“Schedule 80” describes a pipe wall-thickness classification (a “schedule”) used across metal and plastic piping systems; schedule 80 pipes have thicker walls and therefore smaller internal bores and higher pressure/impact resistance than the same nominal size in schedule 40. The schedule number itself does not change the outside diameter for a given nominal pipe size — it only increases wall thickness and weight. Choose Schedule 80 when higher pressure, mechanical protection, or extra safety margin is required, and confirm selection against the relevant standards (ASME/ANSI B36.10/B36.19 for metallic pipe; ASTM and manufacturer catalogs for PVC/CPVC).

What “pipe schedule” means

“Pipe schedule” is a numeric shorthand that represents one axis of the standardization of pipe geometry — specifically nominal wall thickness for a given nominal pipe size (NPS). For a fixed nominal size (for example, “2-inch NPS”), the outside diameter (OD) is constant across schedules in common practice; the schedule number (40, 80, 160, etc.) tells you the wall thickness, which directly controls internal bore (ID), weight per length and pressure capability. Higher schedule → thicker wall → higher allowable working pressure (other factors constant). This is codified in ASME/ANSI pipe dimension tables and in material-specific standards.

What Schedule 80 specifically denotes

-

In common North American practice, Schedule 80 (sometimes written “Sch. 80” or “SCH 80”) designates a relatively heavy wall thickness widely available in carbon steel, stainless steel, and thermoplastic (PVC/CPVC) piping ranges.

-

For steel piping, ASME/ANSI tables show the nominal outside diameter for each NPS and a schedule-dependent wall thickness: the schedule 80 wall is thicker than schedule 40 (and identical to “Extra-Strong” for some small sizes by historical standards).

Standards and where to look for authoritative numbers

Key standards and authoritative sources to consult when specifying Schedule 80:

-

ASME B36.10M / B36.19M — Welded and seamless wrought steel and stainless steel pipe dimensions (schedules & wall thickness tables).

-

ASTM D1785 — PVC pipe (schedules, material grade, dimensions) — commonly referenced by manufacturers for Schedule 40/80 PVC. (Manufacturer catalogs will also quote ASTM references.)

-

Manufacturer technical catalogs (Charlotte Pipe, Spears, Wavin, etc.) publish pressure ratings, temperature derating and fitting dimensions for Schedule 80 thermoplastics.

Always specify both the material standard and the dimension standard in procurement documents (e.g., “ASTM A53 Grade B, in accordance with ASME B36.10M, Schedule 80, plain end” for carbon steel pipe).

