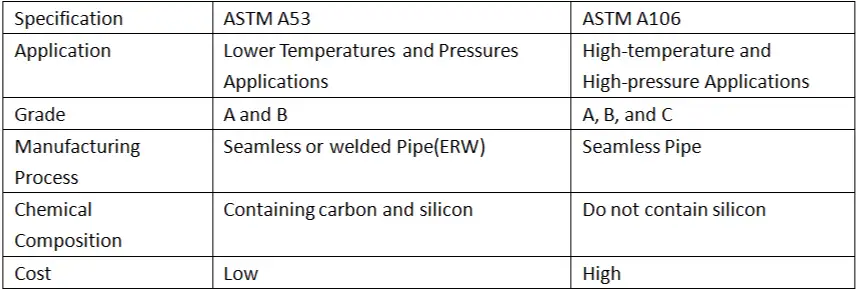

When should one choose A53 over A106? A106 offers higher pressure ratings and seamless construction for critical applications, while A53 provides cost-effective welded options suited to general service needs.

-

Choose A53 for cost-effective, low-to-medium pressure fluid transport or structural uses. Welded options (Type E/F) reduce costs.

-

Specify A106 for critical high-temperature/pressure services (e.g., steam >350°C). Its seamless construction, enhanced chemistry, and heat treatment ensure long-term reliability.

What is ASTM A53?

ASTM A53 covers seamless and welded black and hot-dipped galvanized steel pipe. It’s widely used in structural and low-pressure conveyance applications. Grade B is most common, offering typical yield strength of 35,000 psi and tensile strength of 60,000 psi.

What is ASTM A106?

ASTM A106 applies to seamless carbon steel pipe for high-temperature service. It comes in Grades A, B, and C, with Grade B dominating industry use due to its balance of strength and cost. Its hydrostatic test pressure exceeds that of A53 by about 30% at comparable dimensions.

Mechanical Properties Comparison

| Property | ASTM A53 | ASTM A106 |

|---|---|---|

| Grade B Yield Strength | ≥ 240 MPa (35,000 psi) | ≥ 240 MPa (35,000 psi) |

| Grade B Tensile Strength | ≥ 415 MPa (60,000 psi) | ≥ 415 MPa (60,000 psi) |

| Grade C Tensile Strength | Not available | ≥ 485 MPa (70,000 psi) |

| Elongation (min) | 30% (varies by size) | 30% (Grade B) |

| Impact Testing | Not required | Required for low-temperature service |

Key Insight: While Grade B mechanical properties overlap, A106 offers a higher-strength Grade C option and mandates impact testing for sub-ambient temperatures.

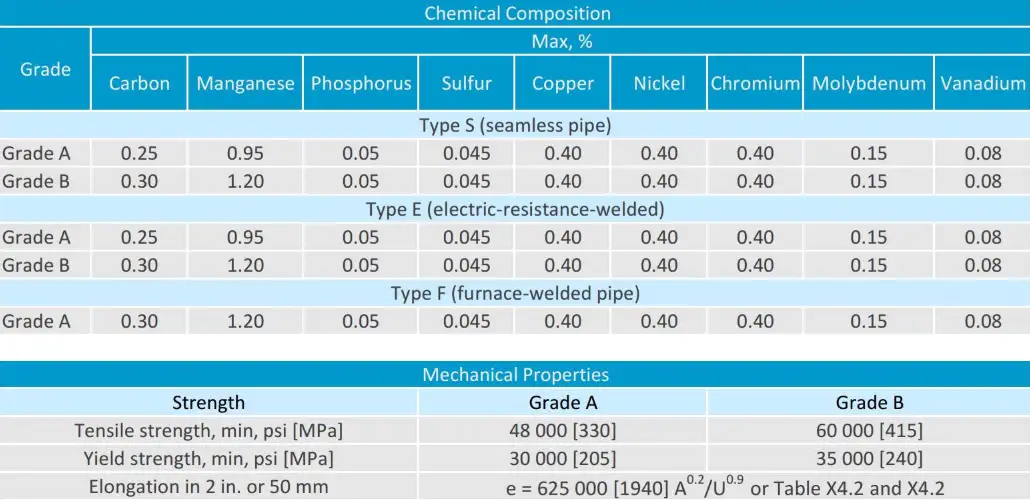

Chemical Composition Comparison (% Weight)

