ASTM A633 is a normalized, high-strength, low-alloy structural steel plate specification intended for welded, riveted, or bolted construction where improved notch toughness at low ambient temperatures is required; Grades A, C, D, and E provide stepped chemical and mechanical limits so designers can select the best balance of strength and impact resistance for marine, offshore, heavy equipment and cold-service structures.

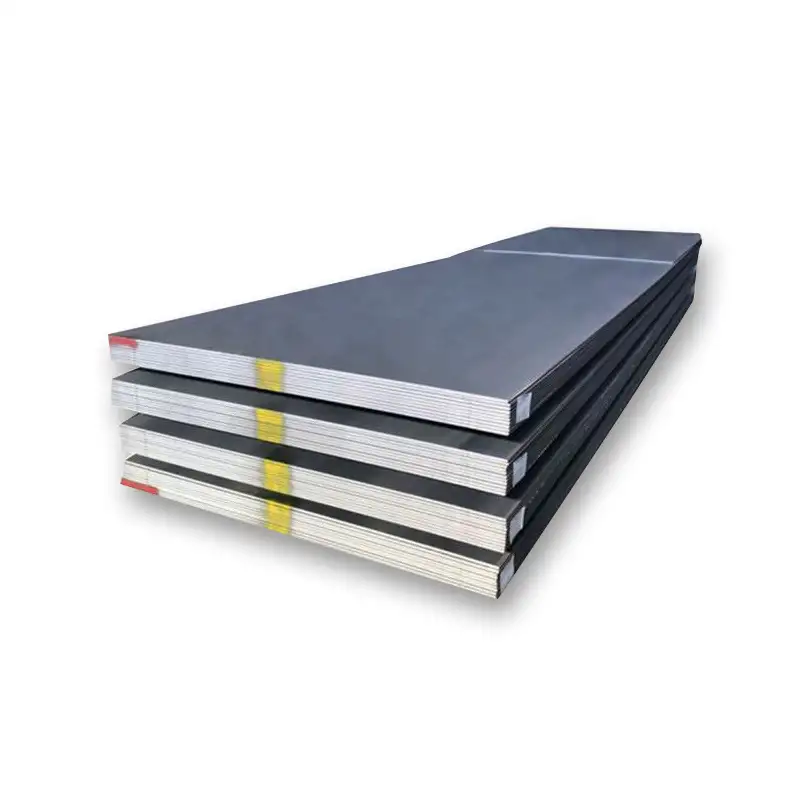

What is ASTM A633 Carbon Steel Plate?

ASTM A633/A633M is the standard specification for normalized high-strength low-alloy structural steel plate intended where superior notch toughness is required in low temperature service. The specification requires normalization heat treatment to refine grain size and improve toughness relative to comparable as-rolled steels. Typical uses include structural components, off-shore and marine items, utility equipment, and heavy machinery frames where fracture toughness at low ambient temperatures is important.

Also read: ASTM A588 Carbon Steel Plate

Standard reference and key clauses

The governing document is ASTM A633/A633M (current edition). Key technical requirements include:

-

Normalization: plates are heat treated to produce a fine austenitic grain size and improved toughness.

-

Chemical composition by heat analysis: the standard sets maximums and ranges for C, Mn, P, S, Si and selected microalloying elements (V, Nb/columbium, Cu, Ni, Cr depending on grade).

-

Tensile testing and yield strength requirements: minimum yield and tensile ranges that vary by grade and thickness.

-

Optional Charpy V-notch (CVN) impact requirements: can be ordered for specified temperatures and notch energy levels for projects that demand verified low-temperature toughness.

Grades overview (A, C, D, E)

-

Grade A — lower carbon and moderate strength; used where notch toughness requirement is modest.

-

Grade C — common for structural use with improved toughness for colder environments; available in thick sections (up to ~4″/100 mm).

-

Grade D — intermediate chemistry with provisions that vary by thickness; often used where weldability and strength must be balanced.

-

Grade E — highest specified strength/toughness envelope in the A633 family; available in thicker plate sizes (reported up to ~6″/150 mm).

Chemical composition

Below is a concise composition table reflecting ASTM A633 heat-analysis limits by grade (wt. %). These are industry standard limits used for mill certificates; always confirm against the purchaser’s specification and the mill MTR.

| Element (wt. %) | Grade A | Grade C | Grade D | Grade E |

|---|---|---|---|---|

| Carbon (C) — max | 0.18 | 0.20 | 0.20 | 0.22 |

| Manganese (Mn) | 1.00–1.35 | 1.15–1.50 | 0.70–1.35 (≤1½") / 1.00–1.60 (over) | 1.15–1.50 |

| Phosphorus (P) — max | 0.030 | 0.030 | 0.030 | 0.030 |

| Sulfur (S) — max | 0.030 | 0.030 | 0.030 | 0.030 |

| Silicon (Si) | 0.15–0.50 | 0.15–0.50 | 0.15–0.50 | 0.15–0.50 |

| Vanadium (V) | — | — | — | 0.04–0.11 (Grade E only) |

| Ni/Cr/Cu/Mo (trace limits) | typically ≤0.35–0.25 depending on grade | see standard | see standard | see standard |

(Table synthesized from ASTM A633 and multiple mill datasheets; purchasers should refer to the ASTM text and the mill’s MTR for heat-by-heat confirmation.)

