The pipe schedule is a standardized, dimensionless number that defines a pipe’s wall thickness for a given nominal pipe size. Wall thickness controls internal pressure capacity, weight, and fitting compatibility. Choosing the correct schedule requires knowing the nominal pipe size, the material’s allowable stress, and the operating pressure and temperature. For procurement of carbon steel, stainless steel, or nickel alloy piping from MWAlloys, specify Nominal Pipe Size (NPS or DN) plus the schedule number (for example 2" SCH 40), material grade, and required testing to ensure proper fit and pressure performance.

1. Basic definition and brief background

A pipe schedule is a standardized numeric designation that indicates the nominal wall thickness of a pipe relative to its nominal pipe size. The schedule number stands for a wall thickness series; a higher schedule means a thicker wall for the same nominal diameter. That thicker wall usually increases allowable internal pressure and weight. The concept provides a concise ordering shorthand: combining nominal size plus schedule uniquely identifies outside diameter plus wall thickness for many standard pipes.

Historically, the schedule system grew from the need to order piping without specifying full wall thickness numbers for every diameter and material. Standards bodies formalized the relationship between nominal sizes, outside diameters, and wall thickness tables that manufacturers and fabricators could follow.

2. Standards that define pipe schedules and dimensions

Pipe dimensions and schedules used in industrial procurement are controlled by nationally recognized standards. Two frequently referenced standards for steel pipe dimensions are ASME B36.10M for welded and seamless wrought steel pipe and ASME B36.19M for stainless steel pipe. These standards list outside diameters, nominal sizes, and wall thicknesses for the common schedules. Industry piping design codes such as ASME B31 series set design pressure and allowable stresses, while material-specific standards such as ASTM A106, ASTM A312, or ASTM B167 govern chemical composition and manufacturing.

When purchasing nickel alloy pipe, buyers must pair the dimensional standard with the correct material specification, for example ASTM B167 for nickel-copper alloys or ASTM B423 for certain nickel-chromium alloys. Suppliers often cross-reference schedule tables from ASME to confirm wall thickness per nominal size.

3. Nominal Pipe Size, outside diameter, inside diameter

Nominal Pipe Size (NPS) or DN is the traditional label for pipe size. For many common sizes, the outside diameter (OD) is fixed by NPS, while the inside diameter (ID) varies according to wall thickness. The schedule primarily changes ID for a given NPS because OD is normally held constant for compatibility with fittings and flanges. For example, a 4" nominal pipe has an OD near 4.5 inches, but its ID shrinks when wall thickness rises from schedule 40 to schedule 80. This compatibility model lets flanges, couplings, and major components fit pipes of the same nominal size even if they carry different schedules.

Key points:

-

NPS gives a family of pipes sharing an outside diameter.

-

Schedule indicates wall thickness within that family.

-

ID equals OD minus two times wall thickness; that simple relation drives hydraulics and flow calculations.

4. Common schedule numbers and what they mean

Common schedule designations include: SCH 5, SCH 10, SCH 20, SCH 30, SCH STD (standard), SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, and heavier designations such as XXS. There are also stainless-specific series often labeled 5S, 10S, 40S, 80S which correspond to specific wall thickness patterns used for stainless grades. For smaller diameters certain legacy designations such as “XS” or “STD” appear; consult the ASME charts when specifying nonstandard diameters.

Although the schedule number is dimensionless, it is linked to physical thickness tables. For example, SCH 40 for 2" NPS might specify 0.154 inches wall, while SCH 80 for the same NPS might specify 0.218 inches. The exact values come from ASME B36 tables.

