Choosing the correct steel pipe grade is determined principally by three constraints: the service environment (corrosion and temperature), the mechanical demands (pressure, impact, and load), and procurement/inspection requirements (standards such as API, ASTM or EN). For most oil & gas and general utility pipelines, carbon grades (API 5L X-grades; ASTM A106/A53) deliver the best cost-to-performance balance; when corrosion resistance is critical, austenitic stainless steels (304/316 series) are typical choices; for chloride-bearing seawater or high-strength lightweight sections, duplex and super-duplex stainless steels (e.g., 2205, 2507) are preferred. The API product-spec level (PSL1 vs PSL2), ASTM grade (A, B, C, TP304, etc.), and whether the pipe is seamless or welded are the three practical levers an engineer uses to meet a design brief.

What are Steel Pipe Material Grades and standards?

Steel pipe “grades” are shorthand labels that combine a standardized specification (ASTM, API, EN/ISO), a grade identifier (A, B, X42, X65, TP304, etc.), and sometimes a process/type (seamless / ERW / EFW). Standards bodies define chemical composition limits, required mechanical properties (minimum yield and tensile strength), testing and inspection regimes, and sometimes acceptable manufacturing processes.

Key standards and bodies to recognize:

-

API 5L — widely used for line pipe in oil & gas; uses X-numbers (X42, X56, X70) and product specification levels (PSL1, PSL2).

-

ASTM / ASME (examples: A106, A53, A333, A252) — cover pressure/seamless/welded pipe, low-temperature service, piling and more.

-

EN / ISO standards — widely used in Europe and internationally (for example EN 10216 series for seamless steel tubes). (See official standards in procurement.)

-

Material designations — “TP304” or “TP316L” is how ASTM labels stainless tube/pipe types (TP = tube/pipe).

Why standards matter: they determine whether a pipe will meet contract requirements for pressure, temperature and environmental exposure. Higher specification levels require additional testing and traceability; for critical systems this is non-negotiable.

How grades are created — composition, processing and the manufacturing fingerprint

A pipe’s grade arises from metallurgy and the production route:

-

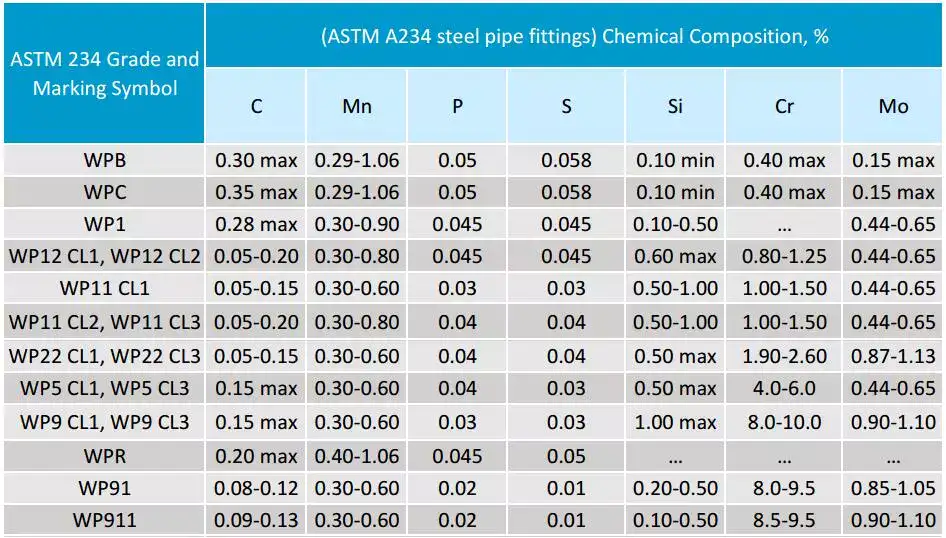

Basic alloy chemistry (carbon, manganese, silicon, chromium, nickel, molybdenum, nitrogen, etc.) sets corrosion resistance, hardenability and baseline strength. For example, adding chromium and nickel produces austenitic stainless grades (304, 316); adding molybdenum improves pitting resistance (316/316L).

-

Thermo-mechanical processing and heat treatment control grain size and microstructure (normalized, quenched & tempered, annealed). For linepipe, modern X-grades often use thermomechanical controlled processing (TMCP) to increase toughness without heavy alloying.

-

Fabrication method (seamless, ERW, UOE, JCOE, EFW) affects residual stresses, anisotropy and typical defect modes — an ERW seam has different failure modes than a seamless pipe.

-

Post-manufacturing tests (tensile, hardness, Charpy V-notch, flattening, hydrostatic, PWHT in some cases) and non-destructive examinations (UT, radiography) establish compliance.

These three components (chemistry, processing, testing) are what standards codify.

