Inconel is a family of nickel-chromium based superalloys whose core is high nickel content combined with chromium and strengthening elements (molybdenum, niobium/columbium, iron, and small additions of titanium, aluminium, etc.), formulated and heat treated to deliver exceptional strength, oxidation resistance, and corrosion resistance at elevated temperatures for demanding aerospace, power-generation, chemical and marine applications.

1. What “Inconel” means and why the family exists

“Inconel” is a trade name (registered by Special Metals and historically by International Nickel Company) used to identify a collection of nickel-base superalloys engineered to retain mechanical strength and resist oxidation and corrosion in extreme environments. These alloys were developed because pure nickel and early stainless steels either softened or oxidized rapidly under prolonged exposure to high temperatures, especially where mechanical loading and corrosive media coexisted. The Inconel family covers multiple compositions tuned for differing combinations of high-temperature strength, fabricability, weldability and corrosion resistance.

2. Core chemistry: which elements define Inconel alloys

At the simplest level, an Inconel alloy is defined by:

-

Nickel (Ni): the matrix element, usually the largest single component (often 50–70 wt%). Ni forms an austenitic matrix (face-centred cubic) that gives ductility, toughness and a stable base for other elements.

-

Chromium (Cr): typically 15–25 wt% in many grades; it forms a protective chromia (Cr₂O₃) scale at elevated temperatures and provides baseline oxidation resistance.

-

Strengtheners and corrosion modifiers: molybdenum (Mo), niobium/columbium (Nb/Cb), tantalum (Ta), titanium (Ti), aluminium (Al), and sometimes cobalt (Co). These elements produce solid solution strengthening, precipitation hardening, or enhance pitting and crevice corrosion resistance.

-

Iron (Fe) and minor elements: Fe is often present as a balance component in certain alloys; small additions of manganese (Mn), silicon (Si), carbon (C), phosphorus (P) and sulfur (S) are controlled tightly for performance.

Different combinations and controlled impurity levels create the separate, standardized alloys known by UNS or ASTM designations.

3. Two canonical grades: INCONEL® 625 and INCONEL® 718 — compositions and roles

To make the chemistry concrete, below are two of the most commonly referenced Inconel grades and their typical composition ranges.

