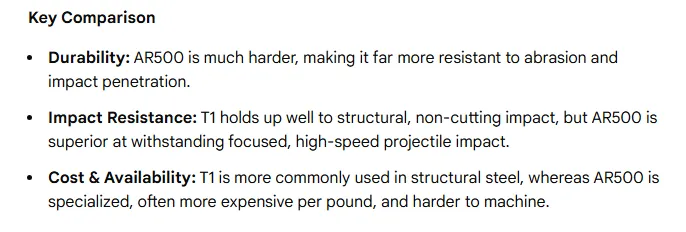

T1 tool steel and AR500 plate serve related but very different roles. In short, T1 (commonly supplied to ASTM A514) suits high strength structural components that still need some abrasion resistance and reliable weldability, while AR500 focuses on extreme wear and ballistic resistance with very high surface hardness but limited use in primary load‑bearing structures. Engineers in mining, construction and defense typically rely on T1 in crane booms, truck frames or structural supports, and choose AR500 in chute liners, impact plates, armor, and shooting targets where sliding abrasion or projectile damage dominates. When weight, code compliance and weld performance sit at the top of the requirement list, T1 usually wins; when maximum wear life or bullet resistance is the priority, AR500 tends to provide better value.

What exactly are T1 steel and AR500 in industry practice?

T1 steel in modern specifications

“T1 steel” started life as a proprietary trade name in the mid‑20th century. Today the closest widely used equivalent in North American and global practice is ASTM A514, a quenched and tempered alloy steel plate with minimum yield strength around 100 ksi (690 MPa). Key points:

- High yield and tensile strength combined with good notch toughness

- Supplied in thicknesses from about 6 mm up to 150 mm, depending on mill

- Used where plate carries significant structural load

- Often used with design codes that refer directly to A514

Industry sometimes still uses the term “T1” in quotes, but mill test reports list ASTM A514 grades (such G, Q, F, etc.), each with slightly different toughness levels and thickness ranges.

AR500 abrasion resistant steel

AR500 is not a single standard such ASTM A514. It is a hardness grade name used by several mills. The designation points to nominal Brinell hardness around 500 HBW, usually in a range near 470–540 HBW, achieved by alloy design and quench‑temper processing. Typical characteristics:

- Very high surface hardness targeting severe sliding or impact wear

- Generally supplied in plate or sheet thickness from 3 mm up to roughly 75 mm

- Weldable with correct procedure, though more sensitive to cracking than mild steel

- Used in mining liners, earthmoving buckets, truck bodies, hoppers, armor plate, targets

Many producers supply AR400, AR450, AR500 and similar grades, where the number indicates approximate hardness. AR500 usually sits at the harder end, with correspondingly higher abrasion resistance and lower ductility.

High‑level comparison table

| Feature | T1 Steel (ASTM A514 type) | AR500 Plate |

|---|---|---|

| Primary design driver | Structural strength with toughness | Abrasion resistance and impact resistance |

| Typical hardness | ~235–320 HBW | ~470–540 HBW |

| Minimum yield strength | ~690 MPa (100 ksi) | Varies by mill, not usually used in design |

| Typical thickness range | 6–150 mm | 3–75 mm |

| Microstructure | Tempered martensite | Tempered martensite, higher carbon content |

| Main use cases | Crane booms, frames, supports, bridges | Liners, targets, armor, spout and chute walls |

| Design code coverage | Extensive (AISC, AWS, etc.) | Limited structural design data |

| Fabrication behavior | Good weldability with procedure control | More cracking risk, higher preheat tendency |

| Key advantage | High strength plus toughness, codified | Extreme wear life and ballistic resistance |

How do chemical composition and microstructure differ?

Typical chemical composition ranges

Exact chemistry varies by grade and producer. Still, some broad trends set expectations.

T1/A514 relies on low to moderate carbon with micro‑alloying to achieve high strength and toughness through quench and temper heat treatment. AR500 usually carries higher carbon and alloy content to hit a very high hardness target.

