The primary distinction between sheet metal and plate metal lies in the gauge or thickness. Sheet metal is classified as metal thinner than 6mm (0.25 inches), while plate metal includes any metal thicker than 6mm (0.25 inches). While both start as continuous cast slabs, their processing methods diverge; sheet metal generally undergoes cold rolling for a smoother finish and tighter tolerances, whereas plate metal is typically hot rolled to prioritize strength and structural integrity over surface finish.

1. Why the Distinction Matters for Your Project

Selecting the correct metal form is the first step in manufacturing and engineering. The choice between sheet and plate affects every downstream process. It dictates the cutting machinery you must use, the welding techniques required, the weight of the final assembly, and the total material cost.

At MWalloys, we frequently see procurement errors where buyers confuse these two categories. A misunderstanding here leads to structural failures or unnecessary expenses. Sheet metal offers flexibility and lightweight properties ideal for enclosures and body panels. Plate metal provides the tensile strength necessary for load-bearing structures like bridges and heavy machinery bases.

This comprehensive resource breaks down every technical nuance, ASTM standard, and processing difference to ensure you order the exact material your specifications demand.

2. Defining the Categories: Foil, Sheet, and Plate

To understand the spectrum of metal products, we must look at the three main classifications based on thickness. While "sheet" and "plate" are the most common terms, they exist on a continuum.

Foil

This is the thinnest category. Foil is metal rolled to a thickness generally below 0.20 mm (0.0079 inches). It is commonly associated with aluminum but can be produced from copper, gold, and other malleable metals. It holds little structural value and serves primarily in shielding, packaging, or insulation.

Sheet Metal

Sheet metal is the workhorse of general fabrication. It is defined by its pliability.

-

Thickness Range: Typically from 0.5mm (0.02 inches) up to 6mm (0.25 inches).

-

Key Characteristic: It can be coiled. Because it is thin enough to remain flexible, manufacturers often ship sheet metal in large rolls or coils, which fabricators then unroll and flatten.

-

Surface: usually requires a high-quality surface finish (like 2B or #4 polish) because it is often used in visible applications like appliances or architectural cladding.

Plate Metal

Plate metal represents the heavy-duty end of the spectrum.

-

Thickness Range: Anything surpassing 6mm (0.25 inches), extending upwards of 300mm for specialized applications.

-

Key Characteristic: Rigidity. Plate metal cannot be coiled. It is produced and shipped exclusively in flat, stacked sections.

-

Surface: Often retains the "mill scale" from hot rolling, a dark, bluish-grey layer, unless it undergoes secondary machining.

3. The Thickness Threshold: Where Does Sheet Become Plate?

The exact dividing line can vary slightly depending on the material (Stainless Steel vs Aluminum) and the governing standard (ASTM vs ISO), but the industry consensus centers on the quarter-inch mark.

The 3mm vs 6mm Debate

In the metric system, the confusion often lies between 3mm and 6mm.

-

Under 3mm: Universally considered sheet.

-

3mm to 6mm: This is a "transition zone." In some light industries, 4mm might be referred to as "light plate," but technical standards usually categorize this as heavy sheet.

-

Over 6mm: Universally considered plate.

Measurement Systems: Gauge vs Inches

One of the easiest ways to identify the material type is the unit of measurement used in the catalog.

-

Sheet Metal is measured in Gauge (ga). A higher gauge number indicates thinner metal (e.g., 18 gauge is thinner than 10 gauge).

-

Plate Metal is measured in Inches or Millimeters. You will order plate as "half-inch" or "20mm," never as a gauge number.

Table 1: Thickness Classification Matrix

| Category | Thickness (Inches) | Thickness (mm) | Gauge Equivalent (Standard Steel) | Primary Form |

| Foil | < 0.006" | < 0.15mm | N/A | Rolls |

| Sheet (Light) | 0.018" - 0.059" | 0.5mm - 1.5mm | 26ga - 16ga | Coils / Flat Sheets |

| Sheet (Heavy) | 0.074" - 0.236" | 1.9mm - 6.0mm | 14ga - 3ga | Coils / Flat Sheets |

| Plate (Light) | 0.250" - 2.00" | 6.35mm - 50.8mm | N/A | Flat Plate Only |

| Plate (Heavy) | > 2.00" | > 50.8mm | N/A | Flat Plate Only |

4. Manufacturing Processes: Cold Rolled vs Hot Rolled

The physical difference in thickness results from the manufacturing process. The method used to create the metal dictates its internal grain structure and mechanical properties.

