For corrosive marine, estuarine and chemically aggressive soils where extended service life and minimal maintenance are required, stainless-steel U- and Z-profile sheet piles deliver the best whole-life value despite higher upfront material cost: they resist chloride and sulfide attack, reduce coating and cathodic-protection needs, and usually cut total lifecycle cost for permanent seawalls, quay walls and sensitive environments. For economy and fast delivery on stock items, MWAlloys supplies standard U/Z stainless sheet piles from China at factory pricing and short lead times.

What U and Z sheet piles are — form, function and typical uses

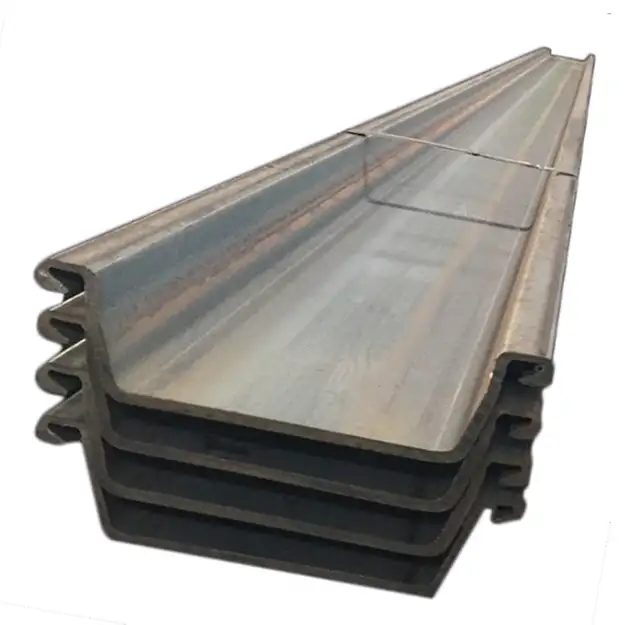

Sheet piles are linear structural elements with interlocking edges that form a continuous wall when driven or vibrated into the ground. The U-profile (also called Larssen U) is roughly a trough that provides a closed, symmetric cross-section, while the Z-profile has flanges offset to one side producing a continuous web-like shape with interlocks on the outside. Both types are available as hot-rolled or cold-formed sections and are selected according to structural requirements, site constraints and installation method. Common applications include quay walls, cofferdams, temporary excavation support, flood protection and waterfront revetments.

Why stainless steel for sheet piling

Stainless steels are chosen where long exposure in chloride-bearing environments, sulfide soils or contaminated sediments makes painted carbon steel either impractical or expensive to maintain. Key advantages:

-

Intrinsic corrosion resistance: Austenitic and duplex stainless grades develop passive films that dramatically slow uniform corrosion and improve resistance to pitting and crevice corrosion in seawater relative to carbon steel.

-

Lower life-cycle maintenance: reduced need for periodic recoating, remedial welding or continuous cathodic protection in many onshore/offshore settings.

-

Thin sections with high durability: stainless grades permit slimmer sections for the same design life in corrosive environments, sometimes reducing weight and offshore load-out costs.

Because the material cost is higher, specification should be based on whole-life economics: life-cycle cost modelling often shows stainless is cheaper where maintenance access is limited, contamination is present, or design life is 50+ years.

Common stainless grades used for piling and their behaviour

Typical grades used for stainless sheet pile applications include:

-

316 / 316L (AISI 316, EN 1.4401/1.4404) — a cost-effective austenitic option for moderately corrosive coastal and estuarine environments. Good general pitting resistance; susceptible to crevice/pitting where chlorides concentrate.

-

2205 duplex (EN 1.4462 / S32205) — higher strength, better pitting resistance than 316, improved fatigue and reduced section thickness for equivalent design capacity. Useful for more demanding marine exposure.

-

904L / 254SMO / high-Mo alloys — for heavily chlorinated or chemically aggressive sites (rare, but used where process fluids or highly polluted effluents are present). These are premium choices.

Design note: choose grade based on detailed environmental data (chloride concentration, sulfide presence, pH, temperature) and required design life. Laboratory test data (ASTM G48 pitting & crevice test, ISO pitting resistance equivalent numbers) should be requested from suppliers.

U vs Z profiles (how to choose)

U profile (Larssen/U-type)

-

Symmetric, closed section; high local stiffness; excellent for cofferdams and shallow to medium depth quay walls. Easier to fabricate interlocks and seal for temporary works.

Z profile

-

Greater section modulus per unit mass for long spans; interlocks are located at the outer flange producing continuous web action. Often chosen for permanent walls where stiffness and reduced bending deflection are critical. Z-type can be more economical for longer walls because it offers higher bending resistance per kg.

