Pick AR400 when impact toughness, on-site cutting/welding, and forming matter more; choose AR500 when maximum surface hardness and sliding-wear resistance are the priority (for heavy wear, shooting targets, and very abrasive chutes). If your application mixes heavy impact with severe abrasion, consider a middle grade (AR450) or engineered solutions like hardfacing or layered construction.

What “AR” means and how grades are assigned

“AR” stands for abrasion resistant and the number that follows — 400, 450, 500 — refers to a nominal Brinell Hardness Number (BHN) target. Those numbers are nominal performance bands set by producers and verified by hardness testing rather than by a single universal chemistry specification. In practice, different mills use slightly different alloy blends and heat treatments to hit the required BHN range.

-

Need high sliding-wear resistance and penetration resistance (targets, chutes with rock-on-rock sliding): consider AR500.

-

Need ductility, easier fabrication, or high-impact toughness (buckets, dump bodies, impact-prone liners): consider AR400.

Hardness, toughness, and the Brinell test — reading BHN properly

Abrasion resistant steels earn their name through quenching and tempering that produce a hard surface. Hardness is measured with the Brinell test (ASTM E10 family of standards). BHN correlates strongly with wear resistance in sliding abrasion situations: higher BHN usually means better surface wear resistance. But higher BHN often reduces toughness and increases susceptibility to cracking under high-impact, so the selection is a tradeoff. ASTM’s E10 is the standard method for Brinell testing and is widely used for acceptance testing of AR plate shipments.

Typical BHN bands (industry practice)

-

AR400: roughly 360–440 BHN (nominal 400).

-

AR500: roughly 460–540 BHN (nominal 500).

Note: mills sometimes report slight overlaps; always verify with MTR and hardness map.

Why chemistry and mill practice vary

There is no single universal chemical formula called “AR400” or “AR500.” Suppliers reach the BHN target with a combination of carbon, manganese, chromium, molybdenum, and controlled heat treatment (quench + temper). The final microstructure and mechanical balance depend on the chemistry and the tempering temperature/time schedule. This is why plate from different mills with the same nominal grade can behave differently in welding, forming, or ballistic events. For deep technical guidance on heat treatment and tempering effects, consult ASM materials references.

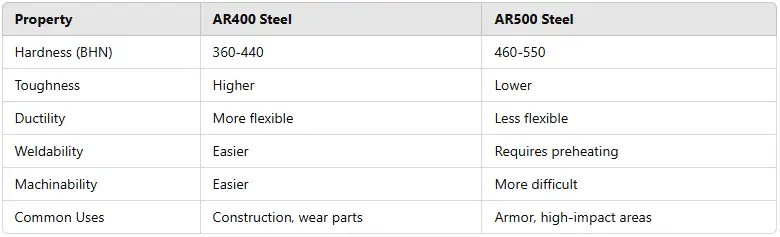

Side-by-side mechanical snapshot

| Property / attribute | AR400 (typical) | AR500 (typical) | Practical note |

|---|---|---|---|

| Nominal BHN | 400 (360–440) | 500 (460–540) | Measure BHN with ASTM E10 test. |

| Toughness / impact | Higher | Lower (more brittle) | AR400 resists impact better. |

| Abrasion resistance (sliding) | Good | Superior | AR500 wins on pure sliding wear. |

| Weldability | Easier | Harder; controlled procedure required | Preheat and low interpass heat essential on AR500. |

| Forming/bending | More forgiving | Limited; risk of cracking | Some mills sell “F” variants that are formable. |

| Typical uses | Buckets, hoppers, wear liners | Targets, armor, high-wear chutes | Choose by wear mode and impact. |

(If you need a downloadable spec sheet for procurement, request mill test reports (MTR) showing hardness map, tensile values, and heat-treatment notes.)

Typical applications — match the wear mode to the grade

-

AR400: ground-engaging components that see shock and impact — loader buckets, bucket teeth adapters, truck bodies, crusher mantles when impact is common. Good when on-site cutting, welding, or forming is expected.

-

AR500: sliding abrasion or severe wear where material abrades by sliding contact — armor plates, ballistic targets, ore chutes and liners that see rock-on-rock sliding, certain mining screens and feeder liners.

-

When both wear and impact appear: AR450 or laminated solutions may provide a compromise. Some OEMs use overlays (hardfacing) or composite constructions to get both performance and toughness.

