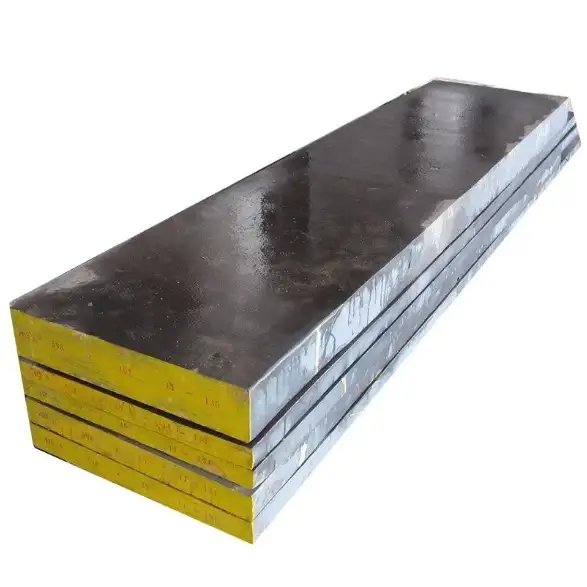

P20 tool steel plate is the industry standard for medium- to large-size plastic injection molds and zinc die-casting dies because it pairs predictable dimensional stability, good machinability, and excellent polishability in a pre-hardened condition. For mold makers who require consistent hardness across big sections, reliable weldability, and a surface that polishes to mirror finish, P20 plate usually offers the best tradeoff between price and performance.

What is P20 tool steel grade

P20 is a low-alloy, chromium-molybdenum tool steel developed for plastic injection molds, die-casting dies for low-melting metals, and large tooling frames. It is typically delivered in a pre-hardened condition that enables direct machining, texturing, and polishing while keeping internal stress low. Common trade names include AISI/SAE P20, UNS T51620, DIN 1.2311 / 1.2738, Chinese standard 3Cr2Mo families and vendor variants with small chemistry shifts for nickel or sulfur additions.

Chemical composition

Below is a practical composition table intended for specification and procurement. Individual mill certificates should be consulted for exact batch chemistry.

| Element | Typical weight % (range) | Function / remark |

|---|---|---|

| C (Carbon) | 0.28 – 0.40 | Strength and hardenability control |

| Mn (Manganese) | 0.60 – 1.50 | Strength, deoxidation |

| Si (Silicon) | 0.20 – 0.80 | Strength, deoxidation |

| Cr (Chromium) | 1.40 – 2.00 | Hardenability, corrosion resistance, polishability |

| Mo (Molybdenum) | 0.20 – 0.55 | Hardenability, toughness |

| Ni (Nickel) | 0.00 – 1.00 (variant P20+Ni / 1.2738) | Toughness and hardenability (present in some variants) |

| Cu (Copper) | ≈0.25 (trace) | Minor effects, sometimes present |

| P (Phosphorus) | ≤0.03 | Impurity limit |

| S (Sulfur) | ≤0.03 (lower in “low-sulfur” grades) | Often controlled for polishability |

This composition summary reflects standard supplier datasheets and industry compilations. Buyers should request a mill test report for each lot.

Mechanical and physical properties

Suppliers typically quote pre-hardened P20 with a hardness near 300 HBW (≈ 30 HRC). Mechanical properties below reflect the pre-hardened supply condition. Variation occurs with heat treatment, manufacture route, and any remelt/ESR processing.

| Property | Typical value (metric) | Typical value (imperial) |

|---|---|---|

| Hardness (prehardened) | 280–320 HBW (≈ 28–32 HRC) | — |

| Tensile strength (ultimate) | 965 – 1,030 MPa | 140,000 – 150,000 psi |

| Yield strength | 827 – 862 MPa | 120,000 – 125,000 psi |

| Elongation (in 50 mm gauge) | ~20% | ~20% |

| Modulus of elasticity | 190 – 210 GPa | ~27,500 – 30,400 ksi |

| Density | ~7.85 g/cm³ | 0.284 lb/in³ |

| Thermal conductivity | ~41.5 W/m·K (typical vendor data) | 24 Btu/ft·hr·°F |

Mechanical characteristics given above originate from consolidated technical datasheets used by global suppliers and technical references.

P20 tool steel plate specifications

P20 plate is offered in many national and supplier formats. Common product designations include 1.2311, 1.2312 (P20+S), 1.2738 (P20+Ni) and vendor premium variants (ESR, vacuum-arc remelt). Typical nominal delivery conditions: pre-hardened 280–320 HB or quenched & tempered to customer hardness.

