Steel pipe dimensions are governed by fixed outside diameters tied to Nominal Pipe Size and by wall thickness tables identified by pipe schedule; The critical conclusion for all buyers and engineers is that Nominal Pipe Size (NPS) rarely equals the actual outside diameter (OD) of the pipe, a distinction that dictates system compatibility and pressure safety. MWalloys resolves this complexity by adhering strictly to ASME B36.10M and ASME B36.19M standards while providing 100% factory-direct pricing, eliminating distributor markups. Whether your project requires standard Schedule 40 carbon steel or customized heavy-wall alloy configurations, our facility delivers precision-engineered piping solutions tailored to exact specifications. This guide serves as your primary technical resource for navigating diameter charts, wall thickness schedules, and weight calculations, ensuring your infrastructure meets the highest global safety and performance benchmarks.

1. The Fundamentals of Steel Pipe Sizing: NPS, DN, and OD

To master steel pipe dimensions sizes, one must first decouple the terminology from the physical measurements. In the industrial sector, the terms used to order pipe are designators, not direct measurements of the object in hand.

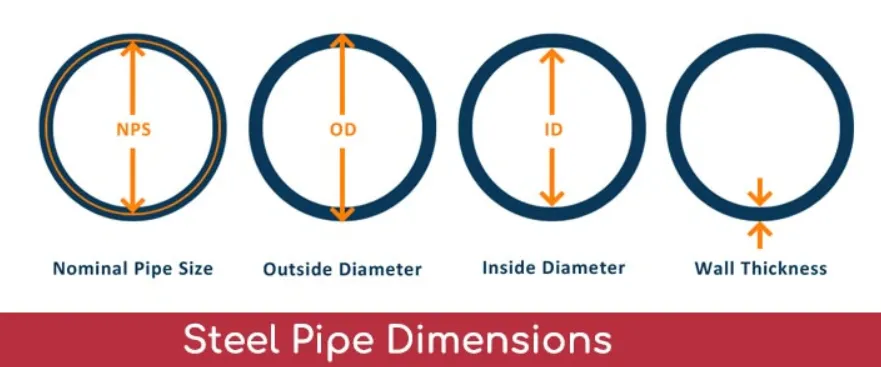

Nominal Pipe Size (NPS) vs. Actual Outside Diameter

The North American standard, known as Nominal Pipe Size (NPS), relies on a set of standardized integers (e.g., 2, 4, 6) to identify pipe. However, a confusing reality for novices is that an NPS 2 pipe does not have an outside diameter of 2 inches. It actually measures 2.375 inches (60.3 mm).

This discrepancy exists due to historical manufacturing practices known as "Iron Pipe Size" (IPS). In the early 20th century, pipes were sized based on a standardized internal diameter (ID). As manufacturing improved and wall thicknesses decreased to save material while maintaining pressure ratings, the inside diameter increased, but the outside diameter (OD) remained fixed to ensure compatibility with mating flanges, valves, and fittings.

The Two Rules of OD:

-

NPS 1/8 to NPS 12: The Actual OD is always larger than the Nominal Pipe Size designator.

-

NPS 14 and Larger: The Actual OD is equal to the Nominal Pipe Size (e.g., NPS 14 pipe is exactly 14 inches on the outside).

Diameter Nominal (DN) and Metric Conversion

Global trade requires fluency in both Imperial and Metric systems. The International Standards Organization (ISO) uses Diameter Nominal (DN), measured in millimeters. MWalloys supplies both markets, so understanding the translation is vital.

Conversion Formula:

NPS×25.4≠DN(This is a common misconception).

The standard defines specific mappings. For example, NPS 3 is DN 80, not DN 76.2.

Table 1: Common NPS to DN to OD Reference

| Nominal Pipe Size (NPS) | Diameter Nominal (DN) | Actual Outside Diameter (Inches) | Actual Outside Diameter (mm) |