Carbon and low-alloy steel pipe grades

Carbon steels are most common for line pipe, utility distribution and structural applications because of cost and predictable mechanical behavior. Below is a practical comparison of frequently specified carbon/low-alloy pipe grades and where they fit.

Table 1 — Common carbon/low-alloy pipe grades and typical uses

| Grade / Spec | Key mechanical range (typical) | Type (seamless/welded) | Typical applications |

|---|---|---|---|

| API 5L Grade B | Yield ≈ 30–35 ksi; Tensile ≈ 60–80 ksi (varies) | Seamless or welded | General line pipe, water, moderate pressure oil/gas. |

| API 5L X42–X70 (X-grades) | Yield from ~42 ksi (X42) up to ~70 ksi (X70) | Seamless / ERW / UOE | High-strength line pipe for long-distance pipelines; higher grades reduce wall thickness. |

| ASTM A106 (A,B,C) | Seamless carbon steel for high-temperature service; Grade B common | Seamless only | Steam pipelines, high-temp service; A106 is a common seamless pipe spec. |

| ASTM A53 (A,B) | Can be welded or seamless; Grade B common | Seamless or welded | Structural and low/medium pressure applications; piping systems. |

| ASTM A333 / A334 | Low-temperature carbon and alloy steel pipe (better toughness) | Seamless or welded | Cryogenic or low-temperature service. |

| ASTM A252 Grade 1/2/3 | Piling & structural pipe grades (specified strength ranges) | Welded or seamless | Piling, structural applications. |

Notes & practical points

-

ASTM A106 requires seamless manufacture; A53 can be welded or seamless — this is a practical procurement distinction that frequently drives vendor selection and cost.

-

API 5L X-grades are normalized/thermomechanically produced to meet higher strength while maintaining notch toughness; for pipeline long runs, higher X-grades (X56–X70) allow thinner walls and lower overall steel tonnage.

Stainless steels, duplex and super-duplex

Stainless and duplex grades are selected where chemical or seawater corrosion, sanitary requirements, or elevated strength-to-weight ratios are critical.

Primary stainless families used for piping

-

Austenitic (300 series): TP304 / TP304L, TP316 / TP316L are the common choices. 316/316L includes molybdenum for improved pitting resistance and is common in seawater, chemical and food applications.

-

Ferritic / Martensitic: used in specialized high-temperature or magnetic applications, less common for general piping.

-

Duplex (e.g., 2205) and Super-Duplex (e.g., 2507): offer about twice the strength of 300-series austenitics, superior resistance to chloride stress-corrosion cracking, and good pitting resistance when alloyed with Mo; they are favored for seawater service, offshore piping, and applications where thinner walls save weight and cost.

Table 2 — Simplified corrosion & mechanical comparison (qualitative)

| Grade | Corrosion resistance (general) | Strength | Typical use cases |

|---|---|---|---|

| TP304 | Moderate (general corrosion) | Moderate | Food service, potable water, HVAC |

| TP316 / 316L | Better pitting resistance (Mo) | Moderate | Chemical, seawater splashes, sanitary |

| Duplex 2205 | High pitting + SCC resistance | High (~2× 304 strength) | Seawater, offshore, heat exchangers |

| Super-Duplex 2507 | Very high pitting + SCC resistance | Very high | Aggressive chloride environments, topside + downhole |

Key design consequences

-

Duplex and super-duplex can drastically reduce wall thickness for the same pressure rating due to higher allowable stress; however, they require skilled welding procedures and careful heat input control.

-

Austenitics (304/316) are much easier to fabricate and weld but may be at risk of chloride SCC in some offshore or brackish conditions.

API 5L PSL1 vs PSL2 — what the specification levels mean in practice

API 5L uses Product Specification Levels (PSL1 and PSL2). The difference is not merely marketing — PSL2 imposes stricter controls and additional testing.

Practical differences

-

PSL1: baseline requirements for line pipe (chemical and mechanical properties, standard testing). Suitable for many onshore and low-risk uses.

-

PSL2: tighter chemical limits, more rigorous mechanical property requirements, mandatory Charpy impact testing for many grades/sizes, more detailed manufacturing records and traceability; required where fracture control, low temperature toughness, or high-reliability operation is needed (e.g., some subsea and high-pressure pipelines).

Table 3 — Selected contractual implications

| Topic | PSL1 | PSL2 |

|---|---|---|

| Charpy impact testing | Optional / limited | Usually required for many grades/sizes |

| Chemical controls | Standard | Tighter ceilings and sometimes tighter element ranges |

| Traceability | Basic | Enhanced (mill tests, traceability, documentation) |

| Typical procurement cost | Lower | Higher (more testing + tighter controls) |

When to require PSL2: a specification writer should ask whether the pipeline faces low temperatures, fracture-critical operation, long repair delays (offshore), or regulatory requirements; if yes, PSL2 is prudent.