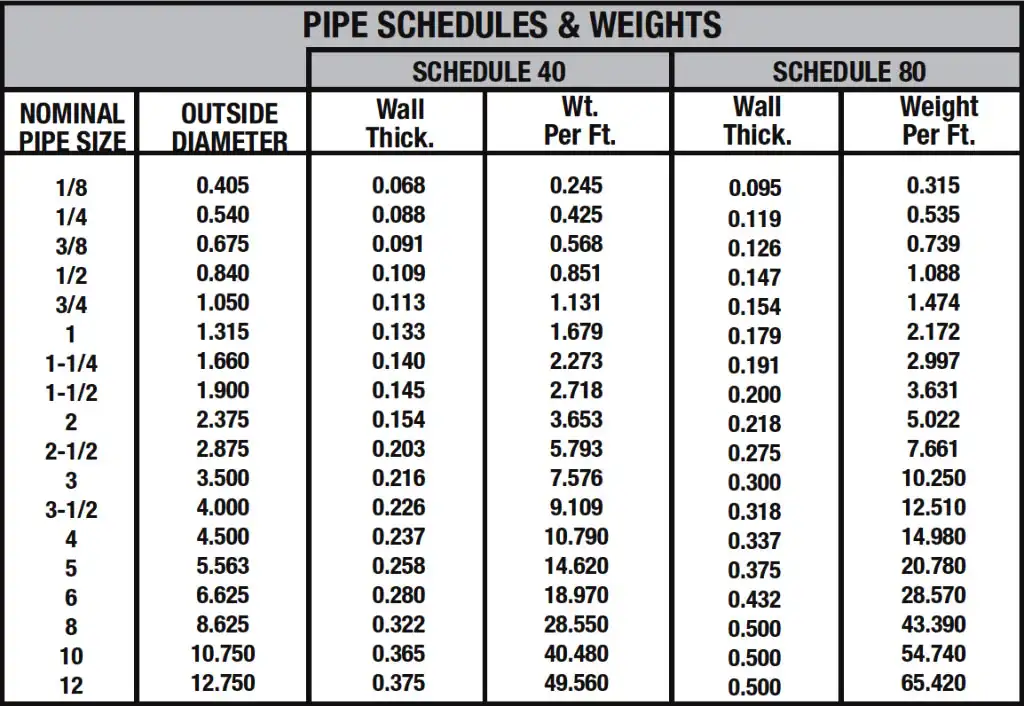

How schedule affects geometry (OD stays constant; ID falls)

Important geometric rules:

-

Outside Diameter (OD): For a given NPS (nominal pipe size), OD is fixed (per ASME tables), independent of schedule (except for some very large sizes and historical exceptions).

-

Wall thickness (t): Increases with schedule number. Schedule 80 wall thickness > Schedule 40.

-

Inside Diameter (ID): ID = OD − 2×t. Therefore, higher schedule → smaller ID → reduced flow area for the same NPS.

-

Weight per unit length: rises with wall thickness.

