For pressure systems where higher wall thickness and greater mechanical strength are required, SCH 80 carbon steel pipe (manufactured to ASME/ASTM standards such as ASTM A53 / ASTM A106 and dimensionalized by ASME B36.10M) provides a cost-effective, widely available solution. It balances pressure capacity, weldability and machinability with straightforward procurement and installation practice. For bulk purchase with 100% factory pricing and fast stock lead times, MWAlloys supplies SCH 80 carbon steel pipe from Chinese mills with competitive FOB/CIF terms and on-demand inventory for common sizes.

What is “SCH 80” means

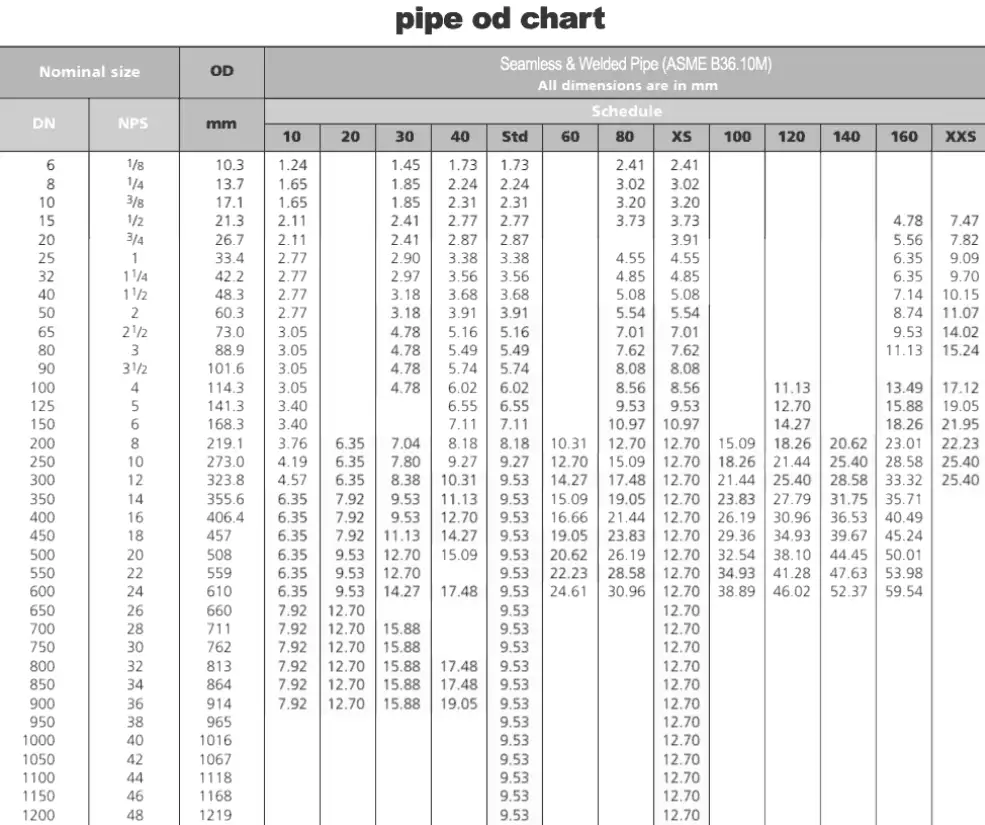

“SCH 80” (Schedule 80) is a nominal pipe schedule that defines wall thickness for a given nominal pipe size (NPS). Schedule values (e.g., Sch 40, Sch 80, Sch 160) let engineers specify a target wall thickness without changing the outside diameter (OD) for a given NPS. In practice, SCH 80 has substantially thicker walls than SCH 40 for the same OD, which raises allowable working pressures, stiffness and weight per length while keeping fittings and flanges compatible where OD is the key parameter. Dimensional standardization for steel pipe schedules is set by ASME/ANSI B36.10M and related documents.

