API 5L Grade B (often written API 5L Gr. B or L245) is a widely used carbon steel line-pipe grade specified by the American Petroleum Institute for transportation of oil, natural gas and water in onshore and offshore pipelines. It represents a general-purpose, low-alloy carbon steel with a specified minimum yield strength around 245 MPa (≈35.5 ksi) in ISO terms and remains a common choice where moderate strength, good weldability, and predictable fracture and toughness behavior are required.

What is API 5L GR B?

API 5L Grade B is a cost-effective carbon steel line pipe grade suitable for many pipeline applications where high strength is not required. It balances mechanical strength with straightforward production and joining methods, making it a standard choice for distribution mains, trunk lines for low/medium pressure service, and many structural uses tied to fluid transport. For projects requiring higher minimum yield strength, low temperature toughness, or stringent fracture control, higher X-grades (X42, X52, X60, etc.) or PSL-2 variants should be considered.

What API 5L covers

API Specification 5L, “Specification for Line Pipe,” is developed and published by the American Petroleum Institute to set dimensional, chemical, mechanical and testing requirements for steel line pipe used in transportation of oil, gas and water. The document covers both seamless and welded pipes, multiple grades (A, B, X-series) and two product specification levels: PSL1 and PSL2, with PSL2 carrying additional testing and control requirements. API updates the standard periodically to reflect advances in manufacturing and field experience.

What “Grade B” means (naming, L245)

-

Grade B is the historical API label for a conventional line pipe carbon steel. In ISO/EN nomenclature it commonly maps to L245, where L = line pipe and 245 refers to the minimum yield strength in MPa (approx. 245 MPa = 35.5 ksi).

-

Grade B is considered a standard strength line pipe grade (lower than X-grades like X42/X52). It is widely available in both seamless and welded forms and is often the economical baseline for many pipeline projects.

Scope, uses and common applications

Typical use cases for API 5L Grade B:

-

Onshore gathering and distribution lines carrying natural gas, crude oil, produced water or potable water at moderate pressures.

-

Non-critical trunk lines where higher grade steels are not required by design or regulation.

-

Structural piping applications where API marking and traceability are valuable but ultra-high mechanical properties are unnecessary.

-

Temporary or utility piping, construction shoring, and some mechanical supports.

Because Grade B is broadly available and weldable using standard procedures, it is often specified where cost and delivery speed are important. For deepwater, sour or high-pressure service, engineers usually step up to PSL2 variants, sour-service qualified materials, or higher-yield grades.

Chemical composition (typical limits)

Note: API 5L provides composition windows and limits that vary by PSL level, pipe wall thickness and heat treatment. The following table shows representative maximum contents used commonly for Grade B (PSL1 / PSL2 may differ slightly). Always refer to the project specification and mill certificates for final values.

| Element | Typical maximum (wt.%) for Grade B (representative) |

|---|---|

| Carbon (C) | 0.26% (PSL1 typical); PSL2 often tighter (≤ 0.24%) |

| Manganese (Mn) | 1.35% — 1.60% |

| Phosphorus (P) | 0.035% — 0.045% max |

| Sulfur (S) | 0.035% — 0.045% max |

| Silicon (Si) | 0.30% — 0.50% |

| Chromium (Cr) | ≤ 0.45% (if agreed) |

| Nickel (Ni) | ≤ 0.50% (if agreed) |

| Molybdenum (Mo) | usually low or trace; added only by agreement |

Comment: These are typical, not normative. API 5L defines the allowable windows and permits project-level agreements for elements such as Cr/Ni/Mo when additional properties are required. Chemical limits affect weldability and toughness, therefore procurement must check mill test reports (MTRs) for any lot.