Sheet Metal: The Cold Rolling Process

Most sheet metal, especially thinner gauges, undergoes cold rolling.

-

Process: The metal passes through rollers at room temperature (below its recrystallization temperature).

-

Result: This work-hardens the metal. It increases yield strength and hardness but decreases ductility.

-

Finish: The rollers are highly polished, transferring a smooth, sleek finish to the sheet. This makes sheet metal ideal for aesthetic purposes where the metal is visible (e.g., car bodies, kitchen backsplashes).

-

Tolerance: Cold rolling allows for extremely precise thickness control. MWalloys ensures sheet metal tolerances within +/- 0.005 inches.

Plate Metal: The Hot Rolling Process

Plate metal is typically too thick to be cold rolled effectively without cracking machinery.

-

-

Process: The steel is heated above 1700°F (926°C), which is above the recrystallization temperature.

-

Result: This allows the metal to be shaped and formed easily. When it cools, it shrinks slightly, which means the dimensional tolerances are less precise than cold-rolled sheet.

-

Finish: The cooling process forms a layer of oxide on the surface known as mill scale. This scale protects the steel from corrosion during storage but must be removed (via grinding or sandblasting) if the plate needs to be painted or welded.

-

5. Comparative Performance Analysis

When engineering a product, you must evaluate the material based on more than just dimensions. You must analyze performance under stress.

Durability and Load Bearing

Plate metal is the superior choice for structural integrity. Because of its mass, it can withstand immense static and dynamic loads. It is used for bridge girders, skyscraper skeletons, and the hulls of military tanks. It does not dent easily.

Sheet metal, while strong relative to its weight, relies on geometry for strength. A flat sheet is floppy. However, if you bend that sheet into a channel or a corrugated pattern, it gains rigidity. Sheet metal is durable against environmental elements (if galvanized or stainless) but offers poor impact resistance compared to plate.

Formability

Sheet metal excels here. It can be deep-drawn into sinks, bent into complex brackets, or rolled into tubes. Its ductility allows it to stretch without tearing.

Plate metal is difficult to form. Bending a 1-inch plate requires a press brake with hundreds of tons of force. Plate is usually cut and welded rather than bent.

Welding Considerations

-

Welding Plate: Generally easier in terms of heat management. The thick material acts as a heat sink, reducing the risk of warping. However, it requires multi-pass welds and beveling (chamfering edges) to ensure full penetration.

-

Welding Sheet: Requires high skill or specialized equipment (like TIG welding or pulsed MIG). The thin material can easily warp, buckle, or burn through if too much heat is applied.

6. Material-Specific Differences

The distinction between sheet and plate changes slightly depending on the alloy family.

Stainless Steel (304/316)

In the stainless world, the visual finish is paramount.

-

Stainless Sheet: Usually sold with a PVC film on one side to protect the finish (2B, BA, or #4 Brushed).

-

Stainless Plate: Usually sold as "HRAP" (Hot Rolled Annealed and Pickled). It has a dull, matte grey finish. It is rarely polished unless specifically requested for architectural columns.

Aluminum (6061/5052)

Aluminum standards are strict regarding thickness.

-

Aluminum Sheet: Often 5052 or 3003 alloys, used for bending and tanks.

-

Aluminum Plate: Often 6061-T6. This "T6" temper means the plate is heat-treated and artificially aged. It is extremely stiff and machines beautifully, making it the standard for aerospace tooling and base plates.