Applicable standards & commonly used grades

Common ASTM/ASME product specifications used for SCH 80 carbon steel pipe:

-

ASTM A53 / ASME SA-53 — general-purpose black and galvanized pipe (seamless and welded); often used for mechanical and pressure applications.

-

ASTM A106 / ASME SA-106 — seamless carbon steel pipe for high-temperature service (Grades A/B/C, Grade B is most common for Sch 80 in pressure systems).

-

API 5L — transmission pipe specification (line pipe) that is sometimes used as an equivalent in oil & gas; API 5L Grade B commonly parallels A106/A53 characteristics.

-

ASME B36.10M — dimension tables and mass (weight) values for welded and seamless wrought steel pipes; schedules are referenced from here for nominal sizes.

When you specify SCH 80 for procurement, also indicate the material standard (for example: SCH 80 A106 Grade B seamless, or SCH 80 A53 Grade B ERW), the pipe length/ends (plain, beveled, threaded), the required testing (hydrostatic, nondestructive tests), and any coatings/linings.

Chemical composition (typical ranges)

Below are representative chemical composition ranges for common carbon-steel pipe grades used for SCH 80 (values are typical maximums or ranges supplied by standards & manufacturer datasheets — always confirm with mill certificates for each lot).

| Element | ASTM A53 Grade B (typ.) | ASTM A106 Grade B (typ.) | API 5L Grade B (typ.) |

|---|---|---|---|

| Carbon (C) | ≤ 0.30–0.35 % | ≤ 0.30 % | ≤ 0.30–0.35 % |

| Manganese (Mn) | 0.27–1.20 % | 0.29–1.06 % | 0.30–1.20 % |

| Phosphorus (P) | ≤ 0.05 % | ≤ 0.035 % | ≤ 0.04–0.05 % |

| Sulfur (S) | ≤ 0.05 % | ≤ 0.035 % | ≤ 0.04–0.05 % |

| Silicon (Si) | 0.10–0.35 % | ≥ 0.10 % (min) | 0.10–0.35 % |

| Copper (Cu), Ni, Cr, Mo (traces) | traces | traces (mill dependent) | traces |

Notes: These figures are representative; specific chemical limits vary by standard edition, grade and mill practice. Mill Test Reports (MTRs) provided with each heat/batch will list exact composition for that shipment.

Mechanical & physical properties (typical)

Representative mechanical properties for commonly supplied carbon-steel pipe grades used in SCH 80:

| Property | ASTM A53 Gr B (typ.) | ASTM A106 Gr B (typ.) | API 5L Gr B (typ.) |

|---|---|---|---|

| Minimum yield strength | ~240–260 MPa (≈35–38 ksi) | ~240–260 MPa | ~245 MPa (L245) |

| Minimum tensile strength | ~415–550 MPa (≈60–80 ksi) | ~415–550 MPa | ~415–550 MPa |

| Elongation (in 2") | ≥ 20–30% depending on OD | ≥ 20–30% | ≥ 20–30% |

| Hardness (typical) | HB < 120–150 (mill dependent) | HB < 140–160 | HB < 140–160 |

Notes & practice: Properties change somewhat with wall thickness, manufacturing method (seamless vs welded), heat treatment/normalization, and grade. Where high temperature or cyclic service is expected, engineers typically choose ASTM A106 Grade B/C (seamless) or higher-spec grades and demand appropriate nondestructive testing.

Dimensional specification, sizes & weight (ASME B36.10M)

ASME B36.10M standardizes outside diameters (OD) for NPS and then specifies nominal wall thicknesses by schedule. A few practical examples for Schedule 80:

| NPS (Nominal) | OD (in) | SCH 80 wall thickness (in) | Weight (lb/ft) (approx.) |

|---|---|---|---|

| 1/2" | 0.840 | 0.109 | 1.68 |

| 3/4" | 1.050 | 0.154 | 2.72 |

| 1" | 1.315 | 0.179 | 4.03 |

| 2" | 2.375 | 0.218 | 8.79 |

| 4" | 4.500 | 0.237 | 18.97 |

| 6" | 6.625 | 0.280 | 29.06 |

| 8" | 8.625 | 0.322 | 41.88 |

(These numbers are illustrative — consult the ASME B36.10M / manufacturer tables for full NPS range and exact mass per length.)

