UNS S31803, commonly known as duplex 2205 or A182 F51 - is a balanced ferritic–austenitic stainless steel that combines markedly higher strength than 300-series austenitics with significantly improved resistance to chloride pitting, crevice corrosion and stress-corrosion cracking. For many oil & gas, petrochemical, desalination and marine applications where higher mechanical performance and localized corrosion resistance are required at an economical nickel content, S31803 is the industry’s workhorse.

What is UNS S31803?

UNS S31803 is a duplex stainless steel grade (nominally “2205”) that was developed to provide a balance of high strength and improved resistance to localized corrosion relative to conventional austenitic stainless steels. It has a two-phase microstructure of roughly equal proportions of ferrite (body-centered cubic) and austenite (face-centered cubic) when solution-annealed. The duplex structure gives S31803 its characteristic combination of mechanical strength, toughness and resistance to chloride-induced failures.

Metallurgy & microstructure

The duplex concept intentionally retains both ferrite and austenite phases. Ferrite contributes higher yield strength and resistance to stress corrosion cracking (especially in chloride or sour environments), while austenite contributes ductility and toughness. The controlled chemistry — higher chromium and molybdenum compared with 300 series plus nitrogen additions — raises the pitting resistance equivalent number (PREN) and improves localized corrosion resistance without the cost penalty of high-nickel alloys. Proper heat treatment (solution anneal and quench) and controlled welding are required to preserve the balanced microstructure and avoid embrittling phases (sigma, chi) that form in certain thermal windows.

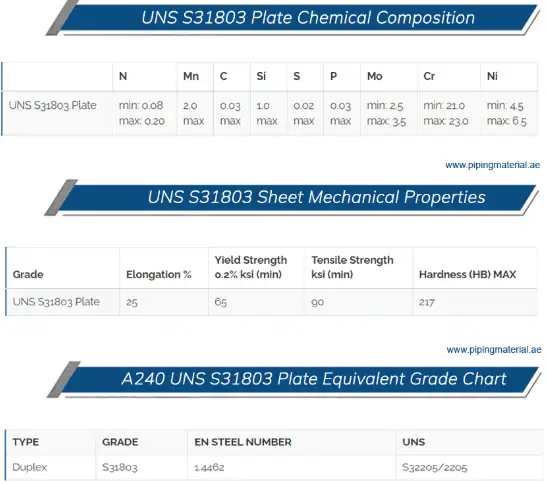

UNS S31803 Chemical composition (typical ranges)

Below is a practical composition table assembled from industry data sheets and standards ranges for the S31803 / 2205 family.

| Element | Typical range (wt.%) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Chromium (Cr) | 21.0 – 23.0 |

| Nickel (Ni) | 4.5 – 6.5 |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.02 |

| Nitrogen (N) | ~0.08 – 0.20 (typical; many datasheets show 0.10–0.20) |

Notes on key alloying roles

-

Cr (21–23%): primary passive film former — raises general corrosion resistance and contributes to PREN.

-

Mo (2.5–3.5%): improves resistance to pitting and crevice corrosion.

-

N (~0.08–0.20%): stabilizes austenite, increases strength and improves pitting resistance.

-

Ni (4.5–6.5%): balances austenite formation and ductility while keeping costs lower than higher-Ni alloys.

UNS S31803 Mechanical properties (typical / minimum values)

The duplex microstructure gives S31803 substantially higher yield strength than typical austenitic grades.

| Property | Typical / Min (annealed, 20 °C) |

|---|---|

| Ultimate Tensile Strength (UTS) | ~620 MPa (min) |

| Yield Strength (0.2% offset) | ~450 MPa (min) |

| Elongation (A50 mm) | ≥ 25% |

| Hardness (Brinell) | ≤ ~290 HB |

| Density | ~7.8 g/cm³ |

(Numbers collated from technical data sheets and standard product datasheets — use certified mill test certificates for design values.)

Engineering implications: where a design calls for higher allowable stress or reduced section thickness compared with 316L/316, S31803 commonly allows thinner components or higher pressure ratings for the same geometry — beneficial in weight-sensitive or pressure-containing equipment.

UNS S31803 Corrosion performance — PREN, pitting and SCC

PREN (Pitting Resistance Equivalent Number) is commonly used for comparative ranking:

PREN≈%Cr+3.3×%Mo+16×%N

Typical PREN for duplex 2205 (S31803 family) is often in the mid-30s (≈ 30–40) depending on exact Mo and N; this is notably higher than 316 (PREN ≈ mid 20s) and makes duplex much more tolerant to chloride pitting and crevice corrosion.

Stress-Corrosion Cracking (SCC): duplex steels are far less susceptible to chloride SCC than 304/316 austenitics because of ferrite content and stronger microstructure. Laboratory evaluations (manufacturer datasheets) show wide operational windows where 2205 resists SCC at temperatures and chloride levels that induce failure in austenitic grades. Nevertheless, designers must still evaluate specific service (temperature, chloride level, stress, crevices).

