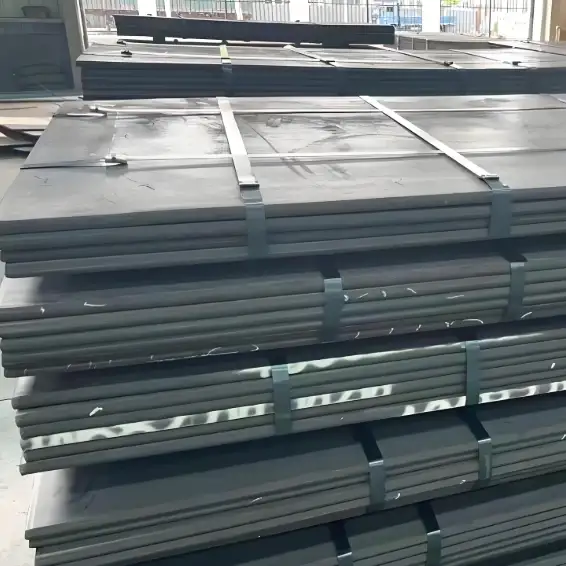

ASTM A573/A573M carbon steel plate is a structural-grade, improved-toughness hot-rolled plate available in three strength levels (commonly called Grades 58, 65 and 70) and is widely used for welded storage tanks, pressure vessels and structural components where notch toughness and weldability matter. For buyers seeking mill-direct supply from China with fast dispatch and competitive factory pricing, MWAlloys offers A573 plates with full mill test reports, 100% factory prices, and rapid stock-to-shipment options tailored to international projects.

What is ASTM A573 / A573M Carbon Steel Plate?

ASTM A573/A573M is a U.S. ASTM material specification titled “Standard Specification for Structural Carbon Steel Plates of Improved Toughness.” The document defines chemical, mechanical and testing requirements for carbon-manganese-silicon steel plates produced for applications where improved notch toughness over conventional semi-killed steels is desired. The standard covers three tensile strength groups and is most commonly applied to welded storage tanks, pressure vessel shells and similar structural fabrications. Plates under A573 are limited in thickness by the standard.

Grades and tensile groups (58 / 65 / 70)

A573 plates are typically supplied in three tensile groupings that are often referred to by their approximate tensile strength: Grade 58, Grade 65 and Grade 70. While producers may label them as GR 58 / GR 65 / GR 70, the specification itself prescribes tensile and yield requirements and impact test criteria appropriate to the grade and intended service. Typical mechanical ranges (illustrative) are:

-

Grade 58: lower tensile end of the A573 band (commonly used where moderate strength + toughness required).

-

Grade 65: mid-range strength.

-

Grade 70: highest tensile band in A573; commonly used where higher tensile strength plus welded fabrication is needed.

Chemical composition

Below is a practical composition summary that is commonly specified for A573 grades. These values are representative: final acceptance limits are determined by the standard’s Table 1 and the mill certificate (MTR / mill test report) must accompany deliveries.

| Element | Typical/Maximum (representative) |

|---|---|

| Carbon (C) | ≤ 0.27% (max — consult MTR) |

| Manganese (Mn) | ~0.85–1.20% |

| Silicon (Si) | ≤ 0.35% (typical) |

| Phosphorus (P) | ≤ 0.035% (max) |

| Sulfur (S) | ≤ 0.040% (max) |

| Copper / Ni / Cr / Mo | Trace or controlled per mill spec (not primary alloying elements) |

Notes: Always verify the exact chemical limits on the mill test report — different suppliers may add purchase-order (PO) or project-specific supplemental requirements (e.g., lowered C for improved weldability). The ASTM tables provide the official heat- and product-analysis requirements.

Material properties

The following table provides commonly quoted mechanical ranges for A573 grades (for engineering estimating only). Refer to the mill test report and the A573 standard for contractually binding numbers.

| Property | Grade 58 (typical) | Grade 65 (typical) | Grade 70 (typical) |

|---|---|---|---|

| Minimum yield strength (MPa) | ≈ 250–290 MPa | ≈ 260–290 MPa | ≈ 290 MPa (min) |

| Tensile strength (MPa) | ≈ 400–520 MPa | ≈ 450–580 MPa | ≈ 485–620 MPa |

| Elongation (in 200 mm, min) | 18% | 18% | 18% |

| Charpy impact | As specified per thickness/grade in ASTM (if required) |

Important: Values above are for planning. For design, pull the exact tensile/yield/elongation numbers directly from the ASTM A573 Tables and the mill certificate.

