DC53 steel usually provides a longer die life, higher resistance to chipping and cracking, and better dimensional stability after heat treatment compared with conventional D2 or SKD11, while the total tooling cost increase is small. For stamping, fine blanking and cold forming dies, engineers who switch from D2 to DC53 often see 1.3 to 2 times die life with fewer emergency stoppages, which is why MWalloys and many die shops now treat DC53 as a primary cold work tool steel rather than a niche material.

What is DC53 steel and why do many engineers now specify it instead of D2?

DC53 is a high toughness cold work tool steel developed originally in Japan as a performance upgrade to SKD11 and D2. It keeps the high carbon, high chromium concept of D2 but introduces controlled additions of molybdenum and vanadium, combined with a refined production route, to raise toughness without sacrificing wear resistance.

Key characteristics in practice:

- High hardness after tempering: typically 60 to 62 HRC, with good stability up to around 200 °C service temperature

- Much higher impact toughness than D2 or standard SKD11

- Improved resistance to chipping and spalling in heavily loaded dies

- Lower heat treatment distortion, which reduces fitting and rework

- Good response to surface treatments such as nitriding and PVD coatings

- Very suitable for wire EDM finishing, with reduced risk of cracking

In many plants, DC53 is now used for:

- Progressive stamping dies for automotive and appliance parts

- Fine blanking tools for gears, rings and precision plates

- Thread rolling dies and cold forming tools

- Shear blades that require both edge retention and robustness

Although DC53 is not yet standardized in every global system like AISI or DIN, it is widely produced in China, Japan and other regions under the DC53 designation, and its composition has become relatively consistent across reputable mills.

MWalloys focuses on this grade because it offers a clear technical advantage for customers looking to reduce unplanned downtime and maintenance cost without jumping immediately to expensive powder metallurgy steels.

How is DC53 steel defined in terms of composition and equivalent grades?

From a metallurgical perspective, DC53 belongs to the family of high carbon, high chromium cold work tool steels. It sits close to D2 / SKD11 on the composition map but with tweaks that change carbide type, size and distribution.

Typical chemical composition of DC53

Exact figures differ slightly between producers, yet reputable sources converge on the following target range:

| Element | Typical content (wt. %) | Function in DC53 microstructure |

|---|---|---|

| C | 0.95 – 1.05 | Hardness, wear resistance through carbide formation |

| Cr | 7.5 – 8.5 | Hardness, corrosion resistance, hardenability |

| Mo | 1.8 – 2.2 | Secondary hardening, temper resistance, toughness |

| V | 0.25 – 0.35 | Grain refinement, formation of hard vanadium carbides |

| Si | 0.8 – 1.2 | Strengthening, deoxidation |

| Mn | 0.3 – 0.6 | Hardenability, helps avoid quench cracking |

| P, S | ≤ 0.03 each | Kept low to maintain toughness and cleanliness |

| Fe | Balance | Matrix |

Compared with D2:

- Carbon is similar

- Chromium is slightly lower

- Molybdenum and vanadium contents are higher and more strictly controlled

This adjustment yields a finer, more evenly dispersed carbide structure after heat treatment.

Relationship to other steel standards

There is no direct AISI or DIN grade that completely matches DC53, but comparisons help positioning:

| Grade | Region / standard | Short description relative to DC53 |

|---|---|---|

| D2 (AISI D2) | USA | Older high carbon, high chromium cold work steel; higher Cr, similar C; lower toughness |

| SKD11 | JIS | Japanese D2 type; DC53 was created as an upgrade to this grade |

| 1.2379 (X153CrMoV12) | DIN / EN | European D2 type; comparable to SKD11 in performance |

| A2 | AISI | Air hardening tool steel, lower C and Cr; less wear resistance but easier to machine and tougher than D2 |

| PD613 / CD650 (China, various mills) | Local trade names | Often positioned as DC53 equivalents; composition should be verified |

| CPM D2 / powder metallurgy variants | Various | Superior wear resistance and toughness but at significantly higher price |

Engineers should treat DC53 as a D2-class steel with upgraded toughness and heat treatment flexibility, not as a powder metallurgy product.

