For general-purpose structural and food-contact applications, AISI/SAE 304 / ASTM A240 plates provide the best balance of corrosion resistance, formability and cost. For chloride-rich or aggressive chemical environments choose 316/316L (higher molybdenum). When higher strength + improved stress-corrosion resistance are required, select duplex (e.g., 2205) or super-duplex (e.g., 2507). For economical flat products for low-corrosion environments use ferritic grades (e.g., 430); for heat-resistant or wear-resistant parts choose martensitic grades (e.g., 410). Final selection must match mechanical, surface finish, weldability, and standard-spec requirements (ASTM A240, EN 10088, JIS), and should be confirmed with mill certificates for chemistry and mechanicals.

What “grade” means for stainless steel plate

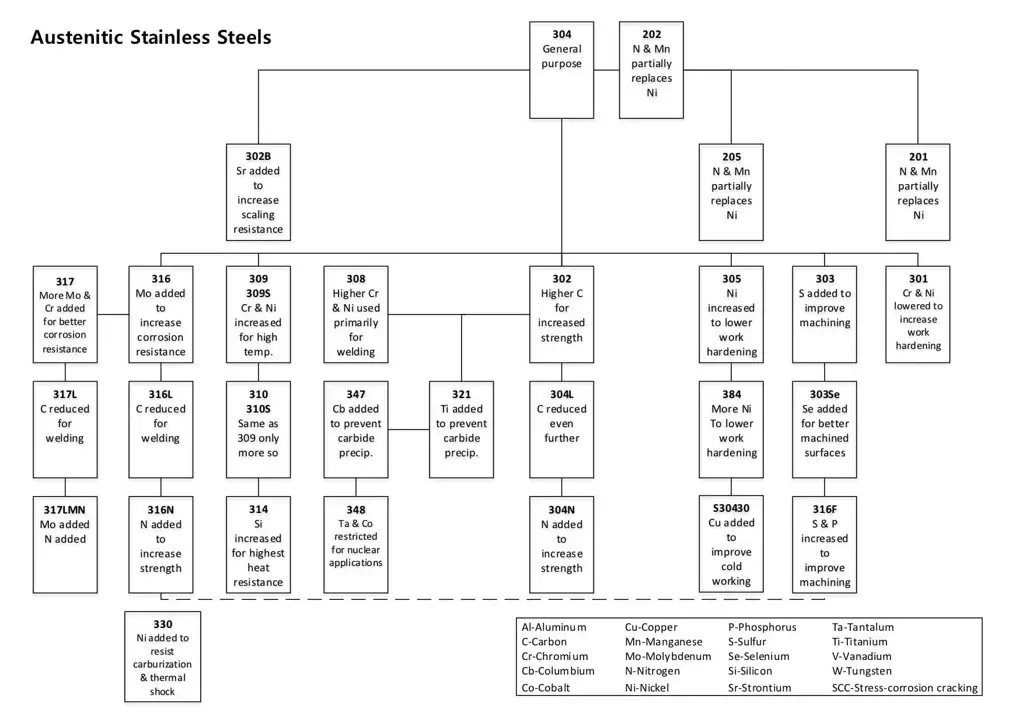

A stainless steel plate grade identifies a defined chemistry, microstructure and performance envelope. Grades fall into families: austenitic (300-series like 304/316), ferritic (400-series like 430), martensitic (410/420), duplex (2205, S31803), super-duplex (2507, S32750), and precipitation-hardening or specialty alloys. Each family has trade-offs: austenitics offer high toughness and formability but moderate strength; duplex grades deliver higher yield strength and improved chloride resistance per unit cost; ferritics are magnetic and lower cost. These families and the way flat products are specified are codified in standards such as ASTM A240 and EN 10088.

Quick reference: recommended grades by application

| Application area | Typical recommended grade(s) | Why (short) |

|---|---|---|

| Food processing, kitchenware | 304 / 304L | Excellent forming, hygienic, economical. |

| Marine fittings, chloride exposure | 316 / 316L | Molybdenum improves pitting resistance |

| Chemical process equipment | 316L, 317L, Alloy 20, 904L | Better resistance to reducing acids / chlorides. |

| Structural / pressure parts needing higher strength | Duplex 2205 | Higher yield strength, good weldability. |

| Highly corrosive oil & gas environments | Super-duplex 2507 | Excellent strength + corrosion resistance. |

| Decorative panels, low-cost corrosion | 430 | Ferritic, good appearance but lower chloride resistance. |

| Heat-resistant parts | 309, 310 | High temp oxidation resistance. |

| Wear / knife blades (hardenable) | 420 / 440C | Martensitic, can be heat treated for hardness. |

(Use this table as a purchasing shorthand. Match final selection to continuous operating temperature, chloride exposure, and mechanical load.)

Key stainless plate grades

-

304 / 304L (UNS S30400 / S30403) — the workhorse: ~18% Cr, ~8% Ni. Good welding and formability; food & architecture.

