Schedule 80 pipes have thicker walls, higher pressure capacity, and better mechanical resistance than Schedule 40 for the same nominal pipe size, which makes Schedule 80 the safer choice where internal pressure, mechanical abuse, chemical exposure or reduced corrosion allowance matter — but Schedule 40 is lighter, usually less expensive, and often the correct choice for routine low-pressure plumbing, drainage and many irrigation systems. Choose by matching the application’s required working pressure, temperature, chemical compatibility, hydraulic needs (inner diameter), code requirements, and budget.

What “schedule” means and where it comes from

The term “schedule” in piping identifies a standardized wall thickness for a nominal pipe size (NPS). The schedule number (e.g., 5, 10, 40, 80, 160) is simply an index — higher schedule number = thicker wall for a given NPS — and it exists so that manufacturers and engineers have a common reference for dimensions and mechanical capability. This schedule-system for steel pipe is codified in the ASME/ANSI dimensional standards and is widely applied to metallic and non-metallic pipes for sizing and pressure classification.

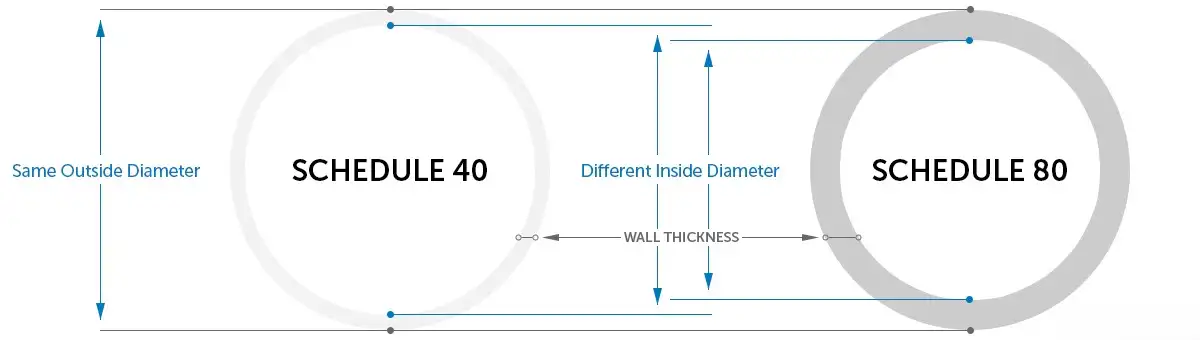

Why that matters in plain terms: thicker walls increase pressure strength and stiffness but reduce the internal bore (ID) for the same outside diameter (OD), which affects flow and the weight of the run.

Materials that commonly use “Schedule” numbers

Schedule numbers apply across multiple pipe materials, but their implications differ by material:

-

Welded/seamless carbon and stainless steel — schedule numbers are standardized by ASME B36.10/36.19 (dimensions & weights). The schedule determines wall thickness used for engineering pressure calculations.

-

PVC and CPVC plastic pipe — manufacturers use the same schedule labels (Schedule 40, 80) and ASTM D1785 / ASTM F441 define dimensions and performance for many sizes; however, the behavior with temperature, chemical exposure and long-term creep is different from metal.

-

Other materials (HDPE, ductile iron, etc.) typically use different classification systems (e.g., DR, PN or class) and do not use the ANSI/ASME “schedule” nomenclature in typical practice.

Physical difference: wall thickness and internal diameter

The defining difference between Schedule 40 and Schedule 80 is wall thickness. For the same nominal pipe size (NPS), Schedule 80 has a larger minimum wall thickness than Schedule 40. Because OD is fixed for NPS in the standard tables, a thicker wall reduces the internal diameter (ID). That ID reduction affects flow capacity, friction loss and velocity — and it slightly increases weight and cost per foot.

Practical consequence summary:

-

Strength: Sch 80 > Sch 40 (burst and working pressure higher for Sch 80, all else equal).