Seamless vs welded (ERW / EFW / UOE)

Manufacturing route influences availability, cost and some mechanical performance aspects.

-

Seamless: drawn or extruded from a billet; historically preferred for high-temperature and high-pressure service because no seam is present to concentrate defects. ASTM A106 is exclusively seamless.

-

ERW (electric resistance welded): common for smaller diameters and many linepipe sizes; modern ERW with proper inspection is robust and widely used.

-

UOE / JCOE (formed and welded): used for large-diameter linepipe and long runs; carefully controlled UOE processes with NDT and hydrostatic testing yield high-quality pipe.

Practical procurement note: Many project specifications will allow both seamless and welded pipe if the manufacturing process and NDT satisfy the standard’s requirements — but some standards (A106) mandate seamless manufacture.

Mechanical properties, toughness and testing expectations

Beyond yield/tensile numbers, toughness at service temperature matters. Key tests and checks:

-

Tensile/Yield: baseline strength numbers used for design.

-

Charpy V-notch impact testing: required to ensure notch toughness at a designated temperature (essential in cold climates or where brittle fracture is a risk). PSL2 often requires Charpy testing.

-

Non-Destructive Testing (NDT): UT, RT, magnetic particle and dye-penetrant tests find volumetric and surface flaws.

-

Positive Material Identification (PMI): sometimes required for corrosion-sensitive alloys to confirm composition.

-

Hydrostatic testing: standard leak/pressure test to validate integrity.

Design tip: Always set the Charpy acceptance temperature below the coldest expected operating temperature with an appropriate safety margin.

International equivalents and quick mapping

Engineers frequently need to translate between ASTM/API and EN/ISO or country-specific labels. Below is a compact mapping table (typical/approximate — always verify the exact standard calls).

Table 4 — Practical grade mapping (common equivalences)

| Common US/API grade | Typical equivalent / comment |

|---|---|

| ASTM A106 B | Common seamless carbon pipe; often quoted alongside A53 and API 5L Grade B. |

| ASTM A53 B | Can be welded or seamless; sometimes used interchangeably with API 5L Grade B in procurement but confirm manufacturing type. |

| API 5L Grade B / X42–X70 | Linepipe family; X-grades map by yield strength ranges. |

| TP304 / TP316 | Equivalent to stainless 304/316 family (EN 1.4301 / 1.4401) — check L/low-C variants for welding needs. |

| Duplex 2205 (UNS S32205) | EN/EN numbers exist — used where chloride SCC is a concern. |

Caveat: “Equivalent” does not mean identical. Acceptance and verification must be done by reviewing both standards’ chemical and mechanical limits.

Selection matrix — step-by-step and worked examples

A simple process to select a pipe grade for a project:

-

Define service conditions: internal fluid chemistry, pressure, temperature range, external environment (soil, seawater), regulatory constraints.

-

Identify mechanical requirements: design pressure, allowable stress, required safety factors, weight constraints.

-

Select candidate families: carbon (cost effective), low-alloy (if higher strength needed), stainless or duplex (if corrosion critical).

-

Decide manufacturing route: seamless if A106 or if thinner sections and fatigue resistance needed; welded for larger diameters or cost control.

-

Specify testing & PSL: choose PSL2 if toughness and fracture control matter; require Charpy V-notch at a specified temperature.

-

Procurement language: call out exact standard, grade, PSL (if API 5L), impact test temperature, NDT requirements, and documentation traceability.

Two short examples

-

Onshore water transmission — moderate pressure, non-corrosive: API 5L Grade B or X42 (PSL1 if non-critical).

-

Offshore seawater riser — high corrosion risk + chloride: Duplex 2205 (or super-duplex) with strict welding controls, PMI, and corrosion allowance; require PSL2-like traceability if pipeline spec.

Procurement language & contract tips

A well-written pipe purchase order avoids costly substitutions. Include:

-

Standard (e.g., API 5L, ASTM A106, EN 10216) and edition/year.

-

Grade (X65, Grade B, TP316L, S32205 etc.).

-

Manufacture method permitted/forbidden (seamless / ERW / UOE).

-

PSL level (for API 5L: PSL1 or PSL2).

-

Testing and acceptance criteria: Charpy temperature and acceptance energy, hydrostatic pressure, UT/RT requirements, PMI (if stainless/duplex), coating and lining requirements.

-

Traceability & documentation: Mill Test Reports (MTRs), heat numbers, NDT reports, welding procedure qualifications (PQR/WPS) when welded spools are to be supplied.

-

Penalties / acceptance: rejection criteria and rework rules for deviations.

