy structural members, I-beams, plates | Excellent | Not typical |

| Large welded assemblies where finish not critical | Excellent | Possible but more costly |

| Precision stamped parts, appliance panels | Poor | Excellent |

| Automotive outer panels (visible) | Rare | Widely used (with coatings) |

| Low cost fencing/landscape | Excellent | Over-spec’d |

| Paint or plating base where finish matters | HRPO ok; cold-rolled best | Best |

Common defects and quality checks

-

Hot-rolled issues: mill scale, edge waves, center buckle, decarburization at surface in some processes. Pickling helps remove scale.

-

Cold-rolled issues: strain-induced defects, annealing discoloration, edge cracking (if reductions too aggressive). Proper mill setup, anneal cycles and tension levelling are key.

Quality checks to request from supplier:

-

Mill test certificate (chemical and mechanical) — always request.

-

Surface finish photos / samples.

-

Dimensional reports (thickness charting, flatness).

-

Results of any non-destructive testing (if requested).

Post-processing: coating, galvanizing, and painting

-

Galvanizing: both HR and CR can be galvanized; however, cold-rolled parts often require pre-treatment and provide a more uniform coating due to smooth surface.

-

Painting / powder coat: cold-rolled with proper pre-treatment yields superior adhesion and gloss control. HRPO is a lower-cost alternative where only moderate finish is required.

Environmental and energy considerations

Hot rolling requires large energy input for reheating slabs but is an efficient high-throughput process for heavy sections. Cold rolling consumes additional energy through tandem mill operation and especially through annealing furnaces. From a lifecycle and emissions standpoint, process optimization (heat recovery, modern continuous annealing lines, efficient reheating) reduces the gap between routes. Mill sourcing and recycled scrap content should be reviewed in sustainable procurement specifications.

Practical procurement checklist (what to specify)

-

Product: sheet, coil, plate, or strip.

-

Specification & grade: e.g., ASTM A1011 Type B (hot) or ASTM A1008 (cold).

-

Thickness & tolerance (include allowable min/max).

-

Width & length or coil OD/ID.

-

Finish: mill, pickled & oiled, cold-rolled bright, oiled, skin-pass.

-

Temper (full hard, quarter hard, annealed, etc.).

-

Coating: galvanize, paint, lubricants.

-

Certificates: mill cert (chemical & mechanical), non-destructive testing if required.

-

Delivery & packaging: wrap, pallets, pallets dimensions.

-

Traceability / origin.

FAQs

1. Is cold-rolled steel stronger than hot-rolled steel?

Generally yes for the same chemical composition in typical tempers: cold rolling increases tensile and yield strengths through work hardening. If the cold-rolled product is fully annealed, its strength may be comparable to hot-rolled. Always check the mill certificate for exact values.

2. Can I weld cold-rolled steel like hot-rolled?

You can weld both, but cold-rolled parts may distort more because of higher residual stresses depending on temper; thicker cold-rolled full-hard material may need preheat or special fixturing. For critical welds check recommended procedures for the exact grade.

3. What does HRPO mean and when do I choose it?

HRPO = Hot-Rolled Pickled & Oiled. Pickling removes mill scale and oil prevents flash rusting. Choose HRPO when a cleaner surface than mill finish is needed but you want lower cost than cold-rolled.

4. Are all cold-rolled steels originally hot-rolled?

Yes — cold-rolled products typically begin as hot-rolled coils (scale removed) and are then cold-reduced. So all cold-finished flat products start from a hot-rolled product.

5. Which is better for stamping and deep drawing?

Cold-rolled, drawing quality (DQ), deep drawing (DDS) and extra deep drawing (EDDS) grades are tailored for stamping and drawing; they have controlled chemistry and anneal schedules to provide the necessary ductility. Refer to ASTM A1008 types when specifying.

6. What are typical tolerances for thickness?

Tolerances depend on spec and thickness. Cold-rolled tolerances are tighter (e.g., ±0.005–0.02 mm for thin gauges), whereas hot-rolled tolerances can be broader. Always request supplier’s tolerance table or reference ASTM ordering options.

7. Which is cheaper?

Hot-rolled is usually less expensive. Cold-rolled includes additional processing cost (cold mill time, annealing, temper pass) which raises price. However, economic tradeoffs may favor cold steel if reduced scrap and finishing lower total part cost.

8. Is surface roughness the same for HRPO and cold-rolled?

No. HRPO is smoother than mill finish but still coarser than cold-rolled bright or skin-passed finishes. For paint gloss and thin coatings cold-rolled is preferred.

9. Can hot-rolled be used for precision parts?

Hot-rolled is acceptable where precision is not critical (structural I-beams, fabrication). For precision stamping, tight flatness, or cosmetic surfaces choose cold-rolled or specify additional machining.

10. Which standards should I request on PO?

For hot-rolled sheet/strip: ASTM A1011 (and related ASTM A568 etc.). For cold-rolled sheet/strip: ASTM A1008. Ask for mill test certificates to confirm mechanical and chemical compliance.

Closing recommendation

-

If you need low cost and heavy section / structural performance: choose hot-rolled (or HRPO for a cleaner surface).

-

If you need controlled thickness, better surface finish, higher strength and precision forming: choose cold-rolled and specify the temper and post-anneal condition.

-

Always request mill test certificates and specify the ASTM / EN standard on the purchase order.

Quick reference tables

Table 4 — One-page quick comparison

| Feature | Hot-Rolled | Cold-Rolled |

|---|---|---|

| Production temp | Above recrystallization temp | At/Below recrystallization temp |

| Surface | Scaled (rough); HRPO available | Smooth; bright/skin-pass |

| Dimensional tolerance | Wide | Tight |

| Strength (same chemistry) | Lower | Usually higher (work-hardened) |

| Ductility/formability | High (bulk forming) | Lower (unless annealed) |

| Typical standards | ASTM A1011 | ASTM A1008 |

| Cost | Lower | Higher |

| Best uses | Structural, heavy | Appliances, automotive, precision parts |

Authoritative references

- ASTM A1008 / A1008M — Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy and Ultra-High Strength

- ASTM A1011 / A1011M — Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, and Ultra-High Strength

- Association for Iron & Steel Technology (AIST) — Technical resources and training on hot-rolling practices

- Nippon Steel — Hot-Rolled Steel Sheets and Coils technical catalog (process and product notes)