Standard specification highlights

-

Scope limit: Plates covered by A573 are limited to a maximum thickness of 1.5 in (40 mm) under the standard’s scope. Projects requiring thicker plates typically specify alternative standards or negotiate supplementary requirements.

-

Weldability: If steel is to be welded, users are expected to apply welding procedures suitable for the grade and service; the standard presupposes fine-grain practice and welding qualification where needed.

-

Testing: ASTM A573 requires heat analysis and product analysis tolerances (subject to A6/A6M), tensile tests per Table 2 and — where required by purchaser — impact testing to verify notch toughness. Always confirm the impact testing temperature and notch energy requirements on the PO.

Sizes & weight: common dimensions and how to calculate weight

A573 plates are produced and stocked in a range of mill and temper-leveled dimensions. Typical hot-rolled plate dimensions offered by modern mills (illustrative ranges):

-

Thickness: commonly 4.8 mm (0.188") up to 38.1 mm (1.5") per many stockists; mill coil conversion may be available at thinner gauges.

-

Widths: 1200–3050 mm typical (mill dependent).

-

Lengths: mill length ranges vary widely (e.g., 1800–25910 mm shown by some mills for thinner plates).

Weight calculation (metric):

Weight (kg) = Length (m) × Width (m) × Thickness (mm) × 7.85 (density) / 1000

Example: a 6.0 m × 2.0 m × 10 mm plate = 6 × 2 × 10 × 7.85 / 1000 = 0.942 ton (≈ 942 kg).

What is equivalent to ASTM A573/A573M Carbon Steel?

There is no single direct universal equivalence between ASTM A573 and European EN grades because specifications control different combinations of chemistry, toughness, heat treatment and testing. Practically:

-

Some vendors and conversion charts map A573 Grade 65/70 roughly into high-strength EN structural grades such as S355 families (S355J2 / S355J2+N) for general structural use, but this is an approximation and must be validated for each application (impact testing, normalized condition, chemical limits and heat treatment may differ).

Recommendation: When specifying an “equivalent,” always list required mechanical values (yield, tensile, elongation), impact-test temperature and acceptance criteria rather than relying on a grade name alone.

Fabrication: welding, forming, and heat-treatment notes

-

Welding: A573 steels are intended to be weldable — the purchaser should ensure a qualified welding procedure (WPS) suitable for grade and thickness. Low hydrogen electrodes and preheat controls recommended for thicker plates and cold service.

-

Forming: Cold forming is feasible within the material’s ductility limits; minimize local cold work and, for tight radii, rely on mill/forming data.

-

Heat treatment: A573 is normally supplied in the rolled condition (some mills offer normalized or controlled-rolled plates upon request). Any post-weld heat treatment (PWHT) must be defined by purchaser if required.

-

Notch toughness: If service requires low-temperature impact performance, specify the temperature and Charpy V-notch energy requirement on the purchase order; some A573 deliveries include mandatory impact testing per customer request.

Typical applications and case examples

-

Storage tanks and pressure vessels: Common historical use — A573 was originally intended for thin- to medium-thickness tank shells where improved toughness over semi-killed steels was required.

-

Welded structural members: where weldability and improved notch toughness are desirable.

-

Fabricated equipment and components in construction, industrial manufacturing and oil & gas that do not require heavy plate thickness beyond A573’s scope.

Procurement & logistics

MWAlloys is positioned as a Chinese factory supplier specializing in structural and pressure-related carbon and alloy plates. For international buyers we recommend the following supply package from MWAlloys:

-

Factory direct pricing: 100% factory price (no trading margin).

-

Stock & fast dispatch: Standard stock sizes for Grades 58/65/70, same-day picking for stock orders, and 7–21 day lead times for mill orders depending on quantity.

-

Documentation: Mill Test Report (MTR) to EN 10204 / 3.1 (if required), dimensional reports, and inspection photos prior to shipment.

-

Inspection: Third-party inspection (SGS / BV / Intertek) available at mill/warehouse at buyer’s request.

-

Export packing & logistics: Sea-worthy packing, LCL/FCL options, and FOB/CIF/DDP shipping terms.