| 1/2 | 15 | 0.840 | 21.34 |

| 3/4 | 20 | 1.050 | 26.67 |

| 1 | 25 | 1.315 | 33.40 |

| 1 1/2 | 40 | 1.900 | 48.26 |

| 2 | 50 | 2.375 | 60.33 |

| 3 | 80 | 3.500 | 88.90 |

| 4 | 100 | 4.500 | 114.30 |

| 6 | 150 | 6.625 | 168.28 |

| 8 | 200 | 8.625 | 219.08 |

| 10 | 250 | 10.750 | 273.05 |

| 12 | 300 | 12.750 | 323.85 |

| 14 | 350 | 14.000 | 355.60 |

2. Decoding Pipe Schedules: Wall Thickness and Pressure Ratings

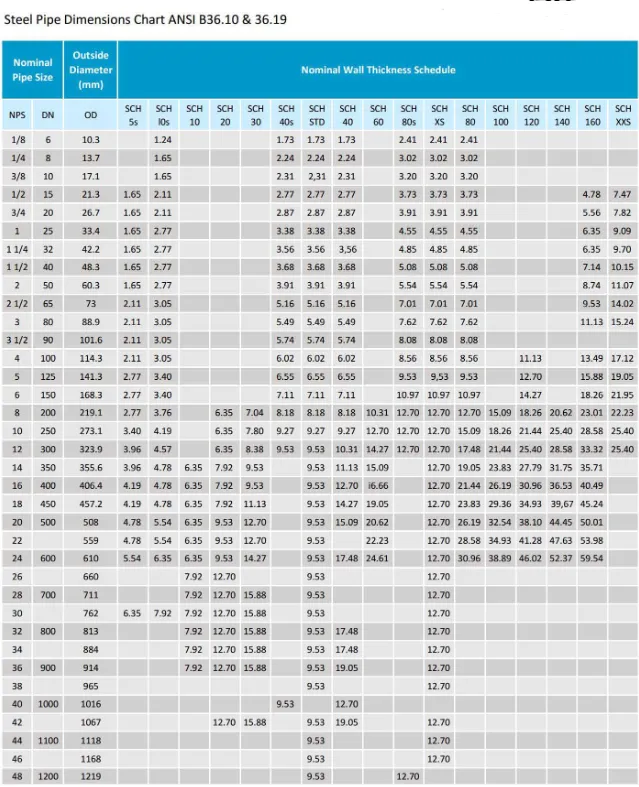

When engineers specify steel pipe dimensions sizes, the "Schedule" (SCH) is the variable that determines the pipe's strength. The Schedule number is not a dimension itself but a classification of wall thickness relative to the OD.

The Engineering Logic of Schedule Numbers

The American National Standards Institute (ANSI) established schedule numbers to replace the older, vaguer terms of Standard (STD), Extra Strong (XS), and Double Extra Strong (XXS).

The schedule number is derived roughly from the formula:

Schedule=1,000×PS

Where:

-

P = Internal Service Pressure (psig)

-

S = Ultimate Tensile Strength of the material (psi)

This means a Schedule 80 pipe is designed to withstand significantly higher internal pressures than a Schedule 40 pipe. At MWalloys, we emphasize that increasing the schedule increases the wall thickness by reducing the Inside Diameter. The Outside Diameter is locked.

