S136 is a high-chromium, martensitic stainless mold steel prized for mirror-finishing, strong corrosion resistance in hardened condition, and excellent dimensional stability for precision injection and optical molds. For projects demanding low-maintenance cavities (medical, optical, corrosive polymers), S136 offers longer service life than standard carbon mold steels while remaining cost-effective compared with premium powder-metallurgy stainless grades.

What is S136 Mold Steel?

S136 is a martensitic stainless tool steel developed and marketed in various regional brand forms (often identified by trade names such as S-136, 1.2083, X40Cr14 or AISI 420 variants). It is specifically formulated to be highly polishable, to accept a stable hardening treatment, and to resist corrosion in both humid environments and when molding chemically aggressive polymers (PVC, ABS with certain additives). Because it can achieve mirror surface finishes with low inclusion levels (especially when made by remelting routes such as ESR), S136 is a first choice for high-quality plastic molds and optical or medical devices.

Quick technical snapshot

-

Material family: Martensitic stainless, mirror-grade mold steel

-

Common identifiers: S136, 1.2083 (DIN), AISI 420 (closest common reference)

-

Typical annealed hardness: ~175–215 HB

-

Typical hardened hardness: ~48–54 HRC depending on heat treatment and ESR/VD processing

-

Core strengths: excellent polishability, good corrosion resistance after hardening, predictable dimensional stability.

Chemical composition (typical / representative)

Below is a widely used composition window for commercial S136 (values are weight percent). Individual mills or ESR/VD variants may differ slightly — always request a mill certificate for critical tooling.

| Element | Typical (wt%) |

|---|---|

| Carbon (C) | 0.36–0.40 |

| Chromium (Cr) | ~13.0–14.0 |

| Silicon (Si) | ~0.6–1.0 |

| Manganese (Mn) | ~0.3–0.6 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.03 |

| Nickel (Ni) | trace — generally not specified |

| Molybdenum (Mo) | trace — depends on supplier |

Source and guidance: representative composition reported in S136 technical data summaries; different producers publish similar bands (example data summary shown by stock suppliers and tool-steel comparison tables). Always confirm with the producer’s certificate.

Material properties — mechanical & physical (typical ranges)

The following table gives practical property ranges used for design estimates. Values change with heat treatment; these are typical published ranges.

| Property | Typical (annealed) | Typical (quenched & tempered) | Notes / design impact |

|---|---|---|---|

| Hardness (HB) | 175–215 HB | 48–54 HRC (depending on tempering) | Hardness affects polishability and wear life. |

| Tensile strength (Rm) | ~600–850 MPa (depends on heat treat) | up to ~1200 MPa at high hardness | Use measured data from supplier for finite-element safety margins. |

| Yield strength (Rp0.2) | ~350–650 MPa | depends on temper | Design cores/cavities with safety factor for shrinkage. |

| Elongation | 8–16% (annealed) | 2–8% (hardened) | Hardened specimens are less ductile — avoid sharp notches. |

| Thermal conductivity | moderate (lower than carbon steels) | similar trend | Heat flow is slower than tool steels like H13 or aluminum; affects cooling design. |

| Density | ~7.7–7.8 g/cm³ | — | Useful for weight/handling estimates. |

Key takeaway: polished S136 in hardened condition balances wear resistance with corrosion resistance while remaining capable of ultra-smooth surface finishes that preserve optical and medical product quality.

S136 specifications and common delivery conditions (table)

| Item | Typical specification or range |

|---|---|

| Standard identifiers | S136, 1.2083 (DIN), X40Cr14, often marketed as a 420 family ESR/improved grade |

| Typical forms | Plate, block, round bar, square bar |

| Typical thicknesses | Plates: 3 mm up to 220 mm (supplier-dependent); blocks commonly 50–300 mm |

| Surface conditions | Annealed, pre-hardened, ESR (electro-slag remelt) variants for mirror grade |

| Hardness on delivery | Annealed ≤241 HB (many suppliers quote ≤230–240 HB) |

| Certification | EN, DIN, mill test certificate (MTC), inspection reports on request |

Notes: ESR or VD remelted variants have far fewer inclusions and are labeled ESR/VD in supplier descriptions; these variants are preferable for mirror optics. Always specify required hardness, certification level, and any additional acceptance tests (polishing trial, Ra targets).

Metal moulding processes and why S136 fits them

S136 shines in tooling where surface quality and corrosion resistance during production are critical.

Practical processes:

-

Injection molding for optical / medical parts: repeated cycles with humidity and potentially chemically active polymers require a steel that resists staining and cavity corrosion. S136 retains a polished finish for longer runs.

