Q195 is a low-carbon, mild structural steel grade defined by China’s GB/T 700 family. It has a guaranteed minimum yield strength around 195 MPa, a low carbon ceiling (typically ≤0.12%) that gives good ductility and weldability, and is widely used for light structural parts, general fabrication, cold-formed sections and low-stress welded assemblies where cost-efficiency and formability are priorities.

What is “Q195” mean?

The symbol Q195 comes from Chinese national practice: the letter Q denotes the yield strength (from Chinese “屈服”, yield) and the number 195 denotes the minimum nominal yield in megapascals. Q195 is part of the GB/T 700 family for carbon structural steels (published as GB/T 700-2006 and updates), which sets composition, mechanical tests and inspection rules for a range of low-carbon structural steels. In short: Q195 = low-carbon structural steel with min. yield ≈ 195 MPa.

Why that matters to buyers: grade designations drive selection: Q195 is purposely at the lower end of structural strength grades so it prioritizes ductility, weldability and low cost over high load capacity.

Chemical composition

Below is the standard ceiling (maximum) values for the most relevant elements associated with Q195 in GB/T 700-style specifications. Manufacturers may report typical values slightly lower than these maxima; always confirm actual mill certificates (MTC).

Table 1 — Typical composition limits for Q195 (wt. %)

| Element | Typical GB/T ceiling (max) for Q195 |

|---|---|

| Carbon (C) | 0.12% |

| Silicon (Si) | 0.30% |

| Manganese (Mn) | 0.50% |

| Phosphorus (P) | 0.035% |

| Sulfur (S) | 0.040% |

| Others (Cu/Ni/Cr) | usually ≤ ~0.30% each (trace/optional) |

(Source: consolidated supplier and standard summaries used by mills producing Q195.)

Notes & interpretation

-

The low carbon ceiling (≤0.12%) is the key reason Q195 exhibits good forming and welding behaviour.

-

Manganese is present to raise strength and hardenability modestly, while silicon acts mainly as deoxidizer.

-

Tight limits on P and S improve toughness and reduce the risk of brittle behavior in forms and welds.

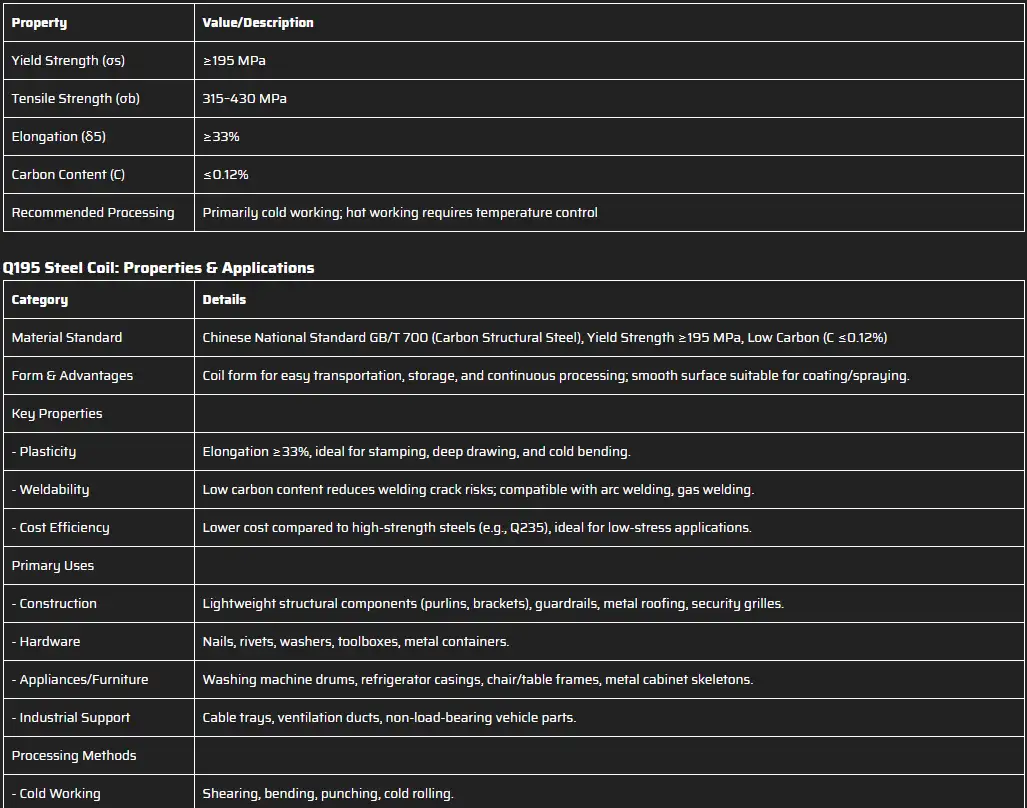

Mechanical properties

Design baseline (minimums by grade):

-

Yield strength (Rp0.2 or proof): ~195 MPa (nominal minimum)

-

Tensile strength: suppliers commonly report ~315–430 MPa for typical 16 mm reference specimens — reported ranges depend on thickness and delivery condition.

