SKD61 is a high-performance hot-work tool steel widely used for dies and molds that must withstand repeated thermal cycling and heavy mechanical loads. Its balanced composition of chromium, molybdenum and vanadium delivers durable hardness, strong red hardness, and good resistance to thermal fatigue. For most mold applications where service temperatures reach several hundred degrees Celsius, SKD61 (equivalent to AISI H13 / DIN 1.2344) offers the best compromise between wear resistance and toughness. MWAlloys supplies SKD61 with factory-direct pricing, abundant stock for rapid shipment, and quality control tuned to industrial specifications.

What is SKD61 tool steel

SKD61 is a Japanese JIS-designated hot-work alloy tool steel. It belongs to the chromium-molybdenum-vanadium family intended for tooling that sees elevated temperatures and repeated thermal shocks. Industry manufacturers commonly specify SKD61 for die-casting, hot forging, extrusion tooling and high-duty injection molds because the grade keeps hardness under thermal load while giving good fracture resistance. Equivalent international names include AISI H13 and DIN/EN 1.2344.

Why choose SKD61 tool steel

Choose SKD61 when tooling will face:

-

Prolonged exposure near 500–600°C.

-

Cyclic heating and cooling with risk of thermal fatigue.

-

Demands for combined wear resistance and high toughness.

For extreme abrasive wear at lower temperatures consider higher-carbon cold-work steels. For maximum toughness when wear concern is low, consider less alloyed hot-work grades. The balance that SKD61 provides makes it the most widely adopted hot-work steel in global toolmaking.

Chemical composition (nominal ranges — JIS JIS G4404)

| Element | Typical range (wt%) |

|---|---|

| C (Carbon) | 0.35 – 0.42 |

| Si (Silicon) | 0.80 – 1.20 |

| Mn (Manganese) | 0.25 – 0.50 |

| P (Phosphorus) | ≤ 0.03 |

| S (Sulfur) | ≤ 0.03 |

| Cr (Chromium) | 4.8 – 5.5 |

| Mo (Molybdenum) | 1.0 – 1.5 |

| V (Vanadium) | 0.80 – 1.15 |

Notes: Carbon level controls final achievable hardness and wear. Chromium supplies hardenability and corrosion/wear resistance. Molybdenum increases red hardness and strength at elevated temperatures. Vanadium refines carbides improving wear resistance and toughness. These ranges reflect JIS J4404 listing for SKD61 and common supplier datasheets.

Material properties — typical, depends on heat treatment

Below are representative values for SKD61 material after standard quench-and-temper cycles (values vary by supplier and exact thermal cycle).

| Property | Typical value / range |

|---|---|

| Hardness (HRC) after quench + temper | 40 – 52 HRC (typical production: 42–48 HRC) |

| Tensile strength (Rm) | ~1200 – 1600 MPa depending on treatment. |

| Yield strength (Rp0.2) | ~1000 – 1380 MPa |

| Toughness (Charpy) | Depends on notch, temper; generally good compared to other hot-work steels |

| Thermal conductivity | ~25–30 W/m·K (room temp) |

| Coefficient thermal expansion | ~10.4 ×10⁻⁶ /°C (20–100°C) |

| Tempering range (recommended) | Pair of tempers between 550–650°C; final hardness tied to temper temp |

| Max recommended service temperature | Typically <= 600°C for sustained exposure; higher for intermittent service with modified cycles. |

Mechanical properties depend heavily on heat treatment details (austenitizing temperature, quench medium, temper schedule). For critical tooling request certified test reports from supplier.

SKD61 specifications and common product forms

| Specification item | Typical values / notes |

|---|---|

| Standards | JIS G4404 (SKD61), ASTM A681 (H13), DIN EN ISO 4957 (1.2344) |

| Typical heat treatment (factory) | Austenitize 1020–1050°C; air or oil quench; triple temper 550–620°C |

| Surface conditions | Hot-rolled plate, forged block, ground bar, turned/machined finish |

| Supply forms | Plate, round bar, rectangular bar, forgings, pre-hardened plates |

| Surface hardness on delivery | Mill normalised/annealed or pre-hardened per buyer spec |

| Certificate | Mill test certificate (chemical + mechanical) on request |

Standards used in procurement should appear on purchase order to ensure traceability and acceptance criteria.