-

Hot-runner systems and sealing plates: where small crevices and polymer additives could otherwise accelerate corrosion or deposit residues; S136 lowers maintenance.

-

Mirror polish tooling: lens molds, camera sensor housings and precision cosmetic components benefit from the ESR-level cleanliness available in S136 variants.

-

Molds for corrosive materials such as PVC blends, flame-retardant polymers and fillers that produce corrosive by-products — S136 prevents pitting and surface discoloration.

Process notes (design & production):

-

Cooling design: S136 has slightly lower thermal conductivity than common carbon tool steels; mold cooling circuits may require closer inverter tuning.

-

Machining: Annealed S136 machines easily; hardened S136 requires carbide tooling and slower feeds. ESR variants machine better and polish more uniformly.

-

Heat treatment: Controlled austenitizing, quench and temper cycles are critical to reach target hardness while minimizing distortion. For critical optics, specify final grinding/polish sequence and measure dimensional changes after heat treatment.

Equivalent grades and how to choose between them

Common equivalents frequently cited:

-

DIN 1.2083 — same family identifier often used in Europe.

-

AISI 420 / 420 ESR — broadly similar chromium content but the ESR (electro-slag remelt) or vacuum remelt (VD) versions are cleaner and preferred for mirror molds.

-

Stavax ESR / Stavax (Uddeholm trade name) — premium through-hardening stainless mold steel marketed by major mills; considered a commercial peer to S136 in many spec sheets.

How to choose:

-

For optical or medical molds requiring Ra ≤ 0.01 µm and absolute consistency, prefer ESR/VD remelted variants (Stavax ESR, S136 ESR).

-

For standard decorative plastics where corrosion risk is moderate, 420-class molds without ESR can be cost-effective.

-

For extreme wear or abrasive fillers, consider powder-metallurgy stainless grades (Elmax, Corrax) or hardened pre-hardened steel — S136 may be compromised if abrasive loading is the dominant failure mode.

What S136 is commonly used for (applications)

-

Precision optical molds: camera lenses, optical housings.

-

Medical device molding: small polymeric medical components where cleanliness and corrosion resistance are crucial.

-

High-quality consumer plastics: glossy cosmetic housings, high-polish consumer lenses.

-

Electrical/connector mold parts: where dimensional stability and corrosion resistance lead to longer duty cycles.

-

Hot-runner sealing plates and inserts: where repeated exposure to molten polymers and additives can otherwise attack cavities.

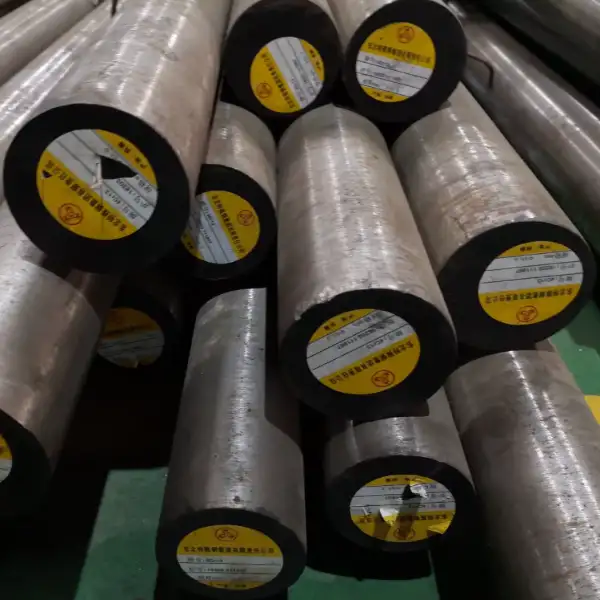

S136 Steel Sizes, forms and weight

Common commercial forms:

-

Plates / blocks: thickness from ~3 mm up to 220 mm (supplier dependent). Suppliers list widths up to 2200 mm for plates.

-

Round bars: diameters from small rod up to large bar stock (varies by mill).

-

Cut-to-size: many service centers offer saw cut and rough machining prior to shipment.

Weight calculation example (practical for procurement)

-

Density ~7.75 g/cm³.

-

Example plate 2000 mm × 1000 mm × 20 mm: volume = 0.04 m³ → mass ≈ 0.04 × 7,750 kg/m³ = 310 kg (approx). Use exact material density and finished dimensions for final logistics.