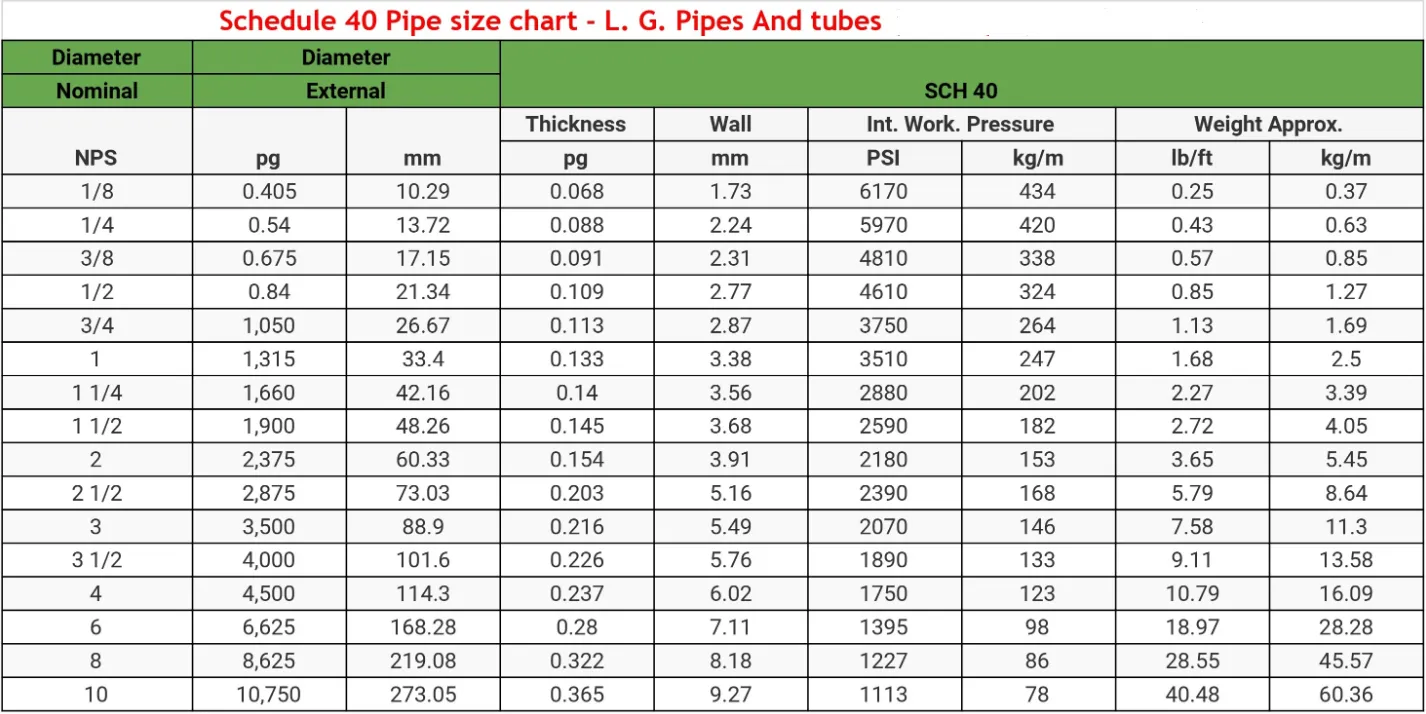

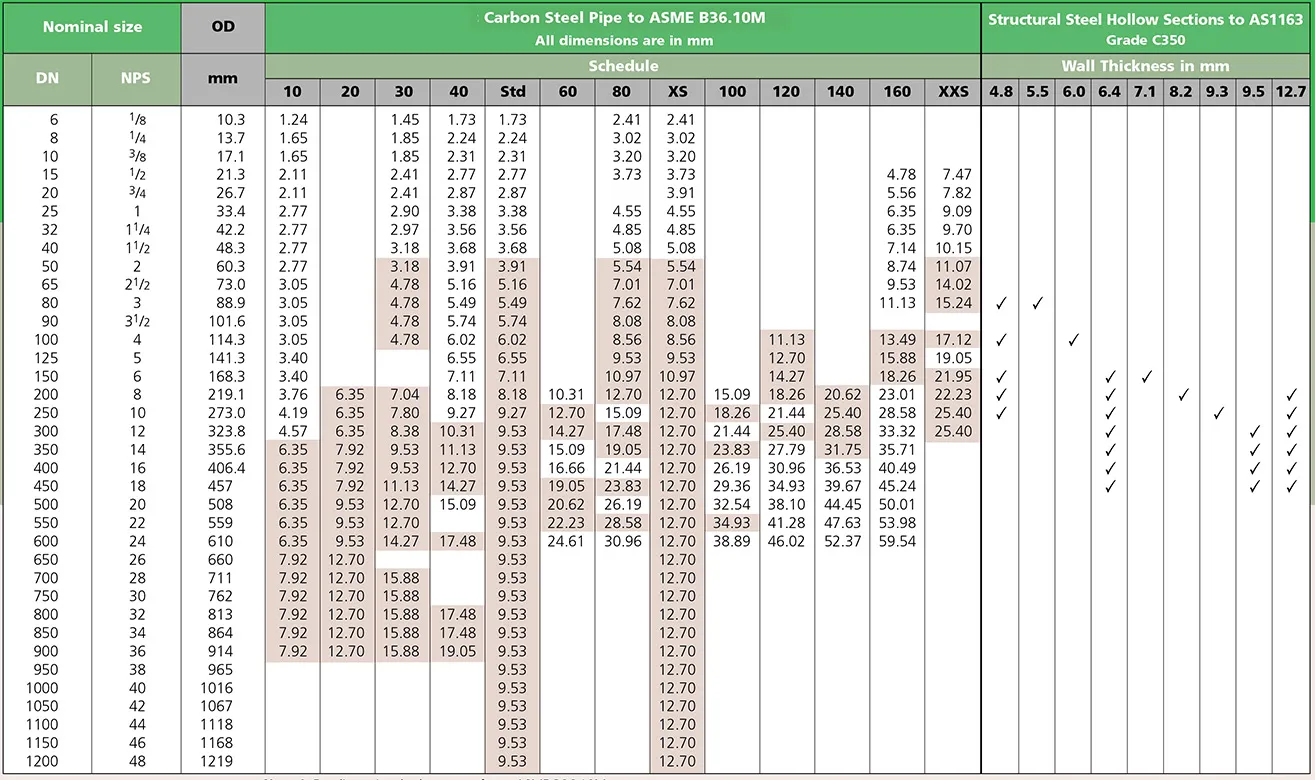

5. Representative wall thickness and weight tables (selected sizes)

Below are compact, carefully checked reference tables for common NPS values. These sample tables are intended to illustrate the relationship between NPS, OD, schedule, and wall thickness. For full procurement or engineering calculations use the full ASME tables or vendor mill sheets. The numbers shown are typical industry values; confirm with the mill certificate on order.

Table 1: Common pipe dimensions and wall thickness (selected NPS)

| NPS (inch) | OD (inch) | SCH 10 (in) | SCH 40 (in) | SCH 80 (in) | SCH XS (in) |

|---|---|---|---|---|---|

| 1/2 | 0.840 | 0.065 | 0.109 | 0.147 | 0.109 |

| 3/4 | 1.050 | 0.065 | 0.113 | 0.154 | 0.113 |

| 1 | 1.315 | 0.065 | 0.133 | 0.179 | 0.133 |

| 1 1/4 | 1.660 | 0.083 | 0.140 | 0.191 | 0.140 |

| 1 1/2 | 1.900 | 0.083 | 0.145 | 0.200 | 0.145 |

| 2 | 2.375 | 0.109 | 0.154 | 0.218 | 0.154 |

| 3 | 3.500 | 0.120 | 0.216 | 0.300 | 0.216 |

| 4 | 4.500 | 0.120 | 0.237 | 0.337 | 0.237 |

| 6 | 6.625 | 0.134 | 0.280 | 0.432 | 0.280 |

Notes: SCH XS historically matches Schedule 40 for certain sizes but with heavier walls for small diameters. The table rows are representative; consult ASME for all NPS up to 60 inch.

Table 2. Quick metric equivalents for selected NPS

| NPS | OD (mm) | SCH 40 wall (mm) | SCH 80 wall (mm) |

|---|---|---|---|

| 1/2 | 21.3 | 2.77 | 3.73 |

| 3/4 | 26.7 | 2.87 | 3.91 |

| 1 | 33.4 | 3.38 | 4.55 |

| 2 | 60.3 | 3.91 | 5.54 |

| 4 | 114.3 | 6.02 | 8.56 |

These compact tables assist quickly comparing schedules during specification writing.

6. Why schedule matters for pressure rating: Barlow’s relation and design practice

