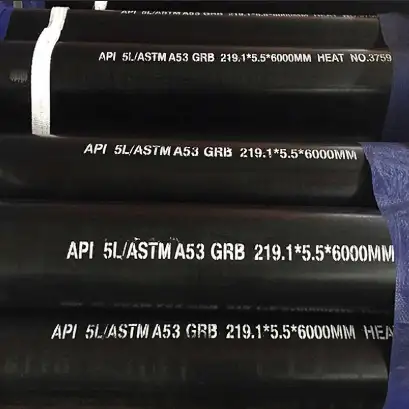

ASTM A53 Grade A & B Carbon Steel Pipes are widely used in various industrial applications due to their exceptional strength, durability, and versatility. These pipes, manufactured according to the ASTM A53 standard, come in two grades – Grade A and Grade B – each offering unique properties suited to different applications. At MWaolloys, we provide these pipes in a variety of sizes, lengths, and wall thicknesses, all produced to meet stringent quality standards. Our pipes are suitable for use in mechanical and pressure applications as well as in structural applications. Whether you are in construction, oil and gas, or the power generation industry, our ASTM A53 pipes offer optimal performance and long-lasting reliability.

What does A53 Grade A and Grade B mean for pipe?

ASTM A53 is a standard specification for carbon steel pipes used in steam, water, gas, and air lines, as well as structural applications. The pipes are available in two grades:

-

Grade A: This grade is suitable for non-pressurized applications.

-

Grade B: This is the most common grade and is designed for pressurized services, offering higher tensile strength than Grade A.

Standard Overview & Grade Definitions

*(ASTM A53/A53M-2024)*

| Parameter | Specification | Key Notes |

|---|---|---|

| Scope | Seamless and welded (ERW/FBW) carbon steel pipes for mechanical, pressure, and general-purpose applications (steam, water, gas, air pipelines) | Max temperature: 540°C; Min temperature: -29°C |

| Types | • Type S: Seamless • Type E: Electric Resistance Welded (ERW) • Type F: Furnace Butt Welded (FBW) |

Type F not suitable for flanging |

| Grades | Grade A (lower strength), Grade B (higher strength) | Grade B dominates industrial use (85% market) |

| Dimensions | NPS 1/8 to NPS 26 (DN 6 to DN 650) | Custom sizes available per order |

| Key Equivalents | • EN: P235TR1/2 • JIS: STPG370 • GB: 20# (GB/T 8163) |

Not fully interchangeable |

Chemical Composition Comparison

(Weight %, Melt Analysis)

| Element | Grade A | Grade B | Permissible Variation | Role |

|---|---|---|---|---|

| C (Carbon) | ≤0.25 | ≤0.30 | ±0.01% | Strength/hardenability control |

| Mn (Manganese) | ≤0.95 | ≤1.20 | ±0.05% | Enhances tensile strength |

| P (Phosphorus) | ≤0.05 | ≤0.05 | ±0.005% | Reduces ductility (strictly limited) |

| S (Sulfur) | ≤0.045 | ≤0.045 | ±0.005% | Weldability risk |

| Cu (Copper) | ≤0.40 | ≤0.40 | ±0.02% | Optional for corrosion resistance |

💡 Grade B Advantage: Higher Mn content (≤1.20% vs. ≤0.95%) enables better strength-to-weight ratio.

Mechanical Properties Comparison

*(Room temperature, per ASTM E8/E8M)*

| Property | Grade A | Grade B | Test Standard |

|---|---|---|---|

| Tensile Strength (min) | 330 MPa (48,000 psi) | 415 MPa (60,000 psi) | ASTM E8/E8M |

| Yield Strength (min) | 205 MPa (30,000 psi) | 240 MPa (35,000 psi) | ASTM E8/E8M |

| Elongation (min) | 12% (50mm gauge) | 12% (50mm gauge) | - |

| Hardness (max) | 163 HBW | 179 HBW | ASTM E10 |

Dimensional Tolerances

(Per ASTM A530)

| Parameter | Tolerance | Critical Notes |

|---|---|---|

| Outer Diameter | ±1% (for NPS ≤4") | ±0.79mm for NPS 2" pipes |

| Wall Thickness | +20%/-12.5% | Negative tolerance capped at -8% for critical projects |

| Length | ±10 mm (for lengths ≤6m) | Custom cuts (e.g., 11.5m) available |

| Straightness | ≤0.3% of total length | Mandatory for structural applications |

Common Sizes, Thickness & Weight Tables

*(Per ASME B36.10M, Schedule 40/80)*

Standard Dimensions & Weights (Grade B, ERW/Seamless)

| NPS | OD (mm) | Schedule | WT (mm) | Weight (kg/m) | Pressure Rating (MPa) |

|---|---|---|---|---|---|

| 1/2" | 21.3 | 40 | 2.77 | 1.27 | 20.6 |

| 2" | 60.3 | 40 | 3.91 | 5.44 | 17.2 |

| 4" | 114.3 | 40 | 6.02 | 16.07 | 13.7 |

| 6" | 168.3 | 80 | 10.97 | 41.67 | 17.2 |

| 8" | 219.1 | 40 | 8.18 | 42.55 | 9.6 |

| 12" | 323.8 | 80 | 12.70 | 97.50 | 12.4 |

| 24" | 609.6 | 160 | 19.05 | 290.20 | 18.9 |

Weight Calculation Formula

-

Metric:

Weight (kg/m) = (OD - WT) × WT × 0.02466 -

Imperial:

Weight (lb/ft) = (OD - WT) × WT × 10.69

Example: 8" Sch 40 pipe (OD=219.1mm, WT=8.18mm):

(219.1 - 8.18) × 8.18 × 0.02466 ≈ 42.55 kg/m

Grade-Specific Applications & Processing

| Grade | Typical Uses | Welding | Surface Treatment |

|---|---|---|---|

| Grade A | Low-pressure plumbing, handrails, fencing | No preheat (<20mm), SMAW/GMAW | Galvanizing (ASTM A123) or black finish |

| Grade B | High-pressure steam lines, structural supports (e.g., geothermal plants), oil/gas pipelines | Preheat ≥50°C (>25mm thickness) | 3PE coating (buried pipelines), epoxy |

Procurement & Quality Alerts

-

Material Substitution Risk: Factories often blend A53B with GB 20#, but Grade B has stricter Mn limits (≤1.20%) enabling -29°C service.

-

Wall Thickness Verification: For critical projects, specify "Minimum WT: Nominal -8%" in purchase orders.

-

Certification: Mill Test Reports (MTRs) must include:

-

Heat analysis (C, Mn, P, S)

-

Hydrostatic test data (≥5MPa for 5s)

-

Heat treatment records (for ERW Grade B)

-

-

Galvanizing Note: Type F (FBW) pipes are not recommended for galvanizing due to weld integrity risks.

Applications of ASTM A53 Pipes

ASTM A53 pipes are crucial in several industries due to their excellent performance under pressure and in mechanical applications. Some key industries include:

-

Oil & Gas: Used in drilling and transmission systems.

-

Construction: Essential for structural frameworks.

-

Power Generation: Utilized in power plant systems for steam and gas lines.

-

Automotive: Employed in manufacturing exhaust systems and chassis.

-

Water & Wastewater: Implemented in piping systems for water distribution and treatment.

Advantages of Choosing MWaolloys ASTM A53 Carbon Steel Pipes

-

High Strength and Durability: Both Grade A and Grade B pipes provide excellent strength, with Grade B offering superior tensile strength, making it ideal for pressurized applications.

-

Versatile Usage: These pipes are compatible with a wide range of applications, from gas lines to structural purposes.

-

Corrosion Resistance: Our pipes are manufactured with anti-corrosive coatings and are tested for durability in harsh environments.

-

Customizable: Available in various sizes and wall thicknesses to suit specific project requirements.

-

Quality Assurance: At MWaolloys, we ensure every pipe undergoes strict quality control measures and meets international standards.

ASTM A53 carbon steel pipe prices for 2025

| 🏷️ Market | Specification/Type | Price per metric ton | Notes |

|---|---|---|---|

| China | ERW ASTM A53 (16–18″ SCH10, Grade B) | $450 FOB | FOB Tianjin, min. 20 MT |

| China | ERW Grade B Schedule 40 (35–660 mm OD) | $660–990 | FOB China, black coated |

| China | Seamless ASTM A53 | $550–650 | From Jiujin supplier |

| Europe | (No specific A53 data found; likely similar to China for ERW, but typically 10–20% higher depending on duties & shipping) | — | — |

| U.S. | ERW A53 Grade B (FOB mill, short ton) | $1,700–1,800 (~$1,880–1,990/MT) | FOB U.S. mills, converted |

| U.S. | ERW A53 Grade A (FOB mill, short ton) | $1,600–1,700 (~$1,770–1,880/MT) | Slightly lower grade |

📌 Insights

-

China offers some of the most competitive pricing globally—as low as $450/MT for welded A53 ERW pipes, with coated/seamless versions ranging up to $990/MT.

-

U.S. prices remain significantly higher, at around $1,880–1,990 per metric ton for Grade B and $1,770–1,880/MT for Grade A—mainly due to domestic mill pricing.

-

Europe lacks direct A53 pricing data in open sources, but market norms suggest European pricing is generally 10–20% higher than China, factoring in tariffs, transport, and manufacturing costs.

