For tools or parts that must resist sudden shocks, repeated impacts, and require very high toughness, S7 tool steel is usually the better choice because of its air-hardening chemistry and higher impact resistance. For general-purpose shafts, pins, gears, and structural components that require strong tensile properties, good fatigue resistance, and easier, lower-cost heat treatment, 4140 (Cr–Mo) alloy steel is normally the preferred option. This recommendation depends on the required final hardness, dimensional tolerance after heat treatment, fatigue requirements, and cost constraints.

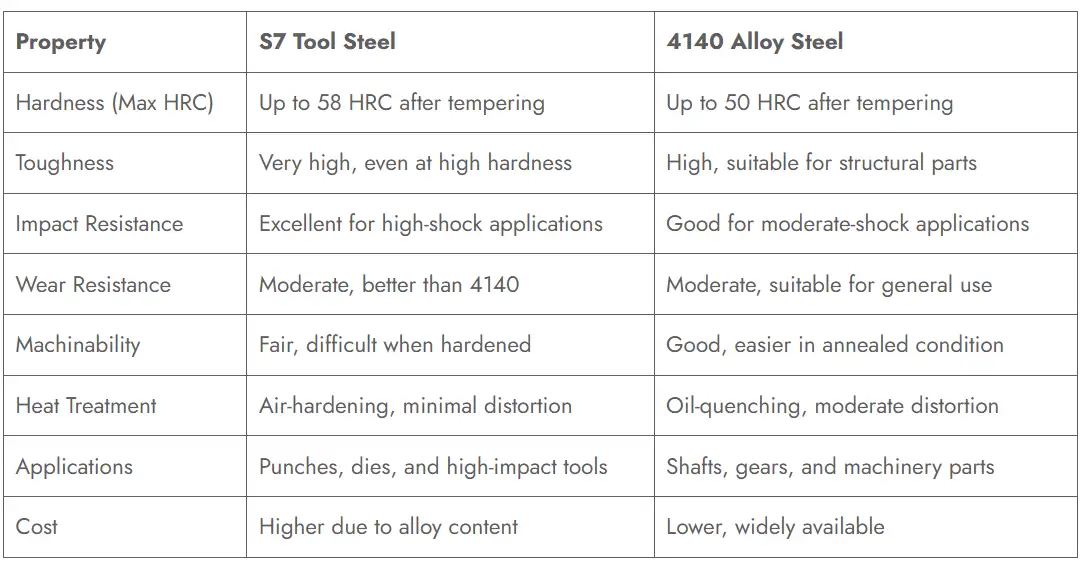

Quick side-by-side comparison (summary table)

| Property / Aspect | S7 (shock-resisting tool steel) | 4140 (chromium-molybdenum alloy steel) |

|---|---|---|

| Typical carbon content | ~0.45–0.55 wt% (higher carbon than 4140) | ~0.38–0.45 wt% |

| Main alloying additions | Cr ~3.0–3.5%, Mo ~1.0–1.8%, small V | Cr ~0.8–1.1%, Mo ~0.15–0.25%, Mn ~0.75–1% |

| Typical applications | Impact tools: punches, chisels, dies, splined tools, shear blades | Shafts, axles, gears, pins, couplings, fasteners |

| Hardness range after quench & temper | Can reach high quenched hardness (up to ~58 HRC in tool grades) | Up to ~50 HRC (typical), easier to quench in oil |

| Toughness / impact resistance | Very high (designed for shock) | Good, but lower than S7 at comparable hardness |

| Hardenability / distortion | Air/oil hardening, good hardenability with low distortion | Good hardenability, usually oil quench; more distortion than S7 |

| Cost / availability | Specialty tool steel; higher price, smaller suppliers | Wide availability, lower cost, commodity alloy steel |

| Standards / designation | AISI S7 / UNS T41907; covered in tool steel specs (ASTM A681 etc.) | AISI/SAE 4140 / UNS G41400; many mills supply to this spec |

Chemical composition and metallurgical role of alloying elements

Understanding composition clarifies why each steel behaves differently in service.