How schedule maps to thickness: Schedule number is not linear — the same NPS will have different wall thicknesses at different schedules. SCH 80 is a heavier wall than SCH 40 and is often used where higher pressure or mechanical robustness is required.

Equivalent standards and cross-reference table

When buying internationally, it’s common to translate ASTM/ASME grades into EN or API equivalents. Common cross-references (consult mill documentation for final confirmation):

| US spec / grade | Common equivalent (EN / DIN / API) |

|---|---|

| ASTM A106 Grade B (seamless) | EN 10216-2 P265GH (seamless) |

| ASTM A53 Grade B (welded/seamless) | EN 10217 / EN 10219 family (depending on welded vs seamless) |

| API 5L Grade B | Often compared to A106/A53; EN equivalent L245 (EN 10208 family) |

| ASTM A333 (low temp) | EN 10216-4 (P265NL etc.) |

Notes: Equivalency tables are approximate; acceptance depends on purchaser specification, required tests (impact, hardness), and intended service. When tendering internationally, always specify both the required US standard and the acceptable EN/API equivalents with exact testing requirements.

Manufacturing processes, end finishes, coatings and testing

Manufacturing types:

-

Seamless (SMLS): typically used for higher temperature and pressure; common with ASTM A106 Grade B.

-

Electric Resistance Welded (ERW) / SAW / Submerged-Arc Welded: economical for larger diameters and lower-to-moderate pressure uses (often to A53).

End finishes:

-

Plain end (PE) — factory cut, common for structural use.

-

Beveled end (BE) — required for butt weld connections.

-

Threaded (NPT/ BSP) — for small diameters and certain fluid systems.

-

Coupling ends or grooved ends — for mechanical couplings.

Common pipe coatings/linings:

-

Black (mill scale) — economical for indoor or protected services.

-

Galvanized — for outdoor or atmospheric corrosion resistance.

-

Fusion bonded epoxy (FBE) or internal cement mortar — used in water distribution or aggressive services.

-

Bituminous or polymer coatings for buried pipe.

Testing & QC typically included or available on request:

-

Hydrostatic testing (or pneumatic as specified).

-

Ultrasonic (UT) thickness and weld seam inspection.

-

Radiographic testing (RT) of welds where required.

-

Flattening, tensile, bend tests, and chemical analysis with Mill Test Report (MTR).

Pressure ratings & engineering considerations

Because SCH 80 has a thicker wall than SCH 40 for the same OD, allowable working pressure is higher. Exact allowable pressures depend on material yield strength, corrosion allowance, temperature, and joint type. Engineers calculate pressure capability using the ASME B31.1 / B31.3 piping codes or other relevant design codes; tables in B36.10 give wall thickness and mass, but pressure capability requires strength formulas (e.g., thin-wall approximation or Lame’s equation for thick walls) plus appropriate safety factors and corrosion allowances.

Practical rule: For moderate diameter (<6") pressure piping at typical carbon-steel service temperatures, SCH 80 will often allow 20–40% higher internal working pressure than SCH 40 (same material grade) — but verify by calculation for your operating temperature and the specific grade’s yield strength. (Always specify design temperature and fluid chemistry to get a correct rating.)