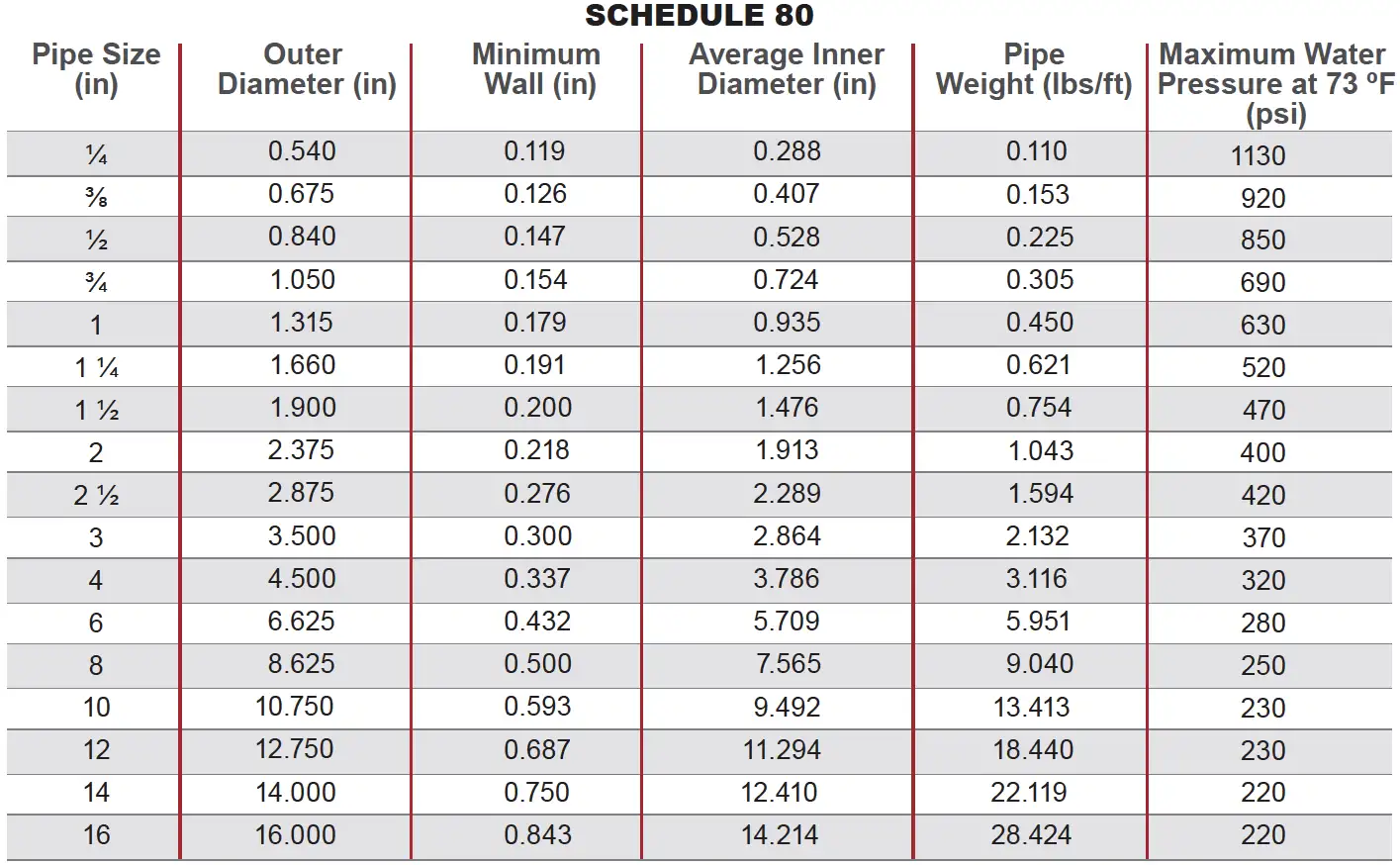

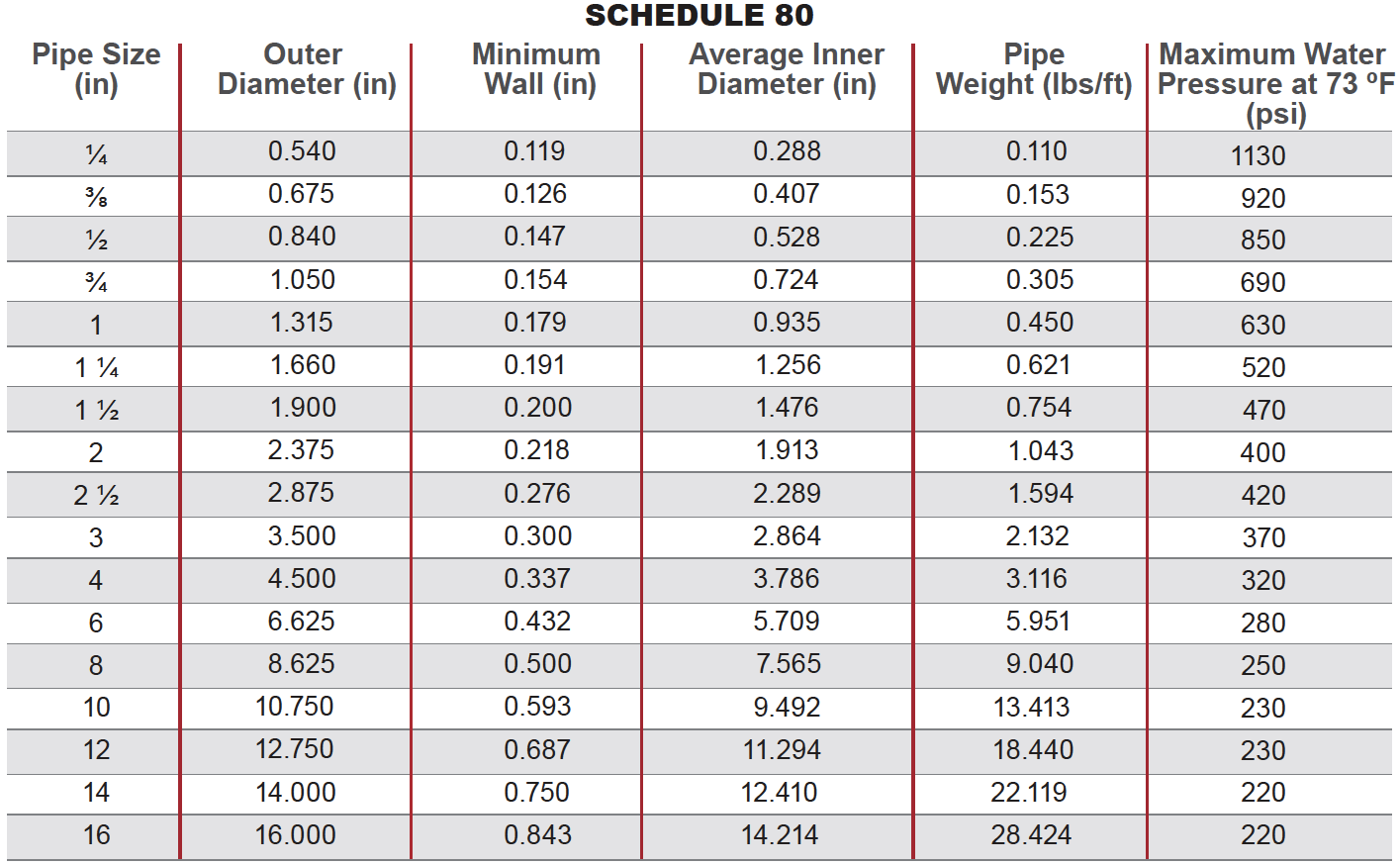

Example (selected NPS sizes, nominal values for quick comparison)

Notes: values below are nominal examples derived from ASME/ANSI tables and common manufacturer charts; use the standard table for project-level calculations.

| Nominal Pipe Size (NPS) | Outside Diameter (in) | SCH 40 wall (in) | SCH 40 ID (in) | SCH 80 wall (in) | SCH 80 ID (in) |

|---|---|---|---|---|---|

| 1/2" | 0.840 | 0.109 | 0.622 | 0.147 | 0.546 |

| 1" | 1.315 | 0.133 | 1.049 | 0.179 | 0.957 |

| 2" | 2.375 | 0.154 | 2.067 | 0.218 | 1.939 |

| 4" | 4.500 | 0.237 | 4.026 | 0.337 | 3.826 |

(Source: ASME/ANSI dimension tables and manufacturer data sheets.)

Materials commonly offered in Schedule 80

Schedule 80 is a designation used across multiple materials. The common ones:

-

Carbon steel (ASTM A53, A106, A333, etc.) — used in industrial piping for water, steam, oil, gas; available in seamless and welded forms. Dimensioned per ASME B36.10M.

-

Stainless steel (ASTM A312, etc.) — for corrosive or sanitary services; dimensions often in ASME B36.19M.

-

PVC / CPVC (plastic) — thermoplastic schedule 80 commonly sold in grey (vs white for schedule 40) and used for higher-pressure, mechanical or UV-exposed applications; see ASTM D1785 and manufacturer catalogs for pressure/temperature limits.

-

Other alloys (Duplex, Alloy steels) — available to order or fabricated to custom thicknesses in some markets.