How does the composition of DC53 influence its microstructure and performance?

The specific balance of alloying elements in DC53 is targeted to control the type, quantity and size of carbides as well as the martensitic matrix that holds them.

Role of key elements

- Carbon (about 1.0 percent)

- Provides high potential hardness when dissolved in austenite.

- Combines with chromium, molybdenum and vanadium to form hard carbides that give strong abrasive wear resistance.

- Excess carbon in D2-style steels can harm toughness; DC53 mitigates this through alloy balance and controlled processing rather than large changes in carbon.

- Chromium (7.5 to 8.5 percent)

- Promotes hardenability and allows air or oil quenching with deep hardness penetration.

- Forms chromium carbides which resist adhesive and abrasive wear.

- Improves mild corrosion resistance, helpful in humid stamping lines or where cooling lubricants are used continuously.

- Molybdenum (around 2 percent)

- Responsible for good tempering resistance, especially at higher tempering temperatures around 520 °C.

- Contributes to secondary hardening; after tempering, hardness returns to a high plateau rather than dropping sharply.

- Supports toughness by reducing coarse carbides and promoting a more uniform structure.

- Vanadium (about 0.3 percent)

- Strong carbide former that creates extremely hard, fine V carbides.

- Refines grain size, which leads to higher impact energy and reduced brittleness.

- Stabilizes wear resistance at high hardness.

- Silicon and manganese

- Silicon raises strength of the matrix and supports deoxidation in steelmaking.

- Manganese helps with hardenability and reduces risk of quench cracks.

- Both are kept at moderate levels to avoid embrittlement.

- Low phosphorus and sulfur

- Clean steel with low P and S contents is crucial for toughness and fatigue resistance.

- Reputable suppliers like MWalloys select mills that use vacuum degassing and strict inclusion control for better die life.

Microstructural features after heat treatment

When DC53 is properly hardened and tempered, the microstructure usually shows:

- Fine tempered martensite matrix

- Dispersed chromium and molybdenum carbides

- Evenly distributed, small vanadium carbides that pin grain boundaries

- Limited retained austenite compared with standard D2 at similar hardness, especially if high temperature tempering is used

This refined structure explains why DC53 can achieve 60 to 62 HRC while still showing significantly better toughness than many conventional high carbon tool steels.

What mechanical and physical properties can engineers expect from DC53?

For design calculations and material selection, engineers often need quantitative property values. These can vary slightly depending on section size, heat treatment and cleanliness, but the following ranges are typical for high quality DC53 supplied by producers such as MWalloys’ partner mills.

Mechanical properties after hardening and tempering

Typical values at 60 to 62 HRC for specimens from standard plate sections:

| Property | Typical value range | Notes |

|---|---|---|

| Hardness (HRC) | 60 – 62 | After oil or air quench and high temperature tempering |

| Tensile strength (Rm) | 2100 – 2300 MPa | Approximate correlation from hardness |

| Yield strength (Rp0.2) | 1600 – 1750 MPa | Approximate, seldom specified for tool steels |

| Charpy V-notch impact energy | 20 – 30 J at room temperature | For 60 HRC, significantly higher than D2 at same hardness |

| Compressive strength | 2500 – 2800 MPa | Important for cold forming and fine blanking tools |

| Toughness ranking vs D2 | Around 1.5 – 2 times | For same hardness and similar section size |

These data highlight the main practical advantage: toughness is considerably better than D2 at equivalent hardness, so edge chipping and catastrophic cracking are less frequent.

Physical properties

While physical constants are not the primary driver in die design, knowledge of them supports distortion control and heat transfer calculations.

| Property | Approximate value at room temperature |

|---|---|

| Density | 7.7 – 7.8 g/cm³ |

| Modulus of elasticity (E) | 210 – 215 GPa |

| Thermal conductivity | 20 – 25 W/m·K |

| Specific heat capacity | 460 – 500 J/kg·K |

| Coefficient of thermal expansion (20 to 200 °C) | 11 – 12 × 10⁻⁶ /K |

These properties are similar to other high chromium tool steels. Dimensional stability during heat treatment is more influenced by transformation behavior and stress reliving than by these bulk constants.

