Alloy 925, also referred to as Nickel Alloy 925, is primarily composed of nickel (45-55%), chromium (18-23%), and molybdenum (3-4%), with additional elements such as copper, titanium, and iron. This composition gives the alloy remarkable resistance to oxidation, corrosion, and stress corrosion cracking, especially in marine and chemical environments. Alloy 925 is designed for applications where both high mechanical strength and excellent corrosion resistance are required, including aerospace, offshore oil and gas industries, and chemical processing.

1. Key Properties of Alloy 925

Physical Properties

The following table summarizes the key physical properties of Alloy 925:

| Property | Value | Details/Remarks |

|---|---|---|

| Density | 8.94 g/cm³ | The density is high, which is typical for nickel-based alloys. |

| Melting Point | 1350°C (2462°F) | High melting point ensures performance at elevated temperatures. |

| Thermal Conductivity | 10.3 W/m·K at 100°C | Low thermal conductivity aids in high-temperature performance. |

| Coefficient of Thermal Expansion | 13.1 µm/m·K (20-100°C) | Low coefficient, useful for reducing stress under thermal cycles. |

Mechanical Properties

Alloy 925 exhibits superior mechanical properties, which are essential for its performance in high-stress environments:

| Property | Value | Details/Remarks |

|---|---|---|

| Tensile Strength | 1030 MPa (150 ksi) | Indicates the alloy's ability to withstand tension before breaking. |

| Yield Strength | 690 MPa (100 ksi) | Shows the material's resistance to plastic deformation under load. |

| Elongation | 45% (in 50 mm gauge length) | High elongation indicates the material’s ductility. |

| Hardness | Rockwell B85 | Measures the alloy's resistance to indentation. |

Corrosion Resistance

Alloy 925 is highly resistant to a variety of corrosive environments, including:

-

Pitting and Crevice Corrosion: Excellent resistance to localized corrosion, making it suitable for marine environments.

-

Oxidation Resistance: The alloy performs well in oxidizing environments, maintaining its integrity even at high temperatures.

-

Stress Corrosion Cracking: Alloy 925 resists stress corrosion cracking, particularly in chloride-rich environments such as seawater.

High-Temperature Performance

Alloy 925 maintains its mechanical properties even at elevated temperatures, with resistance to oxidation up to 1800°F (982°C). This makes it suitable for high-performance applications such as turbines and exhaust systems.

2. Composition of Alloy 925

The alloy’s composition is balanced to provide optimal performance in both mechanical and corrosion resistance properties:

