When selecting the right material for a given application, the choice between alloy steel, carbon steel, and stainless steel is crucial. These three types of steel alloys have distinct chemical compositions, mechanical properties, applications, and pricing trends that directly impact industries ranging from construction and manufacturing to aerospace and automotive. Understanding the differences between these materials is key for ensuring the success of any project.

Steel is one of the most widely used materials in the world, with its strength, versatility, and ability to be molded into different shapes making it ideal for various industries. Alloy steel, carbon steel, and stainless steel are some of the most common types of steel used in modern manufacturing. Each of these materials is designed for specific applications, driven by differences in their chemical composition and mechanical properties.

At first glance, alloy steel, carbon steel, and stainless steel may seem similar, but they are quite different in terms of performance and usage.

Definitions and Types of Steel

Alloy Steel

Alloy steel is a type of steel that contains specific amounts of other elements like chromium, nickel, vanadium, and molybdenum in addition to the primary iron-carbon component. These alloys are designed to enhance the steel's strength, hardness, corrosion resistance, and wear resistance. Alloy steels can be further categorized into low, medium, and high-alloy steels, depending on the amount and type of alloying elements.

Carbon Steel

Carbon steel, as the name suggests, is composed primarily of iron and carbon. The carbon content in carbon steel can range from 0.05% to 2%, which directly impacts the material’s hardness, strength, and ductility. Carbon steel can be further divided into low, medium, and high-carbon steels, each offering varying properties suited for different applications.

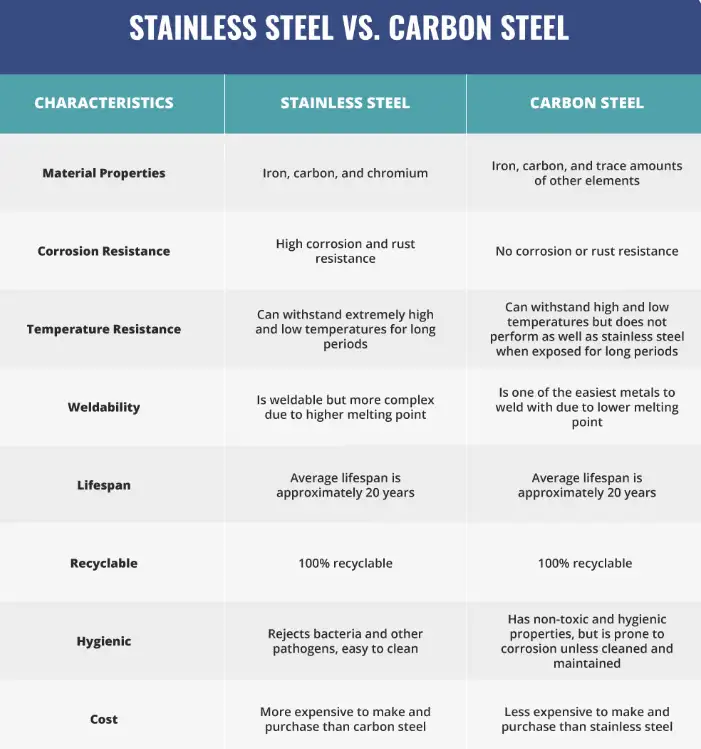

Stainless Steel

Stainless steel is a corrosion-resistant alloy containing at least 10.5% chromium by weight. This high chromium content provides stainless steel with its characteristic resistance to oxidation and corrosion. Stainless steel is commonly used in environments exposed to moisture and chemicals, making it ideal for applications in the food, chemical, and medical industries.

Chemical Composition Comparison

The table below summarizes the typical chemical compositions of alloy steel, carbon steel, and stainless steel:

| Element | Alloy Steel (Typical) | Carbon Steel (Typical) | Stainless Steel (Typical) |

|---|---|---|---|

| Iron (Fe) | 95% - 98% | 98% - 99% | 70% - 75% |

| Carbon (C) | 0.1% - 2.1% | 0.05% - 2% | <0.15% |

| Chromium (Cr) | 0.2% - 10% | <0.1% | 10.5% - 30% |

| Nickel (Ni) | 0.5% - 5% | <0.1% | 8% - 12% |

| Molybdenum (Mo) | 0.1% - 2% | <0.1% | 0.5% - 3% |

| Vanadium (V) | 0.1% - 1% | <0.1% | <0.1% |

Mechanical Properties Comparison

The mechanical properties of alloy steel, carbon steel, and stainless steel differ significantly. The following table compares their tensile strength, hardness, and ductility:

| Property | Alloy Steel | Carbon Steel | Stainless Steel |

|---|---|---|---|

| Tensile Strength | 600 - 2,000 MPa | 400 - 1,000 MPa | 500 - 1,500 MPa |

| Hardness | 200 - 800 HB | 120 - 300 HB | 150 - 300 HB |

| Ductility | 10% - 30% | 15% - 30% | 30% - 60% |

| Yield Strength | 350 - 1,800 MPa | 250 - 700 MPa | 300 - 1,200 MPa |

Note: MPa refers to megapascals, a unit of pressure used to measure tensile and yield strength.

Market Share and Trends

The global steel market has been experiencing steady growth, with alloy steel, carbon steel, and stainless steel playing important roles in the demand-supply equation. The market share of these materials varies by region and industry.

In 2025, carbon steel is expected to dominate the global steel market, accounting for about 70% of total steel production. Stainless steel follows closely with around 20%, while alloy steel holds a smaller share of approximately 10%. However, alloy steel is gaining popularity due to its superior properties in high-performance applications.

Future Trends

-

Carbon Steel: The demand for carbon steel is expected to remain strong due to its cost-effectiveness and wide range of applications in construction, automotive, and machinery manufacturing.

-

Stainless Steel: The growing emphasis on corrosion resistance and hygiene in industries like food processing and medical devices will fuel the demand for stainless steel.

-

Alloy Steel: As industries demand higher strength and durability for complex machinery, the use of alloy steel will continue to rise, especially in aerospace, automotive, and oil and gas sectors.

Global Market and Pricing Trends (2025 Comparison)

Below is a pricing comparison for alloy steel, carbon steel, and stainless steel in major global markets (2025):

| Material | Price per Ton (USD) | China | Europe | United States |

|---|---|---|---|---|

| Alloy Steel | $1,200 - $2,500 | $1,500 | $2,100 | $2,300 |

| Carbon Steel | $500 - $1,200 | $600 | $800 | $1,100 |

| Stainless Steel | $2,000 - $3,500 | $2,300 | $3,000 | $3,200 |

Applications and Industries

Each type of steel serves distinct roles depending on the required mechanical properties:

-

Alloy Steel: Used in high-stress applications such as aerospace components, heavy machinery, automotive parts, and oil and gas equipment.

-

Carbon Steel: Common in construction, pipelines, automotive, and general manufacturing due to its balance of strength and cost-effectiveness.

-

Stainless Steel: Ideal for environments requiring corrosion resistance, such as in medical devices, food processing, chemical industries, and kitchen equipment.

Common Grades and Standards

Each steel type follows international standards for quality and performance. Common grades include:

-

Alloy Steel: ASTM A234 (Pipes), ASTM A335 (Pipes), ASTM A182 (Flanges).

-

Stainless Steel: ASTM A276 (Bars), ASTM A312 (Pipes), ASTM A240 (Sheets).

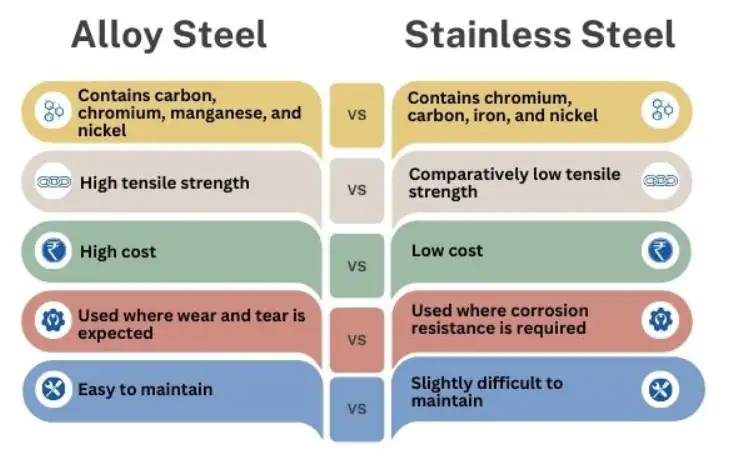

Differences between Alloy Steel, Carbon Steel, and Stainless Steel

The main differences lie in their composition, mechanical properties, and applications. Alloy steel offers superior strength and toughness, carbon steel is more cost-effective and versatile, while stainless steel is unparalleled in corrosion resistance.