How should DC53 be heat treated to gain maximum hardness and toughness?

Heat treatment strongly controls final performance. One of the strengths of DC53 is its ability to use relatively high tempering temperatures around 520 °C, which improves dimensional stability and toughness while maintaining high hardness.

Below is a practical process window used by many heat treaters. Always follow the specific mill datasheet and adapt to part geometry.

Recommended hardening and tempering process

- Preheating

- First preheat: 600 – 650 °C

- Second preheat: 850 – 900 °C

- Purpose: reduce thermal shock, equalize temperature and minimize distortion.

- Austenitizing (hardening)

- Recommended hardening temperature: 1020 – 1040 °C

- Hold time: 20 – 30 minutes once the part is at temperature, depending on thickness

- Atmosphere: protective atmosphere or vacuum preferred to limit decarburization and scaling.

- Quenching

- Media: forced air, vacuum gas quench, or warm oil depending on section size and plant capability.

- Thinner sections: vacuum gas quench or air cooling often sufficient.

- Thicker sections: oil quenching may be used to ensure through hardness, with careful control to minimize cracking risk.

- Target hardness after quench before tempering: typically 63 – 64 HRC.

- Tempering

- Temper immediately after reaching hand-warm temperature to avoid delayed cracking.

- Typical tempering temperature: 510 – 540 °C for high toughness and stability.

- Number of temper cycles: at least two, sometimes three for critical dies.

- Hold time per temper cycle: 1 – 2 hours at temperature, followed by air cooling.

At a tempering temperature around 520 °C, DC53 shows secondary hardening. This allows 60 – 62 HRC hardness together with improved toughness and better relief of residual stresses compared with low temperature tempering commonly used for D2.

Example heat treatment parameter table

| Step | Parameter | Recommended range for DC53 |

|---|---|---|

| Preheat 1 | Temperature | 600 – 650 °C |

| Preheat 2 | Temperature | 850 – 900 °C |

| Austenitize | Temperature | 1020 – 1040 °C |

| Austenitize | Time at temperature | 20 – 30 min |

| Quench | Media | Forced air, gas, or oil |

| Temper 1 | Temperature | 510 – 540 °C |

| Temper 1 | Time | 1 – 2 h |

| Temper 2 | Same as first temper | 1 – 2 h |

| Optional | Sub-zero treatment | -70 to -80 °C then re-temper |

Sub-zero treatment and retained austenite control

For very tight dimensional tolerances or precision cutting edges, sub-zero treatment can reduce retained austenite:

- After quenching, cool to around -70 to -80 °C for 1 – 3 hours.

- Warm slowly to room temperature.

- Temper immediately at high temperature to relieve stresses.

This extra step raises hardness slightly and stabilizes dimensions but should be used with careful control to avoid cracking in complex shapes.

Stress relieving for pre-machined parts

Before final machining of cavities and details, stress relieving is recommended:

- Heat to 600 – 650 °C after rough machining.

- Hold for at least 1 – 2 hours.

- Allow to cool in still air.

This step lowers internal stresses from forging and machining, which helps reduce distortion during hardening.

MWalloys often supplies DC53 in annealed condition for customers who will machine and then heat treat locally, but pre-hardened options can be discussed for specific projects.

In which tooling applications does DC53 perform particularly well?

Due to the balance of high hardness and much improved toughness, DC53 shines in cold work applications where D2 tends to chip or crack, or where heat treatment distortion creates repeated fitting work.

Stamping and forming dies

- Progressive dies for automotive and appliance parts

Continuous high speed stamping places severe cyclic loads on die sections. Thin cutting edges in D2 often chip. DC53 withstands these loads better, especially in stations that combine cutting and forming.