-

Flow: Sch 40 ID > Sch 80 ID → Sch 40 gives slightly lower head loss for a given flow.

-

Weight/cost: Sch 80 heavier and costlier per foot.

-

Fittings: Not all fittings are interchangeable (different wall thicknesses can affect socket fittings, solvent-weld fittings and mechanical couplings).

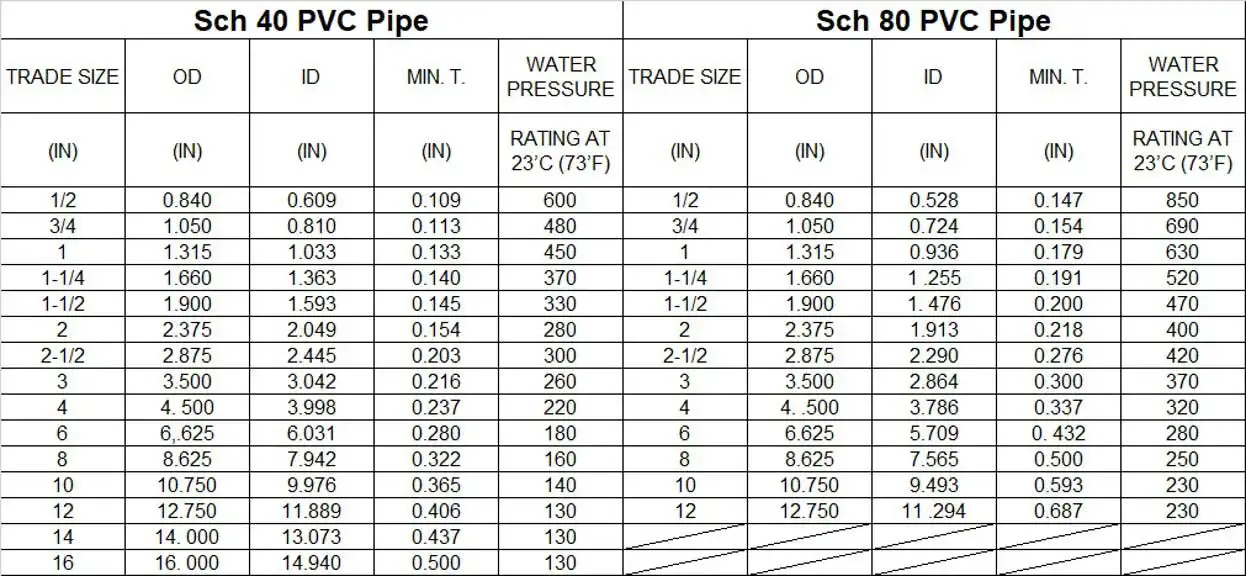

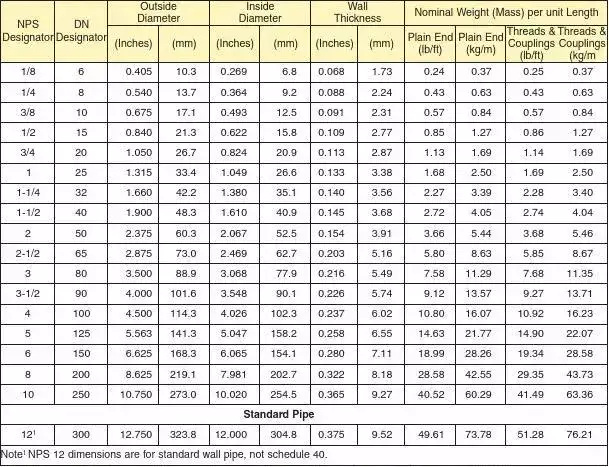

Dimensions — typical values and a compact comparison table

Below is a short technical table with commonly used NPS sizes to illustrate the dimensional difference. OD values are fixed per the NPS standard; wall thickness numbers used are the commonly adopted schedule minimums (ASME/ANSI tables), and internal diameter is computed as ID = OD - 2 × wall_thickness. All dimension facts correspond to ASME/ANSI tables and industry tables.