Material properties

The mechanical property requirements depend on grade and plate thickness. Typical minimums (metric and imperial) used in procurement are shown:

| Property | Up to & incl. 2.5" (≈63 mm) | Over 2.5" to 4" (≈63–100 mm) | Over 4" to 6" (≈100–150 mm) |

|---|---|---|---|

| Yield strength (min) | 345 MPa (50 ksi) | 317–345 MPa (46–50 ksi) | variable by grade (often 345 MPa for some grades) |

| Tensile strength (range) | 485–620 MPa (70–90 ksi) | 448–586 MPa (65–85 ksi) | depends on grade/thickness |

| Elongation (A%) | typically ≥18–22% (depends on thickness) | typically ≥15–20% | specified by ASTM |

| Charpy V-notch (optional) | CVN energy at ordered temperature (customer specified) | — | — |

(These values are representative; check the specific grade and mill test report for contract acceptance.)

ASTM A633 Plate specification

| Item | Typical ASTM A633 supply condition |

|---|---|

| Surface condition | Hot-rolled, normalized finish (mill scale present unless descaled) |

| Thickness range | Thin (<6 mm) up to heavy sections (Grade C to ~100 mm; Grade E to ~150 mm is reported by mills) |

| Width & length | Custom — common widths 1500–4020 mm, lengths up to 27,000 mm in some mills; cut-to-size available. |

| Testing | Heat analysis, tensile test, bend test (when specified), CVN when ordered, compliance with MTR EN 10204 options where required |

| Certification | Mill Test Report (MTR) per ASTM (heat lot traceability), third-party inspection available on request |

What is equivalent to ASTM A633 Carbon Steel?

A direct 1:1 equivalent rarely exists because ASTM designates topology and mechanical requirements; however there are near equivalents in EN and other national systems commonly cited in procurement crosswalks:

-

A633 Gr C / D ≈ EN S355N / S355NL / E355 family (depending on impact requirements).

-

Some suppliers map A633 grades to S355 variants when similar yield/toughness envelopes are required; crosswalk tables vary and must be confirmed by mechanical property comparison and CVN requirements.

When asking for equivalents, always require the mill’s mechanical and CVN test results for the equivalent grade to confirm suitability.

A633 Carbon Steel Plate Sizes and weight

Weight calculation (metric)

Use steel density 7.85 g/cm³. For plate in metric units:

Weight (kg) = thickness (mm) × width (mm) × length (mm) × 7.85 × 10⁻⁶

Worked examples (rounded):

| Thickness | Width | Length | Weight (kg) |

|---|---|---|---|

| 10 mm | 2000 mm | 6000 mm | 942.0 kg |

| 12 mm | 2500 mm | 12000 mm | 2826.0 kg |

| 20 mm | 2000 mm | 10000 mm | 3140.0 kg |

| 50 mm | 2000 mm | 12000 mm | 9420.0 kg |

| 150 mm | 2500 mm | 15000 mm | 44,156.25 kg |

(Examples calculated using the standard density constant; see formula for on-the-fly sizing in purchase quotations.)

Imperial conversion: 1 mm = 0.0393701 in; 1 kg = 2.20462 lb. For convenience many North American suppliers price in CWT (hundredweight) or $/ton (short ton 2000 lb). Typical conversion examples are provided by service centers and mill price notices.

Fabrication, welding and heat-treat considerations

-

Weldability: Low carbon and controlled manganese in A633 grades give good weldability using common welding processes when recommended preheat and interpass controls are applied for thicker sections. Select welding consumables matching required toughness and chemical restrictions (e.g., low-hydrogen electrodes when required).

-

Preheat & interpass: for thicker plates and lower service temperatures, follow sound welding procedure specifications (WPS) with controlled preheat to reduce hydrogen cracking risk.

-

Post-weld heat treatment: normally not required for many structural applications because normalization provides desirable toughness; however project codes (offshore, pressure vessels) may require PWHT — follow client specifications.

-

Machinability & cutting: A633 plates are hot-rolled and can be cut by oxy-fuel, plasma or laser depending on thickness; recommended edge prep for welding should be discussed with fabricators.

