ASTM A234 is the industry standard that defines wrought carbon and alloy steel butt-weld fittings intended for moderate to high-temperature pressure piping; its most common designation, Grade WPB, provides a reliably weldable carbon-steel chemistry (low carbon, controlled manganese, and limits on alloying elements) with minimum mechanical properties tailored for pipeline and pressure-vessel fabrication.

Scope and purpose of ASTM A234

ASTM A234 / A234M is the standard specification covering wrought carbon steel and alloy steel pipe fittings of both seamless and welded construction that are manufactured to the dimensional specifications used in pressure piping (most commonly ASME B16.9 and B16.28). The specification sets required chemical limits, minimum mechanical properties, production and marking rules, and certain heat-treatment/processing options so fittings perform predictably in moderate and elevated temperature service.

Why that matters: specifying A234 tells fabricators and inspectors which raw materials, testing, and marking must be present for a fitting to qualify for pressure piping. It is the usual material reference for butt-weld carbon/alloy steel elbows, tees, reducers, caps, and bends.

Grades, nomenclature and what the letters mean

ASTM A234 uses a grade-lettering convention that indicates weldable pressure-service steels. Common labels you’ll encounter:

-

WPB — wrought pressure Grade B (the most common carbon-steel grade)

-

WPC — another carbon-steel grade with slightly higher tensile range

-

WP1, WP5, WP9, WP11, WP12, WP22, WP91, WP911 — alloy or chromia/molybdenum grades for elevated temperature service (Cr-Mo steels, higher strength)

“W” stands for weldable or wrought, “P” for pressure, and the trailing code (B, 5, 9, 11, etc.) designates the minimum strength/chemistry band. Selection among these depends on design temperature, required tensile/yield, and desired creep/oxidiation resistance for high-temperature systems.

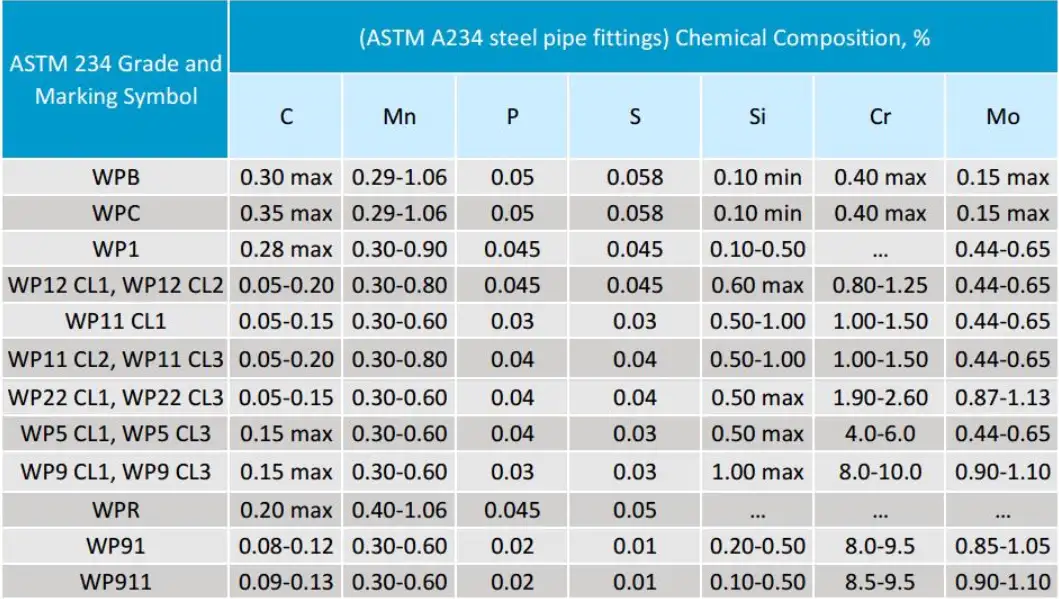

Marking Symbol Chemical Composition

Chemical composition — core values

Below is a focused table for the most requested grade, WPB (typical limits per the A234 specification and common practice). Note that alloy grades have different chemistries (Cr, Mo, Ni additions) and are detailed further in the standard.

| Element | Typical limit / range (WPB) | Notes |

|---|---|---|

| Carbon (C) | ≤ 0.30–0.35 wt% (max, depending on source/parent material) | Lower carbon improves weldability; plate/forging sources may specify 0.35 max. |

| Manganese (Mn) | 0.29–1.06 wt% | Mn range supports strength and hardenability. |

| Phosphorus (P) | ≤ 0.05 wt% | Controlled to limit brittleness. |

| Sulfur (S) | ≤ 0.058 wt% | Controlled to reduce sulfide inclusions. |

| Silicon (Si) | ≈ 0.10 wt% (min) | Deoxidizer; content varies by melt practice. |

| Cu + Ni + Cr + Mo (sum) | ≤ 1.00 wt% (general limit for WPB) | Limits prevent undue alloying that would change weldability and heat-treatment needs. |

Note: alloy grades (WP5, WP9, WP11, WP22, WP91) contain controlled additions of chromium, molybdenum, nickel, etc., and are selected where higher strength or elevated-temperature capability is needed. Always check the clause tables in the standard for the exact permitted ranges.

