There is no universal fastening champion for every sheet-metal job. Choice depends on material type and thickness, joint geometry, accessibility, production volume, environmental exposure, required strength, and service life. For high-volume, low-distortion assembly, clinching and self-clinching fasteners often deliver the best balance of speed and repeatability. For high joint strength in compatible steels, resistance spot welding remains the top option. Where one-side access or strong internal threads are required, blind rivet nuts (rivet-nuts) or solid rivets excel. When sealing, fatigue resistance, or dissimilar metals are concerns, structural adhesives or hybrid weld-bonding provide unique advantages. The practical path to a reliable assembly mixes sound mechanical design, the correct fastener family, proper tooling, and validated process controls.

Executive summary and decision checklist

Fastening sheet metal successfully starts with a short checklist:

-

What is the base metal or stackup? (steel, stainless, aluminum, coated steel, composite)

-

Total stack thickness and thickness range across the joint.

-

Access: is the backside accessible during assembly?

-

Required static and fatigue loads (tensile, shear, peel).

-

Environmental exposure: salt spray, vibration, thermal cycles.

-

Production rate and automation targets.

-

Cosmetic and sealing needs.

-

Reworkability and serviceability.

Answering these items narrows the realistic candidate methods quickly. For example, blind construction (one-side access) pushes toward blind rivets, rivet-nuts, or adhesives. Overlapped sheet joints that must remain flush tend to favor spot welding or adhesive bonds. High volume OEM production often leans on clinching or self-piercing riveting because they reduce part cost and cycle time while avoiding weld fumes or heat distortion. These practical tradeoffs are documented in technical comparisons from industry authorities.

Key selection criteria for sheet-metal fastening

Every fastening decision balances at least these variables:

-

Mechanical requirements: shear and tensile loads, fatigue life, torque-out resistance.

-

Material properties: ductility, work hardening, plating, heat sensitivity.

-

Geometry: edge distances, hole access, required clearance, aesthetic face.

-

Process constraints: on-line automation, cycle time, capital equipment.

-

Service environment: corrosion, temperature, chemical exposure.

-

Inspection and standards compliance: need for standard certification, traceability.

A short rule: choose the least complex method that meets mechanical and environmental needs. Less complexity typically means less variability, simpler inspection, and lower total cost of ownership.

Riveting family

Solid (shop) rivets

Solid rivets are permanent mechanical fasteners installed by deforming the tail (buck) against the head. They produce durable joints that resist shear and vibration; historically common in heavy construction and aerospace. They require access to both sides, a bucking tool, or automated riveting equipment.

Blind (pop) rivets

Blind rivets install from one side. After insertion into a pre-drilled hole, a mandrel is pulled; the body expands to clamp the sheets. They are fast, inexpensive, and widely used for thin gauge work and assemblies with one-sided access. Blind rivets follow ISO/DIN standards (for example ISO 15983 and related norms) that define dimensions and minimum mechanical values; using standard parts simplifies design and testing.

Structural and close-tolerance rivets

For higher strength than standard blind rivets, structural rivets or solid rivets are chosen. They provide greater clamp force, fatigue resistance, and shear capacity. Projects requiring certified mechanical values often reference ASME/ASTM/ISO tables when selecting rivet class and material.

Advantages: quick installation, low skill required for blind types, consistent clamp for pre-dimensioned bodies.

Limitations: permanent nature, limited peel strength for thin sheets, potential for hole distortion if over-sized.

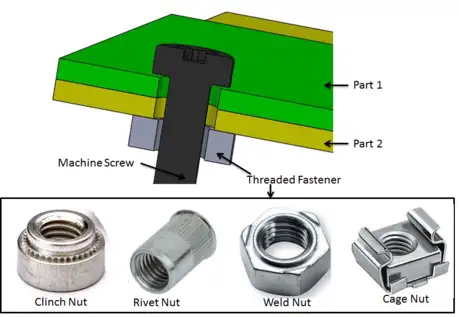

Blind threaded inserts (rivet-nuts / nutserts)

Blind inserts (also called rivet-nuts or nutserts) create a high-quality internal thread in thin sheet metal where thread depth would otherwise be inadequate. They install from one side using specialized tools that expand the insert body into the hole, producing a captive nut.