Typical ranges in weight percent:

| Element | T1 / A514 (typical) | AR500 (typical range) | Commentary |

|---|---|---|---|

| Carbon (C) | 0.12–0.23 | 0.25–0.35 | Higher C in AR500 promotes hardness but lowers weldability and toughness. |

| Manganese | 0.7–1.0 | 0.8–1.5 | Strengthener and deoxidizer in both. |

| Chromium | 0.4–1.0 | 0.5–1.2 | Improves hardenability and abrasion resistance. |

| Molybdenum | 0.2–0.5 | 0.2–0.6 | Supports high strength through tempering, stabilizes carbides. |

| Nickel | 0.4–0.8 | 0–1.0 | Enhances toughness, sometimes higher in premium grades. |

| Boron | 0–0.005 | 0–0.005 | Tiny addition increases hardenability. |

| Silicon | 0.15–0.35 | 0.15–0.50 | Deoxidizer, modest strength contribution. |

| Phosphorus | ≤0.025 | ≤0.025 | Kept low to protect toughness and weldability. |

| Sulfur | ≤0.010–0.030 | ≤0.010–0.030 | Controlled carefully to limit inclusions. |

T1 chemistry aims at a balance between high strength, weldability and notch toughness. AR500 pushes carbon and alloy content higher to reach 500 HBW hardness, while trying to keep weldability within manageable limits.

Microstructure and heat treatment

Both material families are typically supplied as quenched and tempered plate. Microstructure in both cases is predominantly tempered martensite, yet with important differences.

- T1 / A514

- Moderate carbon content supports martensite formation during quench.

- Tempering at controlled temperature provides a balance of strength and toughness.

- Plate through‑thickness properties are important because of structural use. Mills control cooling conditions carefully to reduce residual stress and guarantee consistent strength.

- AR500

- Higher carbon and alloy content in combination with strong quench delivers higher as‑quenched hardness.

- Tempering temperature often kept lower than in T1, which maintains higher hardness at the expense of ductility.

- Surface and near‑surface zones are particularly hard; through‑thickness gradient can exist in thicker plate.

Result in practice: AR500 resists abrasion significantly better, while T1 handles higher strain, bending and dynamic structural load with more margin before cracking.

How do mechanical properties compare in real projects?

Hardness, strength and toughness overview

Key mechanical property comparison:

| Property | T1 / A514 (typical) | AR500 (typical) |

|---|---|---|

| Brinell hardness HBW | ~235–320 | ~470–540 |

| Yield strength (min) | ~690 MPa (100 ksi) | Not always specified, often 850–1100 MPa |

| Tensile strength (min) | ~760–895 MPa (110–130 ksi) | Often 1100–1500 MPa |

| Elongation (in 50 mm or 2 in) | 16–21 percent | 8–14 percent |

| Charpy V‑notch at low temp | Often specified, e.g. 20–50 J at −40 °C | Often limited or not guaranteed in commodity AR |

| Modulus of elasticity | ~200 GPa (similar to carbon steels) | ~200 GPa (similar to carbon steels) |

Notes:

- AR500 has much higher hardness and usually higher tensile strength, yet much lower elongation and often lower Charpy energy, especially at low temperatures.

- T1/A514 provides reliable structural design values backed by ASTM specification data and design codes.

- AR500 producers might offer mechanical data, yet plate is rarely used in primary load‑carrying members under design codes.

Wear resistance vs structural reliability

Hardness correlates strongly with abrasive wear resistance under many conditions. In a typical rubber‑wheel abrasion test such ASTM G65, AR500 usually lasts several times longer than mild steel and clearly longer than T1.

Yet in structures with high stress and cyclic load, high hardness alone does not guarantee reliability. Here T1 has critical advantages:

- Higher fracture toughness

- Better ductility and formability

- Better characterized fatigue performance compared to many generic AR500 offerings

In crane booms, heavy girders or truck frames, engineers usually prioritize T1 or other high strength structural steels over AR500, even though they may see some abrasion, because catastrophic structural failure carries higher risk than liner wear.

Where does each grade perform best in practical applications?

Typical uses of T1 steel

T1, supplied as ASTM A514 plate, has a long track record in applications where high strength reduces weight or plate thickness while still achieving good toughness and weld performance.

Common sectors and roles:

- Construction and lifting equipment

- Crane booms and outriggers

- Concrete pump booms

- Mobile crane chassis members

- Heavy transport and trailers

- Low‑bed trailer frames

- Heavy haul tractor frame reinforcements

- Suspensions, cross‑members, fifth‑wheel supports

- Industrial structures

- Support frames in mining plants

- Structural members carrying large process loads

- Bridges, movable spans, heavy doors where low weight is important

- Energy and pressure equipment supports

- Skids and frames under compressors, turbines or reactors

- Lifting lugs and pad‑eyes designed with high strength plate

T1 can also appear in wear‑prone yet still structural components, such equipment bases or truck bodies that experience both load and moderate abrasion from loading and dumping.