UNS S31803 Standards, specifications and equivalents

Common international designations and equivalents:

-

UNS: S31803 (and S32205 for tighter composition).

-

EN / DIN: 1.4462 (X2CrNiMoN22-5-3).

-

ASTM / ASME: A182 F51 (for forgings), A479 / A240 variations for bars/plates/tubes depending on product form.

-

Trade names: SAF 2205® (Sandvik / Alleima), Duplex 2205 (general).

Important note: Many mills now produce material that meets both UNS S31803 and the tighter S32205 limits; manufacturers often supply dual-certified product (S32205 meets S31803 but the reverse is not necessarily true). This distinction matters for critical corrosion service.

UNS S31803 vs other steels (practical comparisons)

Is S31803 the same as 2205?

Yes — S31803 is one of the UNS designations used for the duplex 2205 family. In practice “2205” is the commonly used grade name; S31803 and S32205 are two UNS captions in the 2205 family where S32205 represents a tighter, higher-assured chemistry (higher minimum N and sometimes Cr/Mo at the top end). Many producers supply material certified to S32205 which automatically meets S31803 limits.

S31803 vs S32205

-

S32205 (F60) usually guarantees higher minimum N and tighter control of Cr/Mo/N — better predictable pitting resistance than the broader S31803 range. If your spec calls for maximum pitting resistance, insist on S32205 or dual certification.

S31803 vs SS316 (AISI 316 / 316L)

-

Strength: S31803 has roughly twice the yield strength of 316.

-

Corrosion: S31803 has superior pitting/crevice resistance and much better SCC resistance in chloride environments (higher PREN).

-

Cost: 2205 typically costs more than 316 on a per-kg basis but often results in lifecycle cost savings due to reduced corrosion/failure risk and possible weight savings due to thinner sections.

UNS S31803 vs F51

-

F51 is effectively the ASTM A182 nomenclature corresponding to the S31803 duplex grade — used in piping, flanges and forged components.

Product forms, fabrication & welding notes

Forms available: plate, sheet, coil, pipe, tube, seamless bar, forged fittings, flanges and fasteners. Duplex 2205 is produced by major mills globally and stocked by service centers.

Welding: duplex steels weld well with standard arc processes (GTAW, SMAW, GMAW) provided correct consumables and procedures control heat-input and interpass temperature to avoid formation of unwanted intermetallic phases. Matching filler metals (e.g., ENiCrMo-type or duplex fillers) are typically recommended depending on required weld properties. Post-weld solution annealing is not usually required for many fabricated parts but post-weld treatment and PWHT must be assessed by the fabricator for critical pressure equipment.

Forming: duplex is less ductile than 300-series; cold forming is possible but requires larger bend radii and appropriate springback allowances.

Typical applications and sector case-uses

S31803 / 2205 is widely used where a balance of strength and corrosion resistance is required:

-

Oil & gas: risers, subsea tubing, chokes, valves, flanges, manifolds (resistance to chloride and H₂S environments).

-

Desalination: piping and heat exchangers where chloride pitting is a hazard.

-

Chemical processing & pulp & paper: equipment handling chloride-bearing process streams.

-

Marine & offshore: seawater systems, deck fittings.

-

Power generation & heat exchangers: where higher thermal conductivity and strength are useful.

Global price snapshot (2025) - ranges, context - caveats

Caveat: stainless steel prices fluctuate daily based on raw-material surcharges (nickel, molybdenum), freight, tariffs and regional supply/demand. Use these numbers as an indicative mid-2025 snapshot and always request current mill quotes and INCOTERMS. Sources and seller listings show a broad range depending on product form (coil, plate, bar, pipe), quantity and certification level.

| Region | Indicative 2025 price range (USD / metric ton) | Source notes |

|---|---|---|

| China — FOB (hot-rolled / coil / plate spot offers) | ~USD 1,200 – 2,000 / ton (typical ranges shown on supplier marketplaces for 2205) | Made-in-China / supplier listings |

| India — Ex-works Mumbai examples | ~USD 1,200 – 2,200 / ton (local stockist quotes vary with size) | Domestic supply & service center quotes |

| Europe — mill / service center guide | ~USD 1,600 – 3,000 / ton (European mills and surcharge models — higher logistics & alloy surcharges) | Outokumpu surcharges & marketplace data |

| USA — distributor / seller listings | ~USD 1,500 – 3,500 / ton (includes some catalog prices for pipe/plate; tariffs and domestic mill pricing influence ranges) |

Contextual drivers (2025):

-

Nickel and molybdenum commodity volatility pushes duplex premiums up and down; mills publish monthly alloy surcharges that materially affect final cost.