Selection rules (practical): choose U-types for short spans, tight handling spaces or where reusability is important; choose Z-types where bending resistance and stiffness are prioritized and where fabrication to length is feasible. Always verify section modulus, moment of inertia and interlock leakage tolerance against the project loads.

Standards and specification checkpoints

When specifying stainless sheet piles, include explicit references for: material chemistry and tensile properties; interlock geometry and tolerance; spot/edge welding procedures; hot-rolled vs cold-formed designation; and required testing (mechanical test certificates, PMI, interlock pressure test, leak test). Typical useful references and standards:

-

National and international product standards: GB/T 20933, JIS A 5528, EN 10248 family, and project-specific ASTM or AISI designations where applicable.

-

Structural guidance: US Army Corps of Engineers Design of Sheet Pile Walls (EM 1110-2-2504) for analysis and detailing rules.

-

Manufacturer catalogues (ArcelorMittal, Nippon Steel) for section properties and selection charts.

Specification checklist to give suppliers: alloy grade and mill heat number control, interlock tolerances, length tolerances, straightness, non-destructive testing plan, identification marking, and packing for ocean shipment.

Manufacturing routes, interlock types and fabrication tolerances

Manufacturing processes: hot-rolled U/Z piles are typical for larger thicknesses and heavy profiles; cold-formed sections are used where smaller thickness and long lengths are required. Interlocks can be rolled (hot rolled) or folded (cold formed). Stainless material requires careful rolling and heat treatment routes to avoid sensitisation (for austenitics) and to preserve duplex phase balance. Ask for mill certificates that confirm post-rolling heat treatment and corrosion testing.

Interlocks & watertightness: interlock geometry influences watertightness and drivability. For permanent seawalls, specify interlock tolerances and, if necessary, gasketed or welded joints. ServiceSteel and major mills publish connector product guides that designers rely on.

Sizes & weights — quick practical reference table (metric)

Below is a compact selection of commonly traded U/Z sections used worldwide. Values are typical examples; final design must use manufacturer tables.

| Profile type | Nominal size (mm) | Thickness (mm) | Typical mass (kg/m) | Typical length (m) | Notes / source |

|---|---|---|---|---|---|

| U 400 × 100 | 400 × 100 | 10.5 | 48.0 | 6 / 9 / 12 / 15 | common Larsen U size (manufacturer listings) |

| Z 400 × 125 | 400 × 125 | 12.0 | 55–62 | 6 / 9 / 12 | Z profiles vary; check manufacturer catalogue |

| U 600 × 210 | 600 × 210 | 13–16 | 90–120 | 6 / 12 | wide U for large quay walls |

| Z 450 × 150 | 450 × 150 | 10–15 | 60–85 | 6 / 12 | high section modulus option |

Important: the numbers above are illustrative and come from common manufacturer listings; always obtain the precise section property table and certificate from the producer for structural calculations.

Procurement and logistics — buying stainless U/Z piles from China (what MWAlloys offers)

As a supplier located in China, MWAlloys provides stainless U and Z sheet piles with the following advantages for international buyers:

-

Factory direct pricing (100% factory price) — cut out middlemen and import from mill or our factory stock to reduce landed cost. Example cold/hot-rolled U/Z piles are available by container or bulk shipment.

-

Stock & fast delivery — we maintain stock of the most common sizes (e.g., 400×100 U type at ~48 kg/m) for export; typical lead times for stocked lengths are shorter than full mill orders.

-

Quality controls — mill test certificates, PMI, mechanical tests and third-party inspection available on request. We follow recognized standards (GB/T, JIS, EN) and can supply to buyer-specified standards.

How to buy from MWAlloys (practical steps): provide profile (U/Z), exact section designation (e.g., U 400 × 100 × 10.5), material grade (e.g., 316L or 2205), length, quantity (tons or linear metres), required certificates, target port and desired delivery window. MWAlloys will respond with FOB/EXW/CIF quotations, factory lead time, and packing details.

2025 global price comparison — practical ranges and context

Material and sheet pile prices vary by alloy, profile, global steel cycle, and freight. Below is a compiled 2025 snapshot of typical market ranges for steel sheet piles and indicative ranges for stainless options (stainless will be priced substantially higher; quoted ranges are approximate). Use these only as planning figures — request forwarder and supplier quotes for final procurement.