-

316 / 316L (UNS S31600 / S31603) — adds Mo (≈2–3%) to improve resistance to chlorides and pitting. Favoured in marine and chemical industries.

-

321 / 347 — stabilized with Ti or Nb for high-temperature service to avoid sensitization.

-

409 — low-alloy ferritic, commonly used in automotive exhaust systems (economical).

-

410, 420 — martensitic, heat treatable, used where hardness is required.

-

430 — ferritic, decorative/architectural and some appliance parts.

-

2205 (Duplex) — balanced duplex microstructure (~22% Cr, 5–6% Ni, ~3% Mo) with high strength and good chloride resistance.

-

2507 (Super-duplex) — higher Cr and Mo; used in offshore oil & gas.

Chemical composition (selected grades)

| Grade | Main alloying (typical wt%) |

|---|---|

| 304 | Cr 17–19, Ni 8–10, C ≤0.08 |

| 304L | Cr 17–19, Ni 8–12, C ≤0.03 |

| 316 | Cr 16–18, Ni 10–14, Mo 2–3 |

| 316L | similar to 316, lower C |

| 2205 | Cr ~22, Ni 4.5–6.5, Mo 3–3.5, N 0.14–0.20 |

| 2507 | Cr ~25–26, Ni 6–7, Mo 3.6–4, N 0.24–0.32 |

| 430 | Cr 16–18, Ni ≤0.75 |

| 410 | Cr 11.5–13.5, C higher for hardening |

(These are indicative ranges; always check the mill certificate and the appropriate standard.)

Mechanical properties (typical plate condition)

| Grade | Yield strength (0.2% Rp0.2, MPa) | Tensile (MPa) | Elongation (%) |

|---|---|---|---|

| 304 annealed | ~205–215 | 520–720 | 40–50 |

| 316 annealed | ~170–205 | 520–700 | 40–50 |

| 2205 duplex (annealed) | ~450 | 620–880 | 25–35 |

| 2507 super-duplex | ~550 | 750–900 | 20–30 |

| 430 | ~200–300 | 450–600 | 20–30 |

(Standards list minimums and vary by thickness; see ASTM A240 and EN 10088 for exact acceptance limits.)

Corrosion behaviour and ranking

Key phenomena affecting plates:

-

General corrosion — uniform material loss; controlled by chromium content and environment.

-

Pitting — localised attack in chlorides; molybdenum and nitrogen improve resistance (PREN = %Cr + 3.3×%Mo + 16×%N is a useful metric for duplex/super-duplex).

-

Crevice corrosion — in stagnant pockets; surface finish and crevice design matter.

-

Stress Corrosion Cracking (SCC) — a concern for austenitics in chloride + tensile stress environments; duplex grades perform better.

Practical ranking (low → high chloride resistance): ferritic 430 / martensitic 410 → 304 → 316 → duplex 2205 → super-duplex 2507 → nickel-alloys (Alloy 625/825). Use PREN predictions for engineered selection. (For chloride thresholds and design guidance, consult specialty corrosion handbooks and the Nickel Institute).

Fabrication notes: forming, welding, annealing, surface finish

-

Forming: Austenitics are cold-ductile and bend well; ferritics have lower ductility and may crack if bent too sharply. Duplex requires controlling deformation ratio to avoid ferrite/austenite imbalance.

-

Welding: Most stainless plates are welded with matching filler metal (e.g., ER308L to 304). Low carbon grades (304L/316L) reduce intergranular corrosion risk after welding. Duplex welding requires strict heat input control and often use of duplex filler metals.

-

Heat treatment: Austenitic grades are generally not hardenable by heat treatment (work hardening occurs). Martensitic grades are heat treatable for hardness. Duplex needs solution annealing after heavy cold work to restore balance.

-

Surface finish: Mill finishes include HRAP, 2B, BA, No.4, No.8; finish affects cleanability and corrosion initiation. For hygienic use choose smooth finishes (No.4 or better).

-

Edge condition & thickness tolerance: These are standardised in ASTM/EN specs; ensure PO notes edge type (sheared, milled) and tolerance class.

Standards and procurement (how to specify)

When purchasing plate, specify:

-

Material standard (e.g., ASTM A240 / A480 for plate/sheet; for pressure vessels see specific codes).

-

Grade and UNS number (e.g., 316L / UNS S31603).

-

Thickness range, width and length tolerance.

-

Surface finish and edge preparation.

-

Heat treatment condition (annealed, solution-treated).

-

Mill test certificate Type 3.1 or 3.2 (traceability).

-

Additional testing: PMI (positive material identification), intergranular corrosion (ASTM A262), hardness, Charpy impact where low-temperature service is anticipated.

Useful references: national standards (ASTM A240), EN 10088 family (flat products), and national specification collections (e.g., JIS G4304 for stainless steel plate/sheet in Japan).