Standard vs. Heavy Wall Configurations

-

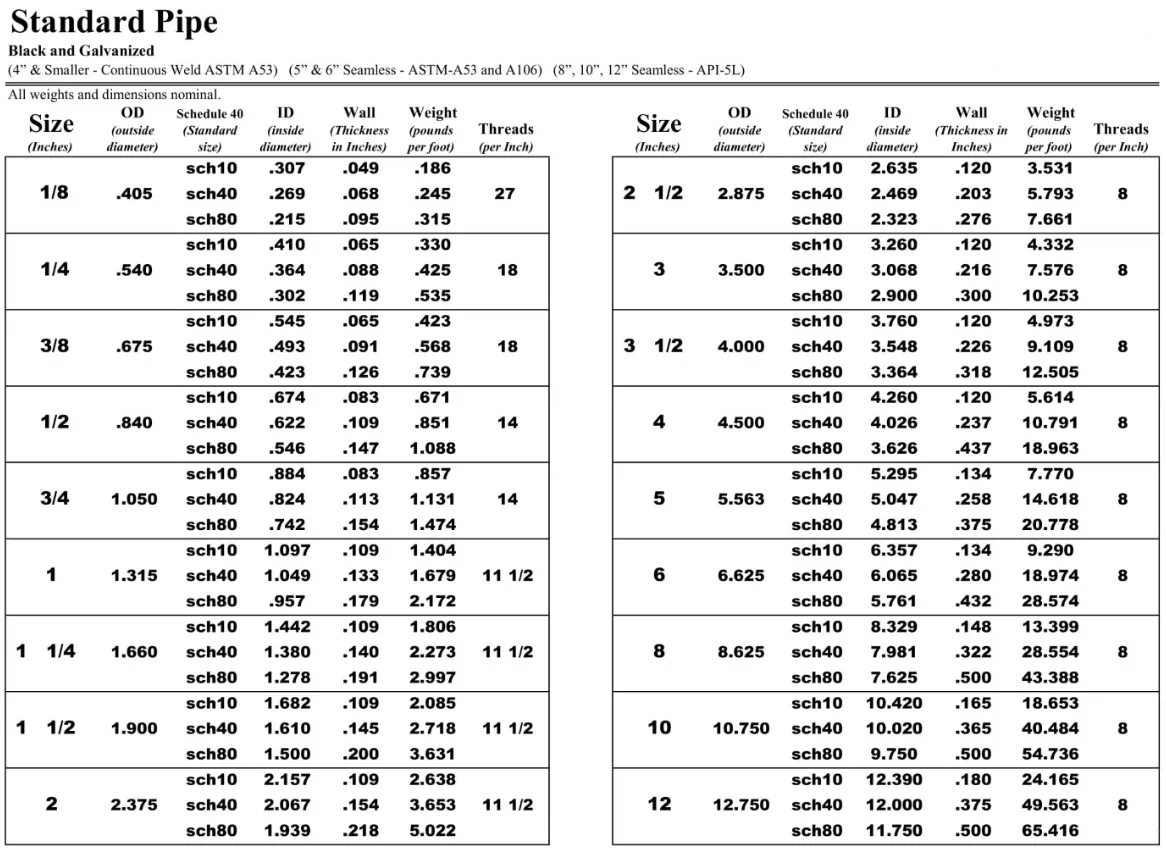

Schedule 40 (STD): The most ubiquitous size for general plumbing, structural applications, and low-pressure fluid transport. For sizes up to NPS 10, Sch 40 is identical to "Standard Weight" (STD).

-

Schedule 80 (XS): Used in high-pressure steam, chemical processing, and hydraulic lines. It provides a thicker wall for corrosion allowance. Up to NPS 8, Sch 80 is identical to "Extra Strong" (XS).

-

Schedule 160 & XXS: Reserved for extreme pressure environments, such as power generation and deep-sea oil extraction.

MWalloys Technical Note:

Procurement officers must note that stainless steel schedules are designated with an "S" suffix (e.g., Sch 10S, Sch 40S) according to ASME B36.19M. These often allow for thinner walls due to the superior corrosion resistance of the material compared to carbon steel.

3. Comprehensive Dimension Charts (ASME B36.10M)

The following data sets represent the core product lines manufactured at MWalloys. We maintain tight controls over these dimensions to ensuring seamless field fit-up.

Chart A: Small Bore Pipe (NPS 1/2 to NPS 2)

Small bore piping is critical for instrumentation and branch lines. Precision here is paramount to prevent vibration fatigue.

| NPS | Schedule | Wall Thickness (in) | Wall Thickness (mm) | Inside Diameter (in) | Weight (lb/ft) | Weight ( kg/m ) |

| 1/2 | 40 (STD) | 0.109 | 2.77 | 0.622 | 0.85 | 1.27 |

| 1/2 | 80 (XS) | 0.147 | 3.73 | 0.546 | 1.09 | 1.62 |

| 1 | 40 (STD) | 0.133 | 3.38 | 1.049 | 1.68 | 2.50 |

| 1 | 80 (XS) | 0.179 | 4.55 | 0.957 | 2.17 | 3.24 |

| 2 | 40 (STD) | 0.154 | 3.91 | 2.067 | 3.65 | 5.44 |

| 2 | 80 (XS) | 0.218 | 5.54 | 1.939 | 5.02 | 7.48 |

| 2 | 160 | 0.344 | 8.74 | 1.687 | 7.46 | 11.11 |

Chart B: Medium Bore Pipe (NPS 3 to NPS 12)

This range constitutes the bulk of process piping in refineries and commercial construction.