S136 mold steel price comparison

Important: mold-steel spot pricing is volatile and varies by remelt method, certification, order size and delivery terms. The ranges below are representative snapshot indicators for 2025 — always request supplier quotes and MTCs.

| Region | Representative 2025 price (per metric ton) | Notes / source |

|---|---|---|

| China (FOB / supplier listings) | US$ 2,000 – 2,800 / t (≈ US$2.0–2.8/kg) | Market listings and manufacturer offers for S136 / 1.2083 grade. Typical for standard (non-ESR) plate lots. |

| Europe (distributor / surcharge indications) | €1,200 – €3,000 / t (wide range) | European service centers and surcharge notices show variable pricing depending on mill, ESR status and demand. Published guidance and distributor surcharges indicate lower base stainless prices for bulk grades but premium for ESR/brand steel. |

| USA (distributor & specialty supply) | US$2,500 – US$6,000 / t | US spot and distributor quotes for mirror-grade or ESR tool steel can carry a premium due to remelting cost, demand and tariffs/shipping. Estimate varies substantially with brand (Uddeholm, Bohler) and ESR processing. |

Notes:

-

Prices for ESR/VD remelted mirror grade or branded mill stock (Stavax ESR, Uddeholm variants) commonly sit at the higher end or above these ranges; premium powder grades are yet more expensive.

-

Small sample or 1-piece orders often carry steep per-kg premiums (processing, cutting, inspection).

-

For accurate budgeting, request a formal quote from MWAlloys — we publish factory-level pricing, certificates and delivery times on request.

FAQs

-

Is S136 corrosion-proof?

No metal is absolutely corrosion-proof. S136 is corrosion-resistant (especially after hardening and with polished surfaces) and far better than carbon steels in humid and mildly corrosive polymer environments. For extreme chemistries, check compatibility and consider more corrosion-resistant options. -

Can I mirror polish S136 to optical finish?

Yes. ESR/VD remelted S136 achieves very high polish levels (Ra targets used in optics). Specify remelt route and surface finish with the supplier. -

Should I pick S136 or P20 for my mold?

Use S136 when corrosion resistance and long-term cavity finish retention matter. Use P20 when cost is primary and corrosion exposure is low. -

How does S136 machine in annealed condition?

It machines readily when annealed. Hardened S136 requires carbide tooling and reduced feeds/speeds. -

Is ESR better than non-ESR S136?

ESR gives much lower inclusion levels; it’s recommended for mirror optical molds and critical medical parts. ESR typically costs more. -

What hardness should I specify for a long-run optical mold?

Common range: HRC 50–52 for mirror work, but final choice depends on wear resistance vs. brittleness trade-offs. Consult heat-treatment supplier and request distortion control steps. -

How to prevent staining when using corrosive polymers?

Use hardened and polished S136, control mold temperature, and schedule finishing passes (e.g., passivation). Consider coatings only if wear is a greater concern. -

Do S136 molds need special heat treatment?

Yes. Controlled quench and temper cycles with dimensional checks are essential; consider stress-relief and trial machining after heat treatment. -

What certificates should I request?

Mill Test Certificate (EN 10204/3.1 or 2.2 depending on need), heat-treatment records, inclusion/analysis reports for ESR variants. -

How quickly can MWAlloys ship standard S136 plates?

For stocked items we offer fast turnarounds; for cut-to-size or ESR lots lead times vary. Contact MWAlloys for exact availability and 100% factory pricing.

Why buy S136 from MWAlloys

MWAlloys supplies S136 and its ESR/VD variants with direct factory prices, full material certificates and rapid delivery from our Chinese service centers. We combine local mill relationships with quality inspection protocols — 100% factory pricing eliminates middle-man margin and shortens lead times for stock items. Typical advantages:

-

Competitive ex-factory pricing for both standard S136 and ESR remelted variants.

-

Rapid stock & cut-to-size service on common plate/bar sizes (fast delivery possible on stocked items).

-

Quality control: full MTCs and traceability, polish checks and optional sample reports.

If you want a formal quote, specify size, form, required hardness, remelt type (ESR/VD/standard), and quantity — MWAlloys will return a detailed offer with inspection plans.

Practical procurement checklist

-

State exact grade and remelt route (S136 ESR, S136H, 1.2083).

-

Provide required hardness and final surface finish (Ra target).

-

Request MTC (EN 10204) and heat-treatment records.

-

Clarify tolerances, straightness and required saw or mill finishing.

-

Verify delivery terms (FOB, CIF, EXW) and incoterms.

-

If optical/medical use: ask for micrograph/inclusion report or ESR certificate.

Closing notes

S136 is a dependable stainless mold steel for many high-finish and moderately corrosive applications, but it is not universally optimal. Choose it when polished cavity life and corrosion resistance matter more than ultimate abrasion resistance. For abrasive charge-filled polymers or extremely high cycle mechanical wear, evaluate higher-wear stainless or PM steels. For any critical program, MWAlloys recommends a small trial cavity or pilot lot, with a final specification agreed before full production.