Typical composition (representative ranges)

| Element | S7 (typical) | 4140 (typical) |

|---|---|---|

| Carbon (C) | 0.45–0.55% | 0.38–0.45% |

| Chromium (Cr) | 3.0–3.5% | 0.8–1.1% |

| Molybdenum (Mo) | 1.0–1.8% | 0.15–0.25% |

| Manganese (Mn) | 0.2–0.8% | 0.75–1.0% |

| Silicon (Si) | 0.2–1.0% | 0.15–0.30% |

| Vanadium (V) | small (~0.1–0.3%) in some S7 variants | usually <0.03% |

| Sulfur & Phosphorus | low, controlled | low, controlled |

Why the chemistry matters

-

Higher chromium and molybdenum in S7 increase hardenability and temper resistance and provide strong carbide formation that helps maintain hardness under elevated operating temperature and repeated impact.

-

Moderate carbon in S7 supports higher hardenability with retained toughness; S7 is formulated to give high impact energy rather than maximizing wear resistance.

-

4140’s lower Cr and Mo balance toughness, ductility, and strength while keeping cost and weldability reasonable. 4140’s chemistry supports high tensile strength with good fatigue resistance after quench & temper.

Mechanical properties: hardness, strength, toughness, impact

Mechanical performance depends strongly on heat treatment state. The tables below present typical ranges from supplier datasheets and materials databases.

Typical mechanical properties (annealed / quenched & tempered)

| Property | S7 (annealed) | S7 (quenched & tempered) | 4140 (annealed) | 4140 (quenched & tempered) |

|---|---|---|---|---|

| Hardness (HB) / HRC | 187–220 HB ≈ 18–24 HRC | up to ~58 HRC (grade/style dependent) | ~170–200 HB ≈ 16–22 HRC | up to ~50 HRC typical |

| Tensile strength (UTS) | ~700–900 MPa (process dependent) | 900–1600 MPa depending on temper | ~600–800 MPa (annealed) | 850–1200 MPa depending on temper |

| Yield strength | ~350–600 MPa | variable | ~350–600 MPa | variable |

| Impact toughness (Charpy) | High — designed for maximum impact energy | Retains good energy at elevated hardness | Good but lower than S7 at equal hardness | Adequate for rotating machinery parts |

Notes: numeric ranges depend on temper temperature and quench medium; S7 typically trades off some wear resistance to maintain elevated impact energy. For typical hardening and tempering windows consult vendor heat-treatment tables.

Heat treatment behavior and processing windows

S7 heat-treatment highlights

-

Nature: S7 is typically an air-hardening, shock-resisting tool steel; it can be oil-quenched in some forms but is often treated to minimize distortion.

-

Typical hardening temperatures: Solution/ austenitize ~1000–1025°C (1830–1875°F) (vendor guidance varies). Pre-heat and soak schedules are important to avoid cracking. Tempering is done at temperatures selected to meet the target hardness while preserving impact resistance. S7 is valued because it can be hardened with lower distortion than many water-quenched high carbon steels.

4140 heat-treatment highlights

-

Nature: 4140 is a through-hardening Cr–Mo alloy; hardenability supports oil quench for many sections; normalized prior to hardening in many procedures.

-

Typical austenitizing: ~845–870°C (1550–1600°F); oil quench is common. Temper temperatures vary from ~200–650°C depending on desired final hardness and toughness. 4140 is forgiving and widely used because heat treatment is well documented and reproducible at scale.

Practical comparison: distortion & dimensional control

-

S7 tends to harden with lower distortion (air-hardening grades designed for dimensional stability), which benefits die and tool makers who need tight tolerances after heat treatment.

-

4140 may require more stress-relief, straightening, or machining allowances when quenched at higher section thicknesses; however industrial familiarity and predictable toughness make it easier for many shops to process economically.

Microstructure, wear behavior, and fracture modes

Microstructure after treatment

-

S7: typically martensitic matrix with alloy carbides (Cr/Mo rich) and fine secondary carbide dispersions; engineered for energy absorption and controlled cleavage resistance.

-

4140: martensitic matrix when quenched, tempered martensite with lower volume fraction of alloy carbides; designed to deliver tensile strength and fatigue life.

Wear and abrasion

-

S7 offers moderate abrasive wear resistance but is not a high-chrome, high-carbide wear steel (that role belongs to high-Cr tool steels like D2). Its prime virtue is surviving impact loading without brittle failure.

-

4140 gives respectable wear resistance when hardened but the lower carbide content compared to tool steels limits abrasive wear performance.

Fracture and failure modes

-

S7 failures typically show large plastic zones and ductile dimpling or shear lips prior to eventual fracture because of high toughness. Under repeated impact, S7 resists catastrophic brittle fracture.