Benefits reported by users include extended intervals between regrinds and fewer emergencies due to die breakage. - Bending and drawing stages

For draw rings, form punches and other components subject to sliding wear and contact pressure, DC53 offers higher surface stability. When combined with PVD coatings, galling resistance improves substantially, particularly on high strength steels and coated sheet.

Fine blanking tools

Fine blanking places extremely high compressive and shear loads on punches and dies. Edge cracking in D2 is common, especially in large diameter or complex shapes. DC53, with its superior toughness, reduces the risk of early chipping.

Advantages in fine blanking environments:

- Longer punch life at similar hardness等级

- Cleaner edge quality over a longer production run

- Lower tendency for catastrophic die fracture

Cold forming, thread rolling and cold forging

For cold forming tools, thread rolling dies and other tools under heavy compressive stress:

- DC53 carries high compressive strength.

- Secondary hardening keeps hardness stable even after multiple temper cycles.

- Toughness helps avoid fatigue cracking at section changes.

While powder metallurgy grades may still be preferable for extreme wear conditions or when production volume is extremely high, DC53 offers a compelling mid-range solution with lower material cost and more conventional processing routes.

Shear blades and slitting knives

Shear blades for bar or strip cutting need:

- High edge retention

- Reasonable shock resistance, especially in scrap handling or when cutting with variable thickness

DC53 provides a balance that surpasses D2 in many cutting lines, mainly by resisting chipping when unexpected impacts occur.

Limitations and when DC53 is not ideal

DC53 is not a universal solution. Engineers should be cautious in these situations:

- Hot work tooling above roughly 250 °C in continuous operation, where hot work steels like H13 are more suitable.

- Plastic moulds that demand extremely high polishability and corrosion resistance for optical parts; dedicated mould steels may be better.

- Extremely abrasive powder metallurgy compacting dies, where powder metallurgy tool steels with higher carbide volume are usually justified.

Nevertheless, in a wide range of cold work situations where D2 is the default, DC53 often yields a practical performance upgrade for moderate cost difference.

How does DC53 compare with D2, SKD11, A2 and powder metallurgy tool steels?

Comparative evaluation is usually at the center of material selection. Engineers and buyers want to understand trade offs in terms of wear resistance, toughness, machinability and cost.

Performance comparison table

The following table positions DC53 relative to some commonly used cold work tool steels, assuming optimized heat treatment for each grade.

| Property / factor | DC53 | D2 / SKD11 | A2 | Powder metallurgy cold work (e.g., CPM D2) |

|---|---|---|---|---|

| Wear resistance | Very high | Very high | Medium to high | Extremely high |

| Toughness | High for this hardness class | Low to medium | High | High to very high |

| Typical working hardness | 60 – 62 HRC | 58 – 61 HRC | 58 – 60 HRC | 60 – 64 HRC |

| Heat treatment distortion | Lower than D2 | Moderate to high | Moderate | Lower, but may need special treatment |

| Machinability | Slightly better than D2, below A2 | Difficult | Easier than D2 | Often more difficult due to high carbide content |

| Price level | Slightly above D2 | Baseline high chromium cold work | Lower | Significantly higher |

| Surface treatment compatibility | Very good | Good | Good | Very good |

| Typical use case | Upgraded cold work dies needing toughness | Conventional dies, low cost | Tools requiring toughness and easier machining | Very high production, severe wear conditions |

Practical takeaways for engineers and buyers

- When D2 works well and there is no history of cracking, D2 may remain sufficient from a cost standpoint.

- When D2 dies fail prematurely by chipping, cracking or distortion, DC53 is usually the first alternative to check before moving to powder metallurgy grades.

- Where only moderate wear resistance is required but impact loads are high, A2 might compete with DC53 on price and machining cost; yet DC53 often provides higher wear resistance at similar toughness.

MWalloys often helps customers evaluate failed D2 components and model the benefits of switching to DC53, including not just die life but also hidden costs such as downtime and fitting time.

What machining, grinding, EDM and surface treatment practices work best for DC53?