Mechanical properties (representative values)

| Property | Minimum (typical) |

|---|---|

| Minimum yield strength (Rp0.5) | ~245 MPa (≈ 35.5 ksi) — L245 designation |

| Minimum tensile strength (Rm) | ~415–450 MPa (≈ 60–65 ksi) depending on product and thickness |

| Minimum elongation (A, on 50 mm or 2 in) | Often ≥ 20–30% depending on diameter and wall thickness |

| Hardness | Not normally controlled for PSL1; PSL2 and sour service may have hardness limits |

These values vary by PSL, pipe manufacturing process (seamless, ERW, SAW), heat treatment, and section thickness. For critical designs, use mill certificates and perform independent verification in accordance with the contract.

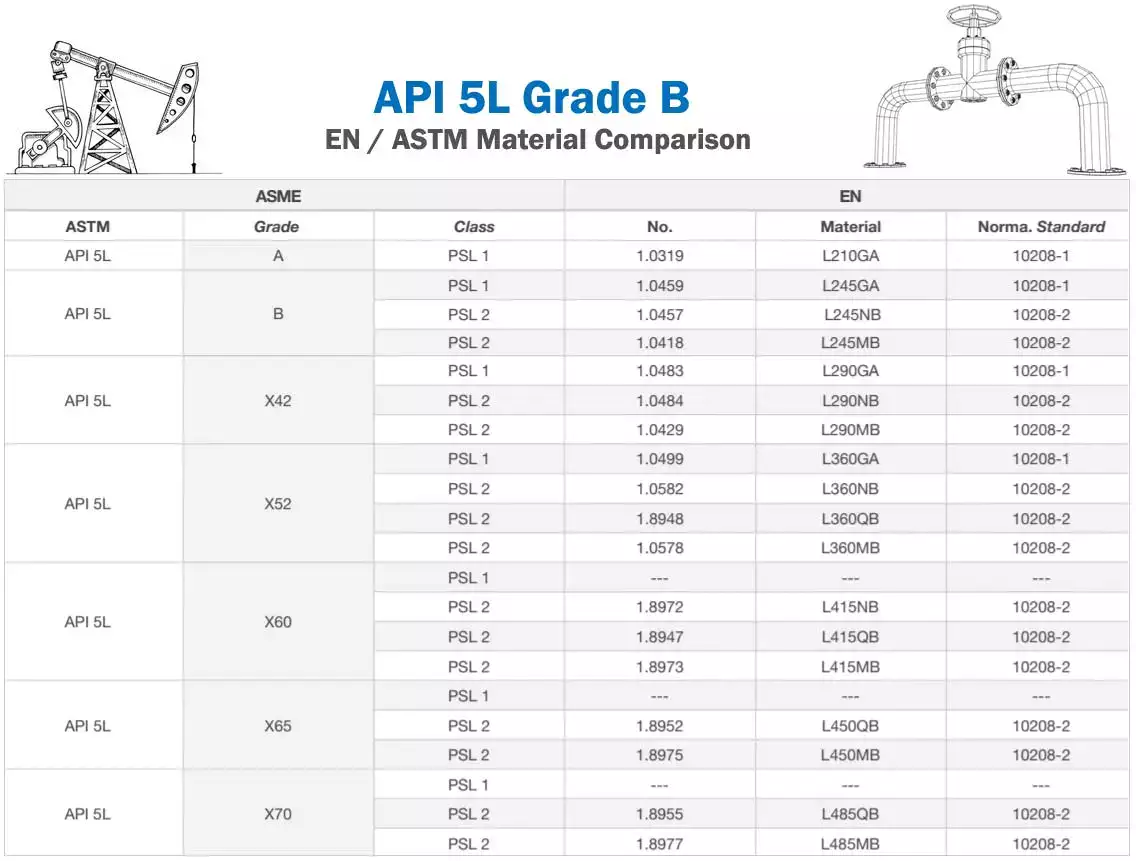

EN/ASTM Material Comparison

PSL1 vs PSL2: what changes when you step up

API 5L has two product specification levels:

-

PSL1 — Baseline quality level; covers a broad set of pipe types and sizes with standard chemical and mechanical controls. Testing is less extensive; impact testing is not always mandatory. This level suits many conventional pipelines and non-critical services.

-

PSL2 — Higher quality level with stricter controls. Key additions include:

-

Tighter chemical composition limits (lower maximum C for many grades).