2025 Price comparison (United States — Europe — China)

Steel price levels change rapidly; the table below shows range estimates for general carbon/structural plate market pricing observed in 2025 for hot-rolled structural plate. These are market ranges (ex-works or FOB) not fixed contractual quotes — for binding pricing always request a formal quote and confirm delivery term.

| Region | Typical 2025 range (approx, per metric ton) | Source / drivers |

|---|---|---|

| United States | USD $800–$1,000 / t (short-term volatility higher due to tariffs) | US market premiums and tariff measures reported; price supports from domestic demand. |

| Europe | EUR €540–€700 / t (≈ USD $620–$800 / t) | Fastmarkets/MEPS reporting regional plate prices in mid-2025 range; seasonal movement. |

| China (export / factory) | USD $450–$650 / t (mill FOB ranges; lower for large volume domestic dispatch) | China mill/export listings and marketplace offers show lower supply-side pricing; Alibaba / Made-in-China listings illustrate competitive FOB ranges. |

Key drivers: tariffs and trade policy (US 2025 tariffs increased duty-paid domestic premiums), freight costs, energy and raw-material (iron ore, coking coal, scrap) inputs, inventory levels and project pipeline (infrastructure stimulus). For large projects, even a small CWT (hundredweight) swing has material cost impact — always lock price and lead time in a formal contract.

Quality assurance & how to specify A573 correctly

When writing a PO or technical specification, include the following to avoid ambiguity:

-

Standard & revision: “ASTM A573/A573M — year (e.g., A573/A573M-20)”.

-

Grade: specify Grade 58/65/70 (or mechanical properties required).

-

Thickness, width, length tolerances: exact dimensions and tolerance class.

-

Impact testing: if required, state Charpy V-notch temperature & acceptance energy.

-

Mill Test Report: require EN 10204/3.1 or equivalent.

-

Heat/product analysis: require product analysis tolerances (per A6/A6M)

-

Surface condition/cut edge: specify pickling, SAW finish, or mill finish.

-

Inspection & TPI: specify third-party inspection if needed (SGS / BV / Intertek).

-

Packaging & shipping terms: FOB / CIF / DDP, palletization, weather protection.

-

Quantity & delivery schedule: define lot sizes, partial shipments and acceptance criteria.

FAQs

-

Q: Is A573 the same as A36?

A: No. A36 is a general structural mild steel; A573 is an improved-toughness structural plate with specific tensile bands. Specify the standard and mechanicals explicitly. -

Q: What thickness range does A573 cover?

A: The standard limits plates to ≤ 1.5 in (40 mm) in its scope — for thicker shells use other standards or negotiate supplemental requirements. -

Q: Can A573 be used for pressure vessels?

A: Yes. historically used for tank and pressure vessel shells — provided the plate meets project toughness, weld and code requirements (ASME, API) and proper testing is performed. -

Q: What documents should accompany a shipment?

A: MTR (EN 10204/3.1 or equivalent), inspection photos, packing list, and any agreed NDT or impact test reports. -

Q: Is A573 stocked by mills or made to order?

A: Both. Some service centers stock common grades/thicknesses; many orders are mill runs or cut-to-length. Check lead times with your supplier. -

Q: How do I calculate plate weight?

A: Weight (kg) = L(m) × W(m) × T(mm) × 7.85 / 1000. (See Section 6 above.) -

Q: Is A573 available with normalized heat treatment?

A: Some mills can supply normalized or controlled-rolled plates on request; include in PO if required. -

Q: Are there common equivalents in EN or JIS?

A: There are approximate mappings (e.g., to S355 family for higher tensile bands), but no guaranteed direct equivalence — always specify mechanical and toughness requirements instead of grade name alone. -

Q: Does MWAlloys offer mill inspection and third-party checks?

A: Yes. MWAlloys arranges third-party inspection (SGS/BV/Intertek) at mill or warehouse on buyer request prior to shipment. -

Q: How can I get a formal quote?

A: Provide required grade, dimensions, quantity (tons or pieces), required certificates, delivery term and target delivery date; MWAlloys will return a pro-forma quote with factory pricing and lead time.

MWAlloys company note (how we add value)

MWAlloys supplies structural and pressure-related steel plates from Chinese mills with export experience. Our value proposition for A573 buyers:

-

Factory pricing: we are mill partners providing 100% factory-level pricing (no trading markup).

-

Quick stock delivery: standard stock for common sizes & grades; expedited cuts & inspection for urgent orders.

-

Technical support: material selection help, welding recommendations, and assistance with inspection/lab reports.

-

Certificates & traceability: EN 10204/3.1 MTRs available; third-party inspection optional.

If you want, I can prepare: (a) a one-page pro-forma quote template, or (b) the sample MTR checklist and the supplier QA checklist that MWAlloys uses.

Closing & recommended next steps

If you need a mill-verified quote for A573 Grade 70 (or 58/65) with exact thickness/size and shipping term (FOB/CIF/DDP), provide: required grade, thickness, width×length, quantity (tons), desired delivery port, and whether you require impact testing or third-party inspection. I’ll prepare a sample pro-forma quotation and a draft purchase-order clause (technical annex) that makes the ASTM requirements unambiguous.