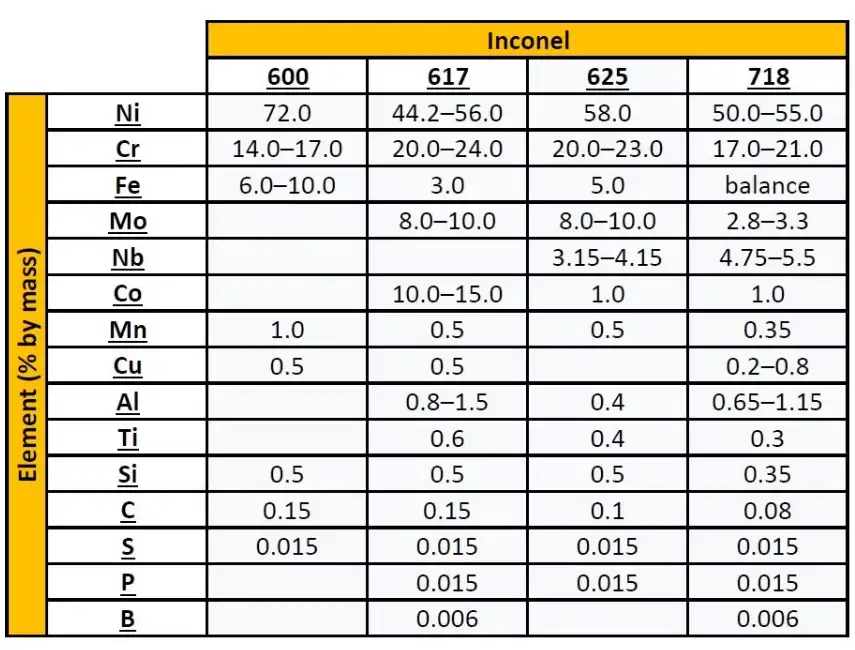

Table 1 — Typical chemical composition (wt%) for INCONEL® 625 and INCONEL® 718

| Element | Alloy 625 (typical ranges) | Alloy 718 (typical ranges) |

|---|---|---|

| Nickel (Ni) | ~58 wt% (balance) | ~50–55 wt% (balance) |

| Chromium (Cr) | 20.0–23.0 | 17–21 |

| Molybdenum (Mo) | 8.0–10.0 | ~2.8–3.3 |

| Niobium + Tantalum (Nb+Ta) | 3.15–4.15 | ~4.75–5.5 (Nb primary) |

| Iron (Fe) | ≤5.0 | ~17–20 |

| Titanium (Ti) | ≤0.40 | ~0.4–1.0 |

| Aluminium (Al) | ≤0.40 | ~0.2–0.6 |

| Carbon (C) | ≤0.10 | ≤0.04 (varies) |

| Manganese (Mn) | ≤0.50 | ≤0.35 |

| Silicon (Si) | ≤0.50 | ≤0.35 |

| Phosphorus (P) / Sulfur (S) | very low (0.015 max typical) | very low |

Sources: manufacturer datasheets and material data compilations for Alloy 625 and Alloy 718.

Notes: Alloy 625 is a solid-solution strengthened nickel-chromium-molybdenum alloy with significant Nb to stabilize strength without precipitation aging; Alloy 718 is a precipitation-hardenable nickel-chromium-iron alloy where Nb and Ti/Al form strengthening precipitates under age treatment.

4. How alloying elements change behaviour — element-by-element roles

Understanding what Inconel is “made of” is best done by looking at why each principal element is present.

-

Nickel (Ni): The matrix. Nickel’s FCC crystal structure remains stable at high temperatures, which preserves ductility and toughness where iron-based alloys might become brittle. High Ni also improves resistance to certain reducing environments.

-

Chromium (Cr): Forms a passive Cr₂O₃ oxide at elevated temperatures that suppresses rapid oxidation and scaling. Chromium also raises corrosion resistance in many aqueous environments.

-

Molybdenum (Mo): Improves resistance to pitting and crevice corrosion and contributes to solid solution strengthening. Mo boosts high-temperature creep strength in many nickel alloys.

-

Niobium / Columbium (Nb/Cb) and Tantalum (Ta): In Alloy 625, Nb combines with Mo to stiffen the matrix (solid solution effect). In Alloy 718 and similar, Nb forms discrete niobium-rich precipitates (e.g., gamma″, gamma′ phases depending on alloy) which enable significant age-hardening.

-

Titanium (Ti) and Aluminium (Al): Together with Nb they participate in precipitation of coherent intermetallic phases (gamma′ Ni₃(Al,Ti) and gamma″ Ni₃Nb in certain alloys) that provide high temperature strength through impediment of dislocation motion.

-

Iron (Fe): Usually present as a diluent or balance in certain alloys (e.g. 718 has significant Fe). Fe lowers cost relative to pure Ni and modifies mechanical and thermal properties.

-

Carbon (C): Kept low to avoid carbide network formation that can embrittle; controlled C can help form beneficial carbides (MC, M₆C) in some service conditions.

This combination of elements is engineered so the matrix plus precipitates or solid solution give the target combination of room-temperature toughness, high-temperature strength, and corrosion/oxidation resistance. Variety in element percentages yields different alloys tailored to specific environments.