Table 2: Common Application Scenarios

| Application | Material Choice | Reason |

| Car Body Panels | Sheet Metal | Formability, smooth finish for paint, lightweight. |

| Bulldozer Blade | Plate Metal | High impact resistance, abrasion resistance, mass. |

| Electronic Chassis | Sheet Metal | Precise thickness (gauge), easy to punch and bend. |

| Pressure Vessel Walls | Plate Metal | Ability to withstand high internal pressure (PSI). |

| Commercial Kitchen Tables | Sheet Metal | Sanitary smooth finish, easy to clean (Stainless). |

| Machine Foundation Base | Plate Metal | Vibration dampening, rigidity, stability. |

7. Cost Analysis: Weight vs. Processing

Budgeting for MWalloys products requires understanding the cost drivers.

Per Unit Weight Cost:

Counter-intuitively, Sheet Metal often costs more per pound than Plate Metal.

Why? Processing intensity. Cold rolling, annealing, pickling, and polishing sheet metal requires significantly more energy and time than simply hot rolling a slab into a plate.

Total Material Cost:

While the rate per pound is higher for sheet, the total cost for a project using plate will be higher simply because you are buying significantly more mass.

Example Calculation:

-

10 sq ft of 1/8" Sheet (approx 40 lbs) @ $1.50/lb = $60.00.

-

10 sq ft of 1" Plate (approx 320 lbs) @ $1.00/lb = $320.00.

Note: Prices fluctuate based on the global commodities market.

8. Case Study: The Chicago Structural Retrofit

At MWalloys, we believe in demonstrating value through results. This case highlights the critical nature of distinguishing sheet from plate.

Project: Industrial Mezzanine Retrofit

Location: Chicago, Illinois, USA

Date: October 2023

The Challenge:

A logistics client needed to expand their warehouse storage by building a second-level steel mezzanine. The original engineering drawings specified "6mm steel flooring." The procurement manager, aiming to cut costs, sourced 6mm "Heavy Sheet" from a generic supplier.

Upon delivery, the site foreman noticed the material had a slight bow and flexed visibly when walked upon. It was cold-rolled 6mm sheet. While technically the correct thickness, the cold-rolling process had induced internal stresses, and the lack of rigidity made it unsafe for forklift traffic.

The MWalloys Intervention:

The client contacted MWalloys for an emergency consultation. We immediately identified that for a load-bearing floor span of that width, they required 0.250" ASTM A36 Hot Rolled Plate.

The Solution:

We supplied the correct A36 Plate within 48 hours.

-

Rigidity: The hot-rolled plate had zero "oil-canning" or flexing effect.

-

Traction: We recommended diamond tread plate (floor plate) for safety, a texture readily available in plate products but difficult to emboss deeply in cold-rolled sheet.

-

Outcome: The project passed the structural inspection. The client avoided a potential collapse scenario.

Lesson: The processing method (Hot vs Cold) tied to the Sheet vs Plate classification determines structural viability, even if the thickness is numerically similar.

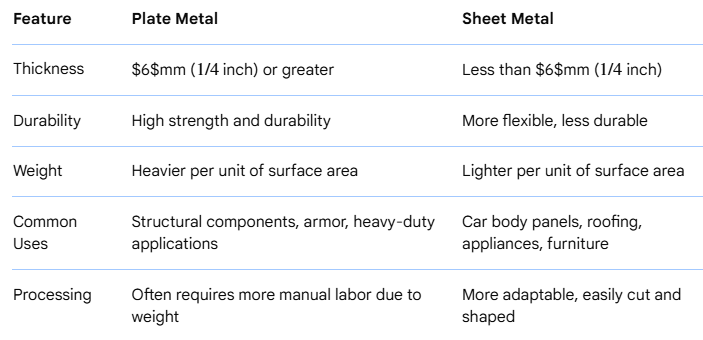

9. Comprehensive Comparison Summary

For a quick reference, use this detailed breakdown of differences.

Table 3: The Master Comparison List

| Feature | Sheet Metal | Plate Metal |

| Thickness Threshold | < 6mm (0.25 inches) | > 6mm (0.25 inches) |

| Manufacturing | Cold Rolled (mostly) | Hot Rolled |

| Measurement Unit | Gauge (ga) | Inches (in) or Millimeters (mm) |

| Standard Size | 4'x8', 5'x10', Coils | 4'x8', 8'x20', Custom cut |

| Surface Quality | Smooth, Polished, Clean | Rough, Mill Scale (Blue/Grey) |

| Dimensional Tolerance | Very Tight (+/- 0.005") | Loose (due to thermal shrinkage) |

| Primary Alloy Types | 304 SS, 5052 Alum, CR Steel | A36 Steel, 6061 Alum, 316 Plate |

| Cutting Method | Laser, Punch, Shear, Waterjet | Plasma, Oxy-Fuel, Waterjet, Saw |

10. How to Measure and Verify Your Material

If you have a piece of metal and are unsure if it is sheet or plate, follow these steps using a Caliper or Micrometer.