Sizes & weight (expanded table example)

Below is a short extract from an expanded sizes & weight chart based on ASME B36.10M (for SCH 80). For full NPS set consult ASME tables or supplier datasheets.

| NPS | OD (in) | Wall SCH 80 (in) | Weight lb/ft (approx.) |

|---|---|---|---|

| 1/8 | 0.405 | 0.068 | 0.34 |

| 1/4 | 0.540 | 0.088 | 0.57 |

| 1/2 | 0.840 | 0.109 | 1.68 |

| 3/4 | 1.050 | 0.154 | 2.72 |

| 1 | 1.315 | 0.179 | 4.03 |

| 1-1/4 | 1.660 | 0.191 | 5.61 |

| 1-1/2 | 1.900 | 0.200 | 7.02 |

| 2 | 2.375 | 0.218 | 8.79 |

| 3 | 3.500 | 0.300 | 16.20 |

| 4 | 4.500 | 0.237 | 18.97 |

| 6 | 6.625 | 0.280 | 29.06 |

| 8 | 8.625 | 0.322 | 41.88 |

(Values are approximations — use the manufacturer/ASME tables for procurement & weight calculations.)

Typical industries and applications

SCH 80 carbon steel pipe is used in:

-

Industrial process piping (petrochemical, chemical feed lines).

-

High-pressure steam lines, heating systems, and condensate return lines.

-

Mechanical systems and structural applications where higher wall thickness is desired.

-

Oil & gas production and distribution when specified to A106/API 5L (depending on service).

-

Water and wastewater for specific membranes and irrigation headers (with appropriate lining/coating if corrosive).

Selection depends on fluid type, temperature, pressure, and environmental corrosion risk.

Sourcing & 2025 price comparison

Price caveat: steel prices vary rapidly with raw material markets, volume, specification, coating, and shipping. The table below consolidates recent 2024–2025 supplier/market indicators (typical FOB/EXW/warehouse price ranges converted to USD/metric ton as of 2025 market reporting — use these as starting points for negotiation; always request current formal quotes and lead times).

| Region | Typical 2025 price range (USD / metric ton) — SCH 80 carbon pipe (representative) | Typical remarks |

|---|---|---|

| China (FOB mills) | USD 600 – 1,000 / ton (depending on grade, seamless vs welded, quantity). | Many mills offer ERW & seamless; MOQ and plate/coil prices affect final. |

| USA (distributor/stock) | USD 1,600 – 2,400 / ton (domestic A106/A53 products, small order premiums). | Higher due to distribution, certification, domestic mill premiums. |

| Europe (mill/distributor) | EUR 1,300 – 2,200 / ton (~USD 1,400 – 2,300 / ton) depending on supplier & testing. | European prices depend on EN equivalents, tests, and logistics. |

How to interpret: Chinese mill FOB prices are generally lowest on a per-ton basis; however import duties, inland logistics, testing/certification requirements and small-order premiums often reduce the final landed cost parity. For projects requiring tight traceability, domestic or regional suppliers may be preferred despite higher unit cost.

Practical buying tips:

-

Request complete Mill Test Reports (MTRs) and traceability for each heat.

-

Include required NDT (UT/RT), hydrotest and any third-party inspection in the commercial terms.

-

Specify packing, marking (heat number), and shipping terms (FOB/CIF/DDP) to receive comparable quotes.

-

For fast delivery, MOQ conformity and off-the-shelf inventory (MWAlloys often holds common SCH 80 sizes) can reduce lead time.

(Sources: market supplier listings and price reports compiled from industry suppliers in 2024–2025.)

Quality control, certification & traceability

For industrial and safety-critical applications, insist on:

-

Mill Test Report (MTR / EN 10204 3.1 or 3.2) specifying chemical & mechanical test results.

-

NDE reports for required weld and base material tests (UT, RT, MPI/DP, etc.).

-

Third-party inspection (by Lloyd’s, Bureau Veritas, TUV, SGS) for large or critical shipments.

-

Heat number marking on each length and referenced on documentation to permit traceability.

A project specification should list exactly which certificates and tests are mandatory; otherwise quotes will omit them, producing surprises in final acceptance.

Handling, storage & corrosion protection

-

Store pipes off the ground on supports with protective spacers to avoid water pockets and deformation.

-

For outdoor storage, cover ends to prevent ingress of debris and rainwater.

-

Consider cathodic protection, coatings, linings or galvanizing depending on soil, seawater, or chemical exposure.