-

Required Charpy impact testing to demonstrate notch toughness at selected temperatures and locations.

-

Stricter non-destructive testing (NDT) and acceptance criteria for seams and welds.

-

Additional requirements for traceability, heat treatment, hardness, and controls for sour service if specified.

-

For Grade B, PSL2 often reduces carbon limits and mandates impact testing for certain thicknesses and end uses. Engineering teams choose PSL2 when fracture control, low-temperature ductility or sour service risk dictate improved material assurance.

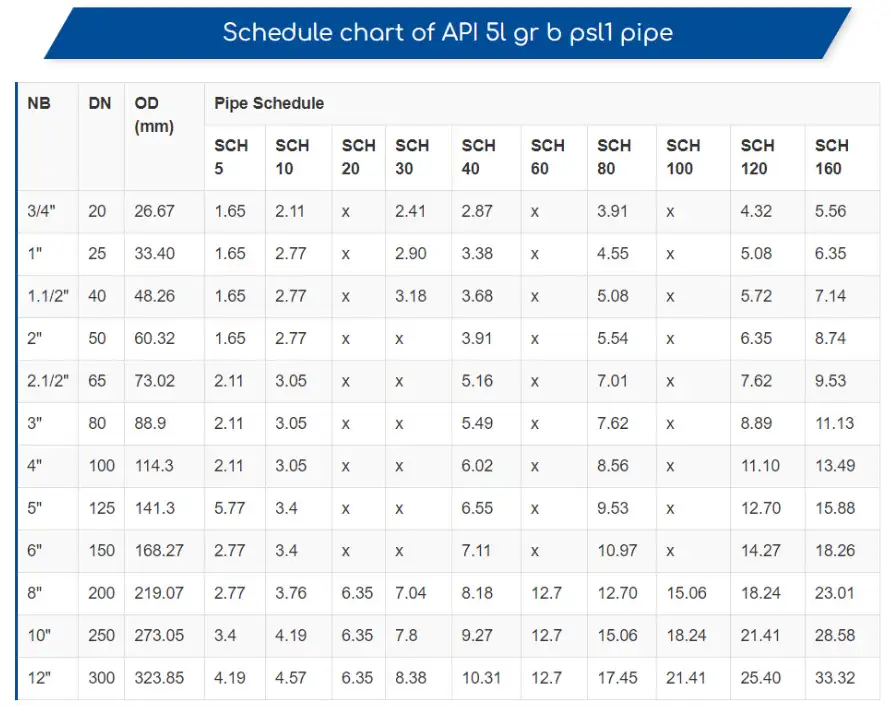

Manufacturing routes, pipe types and typical size range

API 5L Grade B material is available in several manufacturing forms:

-

Seamless (SMLS): Produced from a solid billet, drawn or extruded, used for higher pressure or thicker sections.

-

Electric Resistance Welded (ERW / HFI): Efficient for smaller diameters and thinner walls.

-

Spiral Submerged Arc Welded (SSAW / LSAW): Common for large diameters.

-

ERW or SAW with post-weld heat treatment: When required by spec.

Typical diameter scope ranges from small nominal bore (½" / 21.3 mm) up to very large diameters (100" NB for LSAW in some mills). Wall thicknesses traverse standard schedules (Sch 40, Sch 80, XS, etc.) and project-specific extra-thick plates. Suppliers publish availability tables by mill.

Tests, inspection and acceptance criteria

API 5L contains a suite of tests and inspections; typical ones include:

-

Chemical analysis (heat analysis and product verification).

-

Tensile test (yield, tensile strength, elongation).

-

Flattening/bending tests where called for by pipe type/size.

-

Hydrostatic test: pressure tested to a specified level (mill hydro test) to ensure integrity.

-

Non-destructive examination (NDE): visual inspection, ultrasonic or radiographic for welded pipes as required.

-

Charpy V-notch impact testing: mandatory for PSL2 in many cases and for sour service; notch temperature and energy minima specified in the standard.