-

4140 in highly stressed, poorly tempered, or over-hardened conditions can show fatigue cracking and brittle cleavage; proper tempering and control of residual stress is essential.

Machinability, welding, and fabrication notes

Machinability

-

S7 (annealed): machinable in annealed condition, but in harder conditions it is tough and can be challenging. Carbide-forming elements and higher alloy levels reduce tool life at high hardness. Pre-hardening machining is commonly used.

-

4140: good machinability in normalized or annealed states. Commonly used in turned / milled shafts and bars; tooling and feeds are well established.

Welding

-

S7: welding tool steels demands strict preheat, interpass temperature control, and post-weld heat treatment to avoid cracking and loss of toughness. Welding is possible but requires experienced weld procedures.

-

4140: weldable with appropriate preheat (to avoid cold cracking) and post-weld tempering; many shops weld 4140 routinely when proper procedure is followed.

Surface treatments and finishing

-

Both steels accept common surface processes: nitriding (careful control required), induction hardening (suitable for 4140), plating, and coatings. Choice depends on final application (wear vs corrosion vs fatigue).

Typical applications and comparative case notes

Where S7 excels

-

Tools exposed to sudden loads and repeated impacts: e.g., punches, chisels, shear blades, header dies, hammer parts, cold-forming tools, gripper dies, heavy-duty injection mold cores in certain situations. S7 is often the go-to when tool failure by impact would be catastrophic.

Where 4140 excels

-

Rotating components, structural parts, and common machine elements: crankshafts, axles, pins, flanges, gears (small to medium), fasteners, hydraulic components where a balance of fatigue strength and toughness is needed and cost / supply are important.

Case note (realistic scenario)

-

If a die experiences edge chipping from repetitive impact, switching from a hardened 4140 variant to S7 (properly heat treated) may extend service life despite the higher raw cost, because S7 tolerates impact without brittle chipping. Conversely, a transmission shaft that demands torsional fatigue life at moderate hardness is almost always better in 4140 due to its proven fatigue behaviour and lower price.

Selection criteria, substitution guidance, and cost considerations

Decision checklist for choice

-

Primary load type: impact shocks → lean toward S7; steady/torsional loads → 4140.

-

Desired hardness vs toughness: if you need extreme hardness (>56 HRC) and impact resistance, check S7 grades and temper protocols. If moderate hardness and high fatigue life suffice, use 4140.

-

Dimensional tolerance after heat treatment: low distortion needs push toward S7 or remelted premium variants of S7.

-

Weldability & fabrication ease: 4140 has an edge; S7 requires specialized welding controls.

-

Budget & supply chain: 4140 is widely stocked; S7 is specialty and costs more per kg and per processing step.

-

Surface treatment compatibility: evaluate induction hardening, nitriding, coatings — 4140 is commonly induction-hardened for local wear surfaces.

-

Regulatory / traceability: check project specs — aerospace or safety critical parts may require specific tool steel certification (mill heat traceability, remelted product, etc.).

Substitution notes

-

Substituting 4140 for S7 is acceptable when impact loads are modest and cost is a driving factor, but expect reduced shock resistance and possibly shorter life under repeated impact.

-

Substituting S7 for 4140 is acceptable for high-impact service, but watch for over-engineering: S7 may be unnecessary and expensive for many rotating parts where 4140 suffices.

Standards, specifications, and authoritative references

Key designations and standards to check when specifying material:

-

S7: AISI S7 / UNS T41907; covered under tool steel standards such as ASTM A681 and related tool-steel specifications and vendor datasheets. S7 is often supplied in remelted or premium variants for critical tooling work.

-

4140: SAE/AISI 4140 / UNS G41400 — widely documented with many supplier datasheets and industry references.

Practical selection checklist for engineers & procurement

-

Define service load regime: impact vs cyclic vs static.

-

Choose target hardness and acceptable minimum impact energy.

-

Check dimensional tolerance after heat treatment; request typical distortion figures from mill if tight.

-

Specify remelted / vacuum-treated steel if cleanliness matters (e.g., injection mold cores).

-

Specify heat treatment procedure in purchase order (austenitize temp, quench medium, temper temp, hardness acceptance).

-

Request mill test report (MTR) and certificate of hardness and impact testing if part is safety-critical.

-

If welding is required, include welding procedure specification (WPS) and pre/post heat treatment steps.