-

Elongation (A%): typical elongation for thin sections can be high (20–30% range depending on sample length and thickness).

These mechanical baselines are measured and reported by mills according to GB/T 700 sampling and test rules; thicker sections or different product forms will adjust guaranteed numbers.

Table 2 — Representative mechanical data (indicative, verify MTC)

| Property | Typical value (16 mm reference unless stated) |

|---|---|

| Yield strength (min) | 195 MPa |

| Tensile strength | 315 – 430 MPa |

| Elongation (A) | 20 – 33% (depends on size) |

| Hardness (HB) | usually low (mild steel range) |

Thickness effect: minimum yield and tensile requirements sometimes vary by thickness in the full GB/T specification; confirm the standard table for exact sizing rules for plates, bars and sections.

q195 steel equivalent

Q195 has no single, exact international “equivalent” — only approximate matches used commercially.

Common approximate equivalents (for non-critical, general structural uses)

-

ASTM A283 Grade B / C — most frequently quoted as the closest US/ASTM analogue for Q195 in trade listings.

-

DIN / EN families (St-33 / S185) — often listed as the German / European near-matches (use caution: EN designations have different guaranteed minima and testing rules).

-

JIS SS300 / SS330 (Japanese) — commonly cited in equivalence tables for low-strength structural steels.

Quick technical reminders

-

Q195 nominally means a minimum yield ≈ 195 MPa (so it sits at the low end of structural steels). Always confirm the supplier’s MTC for the actual delivered chemistry and mechanicals.

-

Why no exact single equivalent? Standards (GB, ASTM, EN, JIS) differ in chemistry limits, sampling rules, guaranteed properties and thickness-dependent clauses — so “equivalent” is only approximate and depends on the application.

Product forms and delivery conditions

Q195 is produced and supplied in the following common forms — each form has typical delivery and processing conditions:

-

Hot-rolled plate and coil — common thicknesses from ~1.5 mm up to several hundred mm (plate); coils for thinner stock used for roll forming and sheet fabrication.

-

Strip and wide flats — for stamping and part production.

-

Bars and round rods — used for anchors, light structural components.

-

Welded and seamless pipe/tube — Q195 is often specified for low-pressure structural tubing, wire and light piping.

-

Galvanized wire and galvanized strip — Q195 wire is widely used in fencing and binding wire after galvanizing.

Delivery conditions (terms you will see on orders): as-rolled (AR), normalised (N), control-rolled (CR) or surface finished (pickled, oiled). Specify delivery condition if formability or toughness is critical.

Manufacturing route and quality control

Typical production steps

-

Steelmaking: basic oxygen furnace (BOF) or electric arc furnace (EAF) melt practice; ladle chemistry set to comply with GB/T targets.

-

Secondary refining and deoxidation: ensures low oxygen and controlled Si/Mn.

-

Continuous casting → hot rolling (or forging for bars) → cooling control.

-

Quality control: chemical analysis (spectrometer), tensile tests, bend/impact tests when required, and dimensional checks.

Inspection documents and tests to request (procurement checklist)

-

Mill Test Certificate (MTC) per GB/T 700: chemical analysis and mechanical test results.

-

Non-destructive testing (NDT) if specified (UT/MT for plates/pipes).

-

Coating certificates for galvanized products.

-

Third-party inspection (BV, SGS, Lloyd’s etc.) if required for export or large projects.

Fabrication behaviour: welding, forming and machining

Welding

-

Q195’s low carbon makes standard arc welding (MMAW, MIG/MAG, SAW) straightforward with common filler wires; preheat is often not needed for thin sections. Use compatible filler metal when strength/diffusible hydrogen/toughness targets are specified.

-

For critical welded structures, require Charpy impact tests and specify post-weld heat treatment if service demands require it.

Forming and cold working

-

High ductility and low yield permit easy bending, roll-forming, drawing and stamping. Minimum bend radii are generally generous relative to higher-strength grades.

Machining

-

Q195 machines easily compared to higher carbon steels; standard tooling and feeds give good surface finish with appropriate chip control.