Mechanical properties — baseline numbers

Mechanical limits in A234 are grade dependent. For commonly used WPB the typical room-temperature minima are:

| Property | Typical minimum (WPB) |

|---|---|

| Tensile strength (Rm) | ≈ 60 ksi (415 MPa) (minimum) |

| Yield strength (0.2% offset) | ≈ 35 ksi (240 MPa) (minimum) |

| Elongation (L0) | ~22% (longitudinal) (varies with section and manufacturing route) |

Alloy grades have higher minimum tensile/yield numbers — for example WP12 shows higher tensile/yield bands and is used for higher temperature service where creep resistance is required. Always demand certified mill test reports for the exact heat/part values.

Carbon-equivalent, weldability and heat-affected zone features

When specifying fittings for field welding, the carbon equivalent (C.E.) is critical for predicting the risk of hardening in the heat-affected zone and susceptibility to cracking. ASTM A234 includes guidelines and many vendors require a maximum C.E. ≤ 0.50 for carbon steels, typically calculated with:

C.E. = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

This formula is a widely used screening tool; if C.E. exceeds project limits, preheating, controlled post-weld heat treatment (PWHT), or selection of a lower-CE material may be necessary.

Practical point: when a fitting is fabricated from plate or forging, the mill might accept slightly higher carbon if manganese or other elements compensate, but this must be handled through documented heat analysis and acceptance criteria.

Manufacturing routes, heat treatment and marking

ASTM A234 permits fittings made from killed steel, forgings, bars, plates, seamless tube, or fusion-welded tubular products with filler metal added. Key production notes:

-

Seamless vs welded raw material: seamless raw stock is often preferred for small-diameter, high-service applications for its uniform microstructure; welded or ERW tube is common in larger sizes for cost reasons.

-

Heat treatment: some alloy grades require normalization or tempering. The standard prescribes when heat treatment is required; producers will list the actual heat treatment on the MTC (mill test certificate).

-

Marking: fittings must be marked with grade designation, heat number, manufacturer’s symbol, and the ASTM/ASME specification reference to maintain traceability.

Traceability and MTC (EN 10204 3.1/3.2 where requested) are non-negotiable for critical service.

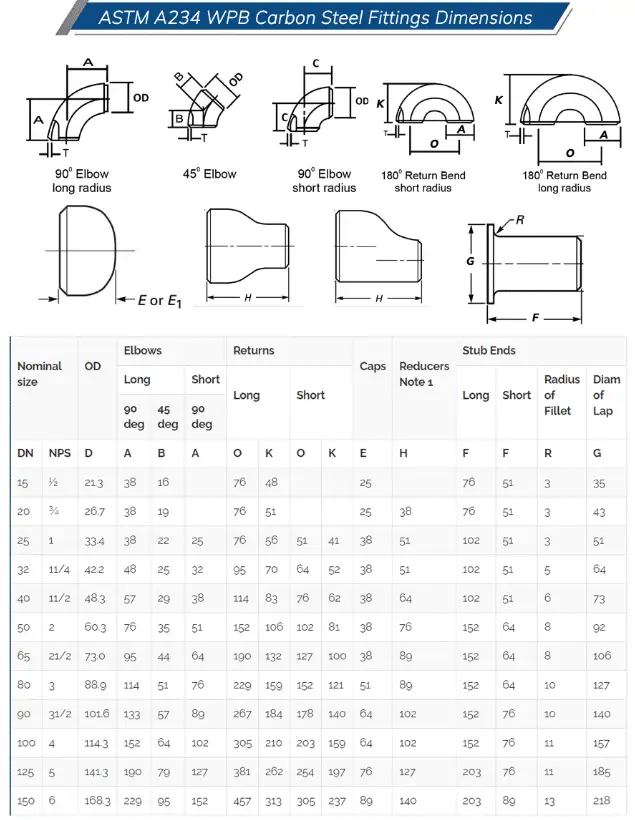

Dimensional and interchange standards

ASTM A234 governs material and testing; dimensional interchange relies on ASME and EN standards:

-

ASME B16.9 — common reference for factory-made butt-weld fittings in NPS 1/2–48 (dimensions, tolerance, end preparation).