Typical uses of AR500 plate

AR500 targets surfaces where abrasive wear or projectile impact shapes lifespan. Examples:

- Mining, quarrying and material handling

- Chute and hopper liners

- Truck bed liners and dump body floors

- Bucket wear strips and side liners

- Screen plates, crusher liners in specific zones

- Construction and demolition equipment

- Excavator and loader bucket liners

- Bulldozer blade liners

- Impact plates in recycling and demolition plants

- Defense, security and shooting sports

- Armor panels in vehicles and fixed positions

- Shooting targets and gongs

- Bullet trap liners and armor backers

- Agriculture and bulk handling

- Grain handling spouts

- Scraper blades

- Conveyor transfer points

When sliding wear with hard particles (ore, rock, sand, scrap) dominates, AR500 frequently delivers much longer service life than T1 or standard structural steel, which in turn lowers maintenance costs and downtime.

Application matrix: T1 vs AR500

| Application scenario | Priority requirement | Recommended plate type | Rationale |

|---|---|---|---|

| Crane boom section | High strength, controlled weldability | T1 / A514 | Structural role with fatigue and code requirements. |

| Dump truck body liner | Severe sliding abrasion by rock, ore | AR500 | Wear life dominates, liner is non‑structural. |

| Low‑bed trailer frame | High yield strength, toughness | T1 / A514 | Structural member under bending and fatigue. |

| Excavator bucket shell | Combination of shape, strength, weldability | T1 / A514 or HSLA | Shell needs formability; wear strips may use AR500. |

| Bucket wear strips and heel pads | Extreme abrasion with impact | AR500 or AR450 | Replaceable elements prioritized by wear life. |

| Stationary ballistic target plate | Projectile resistance and repeated impact | AR500 | Hardness provides ballistic clean hits and long target life. |

| Support frame under crusher or screen | High static and dynamic load | T1 / A514 | Need strong, weldable, code‑covered structure. |

| Armor on light tactical vehicle | Weight‑critical ballistic protection | AR500 or specialized armor | Hard plate tuned toward ballistic performance. |

| Hopper handling moderately abrasive bulk solids | Combined load and moderate wear | Mix of T1 and AR steel | Structure in T1, replaceable liners in AR500. |

This is where hybrid design shines: structural components in T1, then AR500 bolted or plug‑welded on top in wear zones.

How do welding, cutting and forming procedures compare?

Fabrication behavior directly feeds into cost and risk. Both T1 and AR500 require more process control than mild steel, yet T1 usually proves more forgiving.

Welding characteristics

Core welding considerations include carbon equivalent (CE), preheat, interpass temperature and hydrogen control.

Typical carbon equivalent values

Formulae vary; a common approximation uses:

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

Typical ranges:

- T1 / A514 plate: CE around 0.45–0.60 depending on thickness and exact grade

- AR500 plate: CE often 0.50–0.70, sometimes higher

Higher CE means higher risk of hydrogen‑induced cracking, especially in the heat‑affected zone.

Welding comparison table

| Aspect | T1 / A514 | AR500 |

|---|---|---|

| Carbon equivalent | Moderate to high, thickness dependent | High, frequently slightly higher than T1 |

| Typical preheat requirement | Moderate, often 95–150 °C in thick sections | Usually higher preheat, especially in thick plate |

| Filler selection | Matching strength low‑hydrogen consumables | Often lower strength filler to keep HAZ softer |

| Hydrogen control | Low‑hydrogen process strongly recommended | Extremely critical due to high hardness |

| Post‑weld heat treatment | Rare in field constructions | Rare, usually avoided due to risk of softening |

| Weld cracking risk | Medium with correct procedure | Higher, requires tight procedure discipline |

Good practice highlights:

- Maintain strict cleanliness, dry electrodes or wire, and appropriate preheat/interpass temperatures.

- Avoid over‑matching weld metal strength in AR500 to keep weld and HAZ toughness acceptable.

- In T1 structures, still keep diffusible hydrogen low yet design is more forgiving.

Engineers often specify weld procedure qualification records (PQRs) tailored to the exact grade, thickness and restraint level.