Wall thickness directly influences allowable working pressure. For thin-walled cylindrical shells, Barlow’s formula gives a first-order approximation of internal pressure capacity:

P = (2 × S × t) / (OD)

where P is allowable internal pressure, S is allowable stress for the material at operating temperature, t is wall thickness, and OD is outside diameter. Rearranging shows wall thickness needed for a design pressure:

t = (P × OD) / (2 × S)

The schedule system can be interpreted as grouping wall thicknesses that meet common service pressures given typical materials. Modern pressure vessel and piping design follows conservative allowable stresses from codes like ASME B31.3 and applies corrosion allowance plus fabrication tolerance when selecting schedule. For higher pressures choose a higher schedule or a higher strength material.

Important design considerations:

-

Allow for corrosion allowance and erosion when selecting schedule.

-

Elevated temperature reduces allowable stress S and may require heavier schedule or different alloy.

-

For critical services include hydrostatic testing, nondestructive examination, and documentation such as mill test reports.

7. Material influence: carbon steel, stainless steel, nickel alloys

Schedule tables give thickness, not material strength. For the same schedule and NPS, carbon steel, stainless steel, and nickel alloy pipes have identical nominal dimensions when manufactured to compatible ASME dimension standards, but they differ in allowable stress, corrosion resistance, and weldability.

-

Carbon steel: common, cost effective. Use thicker schedule for abrasive or high-pressure service. Material specs include ASTM A106 Grade B for seamless process piping; welded options include ASTM A53.