-

EN 10253 (parts 1–4) — European standards for butt-welding pipe fittings (dimensions and some inspection categories). EN 10253-2 covers non-alloy and ferritic alloy steels with specific inspection requirements.

When specifying fittings for procurement, include both the material specification (ASTM A234/A234M) and the dimensional standard (ASME B16.9 or EN 10253). That prevents ambiguity that can otherwise cause mismatched faces, bevels or weight differences.

International equivalents and mapping table

Project teams commonly need to know equivalent/nearest materials in DIN/EN/JIS systems. The following mapping is a practical cross-reference (representative, not exhaustive):

| ASTM A234 grade | Typical pipe/plate equivalent | Typical EN/DIN equivalent |

|---|---|---|

| WPB | Often paired with ASTM A106 Gr B (pipe) or A516 Gr 70 (plate) for fittings | P265GH (EN 10028 / EN 10222) or 1.0425 / St45.8 depending on application. |

| WP1 / WP5 / WP9 / WP11 / WP12 / WP22 | Equivalent alloy grades in ASTM range | DIN/EN 13CrMo and similar Cr-Mo grades (e.g., 13CrMo4-5, 15Mo3) used for high temp. |

| WP91 / WP911 | High-alloy low-alloy Cr-Mo-V steels for very high temperature | X10CrMoVNb9-1 / 1.4903 or related creep-resistant steels. |

Practical note: equivalence is about service conditions and chemistry; never assume interchangeability without confirming design temperature, creep limits, and required documentation.

Selection criteria — how to choose the right A234 grade

Decision drivers:

-

Design temperature and pressure: elevated temperatures and thermal cycling require Cr-Mo grades (WP11, WP12, WP22, WP91).

-

Weldability needs: carbon-low WPB usually welds easily; confirm carbon equivalent before field welding.

-

Corrosion environment: plain carbon WPB is not corrosion-resistant; for sour service (H₂S), you must check NACE MR0175/ISO 15156 compatibility or choose corrosion-resistant alloys.

-

Fabrication constraints: large diameters often use welded fittings; small diameters may be seamless for better fatigue performance.

Include specific acceptance criteria (C.E. limit, required PWHT, NDT level) in purchase orders.

Inspection, testing and documentation

Minimum tests/requirements buyers normally specify for A234 fittings:

-

Material certification: EN 10204 3.1/3.2 MTC showing heat analysis and mechanical test results.

-

Mechanical testing: tensile, yield, and elongation as per grade.

-

Non-destructive testing (NDT): visual, PMI or spectro for chemistry verification, and radiography or ultrasonic testing where specified for welded fittings.

-

Hydrostatic test: not always done on every fitting, but may be requested depending on design code and service.

-

Hardness: for some alloy grades and where PWHT is required.

-

Traceability: heat number and part marking correlated to MTC.

Standards bodies often recommend additional controls for critical services. For sour service, require NACE MR0175/ISO 15156 compliance where relevant.

Typical applications and failure modes

Applications: oil & gas pipelines, steam lines in power plants, process piping in petrochemicals and refineries, compressed air, water distribution mains, and pressure-vessel connections.

Common failure modes to guard against:

-

Weld HAZ cracking when C.E. is too high or welding procedures are uncontrolled.

-

Temper embrittlement in certain alloy steels if PWHT is incorrect.

-

Corrosion / sulfide stress cracking in sour service when material selection ignores NACE/ISO guidance.

Preventive measures: specify preheat / PWHT procedures, limit carbon equivalent, require appropriate NDT, and select alloy grades for corrosive or elevated temperature service.

Procurement checklist

When creating PO / technical enquiry include:

-

Material spec: ASTM A234/A234M (explicit grade, e.g., WPB / WP11).

-

Dimensional spec: ASME B16.9 or EN 10253-2 (state preferred).

-

Required MTC: EN 10204 3.1/3.2 or equivalent.

-

Chemistry limits: require heat analysis with C.E. calculation and max C.E. value.

-

Tests: visual, PMI, radiography/UT (for welds), hardness (if required), and tensile report.

-

Surface finish, bevel type, and marking instructions.

-

QA: inspection witness points, third-party inspection if critical.