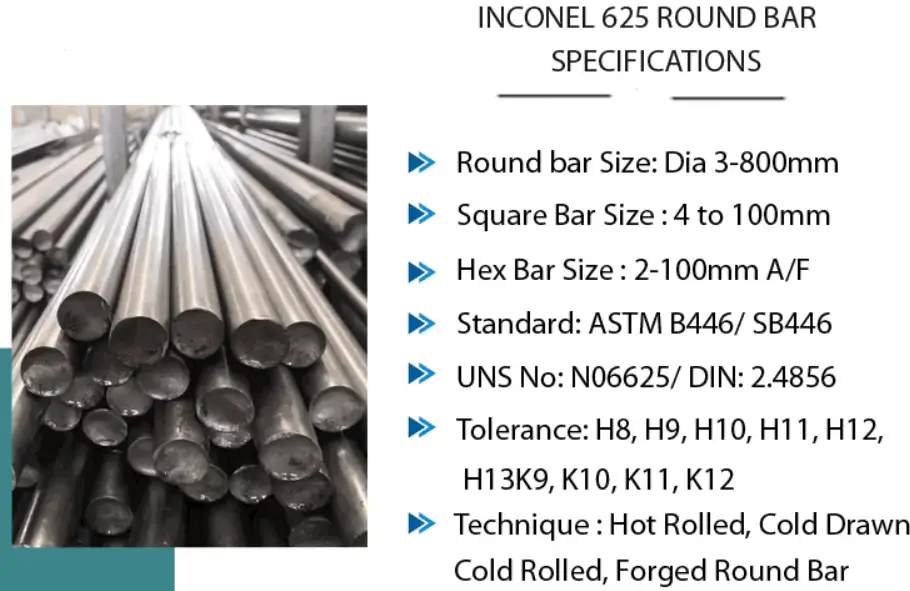

SPECIFICATIONS

5. Typical microstructures and strengthening mechanisms

Inconel alloys obtain mechanical strength by a few principal metallurgical mechanisms:

-

Solid solution strengthening: Alloying elements like Mo and Nb dissolve in the Ni matrix and distort the lattice, raising yield strength even in the annealed condition (prominent in Alloy 625).

-

Precipitation (age) hardening: Carefully controlled heat-treatments promote formation of fine, coherent intermetallic precipitates (gamma′ Ni₃(Al,Ti) and gamma″ Ni₃Nb in 718) which pin dislocations. This is the main mechanism for Alloy 718 strength.

-

Carbide and intermetallic dispersions: In some compositions and exposures, MC-type carbides (NbC, TiC) and complex carbides provide creep stability. Control of C and processing prevents deleterious continuous carbide networks.

-

Work hardening and grain control: Cold working, followed by solution annealing or controlled aging, tailors grain size and dislocation density for specific mechanical responses.

Because these mechanisms respond differently to temperature and time, heat treatment schedules (solutionizing, aging steps and times/temps) are critical design variables.

6. Heat treatment, fabrication and weldability notes

-

Alloy 625: Typically supplied in annealed condition or cold-worked conditions per standards. It obtains much of its strength from solid solution and the addition of Nb; it is relatively weldable and does not require complex age-hardening schedules. That makes 625 a preferred material where both corrosion resistance and fabrication/weldability are needed.

-

Alloy 718: Usually solution treated and then given a two-step aging cycle to precipitate gamma″/gamma′ phases (common practice: solution around 980–1150°C depending on specification, then aging at ~720–760°C and ~620–650°C for specific hold times). 718 is more sensitive to heat-treat history but has excellent weldability among age-hardenable Ni superalloys — welds can be post-weld age hardened to restore strength because of its relatively sluggish precipitation kinetics.

-

Fabrication notes: Hot forming, cold working, machining and additive manufacturing all have accepted routes for Inconel alloys, but tool wear and work hardening mean machining requires conservative parameters. Welding generally uses matching filler materials and controlled interpass temperatures to avoid hot cracking or undesirable precipitate formation.

-

Stress relaxation and creep: Inconel alloys are chosen based on their superior creep-rupture and stress relaxation characteristics at service temperatures that would quickly degrade common steels.

7. Mechanical and physical properties

Below are representative, not exhaustive, property snapshots that engineers commonly consult during selection. Exact values depend on temper, product form and heat treatment.

Table 2 — Representative mechanical properties (typical ranges)

| Property | INCONEL® 625 (annealed typical) | INCONEL® 718 (aged typical) |

|---|---|---|

| Density (g/cm³) | ~8.44 | ~8.19–8.25 |

| Tensile strength (UTS) | ~700–900 MPa (varies by product) | ~1100–1400 MPa (aged) |

| Yield strength (0.2% proof) | ~250–520 MPa | ~800–1200 MPa (aged) |

| Elongation (in 50 mm) | 30–60% | 10–30% (depends on age) |

| Creep temp capability | up to ~650–980°C depending on load | excellent up to ~650–700°C under load |

| Melting range | ~1290–1365°C | ~1260–1336°C |

Source summary: composite of manufacturer datasheets and material data sheets.