Summary tables & quick reference

Table 5 — Quick reference: Which grade to choose by application

| Application | Typical grade family | Why |

|---|---|---|

| Municipal water mains | API 5L Grade B / ASTM A53 | Cost effective, ductile enough |

| High-temperature steam | ASTM A106 | Seamless, high-temp capable. |

| Long-distance gas transmission | API 5L X56–X70 | Higher strength → thinner walls, lower weight. |

| Seawater / offshore | Duplex 2205 / Super-Duplex 2507 | SCC and pitting resistance, high strength. |

| Cryogenic systems | ASTM A333 | Low temperature toughness certified. |

Frequently asked questions

-

Q: What’s the difference between ASTM A53 and ASTM A106?

A: A106 is specified for seamless carbon steel pipe for high-temperature service; A53 can be welded or seamless and is often used for lower-temperature and structural applications. In practice many suppliers will quote A106 for seamless runs and A53 for welded/ERW orders — confirm manufacturing method. -

Q: When should I require API 5L PSL2 instead of PSL1?

A: Use PSL2 when fracture control, low-temperature toughness, or higher reliability and traceability are needed (e.g., subsea, sour service, or critical gas pipelines). PSL2 mandates additional tests and stricter chemistry limits. -

Q: Are stainless 316L and 304 interchangeable?

A: No; 316L contains molybdenum for better pitting resistance and 316L’s lower carbon improves weldability. Use 316L where chloride pitting or chemical exposure is expected. -

Q: Why use duplex stainless instead of 316 in seawater?

A: Duplex provides higher strength and markedly better resistance to chloride stress-corrosion cracking and pitting; it can reduce wall thickness and overall cost for aggressive seawater service despite higher alloy price. -

Q: Is seamless always better than welded?

A: Not always. Seamless has no seam but can be more expensive and limited in diameter; modern welded methods (ERW, UOE) with adequate NDT yield reliable, cost-effective pipe. For certain high-temperature or fatigue-sensitive service, seamless may be preferred. -

Q: How do X-grades (X56, X65, X70) relate to strength?

A: The X number approximates the minimum specified yield strength in ksi (e.g., X42 ≈ 42 ksi, X70 ≈ 70 ksi). Higher X means higher yield strength and potential for thinner walls. Always consult the API 5L table for exact limits and impact test requirements. -

Q: What tests should I require for offshore piping?

A: Charpy V-notch at designated temperature, full UT/RT of seams and welds, hydrostatic proof testing, PMI for duplex/austenitic, and welding procedure qualifications. Consider PSL2 level controls for added assurance. -

Q: Can I substitute ASTM A53 for API 5L?

A: Sometimes suppliers will offer A53 that meets API 5L Grade B limits, but substitution must be approved by the engineer because API 5L includes additional industry-specific requirements and size/grade ranges. Confirm mechanical and testing equivalency before acceptance. -

Q: What are common pitfalls in specifying stainless pipe?

A: Failing to specify L/low-carbon variants for weldability (e.g., 316L), neglecting to require corrosion allowance or protective coatings in aggressive environments, and omitting PMI for critical deliveries. -

Q: How should I handle traceability in procurement?

A: Require full mill test reports (MTRs) with heat numbers, chain-of-custody documentation, NDT reports and a record of any heat treatments or PWHT. For PSL2/API or duplex orders, require enhanced traceability.

References & authority

The technical points and tables above summarize standard practice found in API and ASTM documents, specialist piping suppliers and metallurgy references. The statements about A106 vs A53, API 5L PSL differences, duplex advantages, and general grade descriptions are consistent with authoritative technical sources and suppliers. Key sources used while preparing this material include API and ASTM guidance, major piping suppliers’ specification pages, and metallurgical association technical guides. Representative sources are cited throughout the text for the most load-bearing technical claims.

Practical checklist for your next piping specification

-

Standard + edition (e.g., API 5L 46th Ed. 20XX or ASTM A106/A53 with year).

-

Grade (explicit: X65 PSL2 / A106 B / TP316L etc.).

-

Manufacturing types allowed (seamless / ERW / UOE) and any forbidden processes.

-

PSL level (for API 5L) or equivalent toughness acceptance.

-

Charpy V-notch: test temperature and acceptance energy.

-

NDT requirements (UT/RT, inspection frequency).

-

PMI requirement for duplex/316/2507.

-

Coating/lining and corrosion allowance.

-

Mill Test Reports & traceability requirements.

-

Delivery, inspection hold points, and penalty clauses.

Closing summary

Steel pipe grade selection is an exercise in balancing metallurgy, manufacturing method and project economics. Use carbon grades for general pressure and structural work, specify austenitics or duplex when corrosion or reduced wall thickness are decisive, and always define the standard, test regime, and manufacturing route clearly in procurement documents. For critical infrastructure and offshore work, tighten requirements to PSL2 or equivalent and insist on full documentation.