| Element | ASTM A53 Grade B | ASTM A106 Grade B |

|---|---|---|

| Carbon (C) | ≤ 0.30 | ≤ 0.30 |

| Manganese (Mn) | ≤ 1.20 | 0.29–1.06 |

| Silicon (Si) | Not specified | ≥ 0.10 (deoxidizer for high-temp stability) |

| Phosphorus (P) | ≤ 0.05 | ≤ 0.035 |

| Sulfur (S) | ≤ 0.045 | ≤ 0.035 |

| Residuals (Cr, Cu, Ni, etc.) | ≤ 0.40 (each) | ≤ 0.40 (each), tighter control |

Key Differences:

-

A106 requires silicon for oxidation resistance in high-temperature service.

-

Stricter controls on P, S, and residuals in A106 reduce brittleness and enhance creep resistance.

Specifications & Dimensional Comparison

| Parameter | ASTM A53 | ASTM A106 |

|---|---|---|

| Scope | General fluid service (water, air, gas) | High-temperature/pressure service (steam, oil) |

| Pipe Types | Seamless (Type S) + Welded (Type E, F) | Seamless only |

| Temperature Range | ≤ 350°C (662°F) | -28.9°C to 565°C (-20°F to 1,050°F) |

| Heat Treatment | Optional for Grade B | Mandatory (normalizing/quenching + tempering) |

| Common Sizes | 1/8"–48" OD; SCH 40, 80, XS, XXS | 1/8"–48" OD; SCH 40, 80, XS, XXS |

| Weight | Similar to A106 for same SCH thickness | Marginally heavier due to stricter wall tolerance |

Notes:

-

Both standards cover identical size ranges (1/8"–48" OD).

-

A106’s seamless-only construction and heat treatment ensure integrity under thermal cycling.

Weight Comparison (Example: NPS 12, SCH 40)

| Parameter | ASTM A53 | ASTM A106 |

|---|---|---|

| Outside Diameter | 12.75 in (324 mm) | 12.75 in (324 mm) |

| Wall Thickness | 0.406 in (10.3 mm) | 0.406 in (10.3 mm) |

| Weight (lb/ft) | 49.56 | 49.56 (negligible difference) |

Note: Weight variance is minimal for identical dimensions. A106’s tighter wall thickness tolerances (±12.5%) may marginally increase weight in some batches.

Additional Critical Differences

-

Applications:

-

A53: Low-pressure water lines, structural supports, HVAC.

-

A106: Power plant boilers, refinery steam lines, high-temperature process piping.

-

-

Dual Certification: Pipes meeting both standards (e.g., seamless Grade B) are common for flexibility in procurement.

-

Equivalent Grades:

-

A53 Grade B ≈ GB/T 8163 20# (China).

-

A106 Grade B ≈ GB/T 5310 20G (high-pressure boiler tube).

-

Global Price Comparison 2025 (China, Europe, USA)

| Region | A53 Grade B (USD/ton) | A106 Grade B (USD/ton) |

| China | 650–700 | 700–750 |

| Europe | 800–850 | 850–900 |

| USA | 900–950 | 950–1000 |

Data collected July 2025.

Factors Influencing Price

- Raw material cost (coking coal, scrap steel).

- Energy tariffs in region.

- Seaming vs. seamless process complexity.

- Certification and inspection costs.

Industry Development Trends

In recent years, the carbon‑steel pipeline sector has been reshaped by stringent environmental mandates and evolving energy projects. Seamless A106 grades have benefited from rising demand in high-temperature petrochemical and power facilities, achieving an estimated 6% compound annual growth between 2022 and 2025. Meanwhile, welded A53 applications remain vital for municipal water and gas distribution, buoyed by infrastructure revitalization initiatives worldwide.