Duplex and super-duplex: selection considerations

Duplex alloys (2205) combine an austenitic and ferritic microstructure, offering roughly twice the yield strength of 304/316 with improved SCC resistance in chloride environments. Key points:

-

Design efficiency: thinner sections for equivalent strength (weight savings).

-

Weld procedure: must control interpass temps; use qualified weld procedures and matching filler.

-

Cost: higher alloy content and fabrication care increase price, but lifecycle savings often justify selection in aggressive environments (offshore, chemical processing).

Supply, tolerances, pricing drivers

Price drivers for plate:

-

Grade and alloying elements (Ni, Mo, Cr) — Ni and Mo are expensive; 316 costs more than 304; duplex and super-duplex cost more still.

-

Thickness and plate size — wide plates and heavy thickness increase base cost and bending/straightening processing needs.

-

Finish and special testing — polished finishes, certified heat treatments, and added tests (e.g., PMI) add to lead time and cost.

-

Market cycles — nickel and molybdenum price volatility affects quotes; get updated price confirmations at order placement.

Procurement tip: specify acceptable substitute grades and allow the supplier to propose alternatives (e.g., 316 vs 316L) only if you include clear chemistry/mechanical acceptance criteria and required test certificates.

Inspection, traceability and QA

Require at minimum:

-

Mill test certificate (MTC) Type 3.1 showing chemistry and mechanical results.

-

Material traceability — heat/lot number on plate, and matching MTC.

-

Non-destructive and destructive testing if required (UT for laminations, PMI for onsite verification, hardness).

-

Third-party inspection when safety/pressure service is involved.

Ten practical selection scenarios

-

Kitchen countertop / appliances: 304 or 430 (if cost constrained).

-

Boat railings / marine fittings: 316L or duplex for heavy salt exposure.

-

Chemical plant heat exchanger: 316L, 317L, or a nickel alloy depending on media.

-

Pressure vessel in chloride environment: duplex 2205 or super-duplex 2507.

-

Automotive exhaust: 409 (economical heat-resistant ferritic).

-

High temperature furnace coil: 310 or 309.

-

Cutlery / blades: 420 / 440C (martensitic, heat treated).

-

Architectural cladding: 304/316 with specified finish (No.4 or PVDF coating).

-

Sanitary pharmaceutical tanks: 316L, electropolished.

-

Offshore risers / valves: super-duplex or Nickel alloys (costly but longevity justified).

Correlation table: grade → PREN (simplified indicator)

| Grade | Approx PREN (typical) |

|---|---|

| 304 | ~9–12 |

| 316 | ~20–25 |

| 2205 | ~32–38 |

| 2507 | ~40–50 |

(Use PREN to compare pitting resistance; higher is better in chloride service. Confirm actual chemistry before design.)

Common mill finishes and usability

| Finish | Typical use |

|---|---|

| Hot rolled annealed & pickled (HRAP) | General structural. |

| 2B cold rolled | General flat products, good for shuttering and forming. |

| No.4 brushed | Decorative and hygienic surfaces. |

| Mirror (No.8) | Highly decorative; reflective. |

| Electropolished | Pharmaceutical and sanitary equipment. |

FAQs

1: What is the most commonly used stainless steel plate grade?

Grade 304 (ASTM A240) is the industry standard for general use due to its balanced corrosion resistance, formability and relatively low cost.

2: When should I specify 316 over 304 plate?

Choose 316/316L when service includes chlorides or marine atmospheres; molybdenum content improves pitting resistance.

3: What does ASTM A240 cover?

ASTM A240 defines chemistry and mechanical properties for many stainless steel grades intended for plate, sheet, and strip for pressure vessels and general flat products. Always quote the clause and grade when ordering.

4: How does duplex 2205 compare to 316 in strength?

Duplex 2205 typically has roughly double the yield strength of annealed 316 while providing comparable or better chloride resistance; it allows thinner sections for the same structural capacity.

5: Are stainless steel plates magnetic?

Many ferritic and martensitic grades are magnetic. Austenitic grades (304/316) are generally non-magnetic in the annealed state but can become slightly magnetic after cold work.

6: What tests should I require on a purchase order?

Specify MTC (Type 3.1), PMI spot checks, hardness, and any specific corrosion tests (ASTM A262) or impact testing if low-temperature service is expected.

7: Which finish is best for food/pharma tanks?

Electropolished or high-quality No.4 finishes with passivation provide optimal cleanability and reduced microbial adhesion.

8: Can stainless plate rust?

Localised rust can occur from surface contamination, chloride attack, or mechanical damage to passive film. Correct grade selection and cleaning prevent most issues.

9: How does plate thickness affect corrosion resistance?

Thickness itself does not change the alloy’s corrosion resistance per unit; however, design details (crevices, heat-affected zones) become more important with thicker sections.

10: Is 304L better than 304?

304L has lower carbon to reduce sensitization risk during welding; specify 304L when welding without post-weld anneal is expected.