Tables — practical data that engineers often request

Table A — Representative composition (typical vendor sheet ranges)

| Grade | C | Mn | Si | Cr | Mo | V | Other |

|---|---|---|---|---|---|---|---|

| S7 (representative) | 0.50% | 0.70% | 0.30% | 3.25% | 1.40% | 0.10–0.25% | Fe balance. Source: Carpenter Technology data sheet. |

| 4140 (representative) | 0.40% | 0.80% | 0.20% | 1.00% | 0.20% | trace | Fe balance. Source: AZoM / industry datasheets. |

Table B — Typical heat-treatment window (engineering starting point)

| Grade | Austenitize (°C/°F) | Quench | Temper range (°C/°F) | Typical HRC after temper |

|---|---|---|---|---|

| S7 | ~1000–1025°C (1830–1875°F) | Air or oil (per vendor) | 150–550°C (300–1025°F) | up to ~58 HRC (depending on temper) |

| 4140 | ~845–870°C (1550–1600°F) | Oil quench (common) | 200–650°C (400–1200°F) | up to ~50 HRC typical (depending on section) |

Table C — Typical uses & recommended grade selection

| Application | Priority property | Recommended grade |

|---|---|---|

| Cold-work punches, chisels (impact) | Impact resistance, low distortion | S7 |

| Axles, shafts, pins | Fatigue strength, toughness | 4140 |

| Shear blades | Edge shock resistance | S7 (or high carbon air-hardening tool steel) |

| Gears & splines | Wear + fatigue management | 4140 (or carburized grades, depending) |

FAQs

-

Q: Can 4140 replace S7 in an impact tool?

A: Typically no if impact loading is high. 4140 will survive many loads but does not match S7’s designed shock resistance; if cost pushes the choice, perform prototype testing. -

Q: Which grade warps less during hardening?

A: S7 (air-hardening type) generally shows less distortion than oil-quenched medium-alloy steels in many section sizes. -

Q: Are either of these steels stainless?

A: No. Both are carbon / low-alloy steels; corrosion protection (coats, plating) is required for corrosive environments. -

Q: Which one is easier to weld?

A: 4140 is easier to weld with standard procedures; S7 requires careful preheat and PWHT to avoid cracking. -

Q: Can S7 be nitrided or induction hardened?

A: Surface processing is possible, but check vendor guidance: nitride can improve surface wear; induction hardening is more commonly applied to 4140. Validate on prototypes. -

Q: What tempering temperatures give best impact resistance?

A: Lower temper temps increase hardness but reduce toughness; target temper temperatures chosen by balancing HRC vs Charpy energy, follow vendor heat-treatment charts. -

Q: Which grade is cheaper and more available worldwide?

A: 4140 widely stocked, commodity price; S7 is specialty and often costs more. -

Q: Do mills supply remelted S7 for critical tooling?

A: Yes, remelted (vacuum or ESR) grades exist for critical tooling where cleanliness and fracture resistance are essential. Request remelt certificate if needed. -

Q: Are there drop-in alternatives to S7?

A: Some high-toughness air-hardening tool steels or variants of A2 / L6 may substitute depending on application; however validate toughness and hardness with tests before replacing S7. -

Q: What certifications should I request from suppliers?

A: Mill test report (MTR), heat treatment chart with hardness verification, impact test (if critical), and traceability to specification (ASTM / AISI) for safety-critical parts.

Final engineering notes

-

Prototype and test: When changing steel grades, validate through part-level fatigue and impact tests; lab data alone rarely captures the entire system behavior.

-

Work with your heat treater: Provide complete process specs (austenitize, quench medium, temper temp, acceptable distortion). Experienced heat treaters can tune cycles for minimum distortion.

-

Use remelted S7 for safety-critical tooling: remelted / vacuum-processed S7 offers reduced inclusion content and improved toughness for expensive dies.

Authoritative references

- Carpenter Technology — S7 Tool Steel (technical data sheet / MSDS)

- AZoM — AISI 4140 Chrome-Molybdenum Steel (datasheet & properties)

Closing summary

S7 and 4140 occupy adjacent but distinct niches. Use S7 when your part must resist repeated impacts with minimal failure risk and when dimensional stability after hardening is critical. Use 4140 when you need a widely available, cost-effective alloy with strong tensile and fatigue performance that can be heat treated consistently in industrial shops. Select with a test-driven mindset and specify exact heat-treatment and certification requirements in purchase orders to avoid surprises.