-

NDT & testing: specify required nondestructive testing (UT, RT, MPI) for critical welded connections and acceptance criteria for inspection.

Typical applications

-

Offshore platforms, topside framing and utility structures that face cold ambient temperatures.

-

Heavy equipment frames (mining shovels, crane booms), structural members for freight handling and bridge components.

-

Marine deck structures, ship equipment parts and supports where notch toughness is important.

-

Poles and supports for utilities that require improved low-temperature performance.

Procurement, inspection and certifications

When sourcing ASTM A633, request the following in purchase documents:

-

ASTM A633/A633M referenced by edition/year.

-

Grade and plate thickness range.

-

CVN impact requirements (temperature and minimum energy) if needed.

-

Mill Test Report (MTR): heat analysis, tensile results, CVN (if ordered), traceability to heat/lot.

-

Third-party inspection (optional): for major projects ask for classification society or independent inspection authority oversight (DNV, ABS, Lloyd’s, etc.). Some mills list approvals on product pages.

Pricing snapshot — USA / Europe / China (2025)

Important: steel prices fluctuate rapidly. The table below provides indicative ranges for heavy carbon/structural steel plate pricing observed in market sources and supplier listings during 2025; use it only for early budgeting and confirm current firm quotes with suppliers. Price snapshot date used here: September 18, 2025.

| Region | Indicative price range (USD/metric ton) | Notes / source |

|---|---|---|

| United States | $800 – $1,100 / t | Market base plate and HRC trends published by US service centers; spot prices vary by region. |

| Europe | €550 – €1,000 / t (≈ $600 – $1,100/t) | European base steel pricing observed via MEPS and market reports; premium for specialty grades and CVN testing. |

| China (export FOB) | $450 – $700 / t | China mill & marketplace listings show wide ranges; small-lot export offers often in the lower band but subject to MOQ, shipping, and inspection costs. Example supplier ads list ~$450–$600/ton for A633 types. |

How to use these ranges: For budgeting add processing, cutting, certification, packing, inland freight, and customs. For project procurement obtain at least three firm mill or stockholder quotes with full MTRs.

Storage, corrosion protection and life-cycle

-

A633 is carbon steel and will corrode if left unprotected. Apply primer, shop painting systems, or galvanized coatings depending on service environment.

-

For offshore and marine exposure use certified coatings systems and follow SSPC or NACE guidance for surface prep and coating thickness.

-

Periodic inspection and maintenance help extend service life; design for replaceable wear plates where abrasion or corrosion is expected.

FAQs

-

Is ASTM A633 the same as A36?

No. A36 is a general structural carbon steel with lower specified strength and no normalized toughness requirement; A633 is normalized low-alloy intended for improved notch toughness. -

Which grade of A633 is best for cold climates?

Grades C and E are commonly chosen for low-temperature applications because of their tighter composition and availability with CVN testing. -

Can A633 be welded without preheat?

Small-thickness plates and controlled procedures can be welded without preheat, but thick sections and project codes may require preheat—follow a qualified WPS. -

What impact test temperature should I order?

Select the CVN test temperature based on the lowest ambient temperature the structure will face; common choices are 0°C, −20°C, −40°C depending on region and safety factors. -

Are there EN equivalents?

Near equivalents include S355N/S355NL families but equivalency must be validated by mechanical and toughness data. -

How is plate weight calculated?

Use thickness × width × length × 7.85e-6 = weight in kg. See example table above. -

What inspection documents come with A633?

A full MTR (heat analysis, tensile, CVN if ordered) is standard; third-party certificates are possible on request. -

Can A633 be used for pressure vessels?

A633 is structural steel; pressure vessel codes (ASME) require specific material certifications. Consult code requirements before use. -

What typical tolerances are available?

Mill tolerances follow ASTM and mill practices; specify flatness and thickness tolerances in the purchase order. -

How long does delivery typically take?

Stock items from service centers can ship quickly; mill lead times vary. For urgent orders order from stocked suppliers or mills with available inventory.

How MWalloys supplies ASTM A633

MWalloys is an experienced supplier headquartered in China with regular stocks of commonly used structural and low-alloy plates. Our strengths for A633 supply:

-

Factory-direct pricing: 100% factory outlet pricing for standard mill stock (competitive FOB terms).

-

Quick stock delivery: frequent production runs and warehouse inventory enable expedited shipments for common grades and sizes; cut-to-length service available.

-

Full traceability: Mill Test Reports (MTRs) supplied per ASTM and client requirements; third-party inspection (class society) available.

-

Customization: thickness, width and length cutting, edge treatment, painting and packing to buyer spec.

If you’d like a firm quote, MWalloys can provide an itemized offer including MTRs, packing and logistics timelines.