Important: “Schedule 80” for thermoplastic is a common commercial designation with manufacturer-published pressure ratings; do not assume the same temperature/pressure performance as metallic schedule 80 without checking manufacturer data.

Pressure ratings, temperature derating and safety factors

-

For metallic pipe: Allowable working pressure is a function of material strength (yield/tensile), temperature, wall thickness and joint efficiency; schedule table alone doesn’t give a single “psi” value — you must use piping codes (ASME B31.1 / B31.3) and the material’s allowable stress at operating temperature to calculate design pressure. ASME dimension tables do provide a “maximum allowable working pressure” in many manufacturer datasheets but this must be reconciled with code calculations.

-

For PVC / CPVC: Manufacturer catalogs (Spears, Charlotte Pipe, Wavin) list pressure ratings for Schedule 80 at a reference temperature (typically 73°F/23°C). Ratings fall with temperature; PVC commonly has service temperature limits (e.g., 140°F maximum) and explicit derating tables. Never use PVC schedule 80 for compressed air/gas or high-temperature steam.

Quick example (PVC Schedule 80 typical data)

Manufacturer data often lists numbers like “2-inch Schedule 80 PVC – pressure rating 400–600 psi at 73°F for some product families,” then shows de-rating factors for higher temperatures. Always quote the manufacturer and operating temp when specifying.

