Incoloy 800 (UNS N08800) round bar is a high-temperature, nickel-iron-chromium wrought alloy that balances elevated-temperature strength, excellent resistance to oxidation and carburization, and good resistance to chloride stress-corrosion cracking, making it a top choice for furnace components, petrochemical process hardware, heat-treating parts and steam/hydrocarbon reforming equipment. For buyers seeking factory-direct supply in 2025, MWAlloys offers ASTM/ASME-certified Incoloy 800 round bar at competitive factory pricing and rapid stock dispatch from China (typical lead times for stocked sizes: days to 2 weeks).

1. What is Incoloy 800?

Incoloy 800 (commercial trade name often used by Special Metals and other producers) is a nickel-iron-chromium alloy (UNS N08800, W. Nr. 1.4876) engineered for stable mechanical behavior and corrosion/oxidation resistance at intermediate to high temperatures (service up to ~800–816 °C / about 1500 °F for the base grade). It combines a relatively high nickel content with chromium and iron so that the alloy remains austenitic and ductile while resisting carburization, sulfidation and oxidation in many industrial atmospheres.

2. Detailed Metallurgy: What is Incoloy 800?

Incoloy 800 is a solid-solution strengthened alloy. Unlike precipitation-hardened superalloys that rely on complex heat treatments to gain strength, Incoloy 800 derives its robustness from its base elemental matrix.

The fundamental definition of Incoloy 800 revolves around its Fe-Ni-Cr triad:

-

Nickel (30-35%): This is the defining characteristic. It is high enough to ensure an austenitic structure (Face-Centered Cubic) remains stable even after long-term exposure to elevated temperatures. This nickel content is the primary mechanism preventing chloride-ion stress corrosion cracking—a common failure mode in standard 300-series stainless steels.

-

Chromium (19-23%): Provides the essential oxidation and corrosion resistance. It allows the formation of a passive oxide layer that protects the underlying metal in corrosive atmospheres.

-

Iron (Balance): Keeps the material cost-effective and allows for easier fabrication compared to pure nickel alloys.

The 800 Series Distinction

It is vital to distinguish Incoloy 800 from its siblings, 800H and 800HT.

-

Incoloy 800 (UNS N08800): General use up to 816°C.

-

Incoloy 800H (UNS N08810): Controlled carbon (0.05-0.10%) and larger grain size for creep rupture strength above 816°C.

-

Incoloy 800HT (UNS N08811): Restricted titanium and aluminum chemistry for maximum high-temperature structural integrity.

MWalloys Technical Note: We supply all three variations. However, standard Incoloy 800 is preferred for applications where the temperature remains below the creep range, as it offers superior surface finish and cold formability.

3. Chemical Composition Analysis

The following table represents the standard chemical requirements per ASTM B408. At MWalloys, we use spectrometer analysis to ensure every batch falls strictly within these ranges.

| Element | Symbol | Minimum % | Maximum % | Metallurgical Function |

| Nickel | Ni | 30.0 | 35.0 | Stabilizes austenite; resists stress corrosion cracking. |

| Chromium | Cr | 19.0 | 23.0 | Oxidation and carburization resistance. |

| Iron | Fe | 39.5* | Balance | Base matrix; provides structural bulk. |

| Carbon | C | - | 0.10 | Lower carbon improves ductility; prevents sensitization. |

| Manganese | Mn | - | 1.50 | Deoxidizer during melting; binds sulfur. |

| Sulfur | S | - | 0.015 | Impurity; kept low to prevent hot cracking. |

| Silicon | Si | - | 1.00 | Improves oxidation resistance but can reduce ductility. |

| Copper | Cu | - | 0.75 | Minor addition for corrosion resistance. |

| Aluminum | Al | 0.15 | 0.60 | Works with Ti to improve high-temp strength. |

| Titanium | Ti | 0.15 | 0.60 | Stabilizes against intergranular corrosion. |

*Note: Iron content is technically the balance, but typically ranges heavily to ensure the Ni/Cr ratio is maintained.