Metal moulding and heat-treatment workflow for SKD61

Practical production flow for high-performance mold tooling:

-

Raw material selection: choose vacuum degassed, ESR (electro-slag remelt) or AOD melt steel when service is demanding.

-

Rough machining: leave machining allowance for distortion that will occur during heat treatment.

-

Pre-heat treatments: normalize if material is delivered in as-rolled condition: typical 850–900°C followed by air cool to refine grain.

-

Austenitizing: 1020–1050°C is common; time scaled to cross-section. Avoid overheating since grain coarsening reduces toughness.

-

Quenching: air quench or oil quench depending on section thickness and desired hardness. Air quench preferred for lower distortion when possible.

-

Multiple tempers: typically two or three tempers at 550–620°C to stabilize microstructure and relieve stresses. Final hardness controlled by temper temperature.

-

Stress-relief and straightening: required on large dies to meet dimensional tolerances.

-

Final machining and polish: SKD61 machines and polishes well compared to high-carbon cold-work steels; carbides influence polish quality.

-

Surface treatments (optional): nitriding, PVD coatings, or cryogenic treatments may be applied to extend life but require process and design checks.

Key controls: monitoring austenitizing temperature, soak time, cooling rate, and tempering schedule. For deep sections OEM engineers often request trial runs and destructive testing to validate heat treatment.

SKD61 equivalents (cross-reference)

| Region / Standard | Equivalent grade |

|---|---|

| Japan (JIS) | SKD61 (JIS G4404) |

| USA (AISI / ASTM) | H13 (AISI H13 / ASTM A681) |

| Germany / ISO | 1.2344 / X40CrMoV5-1 (DIN / EN / ISO family) |

| China (GB) | 4Cr5MoSiV / GB variants used in trade listings |

| International designation | X40CrMoV5-1 (common in supplier datasheets) |

Cross-reference sources indicate near interchangeability for many tool applications, yet subtle composition tolerances differ; therefore perform application tests before substituting across standards.

SKD61 typical applications and common failure modes

Applications

-

Die-casting molds for aluminum, magnesium, zinc.

-

Hot forging dies and blocks.

-

Extrusion tooling and container molds.

-

High-temperature injection molds when polymer temperature is high.

-

Shear knives and hot-work punches.

Common failure modes

-

Thermal fatigue cracking from repeated thermal cycling.

-

Wear from abrasive inclusions in processed materials.

-

Adhesive wear or galling on contact surfaces.

-

Fracture from overload if toughness is insufficient.

Design guidance to extend life

-

Use smooth fillets and avoid sharp corners.

-

Select appropriate surface finish and post-treatments (nitriding, coatings).

-

Control preheating and cooling rates in production use.

-

Implement monitoring: scheduled inspections for thermal crack initiation.

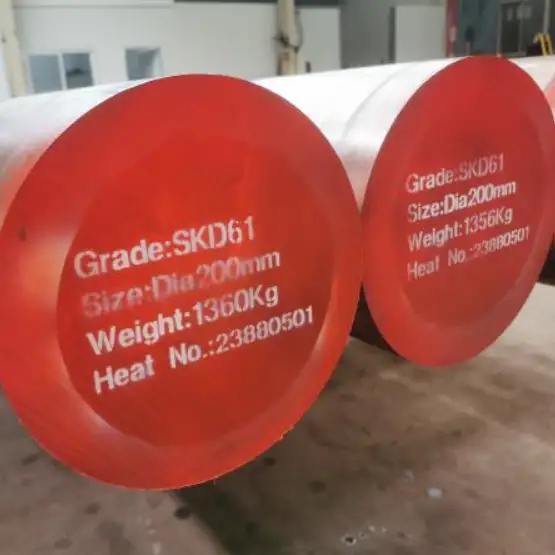

Sizes, formats and weight calculation examples

Common supply sizes

-

Round bars: diameters from 8 mm up to 400 mm (stock and forged sizes).

-

Plates: thickness from 10 mm to 500 mm (depends on mill capability).

-

Forgings: custom blocks up to several tonnes.

Weight calculation (quick method)

-

Steel density ~7.85 g/cm³ (7,850 kg/m³).

-

Example — round bar 100 mm diameter, 1 m length: volume = π × (50 mm)² × 1000 mm = 7,853,982 mm³ = 0.007853982 m³ → weight ≈ 61.6 kg/m.

-

Plate 2000 × 1000 × 20 mm = volume = 0.04 m³ → weight ≈ 314 kg.