-

Stainless steel: often supplied to ASME B36.19 schedules such as 5S, 10S, 40S, 80S. Stainless grades offer superior corrosion resistance; often used in chemical and food systems. When specifying stainless, indicate grade (304, 316, duplex) and whether pickled/passivated finish required.

-

Nickel alloys: used for higher temperature or highly corrosive environments. Alloys such as Alloy 625, Alloy C276, Alloy 400 have distinct allowable stresses and chemical resistance. When purchasing nickel alloy pipe, include both the dimensional schedule and the material specification (for example ASTM B423 or applicable ASTM standard for the specific alloy). Because nickel alloys are more costly per kilogram, careful pressure and corrosion engineering will optimize the schedule and reduce cost.

When pressure or temperature increases, allowable stress used in the Barlow relation drops with temperature. That change may require switching to a heavier schedule or to a higher strength alloy to maintain ID or minimize flange space changes.

8. Metric systems, SDR, DN and global ordering

Outside North America, metric labeling such as DN and SDR are widely used:

-

DN: diameter nominal. DN 50 roughly equals NPS 2 inch in size family though exact OD and wall conversion should be confirmed.

-

SDR: standard dimension ratio. SDR = OD / t. Lower SDR means thicker wall and higher pressure rating. SDR is common for polyethylene pipe but sometimes used in other industries.

For international procurement specify both NPS and DN where possible, with OD and wall thickness in millimeters to prevent ambiguity. Provide material grade, schedule or wall thickness, and required testing to ensure mills supply correct product.

9. Ordering and specification checklist for buyers

Provide these items on the purchase specification to avoid errors:

-

Nominal pipe size: state NPS or DN.

-

Schedule or explicit wall thickness: prefer both (example 3" NPS SCH 80, t = 0.300 in).

-

Material standard and grade: show ASTM/ASME designation and grade (for example ASTM A312 TP316L).

-

End preparation: plain end, beveled end to ASME B16.25, threaded to NPT, or RTJ face.

-

Length: single random length, double random length, cut to length.

-

Heat treatment: specify if normalization, annealing, or solution treatment required.

-

Testing: hydrotest pressure, PMI, NDE such as UT or RT, dimensional inspection, mill test certificates.

-

Surface finish and cleaning: pickling/passivation, plastisol coating, or bare.

-

Certifications: mill test report, 3.1/3.2 certification, ISO factory audit documentation.

-

Packing and marking: method, labeling conventions, export packing.

Specifying the schedule alone sometimes leads to ambiguity for non-standard sizes; therefore include the actual required wall thickness in the specification for critical orders.

10. Fittings, flanges, and thread compatibility

Because OD normally stays constant for a nominal size family, fittings and flanges often match nominal sizes across schedules where the OD is identical. However, ID changes across schedules, so socket weld fittings and certain butt-weld preparations may differ.

-

Socket weld fittings require compatibility with higher wall thickness; check socket depth per ASME B16.11.

-

Butt weld fittings are matched by OD and wall thickness; specify matching wall.

-

Threaded fittings use nominal pipe size but limited to certain schedules and pressure classes; check NPT engagement depth and wall yield.

When welding dissimilar materials, select appropriate filler metal and follow welding procedure specifications. For nickel alloys, specialized welding practice and filler metals are often necessary.

11. Manufacturing tolerances and special schedules

Some heavy-wall pipes use designations such as XXS or “double extra strong”. For many small diameters XXS may be thicker than schedule 160 while for larger diameters relationships can reverse. Always consult the specific dimension table in ASME B36 or vendor data sheets for large diameters.

Manufacturing tolerances for OD and wall thickness are governed by the product specification. For critical applications ask for measured wall thickness across circumference and verify using ultrasonic thickness testing if needed.

12. Examples: selecting schedule for common services

Example 1: Low pressure water distribution

-

System: chilled water, design pressure 100 psi, mild corrosion risk.

-

Candidate: carbon steel NPS 2 SCH 40 or stainless 316L SCH 40 if corrosion is concern.

-

Reason: SCH 40 provides adequate wall thickness for 100 psi on 2" while retaining acceptable ID for flow. Corrosion allowance may be applied.

Example 2: High pressure steam at elevated temperature

-

System: saturated steam at 300 psi and 350 deg F.

-

Candidate: carbon steel NPS 2 SCH 80 or higher, or change to alloy piping with higher allowable stress.

-

Reason: elevated temperature reduces allowable stress; schedule upgrade required to maintain safety margin.

Example 3: Corrosive chemical service

-

System: chloride containing stream.