-

Type (ERW vs seamless, coated vs black) and grade (A or B) heavily influence the price.

Standards and Certifications

Our ASTM A53 pipes meet the following industry standards:

-

ASTM A53: Standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded, and seamless.

-

API 5L: For pipelines in the oil and gas industry.

-

ISO 9001: Certification for our commitment to quality management systems.

Quality Control and Manufacturing Process

Our pipes are manufactured using advanced technology, ensuring dimensional accuracy and robust performance. We adhere to strict quality control protocols, inspecting each pipe for defects and ensuring compliance with ASTM standards. The manufacturing process involves:

-

Material Selection: High-quality carbon steel.

-

Welding & Seamless Processing: For high strength and long-lasting performance.

-

Coating: Anti-corrosive coatings are applied as needed.

-

Testing: Pressure testing, hydrostatic testing, and dimensional checks.

Comparison with Other Carbon Steel Pipes

| Property | ASTM A53 Grade A | ASTM A53 Grade B | ASTM A106 Grade B | ASTM A252 Grade 2 |

|---|---|---|---|---|

| Tensile Strength | 45,000 psi | 60,000 psi | 60,000 psi | 50,000 psi |

| Yield Strength | 30,000 psi | 35,000 psi | 35,000 psi | 35,000 psi |

| Application | Non-pressurized | Pressurized | Pressurized | Piling, structural |

| Wall Thickness | 0.065 to 0.500” | 0.065 to 0.500” | 0.065 to 1.000” | 0.250 to 1.000” |

FAQs

-

What are the key differences between ASTM A53 Grade A and Grade B carbon steel pipes?

ASTM A53 Grade A is suitable for non-pressurized systems, while ASTM A53 Grade B is designed for applications requiring higher strength and is often used in pressurized services. Grade B pipes offer a higher tensile and yield strength, making them more suitable for demanding industrial environments like oil and gas pipelines and power plants.

-

Can ASTM A53 Grade B pipes be used for high-pressure applications?

Yes, ASTM A53 Grade B pipes are specifically designed for pressurized applications. Their enhanced strength makes them ideal for high-pressure systems, including steam lines, gas pipelines, and fluid transfer systems in various industries. The pipes undergo rigorous testing to ensure their durability under pressure.

-

What industries commonly use ASTM A53 carbon steel pipes?

ASTM A53 carbon steel pipes are commonly used in the construction, oil and gas, power generation, and water supply industries. Their versatility allows them to be used in a range of applications such as steam lines, structural frameworks, and fluid transportation systems.

-

Are ASTM A53 pipes corrosion-resistant?

ASTM A53 pipes are generally not inherently corrosion-resistant. However, they can be coated with various anti-corrosive materials, such as hot-dip galvanizing, to improve their resistance to rust and corrosion, especially when used in outdoor or highly corrosive environments. Consult with your supplier for customized coating options.

-

What is the typical lifespan of ASTM A53 carbon steel pipes?

The lifespan of ASTM A53 pipes varies depending on environmental conditions, usage, and maintenance. With proper coating and care, these pipes can last several decades in most applications. In corrosive environments, regular inspections and maintenance are recommended to ensure their longevity.

-

What is the pressure rating of ASTM A53 Grade B carbon steel pipes?

ASTM A53 Grade B pipes are designed for a pressure rating of up to 5000 psi (345 bar), depending on the diameter and wall thickness of the pipe. It's important to consult with a qualified engineer to determine the precise pressure requirements for your specific application.

-

Can ASTM A53 pipes be welded?

Yes, ASTM A53 carbon steel pipes can be welded. These pipes are manufactured using both welded and seamless processes, allowing for easy integration into existing piping systems. However, welding procedures should be done according to industry standards to ensure structural integrity.

-

How do you choose between ASTM A53 Grade A and Grade B pipes?

The choice between Grade A and Grade B depends primarily on the application and the required strength. For non-pressurized systems, Grade A is sufficient, while Grade B is recommended for pressurized systems, offering better strength, making it ideal for high-demand industrial applications.

-

What is the standard length of ASTM A53 carbon steel pipes?

ASTM A53 pipes are typically available in lengths ranging from 20 to 40 feet (6 to 12 meters). Custom lengths can be ordered depending on project specifications, and they can be cut to the desired size during the manufacturing process.

-

How do I ensure the quality of ASTM A53 carbon steel pipes?

To ensure the highest quality, purchase ASTM A53 pipes from reputable suppliers like MWaolloys. All our pipes undergo rigorous quality checks, including hydrostatic testing, dimensional inspections, and compliance with ASTM A53 standards. We provide certifications and documentation upon request to confirm the pipes meet industry standards.