Common stocked blanks

-

Ground bars 40–200 mm dia.

-

Pre-hardened plates 20–200 mm thickness (depending on supplier).

Always confirm actual weight using mill plate dimensions because tolerances vary. Suppliers commonly provide packing weight per bundle for shipping quotes.

SKD61 steel price comparison (2025)

Method note: Price ranges collected from supplier listings, trade platforms and manufacturer offers. Prices vary with form (round bar, plate), surface finish, melting method (AOD/ESR), certification, order quantity, and shipping Incoterms. Figures below present indicative FOB or EXW equivalents converted to per tonne ranges in USD for mid-2025 market conditions.

| Region | Typical 2025 price (USD/tonne) — indicative range | Notes / source |

|---|---|---|

| China (factory FOB/EXW) | $900 – $2,200 / tonne | Trade listings on Made-in-China and Alibaba show broad ranges by quality and MOQ. |

| USA (merchant stock / mill) | $2,200 – $4,000 / tonne | Higher due to lower domestic volumes and processing; premia for certified bars and premachined blanks. |

| Europe (distributor / certified) | $2,000 – $3,800 / tonne | Pricing reflects distribution, CE/EN certifications, and logistics. |

Interpretation tips

-

Lower end pricing often from large-volume Chinese mills offering hot-rolled plate or merchant bars with MOQ.

-

Mid-market reflects pre-hardened or ground stock with certification.

-

Upper end includes ESR/VD/VIM melts, vacuum degassed material, or small-lot custom forgings with mill-cert paperwork.

Buyers should request Mill Test Certificates and clarify INCOTERM. For critical tooling MWAlloys offers 100% factory-direct pricing for large purchases, smaller lot stock for quick delivery, and helps customers choose ESR/ESR+ routes when service life justifies premium.

FAQs

1. What heat-treatment will give 48 HRC for SKD61?

Typical route: austenitize 1020–1050°C, air or oil quench, temper twice at ~560–600°C. Exact cycle depends on cross-section; request supplier guidance for target hardness.

2. Can SKD61 be welded?

Welding is possible with preheat and controlled interpass temperature plus post-weld tempering. Use matching filler and qualified procedure. For critical dies prefer welding by experienced shops then full tempering.

3. Is SKD61 interchangeable with H13?

Functionally yes for many tooling uses, but check tight tolerance specs and chemical limits before substitution.

4. Does SKD61 need ESR or vacuum melt?

Not mandatory for all uses. ESR or vacuum melting improves cleanliness and fatigue life; recommend for high-duty, long-life dies.

5. Is nitriding recommended?

Nitriding increases surface hardness and life for sliding contact. Nitriding depth is shallow; do thermal compatibility checks.

6. How large can SKD61 dies be?

Forgings and blocks of several tonnes are feasible; check supplier forging/rolling capacity.

7. What are common polish results?

SKD61 polishes well to mirror finishes required for injection molds, provided carbide distribution is controlled.

8. Which coating is best?

PVD coatings such as TiN or TiAlN help in some injection molding scenarios; selection depends on polymer chemistry and operation temperature.

9. Is cryogenic treatment useful?

Cryogenic treatment can transform retained austenite and stabilize dimensions; benefit must be validated with trials.

10. How to reduce thermal crack risk?

Design with uniform cross-sections, apply preheating during service, choose ESR melts, and employ controlled temper schedules.

MWAlloys — supply note and why procure from us

MWAlloys is a precision metal supplier focusing on tool and die steels. Our SKD61 offering highlights:

-

Factory-direct pricing: 100% mill-sourced supply chain, giving buyers competitive quotations.

-

Fast stock delivery: standard sizes kept in regional warehouses for quick dispatch.

-

Quality control: mill test certificates (chemical + mechanical), non-destructive testing on request.

-

Customization: plates, forged blocks, pre-machined blanks and pre-hardened stock.

-

Technical support: heat-treatment and design consultation from tooling engineers.

For quotes provide: required form (bar/plate/forging), dimensions, target hardness, certification need, and delivery port. MWAlloys will reply with lead time and exact mill certificate.

Technical authority & standards

Standards and authoritative specifications define chemical limits, testing methods, and acceptance criteria. Reference these in purchase orders to ensure material traceability and conformity. Key standards include JIS G4404, ASTM A681, DIN/EN ISO 4957 and supplier datasheets from major alloy producers.