Heat treatment

-

Q195 is typically supplied in the as-rolled state and is not a heat-treatable strengthening grade (quench-tempering is not normally used to increase strength for Q-grades). For special needs, normalization may be applied to refine grains.

Corrosion resistance, surface treatments and coatings

Q195 is a plain carbon steel and has no inherent corrosion resistance beyond that of mild steel. For outdoor or corrosive environments it must be protected by:

-

Hot-dip galvanizing / electrogalvanizing — common for wire, fittings, and painted structures.

-

Powder coating or industrial painting systems — for architectural or longer-life applications.

-

Plating or specialized coatings (zinc-nickel, epoxy) depending on service.

Galvanized Q195 wire is a common commodity for fencing and agricultural applications; the base steel is chosen for formability and economical cost before coating.

How Q195 compares to neighboring grades and international equivalents

Quick comparison:

| Grade | Min yield (MPa) | Typical use case | Notes |

|---|---|---|---|

| Q195 | 195 | Light structural parts, welded frames, wire | Lower strength, high ductility, low cost. |

| Q235 | 235 | General structural components, higher loads | Common substitute when extra strength needed. |

| ASTM A36 | ~250 (36 ksi) | Structural shapes and plates in US standards | Not an exact match but often treated as a higher-strength analogue; check design requirements. |

Equivalence caution: many suppliers list approximate international analogues (for commercial convenience), but Q195 is not identical to ASTM A36 or EN S235 — chemistry and guaranteed minimum mechanicals differ. For safety-critical or code-governed work, specify the precise standard required rather than relying on “equivalence.”

Typical applications and short case notes

Where Q195 is commonly chosen

-

Light structural members that do not carry high static loads: frames, brackets, racks.

-

Low-pressure welded pipe and tubing for frames and scaffolding.

-

Cold-formed sections and stampings requiring good bendability.

-

Galvanized wire products, fencing, binding wire.

-

General fabrication where cost per kg and formability are decisive.

Where to avoid Q195

-

High-stress, load-bearing structural members (use Q235 or Q345 types).

-

Pressure vessels and applications with codified material requirements (use materials specified by the relevant pressure vessel code).

-

Cryogenic or impact-sensitive applications unless proven by tested toughness.

Illustrative mini case: a manufacturer of light trolley frames selected Q195 plate for body panels because the parts required extensive cold forming and frequent welding; Q195’s low carbon and high elongation reduced splitting and simplified welding procedure qualification.

Procurement checklist and specification drafting

When specifying Q195 in a purchase order or technical specification, include the following unambiguous items:

-

Standard and edition: e.g., “GB/T 700-2006 Carbon structural steels — grade Q195” (include edition/date).

-

Product form and dimensions: plate (thickness x width x length), coil (thickness x width x inner/outer diameter), tube OD x wall, etc.

-

Delivery condition: AR / N / CR / normalized etc.

-

Chemical composition / acceptance criteria: include maxima for C, Si, Mn, P, S and any element restrictions.

-

Mechanical requirements: guarantee yield & tensile values and sampling method per GB/T 700.

-

Testing & inspection: MTC to EN 10204/GB equivalent, NDT level, impact test temperature if required.

-

Surface treatment: bare, oiled, galvanized; specify coating thickness or class.

-

Packing and marking: shipping marks, batch traceability, heat number stamping.

-

Third-party inspection: if required, nominate classification society or independent inspector.

-

Delivery schedule and tolerance: flatness, thickness tolerance, edge condition.

Tip for buyers: request a representative chemical analysis and tensile test report (MTC) from the mill for the first shipment and keep a retained sample for your QC.

Environmental, lifecycle and recycling notes

Q195, like other mild steels, is highly recyclable: steel scrap drives the EAF route and recycled steel content is commonplace in supply chains. For lifecycle assessments, coated Q195 (e.g., galvanized) requires consideration of coating lifecycle and replacement intervals for corrosion protection. Choosing higher-strength steel can sometimes reduce mass and embodied carbon for the same structural performance — so evaluate on a parts-by-parts basis.

Cost drivers and market considerations

Price of Q195 is influenced by:

-

Global steel raw material and scrap prices.

-

Mill capacity and regional demand for low-end carbon steel.

-

Processing steps required (galvanizing, slitting, precision rolling).

-

Certificate and inspection demands (third-party inspections add cost).

-

Transportation and tariffs for cross-border supply.

Because Q195 is a commodity, lead times are generally short if stock is available, and price competition is strong among producers.