Key points:

-

They permit standard screw retention and multiple assembly cycles.

-

Manufacturing and testing often reference product catalogs and practice standards (tooling, proof load tests per ASTM F606 for aerospace / high-performance parts).

Use cases: serviceable panels, enclosures, places requiring torqueed fasteners.

Sheet-metal screws and self-tapping fasteners

Thread-forming screws, sheet-metal screws, and self-tapping screws cut or form mating threads in the sheet. They are low-cost, easy to install, and common in low-to-moderate load applications.

Design notes:

-

Pilot hole diameter matters; follow manufacturer drill charts for grip and thread engagement.

-

Sheet thickness governs the available thread length; use backing or inserts when thicker engagement is required.

-

Coatings and plating influence galling and torque values—important for stainless steel screws into stainless substrates.

Advantages: rapid assembly, field serviceability. Limitations: limited fatigue life, torque-out risk without inserts, potential galvanic issues in dissimilar metals.

Self-clinching fasteners (PEM® style)

Self-clinching hardware embeds into sheet metal by cold flow of the parent sheet into an undercut feature on the fastener. Typical parts include self-clinching nuts, studs, standoffs, and standoffs with threads. They require a properly sized hole and a press to seat the part.

Why choose self-clinching?

-

They become a permanent part of the panel with strong torque and pull-out resistance relative to the sheet thickness.

-

They provide high repeatable thread strength in thin material without welding heat.

-

Installation keeps the panel surfaces clean; no weld spatter or heat distortion occurs. PEM® (PennEngineering) literature summarizes performance and installation rules for these components.

Design tips: control hole finish and diameter; avoid chamfers larger than manufacturer tolerances. Use a calibrated press to avoid under- or over-drive. Self-clinching hardware is typically limited to ductile sheet materials.

Mechanical clinching and self-piercing riveting (SPR)

Clinching (cold forming)

Clinching mechanically forms a joint by plastically deforming the overlapping sheets into a localized interlock. It needs specially profiled tools but no additional fastener material.

Benefits:

-

No additional consumable fasteners; fast cycle times; minimal heat input; effective on coated or painted sheets.

-

Good for automation and environmentally clean production (no fumes, no consumable rivets). TWI and other industry studies compare clinching favorably to spot welding for certain joint types and thin materials.

Drawbacks:

-

Visible dimple on one side; limited for extremely thin or brittle materials; joint strength depends on punch/die design.

Self-piercing riveting (SPR)

SPR drives a semi-tubular rivet through the upper sheet and flares it into the lower one without a pre-drilled hole. It creates a robust mechanical interlock and is common in automotive sheet joining where mixed materials appear.

Comparison: SPR often outperforms clinching for mixed-material stacks or thicker lower sheets. Both methods compete with spot welding when weldability, coating damage, or heat distortion are critical constraints. TWI technical notes provide comparative guidance.

Resistance spot welding and projection/seam welding

Resistance spot welding (RSW) is a staple for joining steel sheets. Electrodes clamp the overlap; large current pulses melt a local weld nugget.

Strengths: highest joint strength for compatible steels; very fast cycle times in automation; minimal hardware cost.

Limitations: only suitable for electrically conductive, weldable materials; coatings may require process adjustments; heat-affected zone and potential distortion. For thin sheets and high cycle production, RSW typically remains the benchmark where electrical resistance and metallurgy permit.

Projection welding and seam welding are variants for welds with specific geometry or continuous seams. Selection depends on joint configuration and production requirements. Industry sources compare spot welding to clinching and SPR when heat input or coatings matter.