Where Schedule 80 is chosen (typical applications)

Choose Schedule 80 when the job demands:

-

Elevated internal pressure compared with schedule 40 for the same nominal bore

-

Mechanical protection (e.g., exposed conduit or outdoor conduits where impacts are possible — schedule 80 PVC is thicker and tougher)

-

Corrosion allowance or piping that may face erosion/cavitation (thicker walls give longer life)

-

Small-bore hydraulic systems or systems with high working pressures where a smaller bore with thicker wall is preferable to moving to a larger NPS

-

Applications requiring extra margin per code or client spec (e.g., critical services, chemical processing, some industrial water systems)

When not to choose it: when interior space/pipe weight or flow capacity is the primary driver and schedule 40 suffices; or where plumbing fittings availability is an issue (some fittings/fusion methods differ by schedule).

Joining, fittings and installation notes

-

Metal pipe: schedule 80 steel is joined by welding (butt weld, socket weld for smaller sizes), flanges, or threaded connections; for threaded connections ensure thread engagement accounts for reduced bore. For high-pressure systems, use welded or flanged joints per code.

-

Thermoplastic (PVC/CPVC): Schedule 80 parts have specific fitting dimensions (tapered socket, male/female NPT adapters etc.). Manufacturer catalogs publish the correct taper and insertion depths. Use recommended solvent cement or mechanical fittings; never pressure-test thermoplastic with compressed air.

-

Threading: If threaded connections are used, schedule 80 threaded fittings are usually recommended for PVC because the thicker wall provides enough engagement; many manufacturers explicitly recommend Schedule 80 only for threaded plastic pipe.

Corrosion, inspection and expected service life

-

Metal pipe corrosion: thicker walls provide longer time-to-failure for uniform corrosion but do not prevent localized corrosion (pitting, crevice, galvanic). If corrosion allowance is required by code, select material+schedule to meet remaining life targets. Use coatings, cathodic protection, or stainless alloys where appropriate.

-

Inspection: schedule 80 piping in critical services should be included in routine NDT and monitoring — thickness gauging, ultrasonic testing, and leak checks. For thermoplastics, inspect for UV degradation, cracking, brittle fracture, and solvent cement integrity.

-

Failure modes: wall thinning (erosion/corrosion), mechanical impact/crack propagation, failure at joints. Thicker walls improve robustness but regular inspection is required.

Purchasing language and specification checklist

When you place an order or include a spec, use precise language. Example clause for carbon steel pipe:

“Carbon steel pipe, ASTM A53 Grade B, seamless, nominal pipe size 2-inch NPS, Schedule 80, plain end; dimensions per ASME B36.10M; hydrostatic test at [X] psi; include mill test certificates (MTRs) and material traceability.”

For thermoplastics:

“PVC Schedule 80, ASTM D1785, SDR/TYPE [if applicable], socket or plain end, pressure rating [X psi] at 73°F per manufacturer datasheet.”

Ask suppliers for: mill test reports, dimensional certs, handling/installation instructions, warranty/temperature derating table, and fitting compatibility statements.

Quick decision matrix (table)

| Factor | Schedule 40 | Schedule 80 | Recommendation |

|---|---|---|---|

| Wall thickness | thinner | thicker | Use 80 for higher pressure/mechanical protection |

| Internal bore | larger | smaller | If flow is priority, consider larger NPS instead of 80 |

| Weight / cost | lower | higher | 80 costs more—justify by pressure/longevity needs |

| Thermoplastic threading | less recommended | recommended | 80 preferred for threaded PVC |

| Corrosion allowance | less | more | 80 gives longer time to failure for uniform corrosion |

Worked examples and quick calculations

Bore impact (2-inch NPS): OD = 2.375 in. SCH40 t ≈ 0.154 in → ID ≈ 2.375 − 2×0.154 = 2.067 in. SCH80 t ≈ 0.218 in → ID ≈ 1.939 in. Flow area difference:

-

SCH40 area = π×(2.067/2)² ≈ 3.357 in²

-

SCH80 area = π×(1.939/2)² ≈ 2.955 in²

This is ~12% reduction in flow area at the same nominal size; evaluate pump head and velocities when changing schedule.