Cutting methods

Both materials cut well using standard industrial methods, yet hardness and plate thickness influence process choices.

- Oxy‑fuel cutting

- Works on both when plate thickness is sufficient.

- Heat‑affected zone hardening can be an issue, especially near edges that will be bent or heavily loaded. Secondary grinding or limited preheating can help.

- Plasma cutting

- Widely used due to good quality and productivity.

- In AR500, keep heat input controlled to limit softening in the cut edge. Water table systems assist by cooling and reducing distortion.

- Laser cutting

- Very precise on thin to moderate thickness, particularly attractive in AR500 targets or liner parts where tolerance matters.

- On very hard plate, require high power and attentive parameter tuning.

- Waterjet cutting

- Cold process, ideal when edge hardness, microstructure or distortion must remain unchanged.

- Common in ballistic plate components, precision liners and parts that will see bending near the edge.

Forming and bending behavior

T1 generally bends more easily than AR500 at comparable thickness due to lower hardness and higher ductility.

Key rules of thumb:

- Use larger inside bend radius with higher hardness plate.

- Orient bend line so it runs perpendicular to the rolling direction when possible.

- Avoid sharp re‑bending or flanging on AR500; cracking risk rises quickly.

Illustrative comparison:

| Property / parameter | T1 / A514 | AR500 |

|---|---|---|

| Ease of cold bending | Moderate | Low to moderate, depends strongly on grade |

| Typical minimum inside radius (t = thickness) | Around 1.0–1.5 t | Often 2.0–3.0 t or higher |

| Risk of cracking in tight bends | Moderate | High, especially across plate thickness |

| Hot forming | Possible in some cases | Usually avoided, may alter hardness profile |

Fabricators often laser or plasma‑cut AR500 components in flat profile then weld segments rather than attempting tight bends in thicker material.

How do wear resistance, impact behavior and ballistic performance compare?

Abrasion mechanisms and hardness role

In many bulk solids systems, wear occurs through:

- Sliding abrasion, where hard particles move over the plate surface

- High‑stress grinding between trapped particles

- Low‑stress scratching in fine powders

- Impact wear when large chunks strike the surface repeatedly

Hardness helps resist plastic deformation from sharp particle contact. AR500’s hardness in the 500 HBW region means:

- Much lower wear rate under sliding abrasion by rock or ore compared with T1

- Superior performance in thin sections where work hardening in austenitic steels cannot develop sufficiently

T1 offers improved wear resistance compared with mild steel because of higher hardness and strength, yet slot into an intermediate region relative to AR500.

Impact and shock loading

Impact behavior is more nuanced than plain hardness:

- T1 / A514

- Balanced hardness and toughness support repeated impact without brittle cracking.

- Frequently used in structures experiencing dynamic loads and fatigue.

- AR500

- High hardness resists surface damage from repeated hits but underlying toughness is lower.

- Under extremely high impact or constrained conditions, brittle cracks can initiate and propagate if design is not conservative.

Designers often place AR500 in locations where impact remains severe but not fully structural. Examples include replaceable impact plates, not frame members.

Ballistic performance

Ballistic resistance depends on hardness, thickness, plate quality and projectile details. AR500 plate sees extensive use in civilian shooting targets and some armor systems.

Key tendencies:

- AR500 at appropriate thickness stops many handgun rounds and lower‑energy rifle rounds with minimal indentation.

- Higher energy or armor‑piercing ammunition requires thicker plate or specialized armor grades.

- T1, with lower hardness, deforms more deeply under bullet impact; penetration occurs more readily at equal thickness.

Because ballistic threats vary widely, specialized armor steels or complex multi‑layer systems may be chosen over generic AR500 in defense projects. Still, AR500 provides a widely accessible starting point in many security and sporting applications.

How do cost, availability and sourcing compare?

Price considerations

Exact pricing depends on region, mill, volume, thickness and market cycle. Trends in many markets:

- Commodity structural steel (A36 or similar) sits at the low end.

- T1 / A514 costs more than mild steel because of alloy content and quench‑temper production, but sits in a mid‑to‑high range among structural grades.

- AR500 typically commands a premium over mild steel and often a modest premium over many T1 thicknesses due to tighter hardness targets and more specialized production.

Non‑structural wear liners typically use AR400 or AR500 rather than T1, because longer wear life offsets higher price per ton.