Table 3 — Common standardized specifications (examples)

| Alloy | Typical specifications / standards |

|---|---|

| INCONEL® 625 | ASTM B446 (rod/bar), AMS 5599/5666 (aerospace bars/sheets), ASTM B443 (wire) |

| INCONEL® 718 | AMS 5663/AMS 5596 (wire/strip), ASTM B637/B670 in some forms, EN/ISO equivalents |

Standards specify chemistry limits, allowed impurities, mechanical tests, heat treatment and acceptance criteria. Conformance matters for pressure-containing and aerospace parts.

8. Corrosion and oxidation resistance mechanisms and limits

Inconel alloys resist corrosion through a combination of passive oxide formation and alloy chemistry:

-

High temperature oxidation: Chromium forms a slow, adherent chromia scale (Cr₂O₃) that limits oxygen ingress. Nickel base reduces rapid volatility of oxides at high temperature. This is why many Inconel grades remain protective at temperatures where iron-based alloys scale heavily.

-

Aqueous corrosion (pitting and crevice): Mo and Nb improve resistance to localized attack in chloride-bearing or acidic environments; 625 in particular is chosen for seawater and acid service because of superior pitting resistance.

-

Stress corrosion cracking: Nickel-rich alloys show better resistance to many SCC modes than austenitic stainless steels; still, environment, temperature and stress state must be considered.

Design caution: While extremely corrosion-resistant, Inconel is not immune to all chemistries. Hot concentrated sulfuric or hydrochloric acids, certain molten salts, or conditions that foster selective attack may require special evaluation and possibly alternative alloys or coatings. Material selection must combine chemistry, temperature, mechanical load and exposure time.

9. Common applications and why Inconel is chosen

Because of its characteristic combination of properties, Inconel is used across several critical industries:

-

Aerospace: turbine discs, compressor blades, seals and rocket motor components where creep and high-temperature strength are mandatory. Alloy 718 is heavily used in aircraft engine components.

-

Power generation / gas turbines: hot section components, shrouds and combustor parts.

-

Chemical and petrochemical processing: heat exchangers, piping, valves and flanges handling corrosive media at elevated temperatures — Alloy 625 is popular in these roles.

-

Marine / submarine: propulsor and seawater hardware, because of 625’s resistance to chloride environments.

-

Nuclear: control rods, reactor internals and components where radiation, high temperature and corrosive coolants coexist.

-

Additive manufacturing and advanced manufacturing: Inconel powders (particularly 718 and 625) are common in metal AM for high-performance parts.

Choice drivers are high-temperature mechanical performance, stability in oxidizing conditions, and long fatigue/creep life under load.

10. Design, inspection, and joining considerations for engineers

-

Specification conformance: Use ASTM/AMS/UNS numbers to ensure the correct grade and condition. Don’t assume “Inconel” without a specific UNS/ASTM reference.

-

Welding and filler selection: Use matching filler alloys specified for each Inconel grade; preheat and controlled interpass practices may be required for thick sections and complex weldments.

-

Nondestructive testing: Because many Inconel components are safety-critical, radiography, ultrasonic testing, PMI (positive material identification) and hardness testing are common QA practices after fabrication and heat treatment.

-

Surface finish and coatings: In some cases, surface treatments improve emissivity, wear or specific corrosion resistance; however, because Inconel already develops protective oxides, coatings are selective and based on application needs.

-

Cost and machinability: Inconel alloys are more expensive than steels and stainlesss; machining rates are slower and tool wear higher — plan for higher manufacturing costs.

11. Sustainability, recyclability and supply chain points

-

Recyclability: Nickel-base alloys are recyclable; scrap streams from machining, turnings and end-of-life components can be reprocessed. Reclaimed Ni commands economic value and helps circularity.

-

Supply chain: Nickel and special alloy supply can be subject to commodity market fluctuations and geopolitical shortages; alloy buyers should lock supply agreements for critical programs.