| NPS (nominal) | OD (in) | Sch 40 wall (in) | ID Sch 40 (in) | Sch 80 wall (in) | ID Sch 80 (in) |

|---|---|---|---|---|---|

| 1/2" | 0.840 | 0.109 | 0.622 | 0.147 | 0.546 |

| 1" | 1.315 | 0.133 | 1.049 | 0.179 | 0.957 |

| 2" | 2.375 | 0.154 | 2.067 | 0.218 | 1.939 |

| 4" | 4.500 | 0.237 | 4.026 | 0.337 | 3.826 |

(ID calculated from OD and wall thickness values shown — source: ASME/ANSI/industry tables).

Notes on the table: the OD shown is the standard outside diameter for the nominal size; wall thickness changes with schedule while OD remains constant for that nominal size. These typical numbers are used in design and pipe stress/burst calculations and are used by fabricators, suppliers and engineers as lookup data.

Pressure ratings and temperature effects (standards & safety)

Pressure capability depends on material, wall thickness (schedule), manufacturing quality, and temperature. For metallic pipe, pressure ratings are computed by design equations (ASME B31.x codes and material allowable stresses) and are a function of the yield/tensile strength and wall thickness. For PVC/CPVC, ASTM D1785 and specific manufacturer datasheets provide pressure ratings and burst pressures for schedules, typically quoted at a reference temperature (commonly 73°F / 23°C). Importantly, plastic pipe ratings fall with increasing temperature due to polymer softening and creep; most manufacturers present tables showing allowable working pressures by nominal size, schedule and temperature.

Key takeaways:

-

Schedule 80 offers a higher allowable working pressure than Schedule 40 for identical diameters and materials because of thicker walls.

-

For PVC, the nominal working pressure at room temperature (73°F / 23°C) is taken from ASTM/producer tables and includes a safety factor — users must consult manufacturer performance sheets for exact numbers and for derating at elevated temperatures.

Hydraulic effects — flow, velocity and friction losses

Even modest reductions in ID change hydraulic behavior:

-

Flow capacity (Q) in a circular pipe scales with the square (area) of internal radius; a small reduction in diameter reduces flow area and increases velocity at the same volumetric flow.

-

Head loss (Darcy–Weisbach) depends on velocity squared and friction factor: smaller ID for a fixed flow raises friction losses — sometimes significantly on long runs.

-

Pump sizing must account for the schedule decision. For example, the 4" Sch 80 ID is ~3.826" vs Sch 40 ID ~4.026"; that ~5% diameter reduction translates to ~10% reduction in cross-sectional area, with a comparable increase in head loss for the same flow.

Design tip: for long pipelines carrying high flow rates, the slight hydraulic penalty of Sch 80 can outweigh its mechanical benefits; for short pressured segments or hazardous-service piping, the added wall thickness can be justified.

Mechanical and durability considerations

Choose Sch 80 when the application includes one or more of the following:

-

High continuous operating pressure near material limits.

-

Elevated temperature where material strength or polymer creep is a concern.

-

Mechanical abuse (impact, wear, repeated loading, vibration) where thicker walls provide resistance.

-

Lower corrosion allowance — if corrosion is expected, thicker walls extend service life before mechanical failure.

-

Safety-critical service (e.g., compressed-air, process piping with hazardous fluids) where conservatism is required.

Choose Sch 40 when:

-

Pressures are low and regulated by building/plumbing code for the intended use.

-

Hydraulic efficiency (maximizing ID) is prioritized.

-

Weight, flexibility, or cost constraints exist.

Example: in chemical plant secondary systems where piping is exposed to possible mechanical damage, Sch 80 metal or PVC is commonly used for resilience and increased safety factor.