| NPS | Schedule | Wall Thickness (in) | Wall Thickness (mm) | Inside Diameter (in) | Weight (lb/ft) | Weight ( kg/m ) |

| 4 | 40 (STD) | 0.237 | 6.02 | 4.026 | 10.79 | 16.07 |

| 4 | 80 (XS) | 0.337 | 8.56 | 3.826 | 14.98 | 22.32 |

| 6 | 40 (STD) | 0.280 | 7.11 | 6.065 | 18.97 | 28.26 |

| 6 | 80 (XS) | 0.432 | 10.97 | 5.761 | 28.57 | 42.56 |

| 8 | 40 (STD) | 0.322 | 8.18 | 7.981 | 28.55 | 42.55 |

| 8 | 80 (XS) | 0.500 | 12.70 | 7.625 | 43.39 | 64.64 |

| 10 | 40 (STD) | 0.365 | 9.27 | 10.020 | 40.48 | 60.31 |

| 12 | STD | 0.375 | 9.53 | 12.000 | 49.56 | 73.88 |

| 12 | XS | 0.500 | 12.70 | 11.750 | 65.42 | 97.46 |

(Note: MWalloys can manufacture up to NPS 48 with wall thicknesses exceeding 2 inches for specialist applications. Contact our engineering desk for large-diameter charts.)

4. Technical Calculations: Weight and Mass Formulas

Logistics planning and structural support design depend heavily on accurate weight calculations. While charts are useful, engineers often need to calculate the weight of non-standard custom lengths or sizes provided by MWalloys.

The theoretical weight of steel pipe (Carbon Steel) is calculated using the following industry-accepted formula:

W=10.69×(OD−t)×tWhere:

-

W = Weight in pounds per foot (lb/ft).

-

OD = Outside Diameter in inches.

-

t = Wall Thickness in inches.

For Metric calculations ( kg/m ):

W=0.02466×(OD−t)×tW=0.02466×(OD−t)×tWhere:

-

OD is in mm

-

t is in mm

Weight per unit length and volume calculations

For design and shipping cost estimation calculate:

-

Cross sectional area = π × (OD² − ID²) / 4

-

Volume per foot = cross sectional area × 12 inches

-

Weight per foot = volume per foot × material density

Typical densities:

-

Carbon steel ~ 0.283 lb/in³ (7850 kg/m³)

-

Stainless steel ~ 0.29 lb/in³ (8000 kg/m³)

Example quick computation for NPS 2 inch SCH 40:

-

OD = 2.375 inch; wall = 0.154 inch; ID = 2.067 inch

-

Area of metal = π × (2.375² − 2.067²) / 4 ≈ 1.009 in²

-

Volume per foot = 1.009 × 12 = 12.11 in³

-

Weight per foot = 12.11 × 0.283 ≈ 3.43 lb/ft

Always use precise numbers from the standard tables or mill certificates for final logistics quotes.

Why Calculation Matters:

Shipping costs are determined by mass. When you purchase from MWalloys, we optimize the loading plan based on these exact calculations to maximize container space. A misunderstanding of "Nominal" vs "Actual" weight can lead to logistical errors. MWalloys guarantees that billed weight aligns with theoretical weight within the tolerances permitted by ASTM standards.

5. Manufacturing Tolerances and Quality Control

A common oversight in searching for steel pipe dimensions sizes is assuming the pipe will be geometrically perfect. In reality, manufacturing standards (ASTM A53, A106, API 5L) allow for specific tolerances. MWalloys prides itself on maintaining tolerances stricter than the standard where possible.

Wall Thickness Tolerance

For most seamless and welded pipes (ASTM A53/A106), the minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

-

Implication: If you order a pipe with 0.500" wall, a spot measurement of 0.4375" is technically acceptable by standard. MWalloys utilizes advanced rotary calipers during production to aim for the nominal mean, ensuring you get the steel you paid for.

Outside Diameter Tolerance

-

NPS 1.5 and under: ±1/64 inch (0.4 mm)

-

NPS 2 to NPS 4: ±1/32 inch (0.8 mm)

-

NPS 5 to NPS 8: ±1/16 inch (1.6 mm)

-

NPS 10 and larger: ±3/32 inch (2.4 mm)

Straightness and Ovality

Pipes must be reasonably straight. MWalloys implements laser straightness checks, particularly for pipes intended for threading or use in automated CNC fabrication centers, reducing downtime for our clients.

6. Material Grades: Beyond the Dimensions

While dimensions ensure the pipe fits, the material grade ensures it lasts. MWalloys stocks and manufactures pipes in various grades that adhere to the dimensional standards of ASME B36.10.