Comparison Prices & notes (2025)

| Feature / Measure | AR400 (2025) | AR500 (2025) | Notes / Why it matters |

|---|---|---|---|

| Typical retail (small-qty) — common sheets (examples) | Retail listings vary; single smaller sheets often show mid-hundreds USD for common thicknesses (examples vary by vendor & size). | Retail single sheets commonly list from ~$350 up to $1,200+ per sheet for common shop cuts (example: 12×12 and 24×24 retail listings). | Retail (single-sheet) prices reflect machining/cut & shipping — good for prototyping or small runs. |

| Typical bulk / per-ton (FOB / manufacturer / China suppliers) | ~USD $600–$2,000 per metric tonne for branded vs. unbranded or different thicknesses; Chinese supplier quotes commonly show ~$700–$1,300/ton ranges depending on MOQ and thickness. | Bulk AR500 usually costs more than AR400 in like-for-like thickness/finish; Chinese export or bulk offers exist but price premium applies for higher hardness/processing. Alibaba/B2B quotes show large variability (depending on spec & MOQ). | Bulk pricing depends on MOQ, shipping terms, currency, tariffs and whether the plate is branded (e.g., Hardox) or a regional equivalent (NM/AR). |

| Representative retail example (3/8" ≈ 0.375") | Retail listings for AR400 vary by vendor and stock — check product pages for exact sizes. | Example retail vendor shows 3/8" AR500 24"×24" = $625 (vendor listing) and other sizes from ~$350 upward. | When quoting per-sheet, thickness & sheet size create wide price swings; heavier sheets ≈ higher absolute price. |

| Lowest reported (MOQ / industrial bulk) offers (examples) | Chinese/Asia supplier listings and factory quotes often show lower per-ton FOB numbers (good for large orders). Typical B2B listing ranges observed. | Similar pattern — AR500 bulk offers appear but include processing premium; very large tonnage orders may reduce per-ton cost materially. | Bulk FOB usually excludes freight, duty and value-added processing. |

| Typical price drivers | Thickness, hardness spec, branded vs generic (Hardox/NM vs AR), surface finish, quantity, delivery terms, regional steel cycle. | Same drivers as AR400 — plus higher heat-treatment/processing costs for AR500 (higher hardness specification). | Always ask vendors to quote thickness, cut size, heat-treatment spec, delivery incoterms. |

Short interpretation for buyers

-

If you need greater wear resistance and higher hardness, AR500 is usually worth the premium — expect higher retail per-sheet costs and a processing premium in bulk quotes.

-

If toughness & cost balance matter, AR400 often delivers the best cost/value — it’s typically cheaper per tonne and easier to weld/fabricate for many applications.

-

For prototypes or small orders, compare distributor single-sheet listings (Onlinemetals, DM Steel, MetalsDepot) for accurate per-sheet pricing.

-

For production & parts — request FOB per-ton quotes from multiple suppliers (include branded options like Hardox and Chinese equivalents NM/AR) and include shipping/taxes in total landed cost.

Fabrication & shop practice (cutting, bending, welding tips)

Cutting: plasma or waterjet typically used. Cut edges will show a heat-affected zone (HAZ) that can reduce local hardness; plan for grinding and QC.

Bending/forming: AR400 often allows limited bending; AR500 is far less forgiving. If bending is required, order a “formable” variant (some suppliers label AR400F, AR450F) or use pre-engineered bends.

Welding: both grades can be welded, but procedures differ.

-

Preheat and controlled interpass temperature recommended, especially for AR500.

-

Use matching or slightly lower hardness filler to avoid brittle welds.

-

Post-weld heat treatment is rarely feasible in the field, so best practice is to design welds to avoid brittle HAZ.

Practical shop recommendation: run trial welds and hardness profiles and document results in the job's MTRs.

Failure modes and real-world tradeoffs

Two primary failure modes for AR plate: abrasive wear and impact-induced cracking.

-

Abrasion: higher BHN reduces material loss rate during sliding wear. In long, sliding wear contacts, AR500 may last significantly longer.

-

Impact / fatigue: collisions and repetitive shocks produce cracks in harder, less ductile materials. AR400 resists this better and thus may survive longer in bucket teeth or impact-prone liners.

Edge effects: cut edges and holes concentrate stress. In AR500, plate edges can start small cracks if holes or bolt patterns are too close to the high-hardened face. Always follow supplier clearance recommendations.

Selection decision tree

-

What is the primary wear mode?

-

Sliding dominant → AR500;

-

Impact-dominant → AR400.

-

-

Do you need field forming/welding?

-

Yes → AR400 or formable variant;

-

No, shop-weld only with controlled procedures → AR500 possible.

-

-

Is weight critical? (harder plates sometimes permit thinner sections)

-

Yes → evaluate AR500 for thinner gauge replacement but check fatigue.