-

Environmental footprint: High alloying content implies higher embodied energy and resource inputs per kg than low-alloy steels; lifecycle assessment should guide material selection when sustainability is a priority.

12. Practical selection checklist for engineers choosing Inconel

-

Define operating temperature and maximum stress (including creep considerations).

-

Identify corrosive species, pH, and presence of chlorides or sulfides.

-

Confirm mechanical properties needed at operating temperature (yield, UTS, creep life).

-

Verify weldability and whether post-weld heat treatment is possible.

-

Check relevant standards (UNS number, ASTM/AMS spec) and required certifications.

-

Estimate manufacturing cost and lifecycle cost (including maintenance intervals).

-

Plan for inspection (PMI, NDT) and traceability methods.

If the application places a premium on fabricability and seawater resistance, choose Alloy 625; if high tensile and creep strengths with age hardening are required, choose Alloy 718 or a similar precipitation-strengthened grade.

13. Frequently Asked Questions (FAQ)

Q1: Is Inconel the same as stainless steel?

A1: No. Both are corrosion-resistant, but Inconel is nickel-based and designed for higher temperature strength and oxidation resistance than most stainless steels. Stainless steels are iron-based and can be more economical for many room-temperature applications.

Q2: Which Inconel alloy is best for seawater?

A2: Alloy 625 is widely used in seawater and marine environments due to its high resistance to pitting, crevice corrosion and stress corrosion cracking in chloride solutions. Proper qualification and cathodic protection considerations remain important.

Q3: Can Inconel be welded easily?

A3: Many Inconel grades have good weldability relative to other superalloys. Alloy 625 is readily welded; Alloy 718 welds well for an age-hardenable Ni alloy but requires proper procedures and may be post-weld aged to regain full properties.

Q4: What is the cost difference between Inconel and titanium or stainless steel?

A4: Inconel is usually more expensive than stainless steels and many titanium alloys on a per-kg basis, owing to high nickel and alloying content plus processing difficulty. Total lifecycle costs must be considered, however, because Inconel can reduce maintenance and downtime in harsh services.

Q5: Are Inconel alloys magnetic?

A5: Most Inconel alloys are austenitic and therefore generally non-magnetic in the annealed condition; cold work can introduce some magnetic response. For critical magnetic requirements, confirm material condition with the supplier.

Q6: What temperatures can Inconel operate at?

A6: Typical usable ranges vary: 625 can be used up to roughly 980°C in oxidation service though creep limits apply at lower temperatures; 718 is commonly deployed up to ~650–700°C under load. Exact service limits must be verified against manufacturer creep-rupture data and design conditions.

Q7: Is Inconel immune to all corrosion?

A7: No. While highly resistant to many corrosive environments, certain molten salts, strong reducing acids at high temperature, or highly oxidizing halide-bearing gases can attack specific alloys, so evaluation for the intended environment is mandatory.

Q8: How do I specify Inconel for procurement?

A8: Specify the UNS number (for example, UNS N06625 for Alloy 625, UNS N07718 for Alloy 718), ASTM/AMS specification, required condition (annealed, aged), and any testing/certification (material test reports, PMI, NDT).

Q9: Can Inconel be 3D printed?

A9: Yes. Alloy powders for 625 and 718 are commonly used in laser powder bed fusion and directed energy deposition processes. Post-processing (stress relief, solutioning, aging) is required to achieve target properties.

Q10: What are the environmental/health handling concerns?

A10: Solid Inconel is safe to handle; machining produces fine swarf and chips that should be collected and recycled. Powder for AM requires controlled handling to avoid inhalation/explosive dust hazards. Standard industrial hygiene applies.

14. Closing summary

“Inconel” is not a single material but a family of nickel-base superalloys engineered with controlled additions of chromium, molybdenum, niobium/tantalum, titanium and other elements so that the final microstructure yields high temperature strength and corrosion/oxidation resistance. Selection between individual Inconel grades is a tradeoff between fabricability, cost, strength at temperature and corrosion resistance — a decision guided by precise chemical compositions (UNS/ASTM) and matched heat treatments. For critical applications, always specify UNS numbers and applicable standards, request manufacturer datasheets and confirm material test certificates before procurement.