Installation, fittings and compatibility

Interchangeability: For metallic threaded, welded or flanged systems, schedule changes matter primarily for wall thickness and strength; fittings are typically manufactured according to schedule or class. For PVC/CPVC solvent-weld or socket fittings, schedule mismatch can create problems — a Sch 80 socket may tightly fit a Sch 40 spigot because of differences in wall thickness and socket geometry, so always follow manufacturer guidance. For mechanical couplings, check coupling manufacturer allowable wall ranges.

Welding and fabrication: Sch 80 steel requires thicker bevels and different welding parameters; for welded systems, ensure welding procedure specifications (WPS) are written for the actual wall thickness & material grade.

Threaded connections: Thread engagement length and strength change with wall thickness; in small-diameter threaded piping, Sch 80 may provide a larger effective thread depth depending on fitting design.

Code, standards and writing procurement specs

When specifying pipes in purchase orders and engineering drawings, use both the nominal size and the schedule, and whenever relevant include the material standard and code, for example:

-

For steel: “NPS 2, SCH 80, ASTM A53 Grade B, seamless, normalized, plain end” and reference ASME B36.10M for dimensions.

-

For PVC pressure piping: “PVC Schedule 40 (ASTM D1785) SDR X, solvent-weld, pressure rating per manufacturer at 73°F” and attach the ASTM or manufacturer datasheet.

Important: codes like the International Plumbing Code (IPC), ASME B31.1/B31.3 and local building regulations often mandate minimum schedule / material combos for certain services—always check local code.

Cost, weight and procurement tips

-

Material cost: Sch 80 typically costs 10–40% more than Sch 40 for the same nominal size, depending on diameter and material (PVC vs steel). The cost difference increases with diameter because the extra wall thickness is more material per foot.

-

Weight: Sch 80 is heavier; consider support design and shipping cost.

-

Lead time: uncommon sizes in Sch 80 (or exotic materials) may have longer lead times. Order with enough lead time for fabrication.

-

Buy smart: ask suppliers for certified mill test reports (MTRs) for steel and product certification for plastics; insist the supplier provides the dimensional and pressure tables used for selection.

Practical decision matrix — pick Schedule 40 when:

-

Domestic cold-water plumbing, drainage, or irrigation is the main function and pressure needs are modest.

-

Weight and cost are critical and safety factors are within specification.

-

Hydraulic performance (ID) is more important than mechanical robustness.

Pick Schedule 80 when:

-

Higher working pressure and mechanical protection is required.

-

There’s an expected or possible chemical or thermal exposure that reduces allowable stresses.

-

System is safety-critical or in a heavy industrial setting.

Short case scenarios

Scenario A — Residential water supply to house:

For typical potable cold-water supply inside a house, Schedule 40 CPVC/PVC (where allowed by code) or Sch 40 copper/stainless is usually adequate and economical.

Scenario B — Compressed air distribution in workshop:

Compressed air often benefits from Sch 80 because of the cyclic pressures and the potential for fatigue and impact — many shops choose metal Sch 80 or larger Sch 40 depending on layout.

Scenario C — Chemical feed line in plant:

If chemical concentration and temperature reduce allowable stress, choose Sch 80 with material compatibility verified, or choose a material with higher chemical resistance; consult manufacturer chemical resistance charts and derating tables.

Tables and technical quick-reference (compact)

Table A — Comparative pros & cons

| Subject | Schedule 40 | Schedule 80 |

|---|---|---|

| Wall thickness | Thinner | Thicker |

| ID (flow) | Larger | Smaller |

| Pressure capability | Lower | Higher |

| Weight | Lighter | Heavier |

| Cost | Lower | Higher |

| Resistance to damage | Less | More |

| Typical use | Domestic, low pressure | Industrial, high pressure |

Table B — When to specify (quick checklist)

-

High pressure (> manufacturer Sch40 rating) → Sch 80

-

High temperature or creep concern → Sch 80 or higher grade material

-

Long run requiring high flow efficiency → consider Sch 40 or larger nominal pipe

-

Corrosive environment with limited corrosion allowance → Sch 80 or choose corrosion-resistant alloy

Frequently Asked Questions

Q: Is Schedule 80 always stronger than Schedule 40?