Production engineers need more than basic property data. They require practical process windows to avoid problems during machining, grinding and finishing.

Machining DC53 in the annealed condition

Most DC53 supplied for machining is in annealed state with hardness around 200 – 230 HB.

Recommended practices:

- Turning and milling

- Use rigid setups with sharp carbide tools.

- Cutting speeds comparable to D2 but slightly higher feed may be acceptable due to somewhat better machinability.

- Apply abundant cutting fluid during roughing, consider semi-dry or minimum quantity lubrication during finishing to control thermal effects.

- Drilling and tapping

- Standard high speed steel drills may be used, although cobalt HSS or carbide drills provide longer life in series production.

- For deep holes, step drilling and peck cycles reduce risk of chip packing.

- Stress relief after heavy roughing

Rough machining of thick sections can introduce considerable stress. Stress relief at 600 – 650 °C before final finishing is recommended to limit distortion during hardening.

Grinding after hardening

DC53 in hardened state at 60 – 62 HRC grinds similarly to D2, but its higher toughness makes it slightly more tolerant of grinding stresses.

Good practice:

- Use suitable grinding wheels for high alloy tool steels, with open structure to avoid burning.

- Manage coolant flow carefully, keeping wheel and part temperatures down.

- Limit infeed and traverse rates to avoid introducing tensile surface stresses that might contribute to cracking.

- Dress the wheel frequently for consistent cutting.

When cracks are observed at edges or corners, grinding parameters should be reviewed and tempering may need to be adjusted to relieve stresses.

EDM and wire cutting behavior

One of DC53’s selling points is its relatively low tendency to crack after EDM, especially when high tempering temperatures have been used.

Recommendations:

- Perform rough EDM passes, then skim cuts with lower energy settings to reduce recast layer thickness.

- Always perform a low temperature tempering cycle (for example 200 – 250 °C) after heavy EDM processing, even if hardness drop is minimal, to relieve EDM-induced tensile stresses.

- For highly stressed die corners or fine details subjected to wire cutting, consider re-tempering at high temperature followed by final polishing.

Surface treatments and coatings

DC53 responds well to various surface engineering processes:

- Nitriding

Produces a hard, wear resistant surface layer with good adhesion. Since DC53 already has high hardness, nitriding mainly helps with scuffing, initial wear and fatigue strength.

Common processes include gas nitriding and plasma nitriding. - PVD coatings such as TiN, TiCN, AlCrN

DC53 is widely used as a substrate for PVD coatings in stamping and forming tools. High tempering temperature improves substrate stability under coating process temperatures. - CVD coatings

Can be used, but process temperatures are higher. Pre-heat treatment design must ensure that the base material retains adequate hardness after CVD.

Polishability is reasonable for DC53, though not at the same level as dedicated plastic mould grades. For precision cutting edges or sealing surfaces, a good polish can be obtained with proper abrasive sequences.

How is DC53 specified, supplied and certified in the marketplace?

Technical performance depends not only on the steel grade but also on product quality, dimension control and certification.

Product forms available

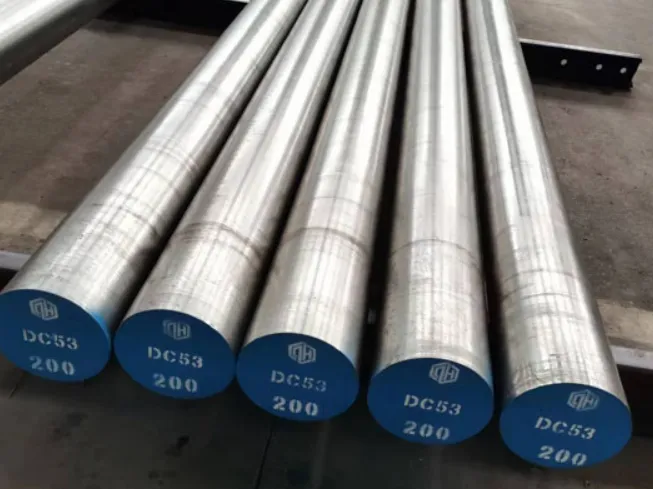

Reputable suppliers such as MWalloys typically provide DC53 in the following forms:

- Hot rolled or forged round bar

- Hot rolled or forged flat bar and plate

- Precision ground flat stock for small die inserts

- Pre-machined blocks for larger dies

- Cut to length blanks and pre-hardened parts on request

Typical size range:

| Product form | Typical size range |

|---|---|

| Round bar | Diameter 16 – 500 mm |

| Flat bar / plate | Thickness 6 – 300 mm, width up to 1000 mm or more |

| Precision ground flats | Thickness 2 – 50 mm, width up to 300 mm |

For very large sections, careful control of cooling and heat treatment is vital to ensure through hardness and low segregation.

Conditions of supply

- Annealed

This is the most common condition for machining. Hardness usually around 200 – 230 HB.

Used by die manufacturers that conduct their own heat treatment. - Pre-hardened

Some users request pre-hardened plates or blocks at 40 – 45 HRC for specific applications.

For critical cold work tools, final hardening at the user side is still recommended, but pre-hardened stock can shorten manufacturing cycles for less demanding parts. - Hardened and tempered to final hardness

Occasionally requested for components such as standardized die sets or punches. In such cases, tight control on flatness and residual stresses is needed.

Certification and testing

Reliable DC53 products are normally supplied with:

- Mill test certificate including chemical composition and hardness

- Heat number for full traceability

- Ultrasonic testing for large bars and plates to confirm absence of harmful internal defects

- Additional tests on request, such as microcleanliness rating, impact testing or specific mechanical tests

MWalloys follows strict internal acceptance standards on inclusion rating, segregation and dimensional tolerances, since problem-free performance in customers’ plants depends heavily on upstream quality.

What are typical 2026 DC53 steel prices in China, the United States and India?

Price is a crucial factor for purchasing decisions. Exact numbers change with raw material costs, energy prices, exchange rates and local competition. The figures below are indicative reference levels for 2026, assuming standard commercial quantities and typical payment terms.

2026 DC53 price comparison China vs USA vs India

Prices are approximate ex-stock or ex-mill values for common sizes of annealed DC53 round bar and plate. Currency is converted to USD per kilogram for easier comparison.

| Country | Product form | Typical 2026 price range (USD/kg) | Notes |

|---|---|---|---|

| China | Round bar 20 – 200 mm | 3.10 – 3.80 | Higher quantities and long-term agreements may reach lower levels |

| China | Plate 20 – 150 mm | 3.30 – 4.00 | Precision ground or special specs can add 10 – 15 percent |

| USA | Round bar 20 – 200 mm | 4.20 – 5.20 | Includes local distribution costs and quality certification |

| USA | Plate 20 – 150 mm | 4.50 – 5.50 | Regional variations depending on supplier and lead time |

| India | Round bar 20 – 200 mm | 3.40 – 4.10 | Imported or locally produced DC53-equivalent material |

| India | Plate 20 – 150 mm | 3.60 – 4.30 | Custom sizes or small lots may be at higher end of range |

These ranges should be treated as a starting point for negotiation rather than fixed quotations. Factors such as mill origin, cleanliness requirements, UL or automotive approval, stainless packaging, and cutting charges can adjust the final price.

Factors influencing DC53 pricing

- Raw material and alloy surcharges

Changes in prices of chromium, molybdenum and vanadium impact total cost. - Order volume and cutting complexity

Large orders for standard dimensions see lower unit prices than small cut pieces in varied sizes. - Quality level and certification

Ultra-clean variants with strict inclusion limits, or material certified for automotive Tier 1 suppliers, often carry a premium. - Logistics and import duties

Ocean freight, local taxes and duties significantly affect final price in end-user countries.

MWalloys maintains stocks in China and cooperates with logistic partners to serve customers in the USA, India and other regions, adjusting sourcing routes according to market conditions.

How should buyers evaluate and select a reliable DC53 supplier such as MWalloys?