Weight example (qualitative): thicker walls increase mass per foot; industrial tables give lb/ft for each schedule and size — use those tables for structural support design.

(Tables and friction/flow calculations should be done with the exact ASME/pipe manufacturer tables for engineering design.)

Common pitfalls and practical tips

-

Don’t assume schedule = pressure rating; for metal pipes you must perform code calculations and for plastics rely on manufacturer pressure tables (temperature dependent).

-

If interior flow is critical, either upsize NPS or use schedule 40 to preserve ID rather than keeping NPS and moving to schedule 80.

-

Verify fitting compatibility (fittings and valves are often schedule-specific).

-

For threaded plastic, prefer schedule 80 due to thicker walls and better thread engagement.

FAQs

-

Q: Is Schedule 80 thicker than Schedule 40?

A: Yes; Schedule 80 has greater wall thickness than Schedule 40 for the same NPS, therefore smaller ID and higher mass. -

Q: Does schedule change the outside diameter?

A: No; for standard pipe sizes, OD remains the same and wall thickness changes. See ASME B36.10/B36.19 for exceptions. -

Q: Can I replace a Schedule 80 pipe with Schedule 40 of a larger nominal size?

A: Possibly — you must check pressure class, flow, structural supports, and fittings. Often upsizing NPS is used to regain ID lost to thicker walls. -

Q: Are schedule numbers the same for steel and PVC?

A: The numeric schedule uses the same convention, but mechanical and thermal behavior differ by material; always consult material standards and manufacturer data (ASTM/ASME and vendors). -

Q: Is Schedule 80 required for high-pressure service?

A: It can be appropriate; for code compliance use piping code calculations (ASME B31 series) rather than schedule alone. -

Q: Are fittings for SCH 80 interchangeable with SCH 40?

A: Not always; some fittings are schedule-specific because wall thickness affects socket depth, thread engagement and butt-weld geometry. Use matching schedule fittings or certified adapters. -

Q: Can I thread schedule 40 PVC?

A: Threading is generally discouraged on SCH 40 PVC for mechanical strength reasons; many manufacturers recommend SCH 80 for threaded plastic connections. -

Q: What standards control Schedule 80 dimensions?

A: ASME B36.10M / B36.19M for metal; ASTM D1785 and manufacturer catalogs for PVC/CPVC. -

Q: How does temperature affect schedule 80 pressure rating?

A: For plastics, pressure ratings are derated with temperature (manufacturer tables). For metals, allowable stresses fall with increasing temperature; use code formulas. -

Q: Where to find the official wall-thickness table?

A: The ASME B36.10M/B36.19M documents (for metals) and ASTM/manufacturer technical catalogs (for PVC/CPVC) contain official dimension tables.

Short checklist before signing off on a Schedule 80 specification

-

Confirm material standard (ASTM number) and ASME dimension standard requested.

-

Specify NPS, schedule, end finish (plain, beveled, threaded).

-

Request MTRs, hydro test pressure, and non-destructive test reports if required.

-

Verify fittings & valves compatibility and confirm pressure/temperature limits at operating conditions.

-

Confirm installation methods and testing: welding procedures, solvent cement for plastics, and acceptable leak testing media (never compressed air for PVC).

Final notes

Schedule 80 is a widely used, easy-to-specify way to get a thicker-walled pipe without changing nominal piping layout. For final design, never treat schedule alone as a substitute for strength/pressure code calculations. Cross-check ASME/ASTM tables and manufacturer data when designing, installing or procuring. For plastics, pay attention to temperature limits and do not test with compressed air. When in doubt, request the manufacturer’s dimensional and pressure tables and ask for written confirmation of fitting compatibility.

Authoritative references

- ASME — B36.10M / B36.19M (Welded and Seamless Wrought Steel & Stainless Steel Pipe standards and tables)

- Spears Manufacturing — Schedule 80 PVC technical bulletin and pressure/temperature derating tables

- ASME Codes & Standards portal — use to acquire the official B36.10/B36.19 documents and latest revisions