Tables & helpful quick-reference charts

Table 3 — Common product dimensions & tolerances (indicative; use mill datasheet)

| Product | Typical thickness range | Typical width | Tolerance (thickness) |

|---|---|---|---|

| Hot-rolled coil | 1.5 – 20 mm | up to 1600–2200 mm | ±0.1–0.5 mm depending on thickness |

| Plate | 3 – 200+ mm | up to 3000–4200 mm | per GB/T tolerances (specify) |

| Strip | 0.3 – 3 mm | 600–2100 mm | ±0.02–0.1 mm in precision strip |

| Round bar | 6 – 200 mm dia | — | ISO/GB tolerance classes vary |

Table 4 — Quick decision matrix: choose Q195 when...

| Condition | If true → choose Q195? |

|---|---|

| Low stress & light load, formability required | Yes |

| Welded frames where aesthetics not critical | Yes |

| High static load or critical structural member | No — use higher grade |

| Requirement tied to international code specifying A36/S235 | No — specify the required standard explicitly |

FAQs

-

Q: Is Q195 the same as ASTM A36?

A: No exact equivalence. Q195’s nominal yield (~195 MPa) is lower than ASTM A36’s minimum (≈250 MPa / 36 ksi). Suppliers sometimes show approximate analogues for trade but do not treat them as identical for code or design purposes. Always specify the exact standard you require. -

Q: Can Q195 be welded without preheat?

A: For thin sections in typical room-temperature service, yes—no special preheat is usually needed. For thick sections or hydrogen-sensitive environments, follow welding procedure qualification and consider preheat/post-weld heat treatment as required. -

Q: What is the typical tensile strength of Q195?

A: Typically around 315–430 MPa, depending on thickness and supplier testing basis (16 mm specimen is a common reference). -

Q: Is Q195 suitable for galvanizing?

A: Yes. Q195 is commonly used as the substrate for galvanized wire and steel sheet products. -

Q: What tests should I require on purchase?

A: Mill Test Certificate with chemical and tensile results, flattening/bend tests if forming critical, NDT for plates/pipes if required, and third-party inspection for large/critical orders. -

Q: Are there deoxidation or N-content variants (A/B/C) for Q195 like Q235B etc.?

A: GB/T naming conventions sometimes append letters to denote deoxidation practice and delivery class. For Q195 the standard tables indicate permitted deoxidation and delivery variants; specify if you require a particular deoxidation type. -

Q: How to test incoming Q195 plate for compliance?

A: Verify MTC, perform spot chemical verification (spectrometer), tensile test sampling (if allowed by purchase), dimensional checks, and surface inspection. For critical projects, request retained sample provision. -

Q: Will Q195 work for outdoor structural use?

A: Only with appropriate corrosion protection (galvanizing, coating). The base steel itself is not corrosion resistant. -

Q: Is Q195 used in pressure piping?

A: Not typically for pressure-boundary piping where codes require specified materials. Q195 is used for structural and low-pressure tubes. Always follow pressure equipment codes. -

Q: How to improve strength without changing grade?

A: Strength beyond the grade can be gained by cold-work or adding welded stiffening features; but for reliably higher yield/tensile, specify a higher grade (Q235/Q345) to keep material consistency and supplier guarantees.

Final practical recommendations for MWAlloys

-

On product pages: always list exact GB/T reference, chemistry maxima, guaranteed mechanicals and sample MTC. Buyers in export markets often ask for ASTM/EN analogues — provide comparative tables but include the caution that these are approximate.

-

Offer: optional pre-shipment third-party inspection and EN/ASTM style MTC to win engineering buyers.

-

For SEO & procurement content: include comparison tables (Q195 vs Q235 vs ASTM A36), formability examples and a downloadable MTC template buyers can use to expedite orders.

Load-bearing summary statements with supporting citations

-

Q195’s designation and inclusion in GB/T 700 (China’s carbon structural steel standard).

-

Typical chemical maxima (C ≤ 0.12%, Si ≤ 0.30%, Mn ≤ 0.50%, P ≤ 0.035%, S ≤ 0.040%).

-

Nominal minimum yield strength ≈ 195 MPa and typical tensile range ~315–430 MPa.

-

Q195 is widely used for light structural parts, galvanized wire and general fabrication tasks where low cost and formability are priorities.

-

Equivalence claims (to ASTM/EN) exist in supplier literature but are approximate — do not substitute when code or design requirements mandate a specific standard.

Authoritative references

- GB/T 700-2006 — Carbon Structural Steels (English summary and PDF listings)

- ISO 630 — Structural steels (official ISO entry; for international cross-reference)

- ASTM A36/A36M — Standard Specification for Carbon Structural Steel (ASTM official)

- World Steel Association — Description of steel products (LCI study document)