Switching from D2 to DC53 or implementing DC53 as a mainstay grade involves not only material properties but also supply chain reliability.

Key criteria for supplier evaluation:

- Metallurgical consistency and traceability

- Confirm that every batch is traceable back to a specific heat number.

- Review long-term stability in composition and hardness rather than only a single certificate.

- Steelmaking route and cleanliness

- Prefer mills that use vacuum degassing and controlled melting routes for low inclusions.

- Ask for inclusion rating or cleanliness data for critical tools.

- Heat treatment recommendations and support

- Suppliers should be able to provide detailed heat treatment parameters and support local heat treaters in tuning furnaces for DC53.

- Dimensional accuracy and cutting service

- Good sawing and flame cutting reduce waste at the die manufacturer.

- Precision ground stock may save significant machining time on small inserts and plates.

- Global logistics and stock availability

- For multinational manufacturers, ability to supply in several regions at stable quality is important.

- Stock positions should be transparent, with clear lead times.

MWalloys positions itself as a technical and supply partner rather than just a material trader, supporting both design engineers and purchasing teams with technical comparison, failure analysis assistance and optimized stock programs.

What common problems occur with DC53 in production and how can they be prevented?

Even a good steel can fail if processing is inadequate. Some recurring issues with DC53 are inherited from its D2 family, while others are linked to incorrect heat treatment or machining.

Cracking during or after heat treatment

Possible causes:

- Overly rapid cooling in thick sections without proper preheating.

- Insufficient tempering, or delayed tempering after quench.

- Excessive grinding or EDM stresses not relieved by subsequent tempering.

Preventive measures:

- Strict adherence to multi-stage preheating and correct quenching practice.

- Immediate tempering at least twice at high temperatures.

- Low temperature temper or stress relief after significant EDM work.

Distortion exceeding tolerances

Although DC53 generally distorts less than D2, issues can still arise.

Contributors:

- Uneven wall thickness and sharp changes in section in die design.

- No stress relieving after heavy rough machining.

- Inconsistent furnace loading and positioning.

Mitigation:

- Design for uniform section thickness where possible.

- Include pre-hardening stress relief in the process route.

- Use fixture support for slender parts during heat treatment.

Premature wear or galling in service

If wear is worse than expected:

- Surface finish quality may be insufficient.

- No coating or incorrect coating choice for the work material.

- Hardness may be too low due to incorrect tempering temperature or insufficient cooling rate in quench.

Countermeasures:

- Improve polishing and grinding finish; avoid deep grinding burns.

- Combine DC53 with appropriate PVD coating for highly demanding applications.

- Re-check hardness across critical areas and adjust heat treatment if needed.

By working with both die makers and heat treaters, MWalloys often helps diagnose the root cause instead of attributing every issue to material origin.

Frequently asked questions about DC53 steel

DC53 Tool Steel: Technical & Machining FAQ

1. Is DC53 really better than D2 in every case?

2. What hardness can DC53 reach after heat treatment?

3. Can DC53 be nitrided or coated?

4. How does DC53 machine compared with D2?

5. Why does DC53 resist chipping and cracking better than D2?

6. Can DC53 replace powder metallurgy (PM) tool steels?

7. Is DC53 suitable for hot work tooling?

8. What is the ideal heat treatment sequence for DC53?

- Austenitize: 1020-1040°C.

- Quench: Vacuum or oil.

- Temper: High temperature temper at 520-530°C (at least twice).

9. What sizes and forms can MWAlloys deliver in DC53?

- Round Bars: 16mm up to 500mm diameter.

- Plates/Flats: 6mm to 300mm thickness in various widths.

- Precision Services: Ground flats and custom CNC cut-to-length blocks.

10. How should buyers compare DC53 offers from different suppliers?

By understanding DC53 steel not only at the level of marketing claims but also from composition, heat treatment and real service behavior, engineers and buyers can use it effectively to improve tool performance and reduce total cost. MWalloys focuses on consistent quality, technical support and global logistics to help customers gain the full benefit of this modern cold work tool steel.