| Element | Percentage (%) |

|---|---|

| Nickel | 45-55% |

| Chromium | 18-23% |

| Molybdenum | 3-4% |

| Copper | 1.5-3% |

| Titanium | 0.5-1.5% |

| Iron | ≤1% |

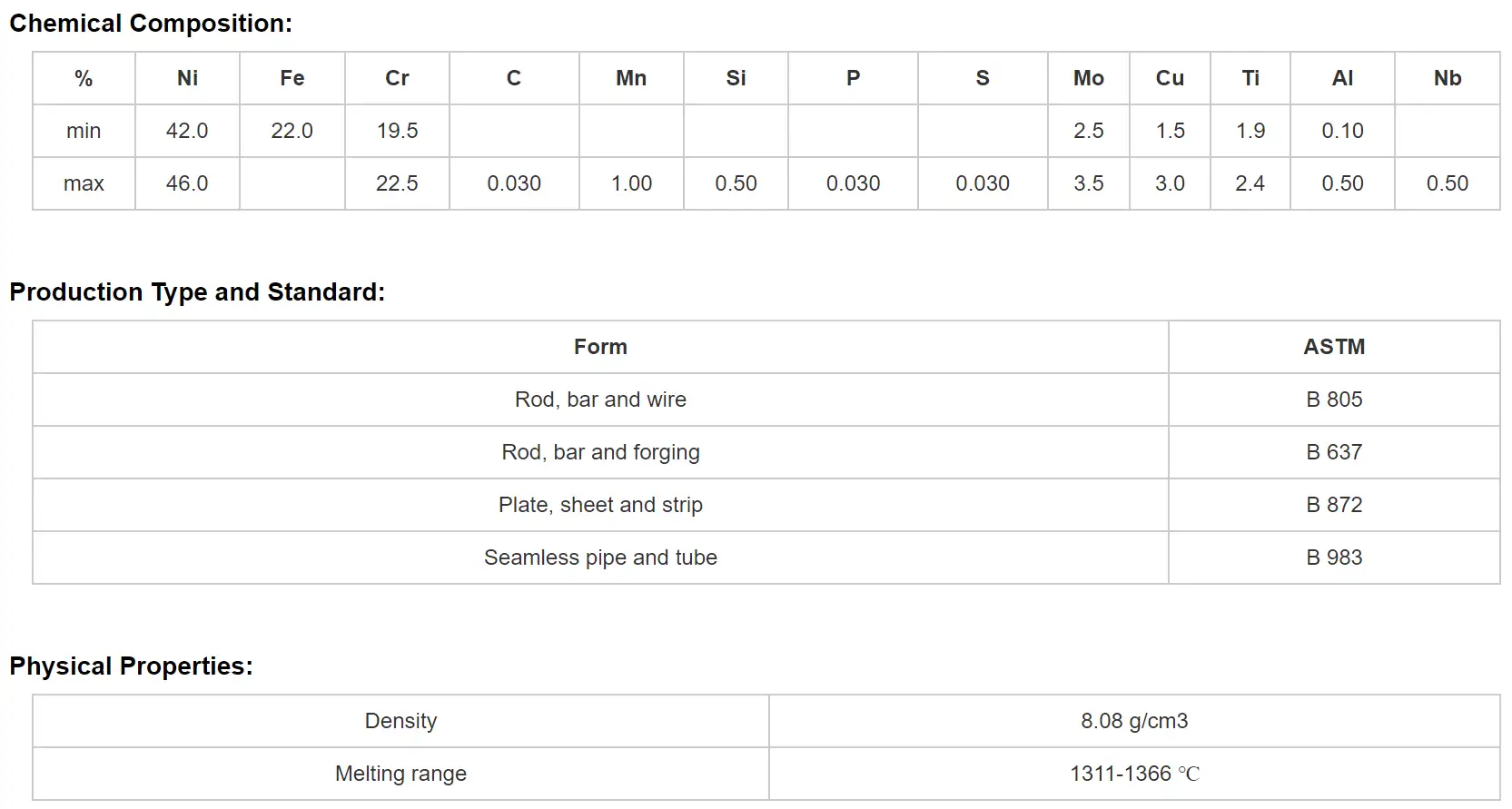

| Element | Composition (wt%) |

|---|---|

| Cr | 19.5 – 22.5 |

| Cu | 1.5 – 3.0 |

| Fe | 22.0 (balance) |

| Mo | 2.5 – 3.5 |

| Ni | 42.0 – 46.0 |

| Ti | 1.9 – 2.4 |

Additional Notes:

-

Ni (Nickel) is the base element, ensuring corrosion resistance and high-temperature stability.

-

Fe (Iron) is present in significant amounts (~22%), classifying Alloy 925 as a nickel-iron-chromium alloy.

-

Ti (Titanium) enables precipitation hardening when combined with Al (though Al content is minimal and not always specified).

3. Applications of Alloy 925

Aerospace Industry

Alloy 925 is used in aerospace for components such as gas turbines, exhaust systems, and engine parts, where both high-temperature strength and resistance to oxidation are critical.

Chemical Processing

In chemical processing industries, Alloy 925 is ideal for components like heat exchangers, reactor vessels, and piping systems, as it resists corrosion from chemicals like sulfuric acid, hydrochloric acid, and seawater.

Offshore Oil & Gas

Alloy 925 is a preferred material in the offshore oil and gas sector for components that are exposed to marine environments and high mechanical stresses. The alloy’s resistance to pitting and crevice corrosion makes it an excellent choice for subsea equipment and pipelines.

Marine Industry

Due to its resistance to seawater corrosion, Alloy 925 is widely used in marine applications such as ship hulls, propellers, and subsea machinery.

4. Why Choose Alloy 925?

Choosing Alloy 925 for demanding industrial applications provides several benefits:

-

Corrosion Resistance: Ideal for industries exposed to seawater or chemical environments.

-

High Strength and Durability: Excellent mechanical strength, ensuring longevity in high-stress applications.

-

Heat Resistance: Can perform well in environments with high temperatures, up to 1800°F (982°C).

-

Resistance to Stress Corrosion Cracking: Ideal for applications in chloride-rich environments, such as marine and offshore drilling.

5. Manufacturing & Forming Alloy 925

Alloy 925 can be produced using a variety of manufacturing techniques, including casting, forging, and welding. At MWalloys, we supply Alloy 925 in the following forms:

-

Plate: Commonly used for structural components and heat exchangers.

-

Bar: Used for shafts, valves, and other mechanical components.

-

Pipe: Employed in high-stress piping systems, such as those in chemical plants and offshore oil rigs.

-

Tube: Used in high-performance heat exchangers and other critical applications.

Welding Alloy 925 requires specific procedures to ensure the material's high corrosion resistance is retained. Common welding methods include TIG and MIG welding, using compatible filler rods that preserve the alloy's mechanical and chemical properties.