-

Carbon Steel (ASTM A106 Gr B / A53 Gr B): The workhorse of the industry. Used for high-temperature service and general fluid transfer.

-

Low Temp Carbon Steel (ASTM A333 Gr 6): Dimensionally identical to A106 but chemically treated to withstand impact at -50°F (-45°C).

-

Line Pipe (API 5L X42 - X80): High-yield pipe for oil and gas transmission. The dimensions follow the same NPS charts, but the walls may be thinner due to the higher strength of the steel.

-

Alloy Steel (ASTM A335 P11, P22, P91): Used in power generation for extreme heat.

Our factory capability allows us to produce custom dimensions within these grades. If a client needs a non-standard wall thickness (e.g., 0.625" exactly) to meet a specific pressure vessel code, MWalloys can adjust the extrusion die to produce it.

7. The MWalloys Advantage: Customization & Factory Direct Model

In a market saturated with trading companies and middlemen, MWalloys stands apart as a manufacturer. Our "100% Factory Price" promise is not just a slogan; it is an operational structure.

Why Factory Direct Matters for Dimensions

When buying from a stockist, you are limited to what sits in their warehouse—typically standard Schedule 40 or 80.

-

Custom Lengths: We cut or manufacture to your exact length (e.g., 11.8 meters) to fit shipping containers perfectly or to reduce onsite welding waste.

-

Odd Sizes: Need NPS 5 pipe? It is a non-standard size often unavailable in distribution centers. MWalloys can manufacture it.

-

Precision Beveling: We apply custom bevel angles (30°, 37.5°, or compound bevels) at the factory, saving hours of manual labor at your construction site.

Supply Chain Efficiency

By integrating the manufacturing and export logic, we handle the entire process from billet selection to Free on Board (FOB) or Cost, Insurance, and Freight (CIF) delivery. Our team understands the nuances of bundling pipe to prevent ovality damage during ocean transit.

8. Installation Considerations Based on Sizing

The dimension of the pipe dictates the method of joining.

-

Butt Welding: Requires precise matching of the ID and OD. If joining a Schedule 80 pipe to a Schedule 40 fitting, the bore must be tapered (counter-bored) to prevent turbulence and erosion corrosion.

-

Socket Weld: Used for small bore (NPS 2 and below). The pipe is inserted into a recess. The OD tolerance is critical here; if the pipe is too large (even within tolerance), it may not fit the socket.

-

Threading (NPT/BSP): Only allowed on Schedule 40 and heavier. Light wall pipes (Schedule 10) do not have enough material to cut threads without compromising structural integrity.

MWalloys provides technical datasheets advising on the recommended joining method for every size and schedule we produce.

9. Advanced Topics: Flow Rate and Internal Volume

A frequently overlooked aspect of steel pipe dimensions sizes is the internal capacity. Because Schedule 80 has a smaller ID than Schedule 40, it holds less fluid per linear foot.

Flow Area Calculation:

Area=π×r2

Where

rris the internal radius.

For an NPS 2 pipe:

-

Sch 40 ID: 2.067" -> Area ≈ 3.35 sq inches.

-

Sch 80 ID: 1.939" -> Area ≈ 2.95 sq inches.

This ~12% reduction in flow area means that to move the same volume of fluid, the velocity must increase, which increases friction head loss and energy consumption. Engineers must balance the need for pressure containment (thicker wall) with energy efficiency (larger ID). MWalloys engineers can assist in these ROI calculations during the material selection phase.

10. Frequently Asked Questions (FAQs)

What is the difference between NPS and OD?

Does the Outside Diameter change with the Schedule?

What does "STD" and "XS" mean in pipe sizing?

Can MWalloys manufacture non-standard pipe lengths?

How do I convert inches to millimeters for pipe sizes?

Why is there a tolerance on wall thickness?

Is Schedule 160 the thickest pipe available?

What is the weight difference between Sch 40 and Sch 80?

Can I thread Schedule 10 pipe?

How do I measure pipe size if I don't have calipers?

Ready to Procure?

Navigating steel pipe dimensions sizes is complex, but buying them shouldn't be. MWalloys combines deep engineering expertise with factory-direct economics. Whether you need standard A106 seamless pipe or custom-fabricated line pipe, our team is ready to provide a quote that fits your budget and technical specifications.

Contact MWalloys today for your personalized quote and experience the power of factory-direct precision.