Stainless steel checker plate is a textured stainless sheet engineered to give durable anti-slip performance with the corrosion resistance of stainless alloys; for most industrial and architectural uses 304 and 316 grades are the market standard because they balance strength, formability and resistance to atmospheric and marine corrosion.

What is stainless steel checker plate?

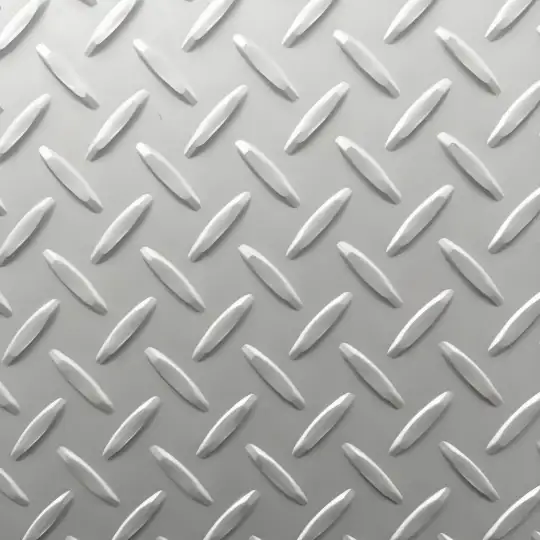

A stainless steel checker plate (also called track plate, chequer plate, tread plate, or diamond plate) is a flat stainless sheet or plate with a repeated raised pattern on one side. The raised pattern offers slip resistance, improves load-bearing friction and conceals minor surface damage. Typical patterns are small diamond lugs, elongated bars, or circular studs pressed or rolled into the sheet. These plates retain the corrosion resistance and hygienic surface properties of stainless steel while adding mechanical traction.

Manufacturing method and pattern types

-

Hot rolling + embossing/rolling: For heavy plate (≥2.5 mm) the pattern is produced by rolling or pressing while the plate is hot or warm; this is common for structural/industrial tread plates.

-

Cold rolling + stamping: For thinner decorative sheets (0.5–2.0 mm), stamping or cold embossing is used to create shallow patterns with tight tolerances.

-

Pattern types: diamond/lozenge (most common), linear bars (strip), circular stud, long-rib strip. Pattern height and pitch vary by supplier and application — higher lugs give better grip but less flat contact for wheeled loads.

Typical stainless alloys used (chemical composition)

Most checker plate is made from common austenitic grades because of their combination of formability and corrosion resistance: 304 / 304L, 316 / 316L; ferritic grades such as 430 are used where magnetic response or lower cost is needed. Below is a compact table of typical composition ranges (wt.%) for the most used grades. These are representative manufacturing ranges (refer to the full standard for exact control limits).

Chemical composition (typical ranges, wt. %)

| Element / Grade | 304 | 304L | 316 | 316L | 430 |

|---|---|---|---|---|---|

| C (Carbon) | ≤ 0.08 | ≤ 0.03 | ≤ 0.08 | ≤ 0.03 | ≤ 0.12 |

| Cr (Chromium) | 18.0–20.0 | 18.0–20.0 | 16.0–18.0 | 16.0–18.0 | 16.0–18.0 |

| Ni (Nickel) | 8.0–10.5 | 8.0–10.5 | 10.0–14.0 | 10.0–14.0 | 0.75–1.5 |

| Mo (Molybdenum) | — | — | 2.0–3.0 | 2.0–3.0 | — |

| Mn (Manganese) | ≤ 2.0 | ≤ 2.0 | ≤ 2.0 | ≤ 2.0 | ≤ 1.0 |

| Si (Silicon) | ≤ 1.0 | ≤ 1.0 | ≤ 1.0 | ≤ 1.0 | ≤ 1.0 |

| P, S | ≤ 0.045/0.03 | ≤ 0.045/0.03 | ≤ 0.045/0.03 | ≤ 0.045/0.03 | ≤ 0.040/0.030 |

For strict compliance use the numeric limits in the relevant product standard (ASME SA-240 / ASTM A240 or EN standards).

Mechanical & physical properties

Below is a concise property snapshot that buyers commonly reference when designing with checker plate.