-

-

Can you do regular inspection and repair?

-

If frequent repairs expected, choose cheaper grade with easier repairs.

-

initial price × (expected service life) to compute cost-per-service-hour — a thinner AR500 plate that lasts longer might still be cheaper across the equipment life.

Short case studies

Case A: Dump body liner

Problem: rocks fall from height and slam into the body; occasional sliding wear.

Choice: AR400 — better toughness reduces cracking under point impacts and the ability to weld/repair on-site reduces downtime.

Case B: Ballistic target/steel plate range

Problem: repeated, high-velocity impacts and need for surface hardness to limit penetration and mushrooming.

Choice: AR500 — higher surface hardness resists penetration and extends target life. Note: ballistic applications have strict safety and certification needs; consult specialized ballistic plate vendors.

Case C: Ore chute with rock-on-rock sliding

Problem: abrasive sliding; low point impacts.

Choice: AR500 or layered solution with hardfacing; check cost-per-life.

Inspection, testing and what to request from suppliers

When purchasing, request and archive the following:

-

Mill Test Report (MTR) with heat-treatment notes.

-

Hardness map showing BHN across plate (ASTM E10 testing).

-

Tensile test results and Charpy impact where available (helpful when impact is expected).

-

Cutting/welding guidance from supplier (preheat, consumables, interpass temperatures).

-

Certifications: EN 10204/3.1(B) MTRs or equivalent, third-party NDT reports if needed.

If ballistic or safety-critical uses are involved, require third-party ballistic certification from the plate vendor.

Environmental, safety and handling notes

-

Ballistic caution: plates used for shooting targets can produce splatter and ricochet; only use AR500 from vendors specializing in ballistic targets if plates will be shot. Use qualified range designs.

-

Cutting fumes: plasma/oxy cutting of high-carbon AR steels can generate hazardous fumes; ensure ventilation.

-

Edge cracks: avoid bolt patterns near edges — use supplier-prescribed edge clearances.

-

Recycling: AR steels are recyclable but may be sold at different scrap premiums due to alloying elements.

Pricing and procurement tips

-

AR500 generally commands a premium vs AR400. However, thinner AR500 replacement may yield weight and lifecycle benefits.

-

Ask suppliers for cost-per-wear-hour case studies or field data. Real buyers often run a small pilot and log incremental downtime and replacement parts to validate ROI.

-

Avoid purchasing from vendors that cannot provide MTRs or hardness tests.

Frequently Asked Questions

-

Can I weld AR500 on-site?

Yes, but welding AR500 requires strict preheat/interpass control and proper consumables. Field welding without controls increases crack risk. If on-site welding is frequent, AR400 or a formable variant is often a better choice. -

Is AR500 bulletproof?

No plate is universally “bulletproof.” AR500 has superior resistance to penetration for some small arms at certain thicknesses, which is why it’s used in targets and some armor systems. Ballistic performance depends on thickness, projectile, velocity, and backing structure; do not assume any steel grade is safe without ballistic data from the vendor. -

What does “AR400F” mean?

The suffix “F” historically meant “formable.” Today some mills still sell “F” variants that are easier to bend without cracking. Always ask the mill for forming limits. -

Which grade is easiest to machine and cut?

AR400 is typically easier to machine, cut, and drill than AR500 due to lower hardness and higher toughness. Use carbide tooling and proper feeds for any AR plate. -

How is hardness checked on the delivered plate?

Brinell hardness testing per ASTM E10 is the common acceptance test; request hardness readings at multiple locations (edge and center). -

Can AR500 replace AR400 in all cases?

Not always. In impact-prone services, AR500’s higher brittleness can cause premature cracking, leading to shorter life despite greater surface hardness. Evaluate wear mode first. -

What is the effect of heat-affected zone (HAZ) near cuts and welds?

HAZ can soften or harden locally depending on thermal cycle; both effects can be detrimental. Control cutting/welding procedures and perform local hardness checks. -

Are any industry standards required for AR plate?

AR plate is typically sold to hardness bands rather than a single ASTM chemistry spec. However, hardness testing per ASTM E10 and standard plate tolerances per ASTM A6 are commonly referenced by suppliers. -

How long will AR500 last compared with AR400?

In sliding-wear environments AR500 can last multiple times longer; in impact environments AR400 can outlast AR500. Field trials usually give best answers for a given machine/system. -

What paperwork should I demand with delivery?

Mill Test Report (EN 10204/3.1 or equivalent), hardness map, tensile test report, and welding/handling guidance from the supplier. Third-party NDT for critical applications is recommended.