-

Regional protective measures (tariffs) or transport costs can create significant price differentials (see recent trade reporting).

Practical procurement tip: ask suppliers for line-item pricing: base steel price, nickel/mo-surcharge, testing/certification costs, packaging and freight — these line items explain most of the differences between quotes.

Procurement & supply — MWalloys company note

I’m writing this as an expert affiliated with MWAlloys (manufacturer & global supplier). MWalloys supplies duplex 2205 (UNS S31803 / 1.4462) in bars, plates, pipes and fittings from our Chinese mills. Our value propositions you can expect:

-

Factory pricing: direct factory (100% factory price advantage) — we produce and sell without middle-man markup.

-

Stock & lead time: we maintain stock for common sizes and can offer rapid dispatch on stocked items; typical stock delivery times for standard bars/plates are faster than OEM lead times (specific lead times depend on order size and certification).

-

Quality & certifications: MWalloys ships with mill test certificates (EN 10204 / 3.1 where required) and can provide NDE / PMI / inspection on request.

-

Export experience: long track record supplying pressure-equipment, piping and fasteners to international OEMs with experience in packing, export compliance and documentation.

(If you would like a tailored quotation from MWalloys — include product form, sizes, quantity, and required certification in your message and we’ll prepare a firm quote.)

FAQs

1) What is the practical difference between ordering S31803 and S32205?

S32205 has tighter composition limits (higher guaranteed N and sometimes tighter Cr/Mo). If your service requires maximum resistance to localized corrosion, specify S32205 (or dual-certified S32205/S31803). Otherwise S31803 may be acceptable and sometimes less expensive.

2) Can S31803 be used in sour (H₂S) environments?

S31803 has better resistance to sulfide stress cracking than many austenitics, but sour service must be assessed against NACE MR0175 / ISO 15156 guidelines and subject to environmental and mechanical stress conditions. Some duplex grades are accepted in sour service with qualifications.

3) How does duplex 2205 compare to 316L for heat exchangers?

2205 provides higher strength and better pitting resistance; heat-exchanger designers frequently choose it when chloride content is a concern or when thinner walls are desired. Thermal conductivity is somewhat higher than austenitics, which can be advantageous.

4) Are there welding consumables for duplex?

Yes — use matching duplex filler or nickel-based filler depending on required weld zone properties and corrosion resistance. Control heat input and interpass temperature to maintain phase balance.

5) What non-destructive tests and certificates come with supply?

Typical documentation: MTC (EN 10204-3.1), PMI reports, UT/RT/MT as applicable, hardness and tensile test reports. For critical projects, request full traceability and testing scope at RFQ time.

6) Is S31803 magnetic?

Yes — duplex stainless steels are magnetic due to the ferritic phase; the material will show magnetic response but less than fully ferritic grades. Magnetism may vary slightly with processing and cold work.

7) What service temperature limits should be observed?

Duplex steels perform well up to ~300–325 °C for continuous service; elevated temperatures risk phase changes that reduce toughness. For cryogenic service they retain good toughness but verify manufacturer data for application limits. Always consult supplier datasheets for specific thermal limits.

8) How to test for correct alloy on arrival?

Use Positive Material Identification (PMI) / XRF for element verification and review MTC. For critical components, full chemical and mechanical test reports per spec should be supplied.

9) Can S31803 be cold-worked?

Yes — but expect higher springback and less formability than 300-series. Cold-work increases strength and reduces corrosion resistance slightly; post-work stress relief and surface finish are considerations.

10) Are there environmental regulations or approvals commonly required?

For oil & gas or pressure vessel use, clients commonly request compliance with ASME, NACE MR0175/ISO 15156, PED (Europe) and project-specific qualifications. Always confirm regulatory needs in the RFQ.

UNS S31803 Specification & standards table

| Standard / Spec | Equivalent designation |

|---|---|

| UNS S31803 | Duplex 2205 (original UNS caption) |

| UNS S32205 | Tighter duplex 2205 variant (often dual-certified) |

| EN / DIN | 1.4462 / X2CrNiMoN22-5-3 |

| ASTM | A182 F51 (for forgings); A479/A240 for bars/plates (product-specific) |

| Trade / Mill names | SAF 2205® (Sandvik / Alleima), Duplex 2205 |

(For engineering procurement, always call out the exact standard and required inspection/certification class.)

Closing procurement checklist (for buyers)

-

Specify exact UNS/EN/ASTM caption and whether S32205 certification is required.

-

Request MTC (EN 10204-3.1), PMI, and NDE scope in the RFQ.

-

Clarify product form (plate/coil/pipe/bar), dimensions, surface finish and tolerances.

-

Ask for line-item pricing including alloy surcharges.

-

Confirm weld filler requirements and whether heat-treatment or PWHT is required after fabrication.

-

For fast delivery: check supplier stock availability and whether they can ship from bonded stock to reduce lead time.