Representative mechanical properties (annealed condition)

| Property | 304 (typical) | 316 (typical) |

|---|---|---|

| Density | ~8.00 g/cm³ (~8000 kg/m³) | ~8.00 g/cm³ |

| Yield strength (0.2% offset) | ~215–275 MPa (varies with thickness & finish) | ~215–275 MPa |

| Tensile strength | ~505–720 MPa | ~515–760 MPa |

| Elongation (A%) | ~40–60% | ~40–60% |

| Hardness (HB) | ~140–200 (annealed) | ~140–200 |

Note: cold working (rolling, forming) raises strength and hardness; final properties depend on supplier rolling and annealing practice. For precise design use mill certificates and test reports.

Sizes, thicknesses, and weight

Standard sheet sizes (typical stocked dimensions):

-

Metric: 1250 × 2500 mm, 1500 × 3000 mm, 1524 × 3048 mm (5’×10’), 1219 × 2438 mm (4’×8’)

-

Imperial: 48" × 96", 48" × 120", 60" × 120" etc.

Common thickness range for stainless checker plate (typical):

-

Thin decorative: 0.5 mm — 1.5 mm

-

Light industrial: 2.0 mm — 3.0 mm

-

Heavy-duty floor/tank access: 4.5 mm — 12 mm and above

Thickness → approximate weight (selected rows) — typical checker-plate weight listings (kg/m²) used for logistics and structural checks. (Values taken from market product tables; use plate dimension to compute total mass.)

| Thickness (mm) | Approx. weight (kg / m²) |

|---|---|

| 1.0 | ~8.0 (thin embossed sheet) |

| 2.3 | 19.7 (example plate size basis; heavy embossing alters effective mass slightly) |

| 3.2 | 26.8 |

| 4.5 | 37.0 |

| 6.0 | 48.8 |

| 9.0 | 72.3 |

| 12.0 | 95.9 |

How weights are used: multiply kg/m² by the planned area to estimate handling weights. For imperial units, Engineering Toolbox tables convert thickness (in) to lb/ft².

Finishes, edge work and inspection points

-

Common finishes: HRAP (hot-rolled, annealed, pickled), No. 4 brushed, 2B mill finish, mirror (8K) for decorative uses. For floor/tank work HRAP and No. 4 are typical.

-

Edge condition & flatness: pattern generation can reduce flatness; edge trimming, leveling or CNC trimming is often supplied to tolerance.

-

Welding & fabrication notes: gap fill and weld-pass polishing may be required to meet sanitation or aesthetic specs; select low-carbon (L) grades if welding without post-heat treatment is required.

Typical applications and sector examples

-

Industrial walkways, catwalks, stairs, ramps and mezzanines (anti-slip under oily/wet conditions).

-

Truck and trailer beds, toolboxes and vehicle steps (resists corrosion and denting better than aluminum in some contexts).

-

Kitchen and catering floors, food processing plant access: stainless keeps hygienic surface.

-

Marine decks, gangways and platforms: 316 recommended where chlorides / salt spray are present.

Advantages vs alternatives

-

Vs aluminum tread plate: stainless is heavier and more expensive per kg but offers superior abrasion resistance, higher temperature capability and better chemical resistance in many service environments.

-

Vs mild steel checker: stainless avoids the need for regular painting and is preferred where cleanliness, corrosion resistance or aesthetics matter.

-

Longevity and life-cycle: in corrosive or hygienic environments stainless often costs less over lifetime despite higher initial material cost.

Standards, codes and technical references (what to request with a PO)

When buying stainless checker plate ask for/verify:

-

Material standard: ASME SA-240 / ASTM A240 (plate, sheet for general use) and the alloy UNS number (e.g., S30400, S31600).

-

Mill test certificate (MTC): EN 10204 / 3.1 or 2.2 as per project procurement rules.

-

Dimensional tolerance & flatness: per customer spec or national/EN plate tolerances.

-

Pattern specification: show sample pattern height, pitch and drawing; some projects specify lug height ≥2.5 mm for stair tread.

2025 Price comparison: USA / Europe / China

Important: stainless market pricing is volatile because nickel and scrap input costs fluctuate. The figures below are ranges indicative of early-to-mid 2025 market levels and/or common supplier quotes; they are not firm offers. Always request updated mill or distributor quotes and confirm delivery/incoterms. Sources used include market pricing services and regional distributors.