Brazing, soldering and friction-based joining

Brazing

Brazing joins metals using a filler metal with lower melting point than base metals. Strong, often hermetic joints result with good fatigue resistance when designed correctly. Brazing is useful when joining dissimilar metals or when a sealed joint is needed.

Soldering

Soldering suits electrical or low-temperature assemblies, not for load bearing in mechanical structures.

Friction stir and friction welding

Friction methods can join thin sheets in niche industrial applications. Their use in sheet metal fastening remains specialized and equipment-intensive.

Structural adhesives and weld-bonding hybrids

Adhesives have matured into structural options for metal bonding. Two-part epoxies, methacrylates, and specially formulated acrylics provide high shear and peel strength with excellent fatigue performance when joint geometry and surface prep are correct.

Authoritative process specifications and industrial guides (NASA PRC-1001, ISO adhesive standards, and manufacturer technical data such as 3M’s metal bonding adhesives) highlight necessary controls: surface cleaning, bondline thickness, environmental qualification, and cure schedules. Adhesives shine when sealing, damping vibration, or joining dissimilar materials. They also pair well with mechanical fasteners to provide load sharing and redundancy (weld-bonding or rivet-bonding).

Key advice: always qualify adhesive choice with lap shear, peel, and environmental testing; reference ASTM D1002 and similar tests when comparing products.

Surface treatment, corrosion and galvanic considerations

Fastener selection couples to surface coatings. Common issues:

-

Galvanic corrosion: use compatible metals or dielectric barriers when dissimilar metals (e.g., stainless screws into aluminum) meet in corrosive environments.

-

Plating and coatings: electroplated zinc, cadmium, or organic coatings alter friction and torque values; adjust installation torque and sealing accordingly.

-

Paint and powder coat: choose blind or flush fasteners that tolerate pre-finishing, or install fasteners after coating to avoid damage.

Designers should consult coating and fastener manufacturers for compatibility charts and use standardized corrosion tests for qualification.

Tooling, installation and inspection

Tooling: correct tools improve joint consistency—manual rivet guns, battery tools, hydraulic presses for self-clinching parts, clinch machines, and resistance welding guns. Calibrate presses and torque tools, track applied forces, and use process control charts for production runs.

Inspection: common tests include visual inspection, pull-out/push-out tests, torque-out evaluation for threaded inserts, lap shear for adhesives (ASTM D1002), and metallurgical examination for welds.

Standards: reference ISO, ASTM, and manufacturer manuals for acceptance criteria; many blind rivet and fastener types have ISO or DIN standards that list mechanical minima and measurement protocols.

Selection matrices and application tables

Table 1 — Quick comparison matrix (high level)

| Method | Backside access | Typical materials | Strength | Cycle speed | Cost per joint | Reworkable |

|---|---|---|---|---|---|---|

| Solid rivet | both sides required | steel, Al | High | medium | medium | no |

| Blind rivet (POP) | one side only | thin metal, coated | Low–medium | high | low | no |

| Rivet-nut (blind insert) | one side only | thin sheets | Medium | medium | medium | yes |

| Self-clinching | both sides ideally | ductile sheet (Al, steel) | Medium–high | high | medium | no |

| Clinching | both sides? usually both accessible | ductile sheets | Medium | very high | low | no |

| Self-piercing rivet | one side | multi-material stacks | High | high | medium | no |

| Spot welding | both sides? electrodes both sides | steel, some coated | High | very high | very low | no |

| Adhesive bonding | both sides not strictly required | many including composites | Variable (can be high) | low–medium | medium | yes (limited) |

(Use this table as a starting point; always verify by testing with your specific materials and thicknesses.)