Looking ahead, decarbonization efforts will steer material innovation. Hydrogen‑compatible steels and low‑carbon variants are undergoing field trials, signaling a shift toward more resilient chemistries. Digital supply‑chain tracking—using blockchain for heat‑number traceability—is gaining traction, heightening transparency and reducing lead‑time variability. By 2030, I foresee a 20% uptick in A106 Grade C pipeline consumption for advanced energy projects, contrasted with a moderate 5% annual growth for A53 in general‑service sectors.

Procurement Standards

When I specify ASTM A53 or A106 tubing for any project, I follow seven key criteria:

- Mill Qualifications: Ensure mills hold ISO 9001 certification plus API 5L (for line pipe) or EN 10216‑2 accreditation.

- Material Test Reports (MTRs): Require full heat‑number traceability, with documented mechanical tests, chemical analyses, and hydrostatic proofs.

- Non‑Destructive Examination (NDE): 100% ultrasonic testing (UT) on seamless lengths; 100% radiographic testing (RT) on circumferential welds for A53 SAW pipes.

- Dimensional Compliance: Verify outer diameter (OD) and wall thickness per ASME B36.10M; concentricity within 3% of wall thickness.

- Surface Treatment: Confirm galvanizing per ASTM A123 for A53; acid pickling and passivation per ASTM A380 for A106 when corrosion resistance is required.

- Third‑Party Verification: Engage certified inspectors (DNV, TÜV) to audit manufacturing and inspect random samples.

- Packaging & Logistics: Mandate plastic‑sealed ends, steel‑banded bundles, and export‑grade wooden crates with clear grade/schedule/size markings.

FAQs

-

What is the primary difference between ASTM A53 and ASTM A106?

ASTM A53 covers both welded and seamless carbon‑steel pipes for general service, whereas ASTM A106 specifies seamless carbon‑steel pipes designed for high‑temperature service up to 450 °C. -

Can ASTM A53 Grade B be used in high‑pressure applications?

ASTM A53 Grade B is suitable for moderate pressure systems (up to Schedule 160), but for critical high‑pressure or high‑temperature service, ASTM A106 Grade B or C is recommended. -

How do the chemical compositions of A53 and A106 compare?

Both standards limit carbon to 0.25–0.30 % and manganese to around 1.06 %, but ASTM A106 imposes stricter limits on phosphorus and sulfur for improved toughness at elevated temperatures. -

Which standard offers better dimensional tolerances?

ASTM A106 seamless pipes generally exhibit tighter concentricity (≤ 3 % of wall thickness) and OD/wall tolerances per ASME B36.10M, whereas A53 welded pipes may vary ± 12.5 %. -

Is ultrasonic testing (UT) mandatory for both A53 and A106?

For ASTM A106 seamless lines, 100 % UT is standard. For ASTM A53 SAW (welded) pipes, radiographic testing (RT) of all circumferential welds is required; UT on seamless sections is often optional but recommended. -

What temperature ranges are covered by A53 vs. A106?

ASTM A53 is rated for –20 °C to 350 °C, making it ideal for water, gas, and low‑temperature services. ASTM A106 supports –20 °C to 450 °C, fitting petrochemical and power‑plant applications. -

How do A53 and A106 compare in price and availability?

Welded ASTM A53 pipes typically cost 5–10 % less per ton than seamless ASTM A106. Availability depends on region—China leads in low‑cost A53, while Europe and North America have robust A106 seamless capacities. -

Which pipe schedule should I choose for A53 vs. A106?

Select pipe schedule based on design pressure and corrosion allowance: use Schedule 40 for lower pressures, Schedule 80 for moderate pressures, and Schedule 160 or higher (available in A106) for high‑pressure systems. -

Are both A53 and A106 pipes suitable for fire‑sprinkler systems?

Yes—ASTM A53 Grade B is commonly used for fire‑sprinkler mains, but for high‑heat exposure (e.g., industrial furnaces), ASTM A106 seamless pipes offer superior creep resistance. -

How can I verify supplier compliance for A53 vs. A106?

Always request Material Test Reports (MTRs) with full heat‑number traceability, mill certifications (ISO 9001, API 5L or EN 10216‑2), and third‑party inspection records (DNV, TÜV) to ensure adherence to ASTM A53 or A106 specifications.