Availability and lead time

In many industrial regions:

- T1/A514 stock exists mainly in medium thicknesses geared to structural work. Very thick or thin sections might need mill rolling with lead times of several weeks or months.

- AR500 stock covers a wide thickness range used in liners and targets. Popular thicknesses such 6, 8, 10, 12 and 20 mm often sit in distributor warehouses.

- Higher toughness variants of AR500, ballistic‑tested plates or unusual thickness combinations can require special order.

MWalloys maintains stocked sizes in both high strength structural plate and AR‑series wear plate. Custom mill rolling or cut‑to‑size service closes gaps when specific dimensions, narrower flatness tolerance or particular test requirements exist.

Sourcing considerations for procurement teams

Factors that purchasing departments often weigh:

- Specification clarity

- T1 should be referenced by ASTM A514 grade, thickness and required impact test conditions.

- AR500 orders should specify hardness range, thickness, flatness tolerance and any additional tests (Charpy, ultrasonic inspection, ballistic testing).

- Total cost of ownership

- Longer wear life from AR500 may reduce liner replacement frequency.

- Lower mass from T1 can cut transportation fuel use or allow larger payloads.

- Fabrication ecosystem

- Availability of local fabricators familiar with either grade.

- Mill support and access to welding recommendations.

MWalloys can assist both engineering and procurement teams in drafting realistic material specifications that balance performance with material and fabrication cost.

How should engineers choose between T1 steel and AR500?

Step‑by‑step selection method

A rational selection approach helps avoid overspecification or incorrect grade use.

- Clarify the component function

- Structural load path or mainly sacrificial wear liner?

- Failure consequences and inspection accessibility.

- Quantify service conditions

- Type and severity of abrasion: sliding, impact, fine or coarse particles.

- Stress level, dynamic loads, fatigue cycles, temperature range.

- Check design code obligations

- Crane, bridge or pressure equipment support will likely reference code‑listed structural grades such T1/A514 before any AR plate.

- Wear liners outside primary load path might be free of formal structural code constraints.

- Assess fabrication constraints

- Welding skill level, shop capabilities, preference for bending versus fabrication from flats.

- Field repair expectations.

- Calculate life‑cycle cost

- Replacement interval, downtime cost, labor and consumable expenses.

- Weight savings from T1 vs mild steel, plus potential payload gains.

Practical decision examples

- Case 1: Mine haul truck body

- Structural shell and stiffeners built with T1 or other high strength structural steels to keep weight down.

- Inner surfaces lined with AR400/AR500 plates in zones that see high abrasion from rock loading.

- Case 2: Stationary chute

- Frame and supporting trusses: T1 or conventional structural steel.

- Drop zones and sliding surfaces: AR500 or AR450, maybe backed by mild steel plate.

- Case 3: Crane boom repair

- Original design with T1 or equivalent structural plate.

- Replacement with AR500 would alter strength, toughness and weldability in ways not covered by design codes; risk to structural integrity.

- Correct practice: replace with matching A514 grade, with proper documentation.

- Case 4: Range targets

- Structural frames or stands: mild steel or T1, where loads are low.

- Target faces: AR500 with chosen thickness based on caliber and distance.

Decision matrix table

| Primary design driver | Service condition example | Recommended material family |

|---|---|---|

| Weight reduction in load‑bearing structure | Crane, trailer, heavy frame | T1 / A514 |

| Maximum wear life under abrasive flow | Chutes, hopper liners, truck body liners | AR500 or similar AR plate |

| Combined strength and moderate wear | Excavator arms, dozer structures | T1 or HSLA, plus localized AR |

| Ballistic protection at moderate thickness | Targets, some vehicle panels | AR500 or dedicated armor steel |

| Low cost structure with mild wear | Simple bins or hoppers with non‑aggressive media | Conventional structural steel plus optional AR500 liners |

What standards, codes and design factors matter?

Structural design standards

T1 approximated by ASTM A514 integrates smoothly with many structural design ecosystems.

- ASTM A514 sets chemistry, mechanical properties, heat treatment and testing requirements.

- AISC Steel Construction Manual references A514, providing design values and guidance.

- AWS D1.1 structural welding code offers procedures and recommendations covering A514.

- European and other regional standards feature equivalent high strength quenched and tempered plate specifications with similar roles.