4. Physical and Mechanical Properties

Engineers rely on Incoloy 800 not just for chemical inertness but for mechanical reliability. The data below reflects annealed round bars.

Mechanical Properties (At Room Temperature)

| Property | Metric Unit | Imperial Unit |

| Tensile Strength (UTS) | ≥520 MPa | ≥75,000 psi |

| Yield Strength (0.2% Offset) | ≥205 MPa | ≥30,000 psi |

| Elongation (in 2") | ≥30% | ≥30% |

| Hardness (Brinell) | 130 - 180 HB | - |

Physical Constants

| Property | Value | Significance in Engineering |

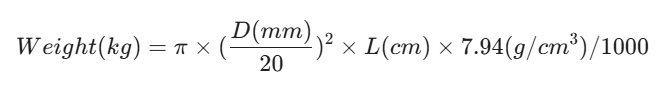

| Density | 7.94 g/cm³ | Essential for weight calculations in large assemblies. |

| Melting Range | 1357℃ - 1385℃ | High melting point prevents structural collapse in furnaces. |

| Specific Heat | 460 J/kg℃ | Determines energy required to heat the material. |

| Permeability | 1.002 (at 200 Oersted) | Remains non-magnetic even after cold working. |

5. The Metal Moulding and Manufacturing Process

Producing high-quality Incoloy 800 round bars requires strict control over the thermal cycle to prevent grain boundary precipitation. At MWalloys, our process flow is as follows:

1. Electric Arc Furnace (EAF) & AOD Refining

We begin with virgin raw materials. The melt is refined using Argon Oxygen Decarburization (AOD) to strictly control carbon, sulfur, and gas levels. This ensures the alloy is clean and free of inclusions.

2. Hot Working (Forging/Rolling)

-

Temperature Range: 1200℃ to 950℃.

-

Incoloy 800 is stiffer than stainless steel. Heavy forging presses are used to break down the cast structure. The finishing temperature must not drop below 870℃ to avoid micro-cracking.

3. Heat Treatment (Annealing)

This is the most critical step.

-

Process: Solution Annealing.

-

Temperature: 980℃ - 1040℃ followed by rapid cooling (water quench or rapid air cool).

-

Purpose: To dissolve carbides and soften the material for machining. If the temperature exceeds 1050℃, grain growth occurs, effectively turning the material into Incoloy 800H properties (which may not be desired for standard 800 applications).

4. Cold Finishing and Machining

-

Peeling/Turning: Removes the oxide scale formed during heat treatment.

-

Machinability: Incoloy 800 is distinctively "gummy." It work-hardens rapidly. We recommend using cemented carbide tools, positive rake angles, and heavy feed rates to cut under the work-hardened layer.

6. Incoloy 800 Round Bar Specifications

Buyers must reference the correct standard to ensure compliance.

| Organization | Standard | Description |

| ASTM | ASTM B408 | Standard Specification for Nickel-Iron-Chromium Alloy Rod and Bar. |

| ASME | ASME SB408 | Boiler and Pressure Vessel Code equivalent. |

| AMS | AMS 5766 | Aerospace Material Specification (rare for standard 800, usually for 800H). |

| ISO | ISO 9723 | Nickel and nickel alloy bars. |

| DIN | DIN 17460 | German specification for high-temp creep resistant steels. |

7. Equivalent Grades and Cross-Reference

Global sourcing often requires matching diverse designations.

| Standard Scheme | Grade / Number | Region |

| UNS | N08800 | USA / International |

| Werkstoff Nr. | 1.4876 | Germany / Europe |

| DIN | X10NiCrAlTi 32-20 | Germany |

| EN | X10NiCrAlTi 32-20 | European Union |

| AFNOR | Z10NC32.21 | France |

| BS | NA 15 | United Kingdom |

| JIS | NCF 800 | Japan |

| GOST | XH32T | Russia |

8. Industrial Applications: What is Incoloy 800 Used For?

The material selection of Incoloy 800 is driven by environments that are too hot for 316SS but do not justify the extreme cost of Inconel 625.