Common Misconceptions

A common misconception is that all types of steel are interchangeable. However, choosing the wrong steel for the wrong application can lead to costly failures. For example, using carbon steel in a highly corrosive environment can result in rapid deterioration.

Purchasing Considerations

When sourcing steel, factors like price, mechanical properties, and available standards should guide purchasing decisions. It is essential to verify that the material meets industry-specific requirements and standards.

Conclusion

The choice between alloy steel, carbon steel, and stainless steel is dependent on the specific needs of the application. Each material has its advantages and drawbacks, and selecting the right one can impact the performance, longevity, and cost-effectiveness of the product. By understanding the chemical compositions, mechanical properties, and global market trends, companies can make more informed decisions and achieve better results.

FAQs

1. What is the difference between alloy steel, carbon steel, and stainless steel?

Alloy steel contains additional elements like chromium, nickel, and molybdenum for enhanced strength and resistance. Carbon steel has a higher carbon content, making it ideal for applications requiring strength but not corrosion resistance. Stainless steel, on the other hand, is highly resistant to corrosion due to its high chromium content and is used in industries like food processing, medical, and chemical sectors.

2. Which steel is the strongest: alloy steel, carbon steel, or stainless steel?

Alloy steel is typically the strongest, as it can be engineered with specific alloying elements to improve its tensile strength, hardness, and overall durability. Carbon steel also offers high strength but is less resistant to wear and corrosion. Stainless steel, while strong, is more focused on corrosion resistance and can be less durable in high-stress environments compared to alloy steel.

3. What are the applications of alloy steel, carbon steel, and stainless steel?

Alloy steel is commonly used in high-performance applications such as aerospace, automotive, and heavy machinery. Carbon steel is versatile and used in construction, manufacturing, and pipelines. Stainless steel is preferred in industries requiring corrosion resistance, such as food processing, medical equipment, and chemical manufacturing.

4. How does the carbon content affect the properties of steel?

The carbon content in steel directly affects its hardness, strength, and ductility. Higher carbon content increases strength and hardness but reduces ductility, making the steel more brittle. Low-carbon steel is more ductile and malleable but less strong than high-carbon steel.

5. Why is stainless steel more expensive than carbon steel and alloy steel?

Stainless steel is more expensive due to its higher chromium content, which provides corrosion resistance but also increases the cost of production. The cost of raw materials, processing, and the specialized manufacturing techniques involved in producing stainless steel further contribute to its higher price compared to carbon and alloy steels.

6. What are the most common grades of alloy steel, carbon steel, and stainless steel?

Common grades for alloy steel include ASTM A234 and ASTM A335. For carbon steel, popular grades are ASTM A36 and ASTM A106. In stainless steel, ASTM A276 (bars), ASTM A312 (pipes), and ASTM A240 (sheets) are frequently used. Each grade has different characteristics tailored to specific industrial applications.

7. What industries benefit most from using stainless steel?

Industries that require materials resistant to rust, oxidation, and corrosion benefit the most from using stainless steel. These include the food and beverage industry, medical equipment manufacturing, pharmaceutical production, and chemical processing industries.

8. How does alloy steel differ in terms of mechanical properties compared to carbon steel and stainless steel?

Alloy steel generally has superior mechanical properties, such as higher tensile strength and wear resistance, due to the presence of alloying elements. Carbon steel offers lower tensile strength but is more cost-effective and versatile for general construction and machinery. Stainless steel excels in corrosion resistance but tends to have lower strength and hardness compared to alloy steel.

9. What are the current pricing trends for alloy steel, carbon steel, and stainless steel in 2025?

As of 2025, the price of alloy steel is expected to range from $1,200 to $2,500 per ton, carbon steel from $500 to $1,200 per ton, and stainless steel from $2,000 to $3,500 per ton. These prices can vary based on region, raw material availability, and market demand, with alloy steel generally being the most expensive.

10. What standards should be considered when purchasing alloy steel, carbon steel, or stainless steel?

When purchasing steel, it's important to consider the relevant industry standards such as ASTM, ISO, and EN. For alloy steel, look for ASTM A234 and ASTM A335. For carbon steel, check ASTM A36 and ASTM A106. Stainless steel should comply with ASTM A240 and ASTM A312 standards. Ensuring compliance with these standards ensures product quality and consistency across different suppliers.