Price comparison table (2025, indicative)

| Region / source | Typical sheet pile price (US$/ton) | Notes / source |

|---|---|---|

| China — hot-rolled U/Z (carbon steel) | $540 – $595 / ton (FOB) | Manufacturer listings and Made-in-China product pages (sample ranges). |

| United States — import average (all sheet piling) Apr 2025 | ~$1,674 / ton (import price) | IndexBox import price trend April 2025 — reflects import basket & duties. |

| European trading/stock (hot-rolled U/Z) | $650 – $720 / ton | Distributor listings and international offers; regionally higher due to freight & standards. |

| China — stainless (indicative premium) | Stainless +30% to +100% vs carbon sheet pile | Exact premium depends on grade (316L, duplex) and global stainless coil price; request alloy-specific quotes. |

| Project landed (typical) | Site cost = material + installation + mobilization — wide range ($/m) | Installation costs dominate: drivability, depth, soil conditions and noise/permit constraints control total price. |

Interpretation: raw carbon U/Z piles from China remain competitively priced on an FOB basis; however, import and regional distribution markups, plus stainless premium, can double or more the landed figure versus simple FOB carbon steel prices. For stainless piles, factor alloy-specific coil prices and fabrication premium.

Installation, corrosion mitigation and quality control

Installation notes

-

Driveability depends on soil stratigraphy and pile geometry. For hard strata, pre-drilling or jetting may be required. Specify allowable vibration, hammer energy and tolerances for the contractor.

Corrosion mitigation

-

Even stainless can benefit from design details: avoid crevices where organic fouling or trapped sediment concentrate chlorides; use welded or gasketed joints in highly aggressive sites; consider sacrificial anodes only where design requires it. Request laboratory pitting resistance values or field references from supplier.

Quality control (factory & on-site)

-

Mill test certificates (chemical, mechanical), interlock pressure/fit checks, straightness and surface finish inspections, and 3rd-party witness testing for critical projects. For marine permanent works, request sample coupons and independent corrosion testing records.

Sustainability, reuse and end-of-life recovery

Stainless steel sheet piles are highly recyclable and retain significant scrap value at end-of-life. For temporary works, cleaned carbon piles can be reused multiple times; stainless piles often offer longer reuse cycles with little refurbishment. Life-cycle assessment for quay walls frequently favors stainless where replacement and maintenance scenarios are costly or disruptive.

Ten short practical recommendations

-

Specify material grade and test certificates in the purchase order.

-

Ask suppliers for the exact section property table (Sx, Ix, width, mass/m) and confirm against structural calculations.

-

For seawater exposure, consider 2205 duplex where strength and pitting resistance are both required.

-

Include interlock tolerance & watertightness in the contract and request sample interlock fit tests.

-

Price evaluation: compare FOB mill vs landed cost and include freight, duties and on-site installation.

-

Request third-party inspection for large or critical orders.

-

For contaminated sediments, require chemical exposure data and adapt alloy selection accordingly.

-

Plan for lifting and handling (longer piles need special packing and lashing).

-

Include weld procedures and qualified welders in the spec if in-field welding is needed.

-

Consider reuse & scrap value in the whole-life cost model.

Frequently Asked Questions

1. What’s the difference between U and Z sheet piles in one sentence?

U is a symmetric trough section ideal for short spans and reuse; Z is an offset flange section with higher bending resistance per kg for longer spans.

2. Can you use 316 stainless for permanent quay walls?

Yes for moderate chloride exposure and where budgets limit higher alloys, but evaluate pitting resistance and consider 2205 for harsher marine conditions.

3. How do I check interlock watertightness?

Request manufacturer interlock test data and, for critical projects, specify gasketed joints or field welds; perform pressure/leak tests before installation.

4. Are custom lengths available from Chinese mills?

Yes — typical lengths 6 / 9 / 12 / 15 / 24 m commonly produced; confirm straightness and packing for long lengths.

5. Do stainless piles require cathodic protection?

Usually not for many stainless grades in seawater, but site specifics may require it if galvanic coupling or heavy contamination exists. Evaluate case by case.

6. How much premium is stainless over carbon sheet piles?

Stainless premiums vary widely — often +30% to +100% depending on grade and coil price; include fabrication and handling premiums.

7. What inspections should I demand on receipt?

Mill certificates, visual inspection, interlock fit, straightness, length verification and third-party witnessed sampling if the contract requires.

8. Which standards govern sheet pile production?

Common references include GB/T 20933, JIS A 5528, EN series and project-specific ASTM requirements — request the standard explicitly in the PO.

9. Can I get sample coupons or trial deliveries?

Yes — reputable mills and suppliers supply sample coupons, small trial shipments or prototypes for fit and weld tests. MWAlloys supports sample handling for validation.

10. What’s the fastest way to get a competitive quote?

Provide exact profile designation, material grade, length, quantity, required certificates and destination port — this enables FOB and CIF pricing quickly. MWAlloys responds with factory quotes and lead time on that basis.