-

Implement periodic visual inspections and ultrasonic wall-thickness monitoring for critical systems.

MWAlloys — how we serve buyers

MWAlloys is a manufacturer / trading group with factory relationships across multiple Chinese mills. Key advantages we emphasize for SCH 80 customers:

-

Factory price: direct mill link ensures 100% factory price advantage for bulk orders (transparent FOB pricing).

-

Stock and fast shipment: maintained stock of common SCH 80 sizes for quick turnaround — suitable when projects need rapid replenishment.

-

Customization: beveling, threading, galvanizing, FBE, internal lining, and special testing (third-party inspection) available.

-

Documentation: we deliver full MTRs, inspection certificates and support for export paperwork.

If you’d like a tailored quote, provide: NPS sizes and quantities, material standard (A106/A53/API 5L), end finish, coating/lining, destination port, and required certification (e.g., 3.1/3.2 MTR, RT/UT).

FAQs

1) Is SCH 80 stronger than SCH 40?

Yes — for the same nominal size, SCH 80 has a thicker wall and therefore a higher cross-sectional area resisting internal pressure and mechanical loads. Use code calculations for exact allowable pressures because material grade and temperature matter.

2) Which is better: ASTM A53 or A106 for SCH 80?

Use A106 (seamless) when high temperature or more stringent mechanical properties are required. A53 is commonly used for general piping where welded pipe or lower cost is acceptable. The final choice depends on service temperature, pressure, and regulatory demands.

3) Can SCH 80 be galvanized?

Yes. Both seamless and welded SCH 80 pipes can be hot-dip galvanized for atmospheric corrosion protection. Specify galvanizing to the supplier and account for slight dimension changes after coating.

4) Are SCH 80 and Schedule 80 identical terms?

Yes — “SCH” is short for schedule; Schedule 80 and SCH 80 mean the same thing.

5) How do I calculate weight for pricing?

Use weight per foot (or meter) from the ASME B36.10M tables multiplied by total length. Suppliers commonly provide mass tables; verify with supplier-provided weight (which is often given in lb/ft or kg/m).

6) Can SCH 80 be used for drinking water?

It can be, but check lining/coating requirements (cement mortar or epoxy lining) and local potable water standards. For potable systems, choose coatings/linings and certifications appropriate for drinking water use.

7) What testing should I request on order?

At minimum: MTR (chemical & tensile), hydrostatic testing, and visual. For pressure-critical or nuclear/oil & gas services, request RT/UT, impact testing and third-party inspection.

8) Is there a European EN equivalent?

Common equivalents for A106/A53 include EN 10216 / EN 10217 series (P265GH / P235 etc.) and API 5L mappings — but confirm specific EN grade and testing equivalence when substituting.

9) What end finish should I order?

For welding: beveled ends. For threading or mechanical couplings, request threaded or grooved finishes. For simple coupling or temporary connections, plain ends may suffice.

10) What delivery lead times can I expect?

Lead time depends on size, quantity, and whether pipe is in stock. Chinese mill FOB with stock can sometimes ship within 2–6 weeks; custom or large seamless runs may take longer. MWAlloys can often dispatch common sizes faster due to warehouse stock — request confirmation in your RFQ.

Practical procurement checklist

-

Specify: NPS, schedule (SCH 80), material standard & grade (A106 B / A53 B / API5L), seamless/welded, lengths, end finish, coating/lining, testing & certificates (MTR 3.1/3.2, NDE), packing, delivery term (FOB/CIF/DDP).

-

Request mill heat numbers on each pipe and MTRs before shipment.

-

For international purchases, confirm incoterms, duties, and quarantine regulations.

Final summary

SCH 80 carbon steel pipe is a mature, well-standardized product used where thicker walls and higher pressure capability are needed. Good procurement practice requires specifying the applicable ASTM/ASME/API standard, required testing, and coating/lining options. For competitive pricing with mill traceability and fast stock delivery, MWAlloys provides direct-factory sourcing and documentation support.