-

Clean the edge: Remove any burrs from cutting.

-

Measure perpendicular: Hold the caliper square to the face.

-

Check the chart: Compare your reading to a standard gauge chart.

Pro Tip: If you measure a thickness of exactly 0.1196 inches, you have 11 Gauge Sheet. If you measure exactly 0.250 inches, you likely have 1/4" Plate. Note that due to tolerances, a 1/4" plate might actually measure 0.240" or 0.260", whereas sheet metal will be much closer to its nominal gauge value.

11. Frequently Asked Questions (FAQs)

Here are the most common questions our team at MWalloys receives regarding this topic.

Q1: Is 1/8 inch considered sheet or plate?

A: 1/8 inch (0.125") is classified as Sheet Metal (specifically 11 Gauge in steel). It is flexible enough to be cold rolled and coiled.

Q2: Can I weld sheet metal to plate metal?

A: Yes, but it is difficult. The thick plate will absorb the heat, preventing the thin sheet from melting, or the heat required for the plate will vaporize the sheet. You must focus the arc on the thicker plate and let the weld pool wash over to the thin sheet.

Q3: Why is plate metal usually cheaper per pound?

A: Plate metal undergoes fewer processing steps. It is hot rolled and cut. Sheet metal requires hot rolling, pickling, cold rolling, annealing, and temper rolling, which adds labor and energy costs.

Q4: What is "Diamond Plate"?

A: Diamond plate can be either sheet or plate, depending on thickness. It is metal with a raised pattern for traction. If the base thickness (excluding the diamond) is over 6mm, it is floor plate. If under, it is tread sheet.

Q5: Which is better for outdoor use?

A: The classification (sheet vs plate) does not determine corrosion resistance; the material chemistry does. However, plate metal lasts longer simply because it has more material to rust through before failure.

Q6: What is the thickest sheet metal available?

A: Generally, 7 Gauge (approx 0.1793") is the thickest standard sheet. Anything thicker usually jumps to 3/16" or 1/4" plate sizing conventions.

Q7: Does MWalloys sell both?

A: Yes. MWalloys stocks a full inventory of cold rolled sheet, galvanized sheet, and hot rolled structural plate in Stainless, Aluminum, and Carbon Steel.

Q8: Can you laser cut plate metal?

A: Yes, modern high-power fiber lasers (6kW to 12kW) can cut plate metal up to 1 inch thick. However, beyond 1 inch, Plasma or Waterjet cutting is often more economical.

Q9: What is "Gauge" and why is it confusing?

A: Gauge is a retrograde scale (larger number = thinner metal). It is confusing because the conversion changes based on the metal. 10 Gauge Steel is a different thickness than 10 Gauge Aluminum. Always specify in decimal inches or millimeters to avoid errors.

Q10: What is "Mill Scale"?

A: Mill scale is a flaky surface of iron oxide that forms on hot rolled plate as it cools. It is hard and brittle. It must be removed before painting, or the paint will flake off with the scale.

12. Conclusion: Making the Right Order

The distinction between sheet metal and plate metal is more than just semantics; it is a technical definition that dictates manufacturing feasibility, structural safety, and project budget.

-

Choose Sheet for enclosures, bodywork, lightweight applications, and projects requiring complex forming or bending.

-

Choose Plate for structural bases, heavy machinery, bridges, and applications requiring high tensile strength and rigidity.

By understanding the 6mm (0.25") threshold and the differences between hot and cold rolling, you ensure the longevity of your project.

Ready to start your fabrication project?

MWalloys offers premium-grade sheet and plate metal with full material traceability. Do not leave your structural integrity to chance.