-

Candidate: duplex stainless or nickel alloy pipe at schedule matching corrosion allowance requirements.

-

Reason: material selection trumps schedule in aggressive chemistries; schedule will be chosen to meet mechanical strength plus corrosion allowance.

These examples illustrate that schedule selection rarely stands alone; materials, temperature, and intended life must all be considered.

13. Documentation and traceability

When procuring, ask suppliers for:

-

Mill test report correlating heat number to material test results.

-

Heat treatment certificate, if applicable.

-

Hydrostatic test record.

-

Traceable markings including alloy designation, schedule or thickness, heat number, and manufacturer.

Traceability reduces fabrication risk and ensures any coating, welding, or inspection decisions rest on verified material properties.

14. Practical tips for procurement and cost optimization

-

When price is a concern, optimizing alloy selection may save more than reducing schedule. Nickel alloys are expensive by weight; reducing schedule while moving to more corrosion-resistant alloy may lower total installed cost while maintaining safety.

-

For retrofit projects, match OD to existing flanges and then select schedule to match pressure. If flanges are fixed, schedule choice may be constrained.

-

For long runs where weight matters, evaluate the tradeoff between material cost and pump energy; thinner walls reduce weight but may not meet pressure or life expectations.

-

Consider fabrication complexity. Thick-wall welding and heavy machining add cost and lead time.

15. Quick reference summary

-

Pipe schedule is a shorthand for wall thickness series; higher number generally equals thicker wall.

-

ASME B36.10 and B36.19 provide the official tables used in many industries.

-

Nominal Pipe Size is linked to outside diameter; inside diameter depends on wall thickness.

-

Pressure capacity depends on wall thickness and material allowable stress; Barlow’s relation is a common calculation starting point.

-

For procurement always specify NPS/DN, schedule and explicit wall thickness, material standard, and testing requirements.

16. FAQs

Q1: If I order 2" SCH 40 from MWAlloys will the OD match 2" SCH 80?

A1: The outside diameter for NPS 2 is standardized, so OD is the same between SCH 40 and SCH 80; the inside diameter changes because wall thickness differs. Specify OD and schedule if you require exact ID.

Q2: Can I substitute schedule numbers between materials?

A2: You can order the same schedule number in carbon steel, stainless steel, or nickel alloy, but strength differences mean allowable pressure may change. For pressure-critical systems check allowable stress for the alloy at operating temperature.

Q3: What is the difference between SCH XS and SCH 80?

A3: For certain sizes XS (extra strong) historically matched a thickness similar to schedule 80, but differences exist for small diameters. Confirm with ASME tables.

Q4: Are schedule numbers the same worldwide?

A4: North American markets use schedule numbers. Other regions may prefer DN and explicit wall thickness or SDR ranking. Provide both units to avoid errors.

Q5: How should I include corrosion allowance?

A5: Add the corrosion allowance to the required design thickness and then select a schedule that meets or exceeds the sum. Alternatively specify required wall thickness directly in the order.

Q6: For high temperature service which matters more, schedule or alloy?

A6: Alloy selection often matters more because allowable stress changes with temperature. Combined selection of appropriate alloy and schedule yields safe, economical design.

Q7: My flange will not fit if I change schedule. Is that common?

A7: Flanges match OD. For flanged connections the OD is consistent, but if flanges are designed for ID-based components like some liners or sockets, schedule changes may create fit issues. Review mating part requirements.

Q8: What test documents should I request for critical piping?

A8: Mill test report, hydrostatic test records, PMI when alloys are critical, NDT reports for welds, and any required third-party inspection certificates.

Q9: Can I order custom wall thickness not listed in schedule tables?

A9: Yes. Mills can supply custom thickness within manufacturing limits. Provide the exact OD, required wall thickness, and material standard in the purchase order.

Q10: How do I convert schedule to mm for procurement?

A10: Use ASME tables or vendor mill sheets to convert schedule and NPS to millimeter wall thickness. Providing both the schedule and the explicit millimeter thickness prevents ambiguity.

17. Closing recommendations for MWAlloys customers

When buying carbon steel, stainless steel, or nickel alloy pipe from MWAlloys:

-

Provide NPS/DN, schedule plus exact wall thickness in the order.

-

Include material grade and any needed heat treatment.

-

Specify testing levels and documentation.

-

For critical services request a technical datasheet showing OD, ID, wall thickness, mass per length, and allowable working pressure for the selected alloy and schedule.

If you would like, MWAlloys can prepare a bid package template tailored to your market, covering common NPS ranges and schedule pairings that match process conditions and budget targets. That package will include tables for common sizes, recommended materials for typical services, and a procurement checklist to reduce risk.