A: For the same material and nominal size, yes — Schedule 80 has greater minimum wall thickness and therefore higher theoretical burst and allowable working pressures; however, strength also depends on material grade and fabrication quality (welds, joints).

Q: Can I replace Schedule 40 with Schedule 80 or vice versa without redesign?

A: Replacing Sch 40 with Sch 80 generally increases safety margin, but you should verify fittings, hangers, and thread or socket compatibility. Replacing Sch 80 with Sch 40 requires engineering review to ensure pressure and fatigue margins remain acceptable.

Q: Do schedule numbers mean the same for PVC and steel?

A: The schedule label is used similarly as an index for wall thickness across materials (PVC, CPVC, steel) but the mechanical and thermal behavior differs by material. Always consult the relevant ASTM/ASME standard and manufacturer tables (e.g., ASTM D1785 for PVC).

Q: Does a higher schedule increase cost a lot?

A: It increases cost due to more material and potentially heavier fittings. The percent increase depends on nominal size and material — larger diameters see larger absolute and percentage differences.

Q: Are fittings the same for Sch 40 and Sch 80?

A: Not always. Socket fittings, solvent-weld fittings and some mechanical couplings are schedule-specific; check the fitting’s datasheet. In metal flanged systems, flange ratings and welding procedures matter more than schedule alone.

Q6: How does temperature change the allowable pressure for PVC Sch 40 and Sch 80?

A: Polymer strength decreases with temperature, so allowable working pressure is typically reduced at elevated temperatures. Manufacturer and ASTM tables provide derating factors — consult them for exact numbers.

Q: Which schedule is used in fire sprinkler systems?

A: Fire sprinkler piping typically follows standards like NFPA and uses pipe classes/schedules specified in those codes. Carbon steel and copper systems follow the applicable code-specified dimensions and class; confirm NFPA and local code. (Consult local code.)

Q: How do corrosion allowances affect schedule choice?

A: If corrosion is expected, thicker walls (Sch 80) provide a larger corrosion allowance before structural failure, potentially increasing service life. However, selecting corrosion-resistant materials or coatings can be more cost-effective than upsizing schedule alone.

Q: Are schedule numbers used internationally?

A: The ANSI/ASME schedule system is widely used globally, but some countries and industries use alternative designations (e.g., PN, Class or SDR). When working internationally, specify both the schedule and the actual dimensions or a standard reference (ASME B36.10M, ASTM D1785).

Q: Where should I find official dimension and pressure data for final design?

A: Primary sources are the standards and manufacturers: ASME B36.10M / B36.19M for metallic pipe dimensions, ASTM D1785 (and manufacturer datasheets) for PVC/CPVC, and trusted manufacturer technical bulletins (e.g., Westlake, Charlotte Pipe) for pressure rating tables at defined temperatures. Always use the manufacturer’s certified tables for final design.

Final notes and best practice checklist

-

Always cross-check schedule selection with the applicable code and manufacturer pressure tables for the specific operating temperature and fluid.

-

For critical or hazardous services, choose the higher schedule or higher-spec material and document the safety margin in the engineering report.

-

When in doubt, ask the pipe supplier for certified datasheets and request calculations to confirm allowable working pressures at design temperature.

Authoritative references

- ASTM D1785 — Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80 and 120

- Westlake Pipe — ASTM D1785 Schedule 80 PVC Pressure Pipe Product Information (manufacturer pressure & dimension bulletin)

- Charlotte Pipe — Technical datasheets for Schedule 40 & Schedule 80 PVC/CPVC (pressure/temperature charts)