AR500 might be referenced in mill standards, but rarely appears directly in structural design codes. Designers sometimes treat it as a special case, yet responsibility then lies heavily on engineering judgement and testing.

Fatigue, fracture toughness and safety margins

Structural members in cranes, bridges or offshore equipment must survive millions of stress cycles without crack growth. For those applications:

- High yield strength alone does not guarantee fatigue resistance.

- Plate toughness and quality (inclusion control, lamination defects, residual stress) play large roles.

- Wide experience with T1/A514 in such roles leads to established design data and safety factors.

AR500 plate sometimes contains higher residual stresses from quench, plus microstructural features tailored to surface hardness rather than long‑life cyclic performance. That reality further points toward use in liners and secondary components rather than primary load paths.

Temperature effects

Both grade families show property changes with temperature.

- At low temperatures, ductility and toughness drop. Many T1/A514 plates have guaranteed Charpy test data at sub‑zero temperatures, especially important in colder climates or offshore projects.

- AR500 may not include low‑temperature toughness guarantees in commodity material, so design margins require extra caution.

- At elevated temperatures, hardness and strength gradually decline. Hard AR plate in particular can lose wear resistance when run too hot, such in high temperature process plants.

When low‑temperature impact conditions or high‑temperature exposure form part of service, consult mill data sheets and, where needed, carry out project‑specific testing.

How does MWalloys approach T1 vs AR500 selection and supply?

MWalloys focuses on high performance alloy steels and wear resistant plate solutions. The engineering and commercial teams typically work through T1 versus AR500 selection alongside customers through these steps:

- Define environment and failure modes

- Is previous plate cracking, thinning by abrasion, suffering fatigue failures, or carrying too much weight?

- What inspection routines exist on site?

- Map the component into structural vs sacrificial zones

- Identify load‑bearing regions where T1 or equivalent structural plate remains essential.

- Highlight surfaces that can function purely as replaceable liners built from AR500.

- Match steel grade families to each zone

- Offer T1/A514 grades with toughness and thickness matched to structural roles.

- Offer AR400, AR450, AR500 or higher hardness plates selecting the optimum trade‑off between cost and wear life.

- Support fabrication planning

- Provide cutting and welding recommendations, preheat ranges, compatible filler metals.

- Suggest bending radii and sequencing to minimize scrap and cracking risk.

- Assist with cost and lead time optimization

- Combine mill‑rolled plate with warehouse stock to match project schedule.

- Propose standard plate sizes and nesting plans to reduce off‑cut waste.

Through that approach, many customers move from single‑material designs toward hybrid structures that use each grade where it brings the greatest return on cost and reliability.

T1 (ASTM A514) vs. AR500 Steel: Structural vs. Wear FAQ

1. Is T1 the same thing as AR500?

2. Can AR500 replace T1 in crane booms or load-bearing frames?

While AR500 is very strong, it lacks the certified toughness, weldability, and fatigue performance required by design codes for primary structural elements like crane booms or bridge members.

3. Which one lasts longer in chute or hopper liners?

In abrasive environments with rock or sand, AR500 will significantly outlast T1. Its much higher hardness (approx. 500 Brinell vs. T1’s ~270 Brinell) makes it the standard choice for liners, while T1 is often used for the structural skeleton behind the liner.

4. Is T1 easier to weld than AR500?

5. Can AR500 be formed or bent?

6. Which grade works better in cold climates?

T1 (ASTM A514) is far superior for cold service. It often comes with guaranteed Charpy impact values at low temperatures (e.g., -40 degrees C). AR500 is generally not characterized for low-temperature toughness and can become brittle and prone to fracture under impact in extreme cold.

7. Can both materials be flame cut and machined?

8. How do I specify T1 correctly on a drawing?

9. What hardness target defines AR500?

10. How can MWalloys help with T1 vs. AR500 selection?

Final recommendations for engineers and buyers

-

Define the primary failure mechanism before specifying a steel grade. If the part fails by edge wear, choose a tool steel such as T1. If it fails by bulk abrasion and repeated impact, choose AR500 or another abrasion resistant plate.

-

For design-critical or safety-critical uses, request mill certificates and supplier test data. Don’t substitute one grade for another without testing.

-

For welding or fabricating, consult with experienced welding engineers; incorrect procedures will reduce service life.

-

If ballistic performance is required, buy plate that has been specifically processed and tested for the intended threat level rather than assuming wear grade equals armor rating.