-

Hardness testing: required for PSL2 and sour service pipelines to avoid brittle failure.

Sour service adds requirements tied to hydrogen sulfide (H₂S) exposure — hardness limits, special manufacturing controls, and sometimes additional mechanical testing to prevent hydrogen-induced cracking. These inspection regimes protect against seam defects, brittle fracture and service-related degradation.

Welding, fabrication and heat treatment points

-

Grade B steels are generally weldable using common processes (SMAW, GMAW, SAW, etc.). Preheat/post-weld heat treatment may be required for thicker sections, especially when carbon equivalent (CE) is high.

-

The carbon equivalent (CE) concept guides preheat and PWHT decisions. Typical Grade B CE values are moderate, which usually permits simple welding procedures without PWHT for thinner sections.

-

For structural welding of pipelines, weld procedure qualification and welder performance tests must follow the governing code (e.g., ASME, ISO, or project specifications).

-

Heat treatment (normalizing, PWHT) may be agreed between purchaser and mill to achieve specific toughness or stress relaxation requirements. Always document through MTRs.

Good welding practices, qualified procedures, and matching filler metals are critical to maintain pipeline performance. Use low-hydrogen consumables for thicker welds or when toughness is a concern.

Corrosion, coatings and service life mitigation

API 5L Grade B is carbon steel and therefore requires protective systems for long life:

-

External coatings: FBE (fusion bonded epoxy), 3PE/3LPE, coal tar enamel, bitumen, concrete weight coatings for subsea weight and external corrosion protection.

-

Internal linings: cement mortar linings, epoxy sprays, or polyethylene linings for potable water or corrosive cargoes.

-

Cathodic protection: typical for buried and submerged pipelines to prevent electrochemical corrosion.

-

Corrosion allowances: thickness design can include corrosion allowance if coatings/Cathodic protection performance is uncertain.

For sour service, Grade B requires special attention — hardness limits, possible alloying changes, and compliance with NACE MR-0175/ISO 15156 may be necessary. When H₂S is present, consult corrosion experts and standards for material selection.

Equivalents and cross-reference table

| API 5L Grade B common equivalents | Notes |

|---|---|

| ASTM A106 Grade B | Widely cited equivalent for seamless high-temperature carbon steel pipe in many supply chains. |

| ASTM A53 Grade B | Often referenced for welded and seamless pipe; similar chemistry and properties for certain schedules. |

| ISO 3183 L245 | ISO counterpart, where L245 denotes ~245 MPa minimum yield. |

| EN / DIN P265 / P265GH (EN 10216/10217) | European equivalents for seamless/welded carbon steel for pressure purposes. |

Equivalencies depend on thickness, heat treatment and PSL; when exact interchangeability is required, compare chemical and mechanical property windows and test matrices, not only grade names.

Selection advice for engineers and procurement teams

When specifying API 5L Grade B material, consider:

-

Service conditions: pressure, temperature, corrosivity (H₂S/CO₂), external environment (buried, submerged).

-

Design codes and safety factors: pipeline design codes may require higher grades for fatigue resistance or seismic loads.

-

PSL level: choose PSL2 for fracture-critical, low-temperature or sour service applications.

-

Weldability & fabrication: check CE and agree preheat/PWHT if thickness and composition demand it.

-

Traceability & documentation: specify MTR requirements, batch traceability, mill witness testing if necessary.

-

Coating/end finishing: determine external coatings, internal linings and coupling preparations at the ordering stage.

Procurement should request full MTRs and verify compliance with all tests and marks required by API 5L and project specification before acceptance.

Traceability, marking and mill documentation

API 5L requires clear marking and documentation so that installed pipe can be linked back to production records. Required items typically include:

-

Grade and PSL (e.g., API 5L Gr B PSL1).

-

Mill heat/lot number.

-

Manufacturer name or trademark.

-

Pipe size and schedule or wall thickness.

-

Test/inspection stamps for hydrostatic test, NDE, and other acceptance evidence.