1. Petrochemical Processing

-

Heat Exchangers: The alloy resists the "sigma phase" embrittlement that affects stainless steels after long exposure to 600℃- 800℃.

-

Pigtails and Headers: Used in the production of ammonia and methanol.

2. Industrial Heating Elements

Sheathing: The protective metal tube surrounding electric heating elements. Incoloy 800 withstands the cyclic heating and cooling without spalling its oxide layer.

3. Power Generation

Steam Superheaters: Handles high-pressure steam with trace chlorides without cracking.

4. Chemical Handling

Nitric Acid Production: Excellent resistance to nitric acid corrosion, specifically where the acid is heated.

9. Sizes, Dimensions, and Weight Calculation

MWalloys stocks standard sizes and offers custom forging for large diameters.

Standard Stock Range:

-

Diameter: 6mm (1/4") up to 400mm (16").

-

Length: Random lengths (3m - 6m) or cut-to-length.

-

Surface: Black (Forged), Peeled, Polished (Bright).

Weight Calculation Formula

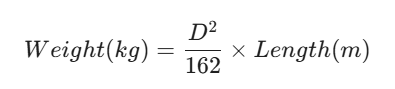

To estimate shipping costs, use this formula for Incoloy 800 Round Bar:

(Where D is diameter in mm. This is a simplified industry rule of thumb based on density).

Precise Calculation:

10. Global Price Analysis 2025: USA vs. Europe vs. China

Pricing for Nickel alloys fluctuates based on the LME (London Metal Exchange) Nickel indices. However, regional manufacturing costs create significant disparities.

| Region | Est. Price Range (USD/kg) | Market Characteristics |

| USA / North America | $38.00 - $48.00 | High premium due to strict environmental regulations, higher labor costs, and "Buy American" compliance surcharges. |

| Europe (Germany/Italy) | $35.00 - $44.00 | High energy costs (electricity/gas) for melting furnaces have kept prices elevated. Strong adherence to PED standards. |

| China (MWalloys) | $22.00 - $29.00 | Best Value. Integrated supply chains, lower energy overheads, and modern volume-production efficiencies allow MWalloys to offer 100% factory pricing without quality compromise. |

Why the Difference?

The chemical composition is identical. The price difference stems from operational efficiency and scale. MWalloys utilizes large-scale vacuum induction melting which amortizes costs more effectively than smaller boutique western mills.

11. Why Choose MWalloys?

MWalloys is not a trader; we are a specialized materials ecosystem rooted in manufacturing excellence.

-

Inventory: We maintain a "Ready-to-Ship" stock of Incoloy 800 in common diameters (10mm-100mm).

-

Verification: Every bar comes with an EN 10204 3.1 Mill Test Certificate. We welcome 3rd party inspection (SGS/TUV) before shipment.

-

Speed: While custom US orders can take 12-16 weeks, MWalloys typically ships stock items in 3-5 days and custom forgings in 2-3 weeks.

12. Frequently Asked Questions (FAQs)

Incoloy 825: Acid & Marine Engineering FAQ

1. What is Incoloy 825 primarily used for?

Specifically designed for chemical processing, it resists sulfuric and phosphoric acids, oil/gas well piping, and nuclear fuel reprocessing.

2. How does 825 differ from Incoloy 800?

3. Is Incoloy 825 resistant to seawater?

Yes, its high Nickel and Molybdenum content makes it nearly immune to chloride-induced stress corrosion cracking in marine environments.

4. Can it handle hydrofluoric acid?

5. What filler metal should be used for welding 825?

6. Does Incoloy 825 meet NACE MR0175 standards?

7. Can it be used in high-temperature service like 800H?

Service is typically capped at 540 degrees C to maintain optimal corrosion resistance.

8. Is 825 prone to pitting in chloride environments?

No, the Molybdenum content provides excellent resistance to pitting and crevice corrosion compared to 316L stainless.