Table 2 — Typical mechanical attributes (illustrative)

| Fastener type | Typical shear (N) | Typical tensile (N) | Typical peel/peel resistance |

|---|---|---|---|

| M4 blind rivet (stainless) | ~2000–4000 | ~2500–5000 | low |

| M6 rivet-nut (steel) | ~5000–9000 | ~6000–11000 | medium |

| Spot weld nugget (2 × 2 mm, mild steel) | >8000 | >9000 | high (for steel) |

| Adhesive lap (epoxy, 1.6mm steel) | depends heavily on prep; 1000–6000 | depends | good (with proper design) |

Numbers are illustrative; use supplier datasheets and standardized tests for design qualification.

Table 3 — Application examples and preferred methods

| Application | Preferred options |

|---|---|

| Automotive outer panel (high speed, coated steel) | SPR, clinching, spot welding |

| Electronic chassis with one-side assembly | Blind rivet, rivet-nut, adhesive |

| Enclosures requiring serviceable screws | Rivet-nut, self-clinching nuts |

| Lightweight aluminum frames | Self-clinching, adhesives, rivets |

| Harsh outdoor exposure | Stainless rivets, sealed adhesives, corrosion-compatible fasteners |

Case examples and process decision trees

Case A — Enclosure for serviceable electronics (one-side assembly, M4 screws): choose rivet-nuts sized to provide full thread engagement with recommended hole tolerances, validate torque-out using the chosen mating screw, and consider a thread locker for vibration. Validate with ASTM F606 proof load tests if needed.

Case B — High-volume automotive floor panel (coated steel, need minimal distortion): evaluate clinching or SPR over spot welding if paint continuity matters; if ultimate strength is required and coating management is feasible, spot welding remains the baseline. Reference TWI comparisons for material stack guidance.

FAQs

-

Which method gives the highest joint strength for carbon steel sheet?

Resistance spot welding typically provides the highest joint strength in compatible steels. Use welding when metallurgical compatibility exists and heat distortion is acceptable. -

Can I create strong threads in thin sheet metal?

Yes. Use self-clinching nuts for ductile sheets or rivet-nuts for blind installations; both produce serviceable internal threads. -

When should I use clinching instead of welding?

Choose clinching when you want no consumables, no heat input, rapid cycles, or better handling of coated panels. Clinching gives good fatigue performance for many designs. -

Are adhesives reliable for structural parts?

Structural adhesives can be very reliable when surface prep, joint design, and environmental qualification are performed per standards (ISO 21368, manufacturer datasheets). Use testing (ASTM D1002) to confirm. -

What standards should I consult for blind rivets?

Refer to ISO standards like ISO 15973 / ISO 15983 family and equivalent DIN documents for dimensional and mechanical requirements. -

Can I mix different methods on one assembly?

Yes. Hybrid joining (e.g., adhesive plus mechanical fasteners or weld-bonding) often improves fatigue, sealing, and load distribution. -

How do coatings affect spot welding and clinching?

Coatings change electrical and mechanical behavior. Adjust welding parameters for coated steels and verify clinch tool geometry to maintain interlock quality. -

What inspection is critical for fastened joints?

Visual checks, pull-out/push-out testing, torque tests for threaded inserts, weld nugget inspection, and adhesive lap shear tests are common. Follow supplier and standards guidance. -

Which method allows easiest field repair?

Threaded fasteners into rivet-nuts or self-clinched nuts. Adhesives or permanent solid rivets are harder to service. -

How to reduce galvanic corrosion risk?

Match metals where possible, add isolating coatings, or use sacrificial anodes. Validate using corrosion testing that mimics service conditions.

Authoritative references

- TWI — Comparison of clinching, self-piercing riveting and spot welding (technical FAQ)

- PennEngineering — Self-Clinching Fastener Handbook (technical manual and installation guidance)

- ISO — ISO 15983 (blind rivets standards and dimensional/mechanical data)

- NASA JSC — PRC-1001 Process Requirement for Adhesive Bonding (procurement and process controls)

- 3M Technical Data — Scotch-Weld Metal Bonder Acrylic Adhesive (product technical datasheet)