Mill Test Reports (MTRs) should contain chemical analyses, mechanical test results, heat treatment conditions, NDT results and any supplementary certifications (NACE, sour service). Proper document control prevents costly rejections at the jobsite.

Common misconceptions and pitfalls

-

“Grade B is the same everywhere.” Not quite—composition windows and required tests depend on PSL level, thickness, and specific mill practices. Always check MTRs.

-

“All Grade B is OK for sour service.” Wrong — sour service can expose steel to H₂S and hydrogen-induced cracking. PSL2 sour-service variants or specially qualified steels are required.

-

“ASTM A106 B is identical.” ASTM A106 B overlaps with API 5L Gr B in many properties, but purchasing documents should call out API 5L if that specification is contractually required because of different testing/marking requirements.

-

“ERW pipes are always weaker.” Not necessarily. Modern ERW can meet API 5L criteria, but seam integrity requirements and NDE records must be reviewed.

Practical tables engineers use in procurement

Table A — Typical mechanical acceptance (example)

| Test | PSL1 typical | PSL2 typical |

|---|---|---|

| Yield strength (min) | 245 MPa | 245 MPa |

| Tensile strength (min) | 415 MPa | 415–450 MPa depending on wall |

| Charpy impact | Conditional / as agreed | Required for specific thicknesses/temperatures |

| Hardness | Not controlled | Often limited (e.g., HRC/HV limits) |

Table B — Example cross reference (quick)

| API 5L | ISO/EN | ASTM |

|---|---|---|

| Grade B (L245) | ISO 3183 L245 / EN P265GH | ASTM A106 Gr B / ASTM A53 Gr B (selective) |

FAQs

-

Is API 5L Grade B suitable for gas transmission mains?

Yes for moderate-pressure distribution mains; for higher pressures or fracture-critical routes, higher X grades or PSL2 should be considered. -

What is the difference between API 5L Gr B and X42?

X42 has a higher minimum yield (42 ksi) and generally requires stricter mechanical/toughness properties than Grade B; X grades are used where higher strength and fracture control are needed. -

Does API 5L Gr B require Charpy impact testing?

Not universally; Charpy tests are more commonly required under PSL2 or when specified for low temperature or fracture-critical service. -

Can API 5L Gr B be used in sour service?

Only if it meets sour-service requirements (hardness limits, specific chemistry and testing); otherwise, upgrade to a material qualified for H₂S environments. -

Are API 5L Gr B and ASTM A106 B interchangeable?

They are similar in chemistry and application, but not automatically interchangeable—contract documents should specify which standard governs procurement. -

What coatings are common for Grade B pipelines?

FBE, 3PE/3LPE, coal tar enamel and concrete weight coatings are typical choices, selected by environment and installation method. -

How is yield strength reported for Grade B?

Usually as minimum Rₚ0.5 (or Rt0.5) in MPa or ksi; L245 designates ~245 MPa minimum yield. -

What documentation should a purchaser require?

Mill Test Reports (MTRs), NDE reports, hydrostatic test certificates, material traceability reports and any sour-service certificates. -

Is heat treatment commonly applied to Grade B?

Not usually for thin pipes used in benign service; heat treatment (normalizing/PWHT) is used when toughness or stress relief is required by the spec or project. -

How do PSL1 and PSL2 affect lead times and cost?

PSL2 generally increases cost and lead time because of additional testing, NDE and traceability demands; evaluate need based on risk and safety requirements.

Closing remarks and specification checklist

If you plan to specify API 5L Grade B material, include the following in your purchase order or material specification:

-

Exact API 5L edition/version (e.g., “API Spec 5L, 46th edition”).

-

Grade and PSL level (e.g., Grade B, PSL2 if higher assurance needed).

-

Required tests (tensile, impact, hardness, hydrotest), acceptance criteria and temperatures for impact testing.

-

Coating/lining requirements and handling/packaging instructions.

-

MTR requirements, traceability and mill witness or third-party inspection if needed.

Well-written contract requirements avoid ambiguity and help ensure on-time delivery of conforming material.