6. Comparison with Similar Alloys

| Property | Alloy 925 | Inconel 718 | Monel 400 |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Very Good |

| High-Temperature Resistance | Up to 1800°F (982°C) | Up to 1300°F (704°C) | Up to 1400°F (760°C) |

| Strength | High | Very High | Moderate |

| Applications | Aerospace, Chemical, Marine | Aerospace, Oil & Gas | Marine, Chemical |

As shown in the comparison table, Alloy 925 offers superior corrosion resistance and high-temperature performance compared to Monel 400, though it doesn't have the same high-temperature capability as Inconel 718.

7. Alloy 925 in Welding

Welding Alloy 925 requires special attention to avoid oxidation or cracking. The alloy can be welded using the following methods:

-

Gas Tungsten Arc Welding (GTAW): Preferred for precision welds.

-

Gas Metal Arc Welding (GMAW): Suitable for thicker sections.

-

Shielded Metal Arc Welding (SMAW): Often used for heavy-duty applications.

Filler rods compatible with Alloy 925 are available to ensure strong, corrosion-resistant welds.

8. Maintenance and Longevity of Alloy 925

When selecting a material like Alloy 925 for industrial applications, it’s crucial to consider how well it will perform over time. This includes both its physical durability and its resistance to wear and degradation. At MWalloys, we prioritize providing customers with long-lasting materials, and Alloy 925 is no exception. Known for its robustness, Alloy 925 can withstand the harshest of environments, ensuring minimal maintenance and long-term reliability.

How Long Does Alloy 925 Last?

Alloy 925 has an exceptional lifespan when used in appropriate applications. The alloy's resistance to corrosion and oxidation ensures that it will not degrade quickly, even in harsh chemical and marine environments. In applications such as offshore drilling, chemical processing, and aerospace, Alloy 925 components can last for decades without significant degradation, provided they are maintained properly.

Performance Over Time

Over time, Alloy 925 will maintain its strength, corrosion resistance, and high-temperature performance. As it is resistant to corrosion from seawater, acids, and many industrial chemicals, it remains an ideal choice for industries with aggressive working conditions. Regular inspection and maintenance, especially in highly dynamic environments like offshore oil rigs or chemical reactors, can extend its longevity and ensure optimal performance throughout its service life.

Fatigue Resistance

One of the standout characteristics of Alloy 925 is its ability to resist fatigue. This property makes the alloy particularly useful in applications that involve repetitive stress, such as components in turbines or pressure vessels. Even under cyclic loads, Alloy 925 retains its structural integrity and does not exhibit cracks or wear, making it a go-to choice for critical parts in high-stress environments.

Long-Term Performance

With proper care and regular inspections, Alloy 925 components can perform reliably for decades. The combination of high mechanical strength, resistance to stress corrosion cracking, and high-temperature tolerance ensures that Alloy 925 can continue to perform efficiently throughout its lifecycle, minimizing the need for repairs or replacements.

9. Global Supply and Availability of Alloy 925

Alloy 925 is widely used across the globe, thanks to its versatility and exceptional performance characteristics. At MWalloys, we pride ourselves on our strong, global supply chain, which ensures that Alloy 925 is readily available for customers across all industries.

Where is Alloy 925 Sourced?

Alloy 925 is produced in several key regions, including North America, Europe, and parts of Asia. Leading manufacturers, such as those based in the United States, Germany, and China, supply high-quality Alloy 925 in various forms and sizes. The alloy is typically certified by international standards, ensuring that customers receive a high-quality product that meets their specific requirements.

Regional Availability

While Alloy 925 is readily available in major industrial regions such as the United States, Europe, and Asia, remote areas may experience longer lead times or availability issues. For customers in regions with limited access to Alloy 925, MWalloys offers fast global shipping to ensure timely delivery. Our worldwide distribution network guarantees that customers in all corners of the world can rely on us for high-quality Alloy 925.

Stock Availability

MWalloys maintains a large inventory of Alloy 925, ensuring that we can fulfill customer orders quickly. From large industrial components to smaller parts and fittings, we stock a wide range of Alloy 925 products to meet our clients' needs. Our large inventory allows us to provide short lead times, so you can receive your Alloy 925 materials without delay.

Supply Chain Considerations

Although Alloy 925 is produced and supplied by a network of trusted manufacturers, the availability of the material can be affected by global supply chain issues, such as raw material shortages or shipping disruptions. However, thanks to our well-established relationships with trusted suppliers, MWalloys is able to maintain a steady supply of Alloy 925 to meet customer demand.

10. Regulations & Standards for Alloy 925

When using Alloy 925 in industrial applications, it’s important to ensure compliance with various industry standards and regulations. These certifications provide confidence that the material meets strict requirements for performance and safety. MWalloys works closely with certified manufacturers to ensure that all Alloy 925 products we supply meet or exceed the relevant standards.

Compliance with Industry Standards

Alloy 925 meets various ASTM and ISO standards, which regulate its composition, mechanical properties, and overall performance. These standards are especially important for industries like aerospace, chemical processing, and oil and gas, where material performance is critical to safety and reliability.