Typical plate supply sizes (examples):

| Parameter | Typical range |

|---|---|

| Thickness | 3 mm → 300 mm (stock tends to concentrate in 6 – 200 mm) |

| Width | 1000 mm → 2600 mm (vendor capability varies) |

| Length | 1000 mm → 6000 mm (cut to customer need) |

| Surface | Hot-rolled black, ground finish, ground & polished |

| Delivery hardness | 280–320 HB (pre-hardened) or custom quenched & tempered |

Vendor technical sheets offer detailed tolerances and roughness figures for ground/polished plates. For mirror surface or optical components, ask about low-sulfur, ESR processed grades.

Thickness and weight: worked calculations

Steel density: 7.85 kg/m² per 1 mm thickness (equivalently 7.85 kg per m²·mm). This factor makes mass calculations straightforward.

Weight per square metre (kg/m²) = 7.85 × thickness (mm)

Example table (careful arithmetic):

| Thickness (mm) | Weight (kg/m²) | Weight for 1.0×2.0 m sheet (kg) | Weight for 1.5×3.0 m sheet (kg) |

|---|---|---|---|

| 3 | 7.85 × 3 = 23.55 | 23.55 × 2 = 47.10 | 23.55 × 4.5 = 105.975 |

| 6 | 47.10 | 94.20 | 211.95 |

| 10 | 78.50 | 157.00 | 353.25 |

| 20 | 157.00 | 314.00 | 706.50 |

| 25 | 196.25 | 392.50 | 883.125 |

| 30 | 235.50 | 471.00 | 1,059.75 |

| 50 | 392.50 | 785.00 | 1,766.25 |

| 100 | 785.00 | 1,570.00 | 3,532.50 |

Notes:

-

Use the 7.85 coefficient for quick checks.

-

For procurement, round final weight to supplier tolerances and include trimming loss, cutting kerf, and surface finish removal in net weight calculations.

What P20 tool steel plate is used for

Primary uses:

-

Injection mold cavities and cores for thermoplastics.

-

Zinc and low-temperature die-casting dies.

-

Large molds, bolsters, support plates, and die fatigue frames.

-

Backers, wear strips, and certain structural tool components where polishability and uniform hardness matter.

P20’s polishability and uniform hardness make it popular for cosmetic parts and for any tooling where surface finish will transfer into the molded part. For high-wear situations, nitriding, carburizing, or hard inserts can extend service life.

P20 equivalents and near-grades

Common near-equivalents and related grades:

-

AISI/SAE P20 (UNS T51620) — baseline P20 designation.

-

DIN 1.2311 — often treated as a common P20 equivalent for 1.2311 variants.

-

DIN 1.2312 (P20+S) — sulfur-improved machinability variant.

-

DIN 1.2738 (P20+Ni) — nickel modified variant for improved toughness and polishability.

-

Vendor premium: P20 ESR, P20 HH, and remelted batches for critical optical surfaces or long life.

When substituting, match chemistry, hardness, and processing history. Finish and impurity levels will affect mirror polishing and fatigue life.

Difference between 4140 steel and P20 steel

Short answer: function and heat-treatment intent determine choice. 4140 is a general-purpose chromium-molybdenum structural alloy known for high strength and impact resistance after quench-tempering. P20 is a pre-hardened mold steel engineered for polishability, dimensional stability during heat treatment, and uniform hardness across thick sections.

Key contrasts:

-

Carbon: 4140 typically contains higher carbon than P20, enabling higher hardening potential.

-

Toughness & strength: 4140 often yields higher toughness after proper quench-tempering.

-

Surface finish: P20 polishes to a superior mirror finish for cosmetic molded parts.

-

Cost: 4140 can be cheaper in commodity markets, but overall cost depends on heat treatment and finishing work.

-

Typical usage: choose 4140 for mechanical parts and lower-volume tooling; choose P20 for injection molds, large molds, and tooling that needs superior polish and dimensional control.

Heat treatment, machining, polishing, and welding notes

-

Delivery condition: pre-hardened 280–320 HB provides a balance of machinability and in-service strength.

-

Hardening: P20 can be hardened further with carburizing or standard quench-tempering cycles if higher surface hardness is required. Carburized P20 is common for wear surfaces.

-

Machining: machinability is high relative to many tool steels; vendors quote roughly 60–80% machinability of a standard free-cutting steel. Low sulfur variants produce better mirror finish but reduce machinability.