Price units: USD per metric tonne (or per kg) for standard 304/316 coil/plate equivalents. Tread / checker plate will carry a shaping/processing premium.

| Region | Typical 304 (USD / tonne) — early 2025 (indicative) | Typical 316 (USD / tonne) — early 2025 (indicative) | Notes |

|---|---|---|---|

| USA (distributor, plate retail) | ~$1,800–$2,500 / t | ~$2,500–$3,400 / t | Domestic sheet/plate spot trades and distributor lists — mill and cut-to-size add service charge. |

| Europe (delivered) | ~€1,900–€3,200 / t (approx $2,000–$3,300/t) | ~€2,700–€4,000 / t | Price series show regional variations and periodic surcharges; check MEPS / Fastmarkets. |

| China (factory FOB) | ~$850–$1,800 / t (wide spread by grade & MOQ) | ~$1,200–$2,200 / t | China suppliers often quote on tonnage lot basis; smaller cut sizes or plate processing raise per-ton price. Examples from supplier platforms show $850–$1,200 / t for commodity 304 coil in some listings. |

How to translate to plate price: checker/tread plates carry additional processing (pattern rolling, leveling), plus local delivery and customs. For a rough buyer estimate, add 5–20% processing + cut/edge work and shipping.

Why figures differ: Europe and USA include delivered and distributor margins; China quotes often are FOB mill with MOQ and require sea freight and customs to compare landed cost.

Procurement checklist and MWAlloys offer

When specifying/ordering stainless checker plate, include in the PO: grade (UNS), thickness, pattern type, pattern orientation, sheet size, finish, tolerances, MTC type (EN 10204), heat number traceability, and delivery/incoterm.

What MWAlloys (the manufacturer behind this content) offers:

-

Factory-direct supply from China (MWAlloys factory) — 100% factory price model for volume orders, stable MOQ options for stocked sizes.

-

Stocked common sizes and fast processing for typical cut-to-size orders; typical short lead times for stocked inventory (confirm per order).

-

Grades: 304 / 304L / 316 / 316L / 430 available; pattern types and bracketed thickness ranges available.

-

Mill traceability and certificate compliance on request (EN / ASME / ASTM style MTC).

-

Global shipping options with packaging to export standard.

Contact note: provide drawing, grade and target delivery port to MWAlloys for a written quote that includes packing, lead time and final price.

FAQs

-

Which grade should I choose for outdoor decking near the coast?

Prefer 316 / 316L in marine environments because the added molybdenum increases pitting resistance to chlorides. -

Can checker plate be welded?

Yes — use appropriate filler metal and welding procedure; choose low-carbon L grades for welded assemblies where post-weld heat treatment is not practical. -

How do I calculate weight for transport?

Multiply sheet area by kg/m² from the thickness table (or use Engineering Toolbox imperial tables to convert in→lb/ft²). Always add pattern and coating allowance if specified. -

Is pattern height standardized?

No universal single standard — suppliers publish lug height and pitch; specify minimum lug height if grip requirements are critical. -

Are there anti-skid alternatives that are lighter?

Aluminum diamond plate is lighter (lower density) but offers different wear and chemical resistance; choose by application. -

How can I ensure the plate is sanitary for food plants?

Request No. 4 finish or mill finish per spec, provide MTC and ensure polishing/weld cleaning procedures meet hygiene protocol. -

What finish should I pick for decorative indoor walls?

Mirror (8K) or No. 4 brushed finishes give better aesthetics — confirm pattern depth to avoid strong reflection distortion. -

Do standard plates come cut to size?

Many mills and distributors offer cut-to-size. Factory direct offers from MWAlloys can include CT-s for batch orders. -

How much more does diamond pattern add to cost?

Pattern rolling/stamping is a processing premium; expect processing and finishing to add a single-digit to low-double-digit percentage on top of raw plate cost depending on order size. -

What certificates are standard?

EN 10204 type 3.1 (or 2.2) MTCs and compliance with ASME SA-240 / ASTM A240 grade specifications are commonly requested.

Practical tips for specifying checker plate in a tender

-

Attach a physical sample image or drawing that shows lug pitch and height.

-

Specify the finished thickness (pattern reduces flat thickness in contact areas).

-

Ask for a mill test certificate (MTC) with heat number traceability.

-

For outdoor use select 316 / 316L or duplex varieties where budget allows.

-

For welded, load-bearing structures require an engineer’s sign-off with actual yield strength from MTC.