Key standards that Alloy 925 complies with include:

-

ASTM B425: Standard Specification for Nickel-Chromium-Molybdenum-Copper Alloy Sheet, Plate, and Strip for Marine Service and Other Applications

-

ISO 9001: Quality Management System certification for consistent quality and performance.

-

ASTM B575: Specification for Nickel-Chromium-Molybdenum-Copper Alloy Fittings.

Certifications

For customers requiring material certification, MWalloys provides full documentation for all Alloy 925 products. This includes certificates of compliance, detailed test reports, and certificates of origin, confirming the material's quality and adherence to industry standards. These certifications give customers peace of mind that they are receiving the highest-quality product available.

Regulatory Considerations

Depending on the region and application, Alloy 925 may be subject to additional regulations, particularly in the aerospace, marine, and nuclear industries. In the U.S., for example, aerospace components using Alloy 925 must meet the standards set by the Federal Aviation Administration (FAA). In the marine industry, compliance with ISO 9001 and other industry-specific certifications ensures that Alloy 925 meets all relevant performance criteria for underwater and marine environments.

11. Alloy 925 Pricing

Pricing for Alloy 925 is influenced by a variety of factors, including raw material costs, market demand, and manufacturing complexity. While Alloy 925 can be more expensive than other materials like stainless steel, its long-term durability, resistance to corrosion, and high-performance properties justify the investment for industries requiring high-quality materials.

Cost Factors

The cost of Alloy 925 is impacted by:

-

Material Form: Whether you require plates, bars, pipes, or tubes, each form has different pricing.

-

Grade and Certification: Higher-grade Alloy 925 or products with specific certifications may come at a premium.

-

Market Demand: Fluctuations in the global market for raw materials or specific applications (e.g., aerospace or oil and gas) can affect pricing.

Price Comparison

While Alloy 925 is more expensive than many standard alloys like carbon steel or stainless steel, its ability to withstand extreme temperatures and corrosive environments can offer significant savings in the long term. The reduced maintenance, extended lifespan, and fewer replacements in critical applications make Alloy 925 a cost-effective choice over time.

At MWalloys, we ensure competitive pricing for Alloy 925 by working directly with trusted suppliers, passing on cost savings to our customers while maintaining the highest standards of quality.

12. Sustainability and Recycling of Alloy 925

Sustainability has become an essential consideration in material selection, and Alloy 925 aligns with environmental goals due to its recyclability and long lifespan. By using Alloy 925, industries not only benefit from its superior performance but also contribute to sustainable practices.

Recycling Alloy 925

Alloy 925 is fully recyclable without losing its critical properties. This makes it an environmentally friendly choice for industries aiming to reduce waste and energy consumption. Recycling Alloy 925 helps minimize the environmental impact by reducing the need for virgin materials and lowering carbon emissions associated with mining and processing.

Sustainable Manufacturing Practices

At MWalloys, we are committed to sourcing materials from suppliers who prioritize sustainability in their manufacturing processes. By promoting the use of recycled materials and reducing waste during production, we ensure that Alloy 925 products have a lower environmental impact.

By choosing Alloy 925, customers can contribute to a circular economy, helping industries reduce their environmental footprint while benefiting from a high-performance material that supports long-term sustainability goals.

13. FAQs about Alloy 925

-

What industries use Alloy 925?

Alloy 925 is used in aerospace, marine, offshore oil & gas, and chemical processing due to its excellent corrosion and temperature resistance. -

What are the benefits of using Alloy 925 over other alloys?

Alloy 925 provides exceptional resistance to corrosion, particularly in chloride-rich environments, and performs well at high temperatures. -

Can Alloy 925 be welded?

Yes, Alloy 925 can be welded using methods like TIG, MIG, and SMAW, with appropriate filler rods to preserve its properties. -

What is the temperature resistance of Alloy 925?

Alloy 925 can withstand temperatures up to 1800°F (982°C) without degrading, making it suitable for high-temperature applications. -

How does Alloy 925 compare to Inconel 718?

While Inconel 718 offers superior high-temperature resistance, Alloy 925 excels in corrosion resistance and is more suited for applications exposed to harsh chemical environments.

Conclusion

In conclusion, Alloy 925 is an excellent choice for industries requiring high strength, corrosion resistance, and high-temperature performance. Whether you are in aerospace, chemical processing, marine, or offshore oil and gas, Alloy 925 offers the durability and reliability needed in challenging environments. At MWalloys, we ensure that you have access to the highest-quality Alloy 925 products, with competitive pricing and rapid delivery, backed by our commitment to customer satisfaction.

With our global supply chain, certification, and sustainable practices, MWalloys is your trusted partner for Alloy 925 materials that deliver exceptional performance, long-term value, and reliability.