Tables engineers actually use

A — Quick grade selection table

| Service need | Typical A234 grade |

|---|---|

| General piping, welded, moderate temp | WPB |

| Elevated temp, creep-resistant | WP11 / WP12 / WP22 |

| Very high temp power / petro | WP91 / WP911 |

| Low temp (cryogenic) | Use low-temperature specs (consider A420 WPL3 for low temp) |

B — Common parent material pairings (for fitting manufacture)

| Fitting raw material source | Typical parent material matched |

|---|---|

| Seamless pipe | ASTM A106 Gr B / Gr C |

| Plate | ASTM A516 Gr 60 / 70 |

| Forging | ASTM A105 (for forged fittings; note A234 is for wrought buttweld fittings) |

Case study

A refinery replacing an aged steam header specified ASTM A234 WPB elbows made from plate. The engineering team required: MTC EN 10204 3.1, a C.E. ≤ 0.45 (project limit), radiography on all butt welds, and PWHT for welds > specified thickness. By insisting on mill heat analysis and third-party verification, they avoided late discovery of high carbon heats that would have required rework and extended shutdown.

Lesson: project limits and verification at order stage reduce rework risk and schedule impact.

Best practices — specification language

Use a compact, enforceable clause:

“Fittings shall conform to ASTM A234/A234M; material grade: WPB (or specify alloy grade). Dimensional standard: ASME B16.9 (or EN 10253-2). Supplier shall provide EN 10204 3.1 mill test certificates with heat analysis, manufacturing route, and heat number stamped on each fitting. Carbon-equivalent shall not exceed 0.50; for C.E. above 0.45, submit welding procedure and PWHT plan for approval. Third-party inspection [if required] to witness chemical analysis and NDT.”

This wording forces supplier compliance and sets the technical bar.

FAQs

-

Q: Can I use ASTM A234 WPB fittings with ASTM A106 Grade B pipe?

A: Generally yes; A234 WPB is the common fitting material paired with A106 Gr B pipe for moderate temperatures, provided design code and pressure/temperature ratings match. Always confirm MTCs, chemical compatibility, and heat numbers. -

Q: What is the difference between ASTM A234 and ASTM A105?

A: A234 covers wrought carbon and alloy steel butt-weld fittings (seamless/welded), while A105 is a forged carbon steel standard commonly used for forged flanges and fittings. Different manufacturing routes and mechanical property expectations apply. -

Q: Is PWHT required for A234 fittings?

A: PWHT depends on grade, wall thickness, and project code. Many carbon-steel WPB fittings do not mandate PWHT; chromia-moly grades often require specific PWHT cycles—specify in PO. -

Q: Can A234 WPB be used in sour service (H₂S)?

A: Not by default. Sour environments must meet NACE MR0175/ISO 15156 selection rules; in many cases, modified low-sulfur, carburized, or corrosion-resistant alloys are needed. Require NACE compliance where H₂S is present. -

Q: What testing must the supplier provide?

A: At minimum: MTC (EN 10204 3.1/3.2 if requested), heat analysis, mechanical test reports, visual inspection, and specified NDT (RT/UT) for welds. Include witness points in the PO for critical projects. -

Q: Are A234 fittings covered by ASME codes?

A: The material specification is separate but used together with ASME dimensional and pressure standards such as ASME B16.9 for butt-weld fittings. Use both for full technical coverage. -

Q: How do I compare A234 with EN 10253?

A: ASTM A234 controls material and related testing; EN 10253 controls European dimensional and inspection classes. For interchange, map grades and confirm testing/inspection class equivalence. -

Q: What is carbon equivalent limit for safe welding?

A: A practical screening C.E. limit often used is 0.50. Project owners may set lower limits (e.g., 0.45) for critical welds. Use the standard C.E. formula for calculation. -

Q: Can welded fittings be marked with a “W” in their grade?

A: Yes. Fittings manufactured from welded material shall have the letter “W” appended to the grade marking to indicate welded construction; the standard calls for marking practices to preserve clarity. -

Q: If an alloy grade is needed, which A234 grades are common?

A: For elevated temperature service select WP11, WP12, WP22, or WP91 depending on the required creep and tensile properties. Confirm exact chemistry and mechanicals in the standard tables.

Final practical tips for engineers and buyers

-

Always request heat traceable MTCs and check the reported heat analysis against the project requirement.

-

For welding on site, insist on the supplier’s C.E. calculation and approved PWHT/welding procedure if C.E. is near project limits.

-

When sour service is possible, require explicit NACE MR0175/ISO 15156 statements.

-

Require dimensional standard callouts (ASME B16.9 or EN 10253) together with ASTM A234 in purchase documents to prevent mismatch.

Authoritative references

- ASTM A234 / A234M — Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service (ASTM International)

- ASME B16.9 — Factory-Made Wrought Buttwelding Fittings (ASME)

- EN 10253-2 — Butt-welding pipe fittings: Non-alloy and ferritic alloy steels (CEN/BSI, public copy)

- ASME SA-234 / SA-234M — Material Standard Overview and Related Documents (ASME catalog entry)

- NACE MR0175 / ISO 15156 — Materials for Use in H2S-containing Environments (NACE / ISO)