-

Polishing: low inclusion content and controlled sulfur produce a mirror finish. For highest optical quality use ESR or low-sulfur variants.

-

Welding: recommended practice involves preheat, low hydrogen consumables, and post-weld stress relief. For critical molds, consider welding only with qualified procedures and certified filler wires.

-

Nitriding & surface treatments: nitriding delivers wear resistance without bulk hardness increase. PVD, chroming, or hard coatings can be used on a case-by-case basis.

2025 price comparison (USA, Europe, China)

Market prices for P20 plate depend strongly on grade variant, heat treatment, surface finish, remelting, thickness, order quantity, and freight. Below table offers honest market ranges gathered from multiple trade suppliers and major marketplaces in 2024–mid-2025. Use these figures for budgeting only. Request live quotes for project procurement.

Price drivers: grade variant (P20, P20+Ni, P20+S), pre-hardened vs quenched, low-sulfur or ESR, thickness, cut-to-size, shipping, and order volume.

| Region | Typical 2025 price range (USD/metric ton) | Notes / sources |

|---|---|---|

| China (domestic FOB) | ~USD 700 → 2,800 / t | Wide spread reflects small-lot retail sellers and bulk mill pricing; some listings show prices near $700/t for heavy-bulk hot-rolled lots, others list $1,800–2,800/t for polished/ground pre-hardened plates. |

| Europe (distributor / processed plate) | ~USD 1,500 → 3,500 / t | Higher processing, tighter tolerances, and inland freight add cost; premium ESR or remelted plates toward upper band. |

| USA (distributor / small orders) | ~USD 1,800 → 4,000 / t | Single-sheet purchasing, quick delivery, cut-to-size, and certified tests push price higher for small orders; bulk mill orders reduce unit price. |

Important procurement note: These ranges include typical pre-hardened P20 plate. Price for carburized, nitrided, ESR, remelted or premium ground and polished plates will be higher. Freight, duties, taxes, and currency fluctuations will change landed cost. Always request mill certificates, heat-treatment records, and sample inspections before placing firm orders.

Buying guidance and quality checks

When procuring P20 plate, insist on:

-

Mill test report (chemical and mechanical per lot).

-

Heat treatment statement showing delivered hardness and whether any post-processing occurred.

-

Surface condition photo and roughness figures for ground/polished plate.

-

Certificate for remelt/ESR if required for long life or optical finishes.

-

Traceability marks linking plate to test report.

-

Warranties for non-conformance and agreed return procedure.

For cosmetic tooling, prefer low-sulfur or ESR processed P20. For high wear, specify carburized case plus core toughness requirements.

MWalloys brand note

MWalloys offers P20 tool steel plate in standard and premium variants, with stock maintained for common thicknesses. Our company provides factory pricing direct from our mills, full mill test documentation, and rapid cut-to-size service. Typical lead time for stocked items: fast shipment within days when stock exists; bulk orders are fulfilled per contract. Contact MWalloys sales for sample pieces, MTRs, and delivery timelines.

FAQs

-

What hardness comes from vendor supply?

Pre-hardened P20 commonly ships at 280–320 HB (≈28–32 HRC). -

Can P20 be hardened further?

Yes; carburizing or quench-tempering cycles permit higher surface hardness. Nitriding yields surface wear resistance without bulk hardening. -

Is P20 good for long-run injection molds?

P20 suits medium-run molds. For extremely high cycle counts, consider high-chromium tool steels, inserts of hardened steel, or surface coatings. -

What grade should I pick for mirror polish?

Low-sulfur or ESR processed P20 yields the best mirror finish. Specify ground & polished surface finish from vendor. -

How does P20 handle welding repair?

Welding is possible with proper preheat/post-weld procedures and matching filler metal. Seek qualified welding procedure specification (WPS). -

Is P20 magnetic?

Yes — P20 is ferromagnetic like most tool steels. -

What tolerances can I expect on ground plate?

Ground plate tolerances depend on supplier; typical flatness and thickness tolerances should be supplied with product specs. -

Can P20 be nitrided without cracking?

Proper process control minimizes cracking. Consult with heat-treatment vendor for cycle selection and prior stress relief. -

Which international standard lists P20 chemistry?

P20 appears in SAE/AISI listings under UNS T51620; nearby DIN designations include 1.2311, 1.2312, 1.2738 depending on variant. -

How should I specify P20 in a purchase order?

Provide grade (P20 / 1.2311 / 1.2738), thickness, width, length, surface finish (hot-rolled / ground / polished), delivery hardness, required MTRs, and any remelt/ESR demand.